文章编号:1004-0609(2007)05-0704-06

Al基和Al-6Si基闭孔泡沫铝的动态压缩性能

尉海军,李 兵,郭志强,姚广春

(东北大学 材料与冶金学院,教育部材料先进制备技术工程研究中心,沈阳 110004)

摘 要:

利用熔体转移发泡法制备了不同密度的Al基和Al-6Si基闭孔泡沫铝(CCAF),探讨了CCAF基体的微观形貌及物相组成,对其动态压缩性能进行了研究。结果表明:Al基CCAF基体微观形貌较单一,基本上是小块状(Al20CaTi2);而Al-6Si基CCAF基体微观形貌复杂,主要呈大片状(Al3.21Si0.47和CaAl2Si3)、长针状(Al3Ti)和小白点(Al2O3)。动态压缩结果显示:Al基CCAF压缩应力—应变曲线较平缓,断裂层有明显的材料撕裂痕迹;而Al-6Si基CCAF压缩应力—应变曲线不光滑,个别曲线波动较大,断裂层出现显著的脆性材料断裂特征;随着相对密度的增加,Al基和Al-6Si基CCAF屈服强度(σpl)和表观弹性模量(E0.2)整体趋势都在增加。

关键词:

中图分类号:TG 146.21 文献标识码:A

Dynamic compressive property of closed-cell aluminum foam with Al matrix and Al-6Si matrix

YU Hai-jun, LI Bing, GUO Zhi-qiang, YAO Guang-chun

(Engineering and Researching Centre of Advanced Preparation Technology of Materials, Ministry of Education,

School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China)

Abstracts: Closed-cell aluminum foam (CCAF) with Al matrix and Al-6Si matrix was prepared by method of molten body transitional foaming process, the metallography of matrix was discussed, and its dynamic compressive property was researched. The results show that the metallography of CCAF with Al matrix is simple, basically existing as small pieces (Al20CaTi2), whereas the metallography of CCAF with Al-6Si matrix is complex, mainly existing as big pieces (Al3.21Si0.47 and CaAl2Si3), long needles (Al3Ti) and small white flakes (Al2O3). Dynamic compressive results display that the stress—strain curves of CCAF with Al matrix are smooth, the zone of fractures has obvious teared trace, whereas the stress—strain curves of CCAF with Al-6Si matrix are not smooth, certain curve fluctuates markedly, and zone of fracture indicates obvious fracture characteristic of brittle materials. With increasing relative density, the whole trend of yield strength (σpl) and apparent elastic modulus (E0.2) also increases.

Key words: closed-cell aluminum foam; dynamic compression; relative density; yield strength; apparent elastic modulus

泡沫铝是一种由金属骨架和泡孔组成的新型多功能材料,具有质轻、吸声、隔声、电磁屏蔽、吸能缓冲、隔热、耐火等优良特性[1-7],因此应用领域很广泛,具有广阔的发展前景。根据泡沫铝孔型结构的不同,可以将其分为两类:一种是通孔泡沫铝(OCAF);另一种是闭孔泡沫铝(CCAF)。由于CCAF制备成本低,且孔与孔之间由孔棱和孔壁连接,因此与OCAF相比较,强度更高,更加适于作为缓冲材料应用。泡沫铝在吸能缓冲的过程中受内在因素(基体成分、孔形状、孔大小等)和外在因素(应变率、压缩方式等)等诸多方面的影响, 因此,科研工作者对CCAF的压缩性能进行了一系列的研究,例如:McCullough等[8]对Al-Mg1-Si0.6和Al-Mg1-Si10的准静态压缩性能进行了深入的研究,Gibson和Ashby[9-10]则采用正方体模型对CCAF和OCAF理论压缩性能进行了模拟;Lopatnikov等[11-12]利用冲击波理论研究了泡沫金属一维高速冲击性能,并利用LS_DYNA数值模拟该过程;Deshpande和Fleck[13]系统地研究了开孔Duocel和闭孔Alulight泡沫铝的应变率效应,此外,Kanahashi等[14-15]和Feng等[16]对不同热处理和时效处理泡沫铝的动态压缩性能进行了研究。但迄今为止,国内外还未见有人研究不同基体成分CCAF的动态压缩性能。因此,本文作者不但对熔体转移发泡法进行了工业化放大实验,制备出均匀性良好的CCAF,而且对不同硅含量基体的CCAF微观形貌及成分组成进行了分析,并结合分析结果对其动态压缩性能进行了深入研究。

1 实验

本实验采用熔体转移发泡法(图1)制备Al基和Al-6Si基CCAF,该方法共分如下5个步骤:1) 在电炉里熔化Al-12Si合金或纯Al以及金属Ca的混合物;2) 向熔体里加入TiH2;3) 将熔体转移到发泡箱;4) 将发泡箱放入保温炉中并发泡;5) 泡沫铝后加工过程[7]。

图1 熔体转移发泡法制备泡沫铝示意图

Fig.1 Sketch map of preparing CCAF by molten body transitional foaming process

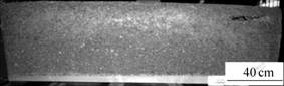

图2所示为目前国内工业化实验制备的最大块Al-6SiCCAF(2 000 mm×1 000 mm×600 mm),利用线切割从大块泡沫铝上制备压缩试样,加工成d30 mm× 30 mm(GB7314—87)的圆柱体,表观密度通过用天平称试样的质量并用游标卡尺测量其体积来计算。在计算相对密度时,取Al基CCAF基体的密度为2.67 g/cm3,Al-6Si基CCAF基体的密度为2.64 g/cm3。Al基泡沫铝试样相对密度分别取0.108、0.154、0.255和0.310,Al-6Si基CCAF试样相对密度取0.106、0.174、0.220和0.356。

图2 工业化实验制备的Al-6Si基CCAF

Fig.2 Photo of CCAF with Al-6Si matrix prepared by industrialized experiment

动态压缩实验是在轧制技术与连轧自动化国家重点实验室进行的,所选用的设备是Gleeble1500型材料热力模拟测试机,试样应变率为133 s-1, 每次实验进行到试样被压实为止。

2 结果与讨论

2.1 Al基和Al-6Si基CCAF形貌

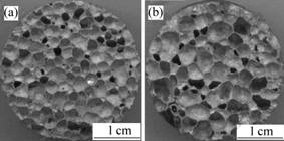

图3所示为Al基和Al-6Si基CCAF的宏观形貌。可以看到,整体形貌都较均匀,泡孔形状很规则,基本上呈圆形和六边形,孔壁之间以Y型连接,夹角较一致,为120?。

图3 Al基体和Al-6Si基体CCAF宏观形貌

Fig.3 Macroscopical pictures of CCAF with Al matrix(a) and Al-6Si matrix(b)

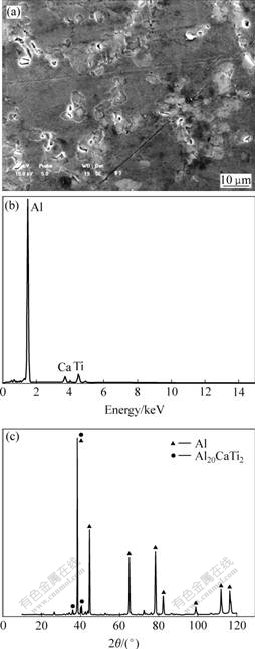

图4(a)所示为Al基CCAF基体微观形貌。可以看出:微观形貌较规则,以小块状和球状金相出现,无大块或长条状金相,EDX分析结果(见图4(b))表明块状或球状金相主要化学成分为Al、Ca和Ti,结合X射线衍射(见图4(c))分析可知,其化学式是Al20CaTi2。

图4 Al基CCAF的SEM像(a), EDX谱(b)和XRD谱(c)

Fig.4 SEM image(a), EDX patterns(b) and XRD patterns(c) of CCAF with Al matrix

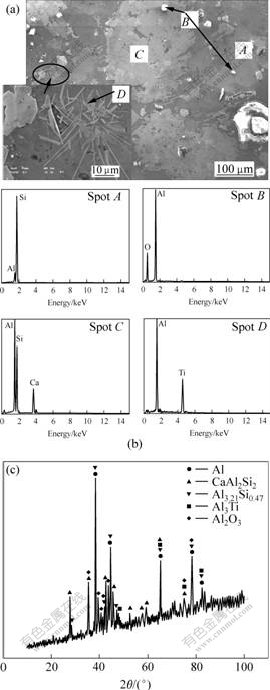

图5(a)所示为Al-6Si基CCAF微观形貌,发现微观形貌较复杂,主要以暗色大片状、小白点、明亮大片状以及长针状存在,这些金相的主要成分如图5(b)所示。由X射线衍射分析(图5(c))可知,其化学成分分别为Al3.21Si0.47、Al2O3、CaAl2Si3和Al3Ti。Al-6Si基CCAF中存在这么多的物相,尤其是含有呈大片状形貌的Al3.21Si0.47、CaAl2Si2和长针状形貌的Al3Ti,势必会割裂Al-6Si基CCAF基体,当CCAF受到外力时,产生微观裂缝,进而影响CCAF的力学性能。

图5 Al-6Si基CCAF的SEM像(a) (左下角图为圆圈内形貌放大图), EDX谱(b)和XRD谱(c)

Fig.5 SEM images(a) (figure on left corner is magnified figure from circle), EDX patterns(b) and XRD pattern(c) of CCAF with Al-6Si matrix

2.2 单轴动态压缩形变特征

图6所示为不同基体不同密度CCAF动态压缩应力—应变曲线。可以看到,所有的压缩特性曲线都显示出了与其它固态材料相同的压缩变形三阶段:线弹性阶段、崩溃阶段、致密化阶段[9]。

图6 Al基(a)和Al-6Si基(b)CCAF动态压缩曲线

Fig.6 Curves of CCAF dynamic compression with Al matrix(a) and Al-6Si matrix(b)

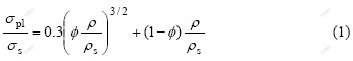

CCAF的线弹性阶段存在于较小的应变范围内,一般ε<0.025,此区间内应力—应变为直线,直线的斜率为对应泡沫铝材料的表观弹性模量,直线的顶端所对应的最大应力值为材料的屈服强度(σpl)。根据Gibson和Ashby的模型可知,CCAF的压缩屈服强度(σpl)与其相对密度(ρ/ρs)的关系为[9]:

式中 σs指基体材料屈服强度,ρs为基体材料密度,![]() 指孔棱占基体材料的体积分数。

指孔棱占基体材料的体积分数。

同样,CCAF的表观弹性模量(E0.2)与相对密度(ρ/ρs)也可以写为[9]:

式中 Es为基体材料弹性模量。

弹性变形的机理主要是孔壁发生弹性弯曲[9]。当弹性应变增大到一定值时,CCAF的压缩应力—应变

进入崩溃阶段。这一阶段的主要特征为在很小的应变作用下,应力增加量下降,这与静态实验中应力大幅下降到小于屈服强度的情况不同[8]。动态崩溃机理主要是当CCAF材料受到的外力大于其屈服强度时,CCAF的孔壁被压垮,导致应力突然释放,但对于CCAF来说,孔与孔之间没有连通,所以高速压缩时,不但孔壁承载外力,孔里的空气由于突然压缩不能及时冲出也会起到一定的作用,弥补孔壁压垮后的应力突然下降现象,这一点在Gibson和Ashby的研究中也有提到[9],因此图6崩溃阶段没有出现静态压缩时的应力大幅下降现象。至于图6所示平台应力随泡沫铝相对密度的增加呈现非均匀性增加的原因主要是试样相对密度的增加不等量造成的。

当所有的孔壁都被压垮后,孔壁之间相互接触,进一步的应变越来越多地由基体材料本身所提供,导致应力随应变的增加而急剧增加。表现为图6的应力—应变曲线的致密化阶段,根据文献[9],致密化应变(εd)可以定义为

从图6还可以看到,基体成分不同时,曲线的形状有很大差异。Al基CCAF的曲线非常光滑,三阶段应力都呈显著上升趋势,说明形变过程非常平稳显示出典型的塑性泡沫材料特征;相比之下,Al-6Si基CCAF压缩曲线有明显的起伏,尤其是密度较大的Al-6Si基试样曲线,显示出脆性材料的压缩特征,这主要是由于Al-6Si基CCAF基体中含有大片状和长条状金相以及大量的脆性相的缘故(见图5)。这些脆性相的存在会导致此CCAF基体孔壁的变形几乎全在弹性范围内,应力集中敏感,断裂呈爆炸式。当应力超过某一层的屈服强度后,该层迅速破裂,破裂后部分试样脱离压缩区域,应力突然下降,但由于冲击速度较快,应变增加后,下一层泡壁继续承载压力,因此应力又有所升高,直至下一层破碎。整个试样的破碎以这种方式重复进行,故压缩曲线波动较大。

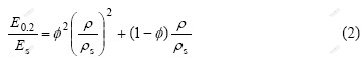

图7所示为Al基和Al-6Si基CCAF动态压缩后形貌。由图可见,Al-6Si基CCAF压缩后试样破碎程度较Al基CCAF严重,Al基CCAF的断裂面微观形貌表现出了塑性材料撕裂的痕迹,而Al-6Si基CCAF断裂面微观形貌较尖,棱角突出,呈明显的解理断裂。实际上,Al基CCAF压缩后表现为压实的‘圆饼’,而Al-6Si基CCAF压缩后试样已不完整,碎裂的小块到处散落。

图7 Al基(a)和Al-6Si基(b)CCAF压后形貌及局部放大图

Fig.7 SEM images of CCAF after compression and magnified figures of local region with Al matrix(a) and Al-6Si matrix(b)

2.3 密度对压缩性能的影响

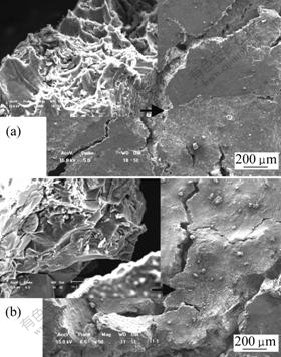

表1所列为不同密度不同基体CCAF屈服强度(σpl)和表观弹性模量(E0.2)。从中可以看到,随着相对密度的增加,Al基和Al-6Si基CCAF的屈服强度(σpl)和表观弹性模量(E0.2)整体趋势都在逐渐增加。密度相同的Al基CCAF表观弹性模量(E0.2)与Al-6Si基CCAF表观弹性模量(E0.2)基本相同,但前者的屈服强度(σpl)却要比后者的高很多,这也是因为Al-6Si基CCAF中含有大量脆性相的缘故。

表1 不同密度时不同基体CCAF的屈服强度(σpl)和表观弹性模量(E0.2)

Table 1 Yield strength and elastic modulus of CCAF with Al and Al-6Si matrix

对于Al基CCAF基体材料,维氏硬度HV为750 N/mm2, 对应的基体材料屈服应力为σs≈250 MPa;对

于Al-6Si基CCAF,维氏硬度HV为2 200 N/mm2, 对应的孔壁材料屈服应力为σs≈734 MPa(假定σs≈HV/3)。

Al基和Al-6Si基CCAF基体材料的屈服应力(σs)分别为250 MPa和734 MPa,图8所示为相对密度对Al基和Al-6Si基CCAF屈服强度的影响,与式(1)的预测结果比较,得到一条最恰当的拟合线,其中![]() ≈0.97,这与McCullough[8]中得到的

≈0.97,这与McCullough[8]中得到的![]() ≈0.92基本一致。

≈0.92基本一致。

图8 相对密度对Al基和Al-6Si基CCAF屈服强度的影响

Fig.8 Effect of relative density on yield strength for CCAF with Al and Al-6Si matrix: Dotted lines are predictions from Eqn.(1). Full line is the best fit.

Al基和Al-6Si基基体材料弹性模量(Es)为70 GPa。图9所示为相对密度对表观弹性模量(E0.2)的影响,与式(2)预测结果比较,得到一条最恰当的拟合线(![]() ≈0.2),与

≈0.2),与![]() ≈0.97的曲线相差较远。这主要是由于本实验选择的弹性模量为表观弹性模量(E0.2),直观上可以描述材料的相对密度与弹性模量的关系,但与材料的真实弹性模量有偏差的缘故。有关CCAF材料接近真实弹性模量的研究将在以后的工作中进行。

≈0.97的曲线相差较远。这主要是由于本实验选择的弹性模量为表观弹性模量(E0.2),直观上可以描述材料的相对密度与弹性模量的关系,但与材料的真实弹性模量有偏差的缘故。有关CCAF材料接近真实弹性模量的研究将在以后的工作中进行。

图9 相对密度对Al基和Al-6Si基CCAF表观弹性模量的影响

Fig.9 Effect of relative density on elastic modulus for CCAF with Al or Al-6Si matrix: Dotted lines are predictions from Eqn.(2). Full line is the best fit.

3 结论

1) Al基CCAF微观形貌较单一,基本上以小块状的Al20CaTi2的存在;而Al-6Si基CCAF微观形貌复杂,主要以大片状(Al3.21Si0.47和CaAl2Si3)、长针状(Al3Ti)和小白点(Al2O3)存在。

2) Al基CCAF的动态压缩曲线非常光滑,三阶段应力都呈显著上升趋势,说明形变过程非常平稳,显示出典型的塑性泡沫材料特征;相比之下,Al-6Si基CCAF压缩曲线有明显的起伏,尤其是密度较大的Al-6Si基试样曲线,显示出脆性材料的压缩特征。

3) 随着相对密度的增加,Al基和Al-6Si基CCAF屈服强度(σpl)和表观弹性模量(E0.2)整体趋势都在增加,预测得到最佳拟合曲线,其中![]() 值分别为0.97和0.2。

值分别为0.97和0.2。

REFERENCES

[1] Zhao C Y, Lu T J, Hodson H P. Natural convection in metal foams with open cells[J]. Int J Heat Mass Transfer, 2005, 48: 2452-2463.

[2] YU Hai-jun, YAO Guang-chun, LI Bing, WANG Xiao-lin, LIU Yi-han, LI Hong-bing. Sound insulation property of Al-Si closed-cell aluminum foam sandwich panels[J]. Appl Acoust, 2006 (in press).

[3] 尉海军,姚广春,李 兵,郭志强. Al-Si闭孔泡沫铝电磁屏蔽效能[J]. 功能材料, 2006, 37(8): 1239-1241.

YU Hai-jun, YAO Guang-chun, LI Bing, GUO Zhi-qiang. Electromagnetic shielding effectiveness of Al-Si closed-cell aluminum foam[J]. J Functional Mater, 2006, 37(8): 1239-1241.

[4] Banhart J. Manufacture, characterization and application of cellular metals and metal foams[J]. Prog Mater Sci, 2001, 46: 559-632.

[5] YU Hai-jun, YAO Guang-chun, WANG Xiao-lin, Li Bing, LIU Ke. Research on sound insulation property of Al-Si closed-cell aluminum foam bare board material[J]. Trans Nonferrous Met Soc China, 2006, 17(1): 93-98.

[6] Banhart J, Baumeister J. Deformation characteristic of metal foams[J]. J Mater Sci, 1998, 33: 1431-1440.

[7] YU Hai-jun, YAO Guang-chun, LIU Yi-han. Research of tensile property of Al-Si closed-cell aluminum foam[J]. Trans Nonferrous Met Soc China, 2006, 16(6): 1335-1340.

[8] McCullough K Y G, Fleck N A, Ashby M A. Uniaxial stress-strain behaviour of aluminum alloy foams[J]. Acta Mater, 1999, 47(8): 2323-2330.

[9] Gibson L J, Ashby M F. Cellular Solids: Structure and Properties[M]. Oxford: Pergamon Press, 1997: 113.

[10] Gibson L J. Mechanical behavior of metailic foams[J]. Annu Rev Mater Sci, 2000, 30: 191-227.

[11] Lopatnikov S L, Gama B A, Haque M J, Krauthauser C, Gillespie J W. High-velocity plate impact of metal foams[J]. Int J Impact Eng, 2004, 30: 421-445.

[12] Lopatnikov S L, Gama B A, Haque M J, Krauthauser C, Gillespie J W, Guden M, Hall I W. Dynamics of metal foam deformation during Yaylor cylinder-Hopkinson bar impact experiment[J]. Compos Struct, 2003, 61: 61-71.

[13] Deshpande V S, Fleck N A. High strain rate compressive behaviour of closed-cell aluminum foams[J]. Int J Impact Eng, 2000, 24: 277-298.

[14] Kanahashi H, Mukai T, Yamada Y, Shimojima K, Mabuchi M, Aizawa T, Higashi K. Experimental study for the improvement of crashworthiness in AZ91 magnesium foam controlling its microstructure[J]. Mater Sci Eng A, 2001, A308: 283-287.

[15] Kanahashi H, Mukai T, Yamada Y, Shimojima K. Dynamic compression of an ultra-low density aluminum foam[J]. Mater Sci Eng A, 2000, A280: 349-353.

[16] Feng Y, Tao N, Zhu Z G, Hu S S, Pan Y. Effect of aging treatment on the quasi-static and dynamic compressive properties of aluminum alloy foams[J]. Mater Lett, 2003, 57: 4058-4063.

基金项目:国家高技术研究发展计划资助项目(2002AA334060)

收稿日期:2006-06-29;修订日期:2007-04-28

通讯作者:姚广春,教授;电话:024-83686462;E-mail: yuhaijunneu@163.com 或gcyao@mail.neu.edu.cn

摘 要:利用熔体转移发泡法制备了不同密度的Al基和Al-6Si基闭孔泡沫铝(CCAF),探讨了CCAF基体的微观形貌及物相组成,对其动态压缩性能进行了研究。结果表明:Al基CCAF基体微观形貌较单一,基本上是小块状(Al20CaTi2);而Al-6Si基CCAF基体微观形貌复杂,主要呈大片状(Al3.21Si0.47和CaAl2Si3)、长针状(Al3Ti)和小白点(Al2O3)。动态压缩结果显示:Al基CCAF压缩应力—应变曲线较平缓,断裂层有明显的材料撕裂痕迹;而Al-6Si基CCAF压缩应力—应变曲线不光滑,个别曲线波动较大,断裂层出现显著的脆性材料断裂特征;随着相对密度的增加,Al基和Al-6Si基CCAF屈服强度(σpl)和表观弹性模量(E0.2)整体趋势都在增加。