J. Cent. South Univ. (2021) 28: 1266-1278

DOI: https://doi.org/10.1007/s11771-021-4694-x

Performance improvement of Fe-6.5Si soft magnetic composites with hybrid phosphate-silica insulation coatings

WANG Jian(王健)1, 2, 3, LIU Xin(刘辛)1, 2, 3, LI La(李腊)1, 2, 3, MAO Xin-hua(毛新华)1, 2, 3

1. Institute of Materials and Processing, Guangdong Academy of Sciences, Guangzhou 510650, China;

2. Guangdong Provincial Key Laboratory of Metal Toughening Technology and Application,Guangzhou 510650, China;

3. National Engineering Research Center of Powder Metallurgy of Titanium&Rare Metals,Guangzhou 510650, China

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2021

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2021

Abstract:

Fe-6.5Si soft magnetic composites (SMCs) with hybrid phosphate-silica insulation coatings have been designed to improve their comprehensive property via chemical coating combining sol-gel method in this work. The microstructure and magnetic performance of the Fe-6.5Si SMCs with hybrid phosphate-silica insulation coatings were investigated. The hybrid phosphate-silica coatings with high heat resistance and high withstand pressure, formed on the surface of the Fe-6.5Si ferromagnetic powders, were found stable in the composites. Compared with Fe-6.5Si SMCs coated by single phosphate or single silica, Fe-6.5Si SMCs with hybrid phosphate-silica show much higher permeability and lower core loss. The work provides a new way to optimize the magnetic performance of soft magnetic composites.

Key words:

Cite this article as: WANG Jian, LIU Xin, LI La, MAO Xin-hua. Performance improvement of Fe-6.5Si soft magnetic

composites with hybrid phosphate-silica insulation coatings [J]. Journal of Central South University, 2021, 28(4): 1266-1278. DOI: https://doi.org/10.1007/s11771-021-4694-x.

1 Introduction

Soft magnetic materials and downstream applied devices such as inductors, transformers and electrical machines have been extensively studied in recent years [1-3]. Among numerous soft magnets, the traditional materials like soft magnetic ferrites and electrical steels are challenged by soft magnetic composites (SMCs) in applications with alternating magnetic field. SMCs, usually fabricated by coating ferromagnetic powder particles with insulating layers, are well known to offer 3D thermal and magnetic isotropy, relative low eddy current loss, design flexibility, economical benefits, etc. [4, 5]. To improve the SMCs capable of efficient operation at high frequencies with lower core loss is drawing much attention of researchers. Therefore, the insulation coating is crucial to improve magnetic performances of SMCs by increasing electrical resistivity and reducing the eddy current.

Owing to the excellent magnetic performance including high magnetic permeability, low coercive force and near-zero magnetostriction, Fe-6.5Si alloy is believed to be a good candidate to realize the high power density and low energy consumption for electromagnetic conversion device applied in higher frequency. However, the application of the alloy is limited by its poor workability due to the almost-zero ductility and high hardness at room temperature [6]. As such, powder metallurgical methods were employed to overcome this problem. High pressure (>1.0 GPa) compression, followed by a high temperature annealing process to release the residual stress is required for Fe-6.5Si compacted core. Thus the insulating layer with high heat resistance, high pressure endurance, high stability and high resistivity is imperative and urgently needed.

In spite of their good adhesion and flexibility, thermal resistances of conventional organic materials such as acrylics, polyesters, polyurethanes [7-10] are not very high and they are prone to decompose at the temperature lower than 300 °C [11]. Thus organic coating is not suitable for soft magnetic composite needing high temperature annealing. On the other hand, inorganic coatings, such as phosphate materials [12], metallic or nonmetal oxides like SiO2 [13, 14], TiO2 [15], Al2O3 [16, 17], Fe3O4 [18], even Mn-Zn ferrite [19] and Ni-Zn ferrite [20], have been selected to achieve higher annealing temperature. But single inorganic layer exhibited weak adhesion to ferromagnetism powder. Besides, inorganic is brittle and difficult to withstand high pressure. Consequently, hybrid coating combining the advantages of different materials was proposed [21-24]. For example, hybrid phosphate-alumina insulation coatings [23] enhanced magnetic performance of FeSiAl SMCs by improving adhesion of the inner phosphate layer and the protection against its decomposition by the outer Al2O3 layer during annealing.

In our previous works, single phosphate layer was chosen to coat Fe-6.5Si powders and the effect of phosphate concentration on the microstructure and magnetic properties of Fe-6.5Si phosphate powder and SMCs was studied [25]. High phosphate concentration gives rise to stress accumulation in interface, and thus the coating layer becomes more susceptible to breakdown and damage. And for low concentration, the phosphate coating is too thin to be consolidated and compacted. A hybrid phosphate-silica coating (see Figure 1) is designed as insulation layer for Fe-6.5Si powders in this work, in attempt to establish a double inorganic coating structure with high withstand pressure, high heat resistance and high resistivity. With good adhesivity and high homogeneity, inner phosphate closely reacts with the powder matrix, forming a complete and compact coating. And external silica with high heat resistance and three-dimensional random network structure is expected to protect the inner layer from decomposition by high temperature. Especially, this hybrid phosphate-silica coating shows the structural advantage of crack deflection when compared with single phosphate or silica coating. The single phosphate or silica insulation layer will fail completely upon crack formation under high pressure, while the hybrid phosphate-silica coating remains completely or partially unbroken. In the absence of inner phosphate layer with some viscosity and elasticity, fracture energy is not enough to across the phosphate layer to bring about the plastic deformation, so the propagation path of crack will change instead of following the original path [26, 27]. This hybrid phosphate-silica coating was achieved by chemical coating combining sol-gel method and the microtopography and phase structure of it were investigated in detail. Evolution of the single phosphate, single silica coating and hybrid phosphate-silica coating during annealing has been explored to expound the enhanced magnetic performances of Fe-6.5Si SMCs with hybrid phosphate-silica coating.

Figure 1 Schematic design of hybrid phosphate-silica coating

2 Experimental

2.1 Preparation of Fe-6.5Si SMCs with hybrid phosphate-silica insulation coatings

Gas atomized Fe-6.5Si powders with the size below 75 μm were passivated in the mixed solution of phosphoric acid (85%) and absolute ethyl alcohol (99.9%). The powder/solution ratio follows the rule of 2.5 g/mL to ensure that all particles are passivated. After being washed by absolute ethyl alcohol 3 times, the phosphated Fe-6.5Si powders were immersed into the mixture of aminopropyltriethoxysilane (APTES, 99%), absolute ethyl alcohol (99.9%) and deionized water (homemade) in definite proportions. After stirring for 60 min, the tetraethoxysilane (TEOS, 99%) was added to the mixture and kept stirring for 3 h in (40±2) °C thermostat water bath. Powder products were washed with absolute ethyl alcohol and then dried at 100 °C for 60 min under vacuum. The obtained composite powders were compacted into toroidal core (outer diameter=26.9 mm, inner diameter=14.5 mm, .0 mm) under the pressure of 1.1 GPa and annealed at 600 °C for 60 min under mixture of Ar and H2 gas atmosphere. For comparison, Fe-6.5Si SMCs coated by single phosphate and single silica were also prepared from the phosphated Fe-6.5Si powder and silica coating powder under the same condition.

2.2 Characterizations

Surface topography, fracture appearance and cross section morphology of powders and composites were observed by scanning electron microscope (SEM, JEOL JXA-8100) and the corresponding elements scanning was obtained by the equipped energy dispersive X-ray spectroscopy (EDS). The thermogravimetric analysis was investigated using a NETZSCH high-temperature integrated thermal analyzer (SAT 409 PC/PG) under Ar atmosphere from room temperature to 1100 °C with a heating rate of 10 K/min. Phase analysis of samples was tested by X-ray diffraction analysis (XRD, Rigaku D/MAX-RC) at 2θ=10°-120° using Cu Ka radiation. The chemical structure and state of coating layer were observed by Fourier transform infrared spectra (FTIR, Bruker VERTEX 70). Static magnetic properties were obtained by vibrating sample magnetometer of quantum design (Lake Shore 7407). AC magnetic performance (core loss and permeability measured at 50 mT was obtained by an B-H analyzer (MATS-2010SA).

3 Results and discussion

Figure 2 shows the the surface morphology and particle size distribution of Fe-6.5Si powders. Gas atomized Fe-6.5Si powder exhibits good degree of sphericity and its surface is bright and clean. With continuous distributions, the particle size is distributed in less than 75 μm and the half-content diameter D(50) is 22.2 μm.

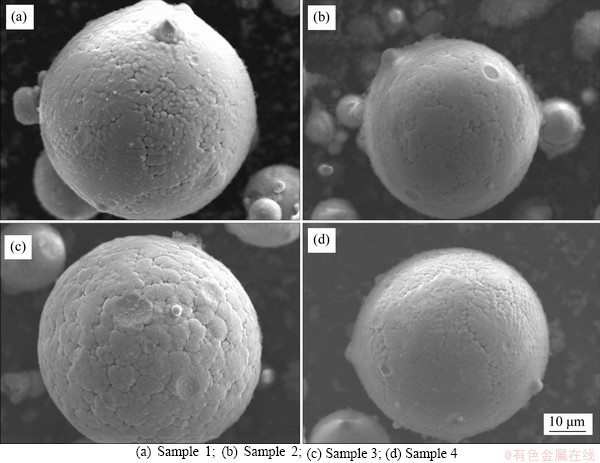

Figure 3 illustrates the surface morphology of Fe-6.5Si powders coated with hybrid phosphate-silica. It is seen from Figure 3(a) that only small amount of SiO2 particles are adhered on the surface of Fe-6.5Si powders without adding APTES. The smooth surface of the Fe-6.5Si powder tends to be rough and is wrapped with continuous flocs of SiO2 with 1 mL addition of APTES. The amount of those flocculent SiO2 increases significantly with increasing the TEOS and some flocculent aggregative nano-SiO2 particles exist in free state in Figures 3(b)-(d). After surface modification by APTES,a nonpolar layer is formed on the surface of Fe-6.5Si powders, which makes it possible for SiO2 to adhere on the powders by dehydration and condensation of TEOS [28]. Silica coatings were fabricated by sol-gel method via hydrolysis and polycondensation of TEOS (see Eqs. (1) and (2)). As the silica source precursors, the addition of TEOS mainly affects the coating amount and thickness of SiO2 layer.

(C2H5O)4Si+4H2O→Si(OH)4+4C2H5OH (1)

Si(OH)4→SiO2+2H2O (2)

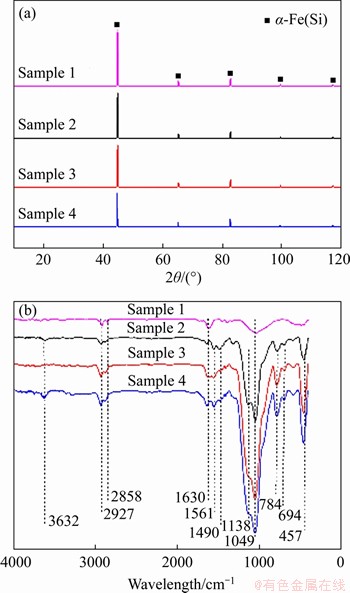

Figure 4 displays the XRD patterns and FTIR curves of Fe-6.5Si powders coated with hybrid phosphate-silica. Only characteristic peak of α-Fe(Si) phase is observed in the XRD patterns of Fe-6.5Si powders coated with hybrid phosphate-silica and peaks of FePO4 and SiO2 are absent as shown in Figure 4(a). Amorphous phase FePO4 appears during passivation of Fe-6.5Si powders by phosphate [29]. Our previous research showed that characteristic peak of FePO4 existed in the XRD patterns of Fe-6.5Si powders phosphated with high concentrations (great than 0.18) [25]. And the silica prepared by sol-gel method is always amorphous [30]. The FTIR curve of sample 1 without APTES shows peaks of symmetric or/and asymmetric stretching vibration absorption of adsorbed CH3 group from residual C2H5OH or/and (C2H5O)4Si at 2927 and 2856 cm-1.

Table 1 Experimental conditions of hybrid phosphate-silica coatings via chemical coating combining sol-gel method

Figure 2 SEM images (a, b) and size distribution (c) of Fe-6.5Si powder particles

Figure 3 SEM micrographs of Fe-6.5Si powders coated with hybrid phosphate-silica:

Figure 4 XRD patterns (a) and FTIR curves (b) of Fe-6.5Si powders coated with hybrid phosphate-silica

The absorption bands appearing in the spectra of all samples around 1049 and 1630 cm-1 should be related to Si—O—Si and P—O—H/water, respectively [31]. More peaks with higher intensities are observed after addition of APTES, as seen from the curves of samples 2-4 in Figure 4(b). The bands at 3632, 1561 and 1490 cm-1 might result from the infrared absorption peak of O—H [32]. Characteristic peaks of phosphate are observed at the band of 1138 cm-1 [23]. Broad absorption bands at 1049, 784 and 457 cm-1 originate from the symmetric, asymmetric and bending vibration absorption of Si—O—Si. Bands at 694 cm-1 is ascribed to the lattice vibration of Fe2O3 [33], revealing that certain amount of Fe is oxidized during the coating process. Characteristic peaks of phosphate and SiO2 detected in the FTIR curves confirm that the layer coated on the ferromagnetism particles is hybrid phosphate- silica.

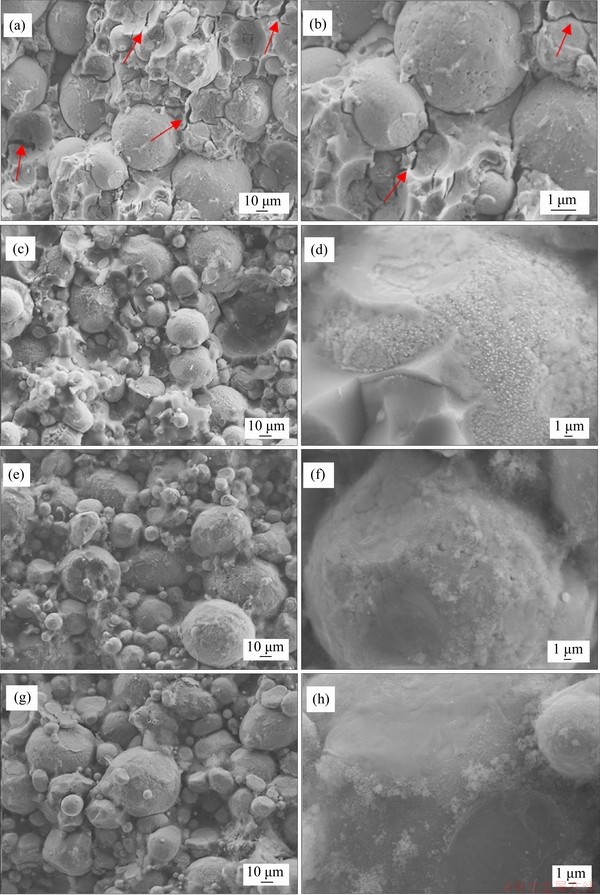

It must be pointed out that the Fe-6.5Si powders coated with hybrid phosphate-silica prepared without addition of APTES (sample 1) are difficult to be compacted, So, only samples 2-4 are discussed in the next content. Seen in Figure 5(a) for Fe-6.5Si SMCs coated with phosphate and the corresponding morphologies at higher magnification (Figure 5(b)), high pressure (1.1 GPa) compression has created many obvious cracks. Figures 5(c, e, g) illustrate the fracture morphologies of Fe-6.5Si SMCs with hybrid phosphate-silica coating (sample 2, sample 3 and sample 4) and Figures 5(d, f, h) show the corresponding morphologies at higher magnification. Ferromagnetic powder particles are tightly bound with each other and coating layer composed of nano-SiO2 is observed. The increments of size and quantity of the SiO2 deposits are insignificant as the amount of TEOS increases. This might be ascribed to the generation of dissociative SiO2 in solution that can not stick on the surface of Fe-6.5Si powders during the sol-gel process. Few cracks are observed in the fracture morphology of Fe-6.5Si SMCs with hybrid phosphate-silica coating. Compared with single phosphate coating, hybrid phosphate-silica coating with multilayered structure can withstand greater pressure.

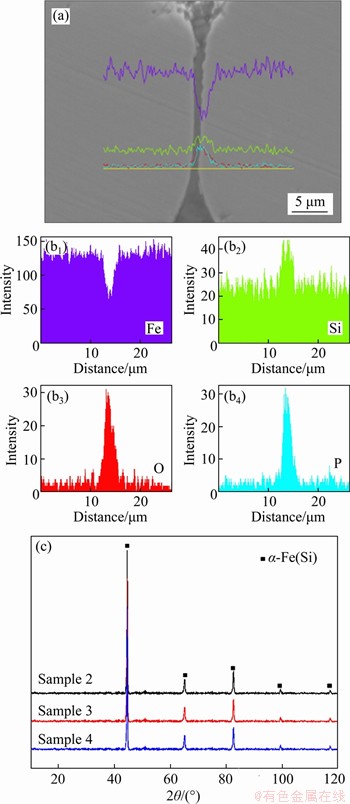

Figure 6(a) demonstrates the cross-sectional image of Fe-6.5Si SMCs with hybrid phosphate-silica coating and Figure 6(b) presents the corresponding EDS line scanning results of Fe, Si, O and P elements. No obvious porosity can be observed from the cross section of dense magnetic body and the gaps among ferromagnetic particles are filled with coating materials. Fe element distributes in the grey white region of ferromagnetic particles, while Si, O and P element concentrated within the coating layers between adjacent particles. XRD patterns of Fe-6.5Si SMCs coated with hybrid phosphate-silica are shown in Figure 6(c). Comparing to α-Fe(Si) phase found in the curves of XRD patterns, no visible peaks of crystalline FePO4 or SiO2 after crystallization are observed for Fe-6.5Si SMCs coated with hybrid phosphate-silica. It is further proved that the existence of hybrid phosphate-silica coating and its good heat resistance at temperatures of 600 °C.

Figure 5 Fracture morphology of Fe-6.5Si SMCs coated with phosphate (a, b) and hybrid phosphate-silica ((c, d) Sample 2; (e, f) Sample 3; (g, h) Sample 4)

Figure 6 Cross-sectional image (a) and corresponding elements scanning (b) of Fe-6.5Si SMCs coated with hybrid phosphate-silica (sample 2); XRD patterns (c) of Fe-6.5Si SMCs coated with hybrid phosphate-silica

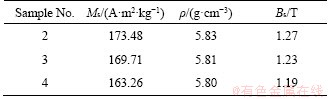

Physical and static magnetic properties of Fe-6.5Si SMCs coated with hybrid phosphate-silica are listed in Table 2. Both of the Ms, ρ and Bs of Fe-6.5Si SMCs decrease with the increasing of TEOS. The decrease in Ms can be explained by the core- surface model [34]. According to different magnetic properties, the magnetic composite can be divided into core and surface layer. For a spherical magnetic particle coated with layer, d and t represent the diameter of magnetic particle and the thickness of surface layer, respectively. And MsP and MsL are the saturation magnetizations of the particle and layer. V corresponds to the volume. The total saturation magnetizations of magnetic composite is

(3)

(3)

Thus the Ms of Fe-6.5Si SMCs coated with hybrid phosphate-silica decreases with the increasing nonmagnetic TEOS. The pressing properties can be improved by adding a modicum SiO2 adhered to the particle powders. More dissociative SiO2 generates with superfluous addition of TEOS, which makes it more difficult to be compressed. The saturation induction density (Bs) of Fe-6.5Si SMCs can be calculated by formula (4).

(4)

(4)

Due to the low magnetic moments and low densities of phosphate and SiO2 compared to the matrix material, high content of SiO2 will inevitably cause the decline of Bs. Fe-6.5Si SMCs with hybrid phosphate-silica prepared by adding 1 mL APTES and 2 mL TEOS exhibit both the highest ρ and Bs with values at 5.83 g/cm3 and 1.27 T. Introduction of proper amount of SiO2 is beneficial to compaction and further addition leads to the decline of Ms andρ of SMCs.

Table 2 Physical and static magnetic properties of Fe-6.5Si SMCs coated with hybrid phosphate-silica

Dynamic magnetic properties (effective permeability and core loss) of Fe-6.5Si SMCs coated with hybrid phosphate-silica are presented in Figure 7. With the TEOS amount increasing from 2 to 10 mL, μ of Fe-6.5Si SMCs decreases significantly, and reaches the maximum value at about 36 with SiO2 concentration of 0.04. Hybrid phosphate-silica coating favors better integration of ferromagnetic powder particles and denser structure, hence the permeability increases. And excessive addition of SiO2 might cause the decline of μ. The core loss of SMCs increases in proportion to the applied frequency. When keeping the amount of APTES unchanged and increasing the addition of TEOS, core loss increases slightly at first and then decreases, showing the lowest value of about 627 mW/cm3 at 100 kHz with adding SiO2 content of 0.04.

Figure 7 Effective permeability (a) and core loss (b) of Fe-6.5Si SMCs coated with hybrid phosphate-silica

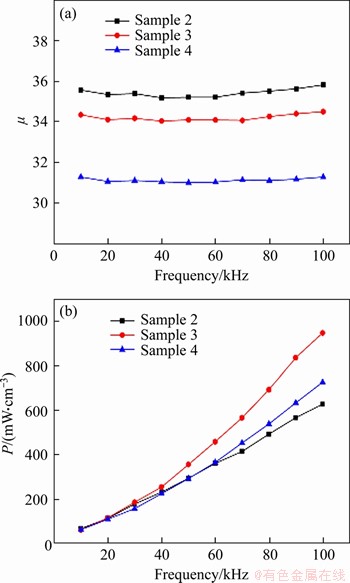

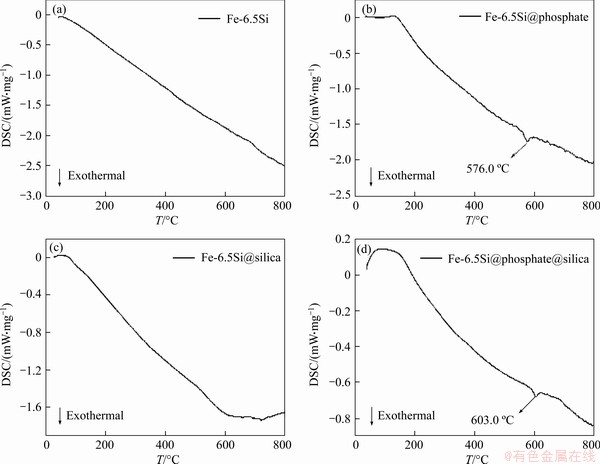

The DSC thermograms of Fe-6.5Si powder and Fe-6.5Si powders coated with single phosphate, single silica and hybrid phosphate-silica layers are demonstrated in Figure 8. For raw material of Fe-6.5Si powders without coating layer, no obvious exothermic and endothermic peaks appear in the DSC thermograms as the temperature rises to 800 °C (Figure 8(a)). As seen in Figure 8(c), there is also no obvious characteristic peak for Fe-6.5Si powders coated with single silica. SiO2 usually exists in form of α-SiO2 at room temperature, which transforms into β-SiO2 and γ-SiO2 as the temperature rises to 573 °C and 846 °C, respectively. The transformation is supposed to cause heat variations at corresponding temperatures; however, no obvious endothermic and exothermic peaks are observed and this might be ascribed to the very low content of SiO2 coatings. As for DSC curves of Fe-6.5Si powders coated with single phosphate and hybrid phosphate-silica coating layer, an exothermic peak at 576 °C and 603 °C is presented in Figures 8(b) and (d), respectively, and is attributed to the crystallization of amorphous FePO4. Crystallization of amorphous FePO4 was reported to occur between 500 °C and 600 °C [35] and decreased the resistivity, which is detrimental for powder particle insulation. Compared with single phosphate, the hybrid phosphate-silica coating exhibits a higher crystallizing temperature, and the outer silica layer significantly improves the stability of amorphous FePO4 by acting as a thermal barrier that successfully retards the crystallization temperature of FePO4.

XRD patterns of Fe-6.5Si powders coated with single phosphate, single silica and hybrid phosphate-silica layer before and after annealing at 600 °C are displayed in Figure 9. XRD patterns of Fe-6.5Si powders with different coatings before annealing in Figure 9(a) are very similar for each other and only diffraction peak of α-Fe(Si) phase is observed.Peaks of FePO4 and Fe2O3 are detected from the XRD curve of Fe-6.5Si powders coated with phosphate after annealing in Figure 9(b). The passivation reaction product of phosphate for iron is the mixture of Fe3(PO4)2 and FePO4, and the latter takes relatively major proportion [36, 37]. FePO4 is prone to be reduced and decomposed into Fe2P at high temperatures and reductive environment [38]. Formation of Fe2O3originates from the oxidation of Fe2P and unprotected Fe-based basic material after the coating is destroyed. Thus the single phosphate coating is easier to crystallize and decompose with the rise of temperature and existence of reducing gas compared with single silica and hybrid phosphate-silica coating for Fe-6.5Si powders.

FTIR analysis has been carried out and the results are shown in Figure 10 for the Fe-6.5Si powders coated with single phosphate, single silica and hybrid phosphate-silica layer before and after annealing at 600 °C. FTIR curve of the Fe-6.5Si powders without coating is shown in Figure 10(a) and no distinct band is observed. Broad absorption band around 3329 cm-1 originates from the absorbed water. Curves of Fe-6.5Si powder coated with single phosphate before and after annealing are also shown in Figure 10(a). The adsorption bands at 1630, 1050 and 522 cm-1 are attributed to the bending mode of P—OH bonds, the symmetric stretching vibrations of P—O- and the deformation modes of  groups, respectively [39, 40]. Weak absorption bands at 2317 cm-1 are related to P—O—H or water, which may be introduced by air moisture during the sample preparation for FTIR measurements [41]. And the bands around 1104, 803 and 470 cm-1 correspond to the PO3 groups, Si—O—Si and Fe—O bonds, respectively [23, 39]. Compared with the curve of Fe-6.5Si powders coated with single phosphate without annealing, additional infrared absorption peaks of Si—O—Si and Fe—O bonds indicate the oxidization of Fe-6.5Si powder caused by the decomposition of phosphate coating layer after annealing. Figure 10(b) exhibits the FTIR curves of Fe-6.5Si powder coated with single silica before and after annealing. The broad absorption bands around 2927 and 2856 cm-1 are attributed to the symmetric or/and asymmetric stretching vibration absorption of adsorbed CH3 group from residual C2H5OH or/and (C2H5O)4Si. The bands at 1639 and 1651 cm-1 are owing to the H2O from KBr or Fe-6.5Si composites [31]. Broad absorption bands at 1049, 784 and 457 cm-1 originate from the symmetric, asymmetric and bending vibration absorption of Si—O—Si, while the strong bands at 694 and 580 cm-1 are due to the lattice vibration of Fe2O3 [32]. The results of FTIR further confirm that the obtained coating layers on the surface of Fe-6.5Si particles are SiO2 and some of Fe is oxidized during the coating process. Figure 10(c) displays the FTIR curves of Fe-6.5Si powders coated with hybrid phosphate-silica before and after annealing. Similarly, bands of 2927 and 2856 cm-1 are attributed to the-CH3 group from residual C2H5OH or/and (C2H5O)4Si. The bands at 1630 and 1138 cm-1 are assigned to the bending mode of P—OH bonds and the symmetric stretching vibrations of P—O bonds [42], respectively. Band at 1561 cm-1 owing to the H2O and 1490 cm-1 originates from the bending vibration of C—H [39]. Bands at 1049, 784 and 457 cm-1 originate from the symmetric and bending vibration absorption of Si—O—Si, and the strong band at 694 cm-1 is owing to the Fe2O3. Above mentioned absorption peaks related to phosphate and SiO2 in Figure 10(c) reveal the stable existence of hybrid phosphate-silica coating after annealing.

groups, respectively [39, 40]. Weak absorption bands at 2317 cm-1 are related to P—O—H or water, which may be introduced by air moisture during the sample preparation for FTIR measurements [41]. And the bands around 1104, 803 and 470 cm-1 correspond to the PO3 groups, Si—O—Si and Fe—O bonds, respectively [23, 39]. Compared with the curve of Fe-6.5Si powders coated with single phosphate without annealing, additional infrared absorption peaks of Si—O—Si and Fe—O bonds indicate the oxidization of Fe-6.5Si powder caused by the decomposition of phosphate coating layer after annealing. Figure 10(b) exhibits the FTIR curves of Fe-6.5Si powder coated with single silica before and after annealing. The broad absorption bands around 2927 and 2856 cm-1 are attributed to the symmetric or/and asymmetric stretching vibration absorption of adsorbed CH3 group from residual C2H5OH or/and (C2H5O)4Si. The bands at 1639 and 1651 cm-1 are owing to the H2O from KBr or Fe-6.5Si composites [31]. Broad absorption bands at 1049, 784 and 457 cm-1 originate from the symmetric, asymmetric and bending vibration absorption of Si—O—Si, while the strong bands at 694 and 580 cm-1 are due to the lattice vibration of Fe2O3 [32]. The results of FTIR further confirm that the obtained coating layers on the surface of Fe-6.5Si particles are SiO2 and some of Fe is oxidized during the coating process. Figure 10(c) displays the FTIR curves of Fe-6.5Si powders coated with hybrid phosphate-silica before and after annealing. Similarly, bands of 2927 and 2856 cm-1 are attributed to the-CH3 group from residual C2H5OH or/and (C2H5O)4Si. The bands at 1630 and 1138 cm-1 are assigned to the bending mode of P—OH bonds and the symmetric stretching vibrations of P—O bonds [42], respectively. Band at 1561 cm-1 owing to the H2O and 1490 cm-1 originates from the bending vibration of C—H [39]. Bands at 1049, 784 and 457 cm-1 originate from the symmetric and bending vibration absorption of Si—O—Si, and the strong band at 694 cm-1 is owing to the Fe2O3. Above mentioned absorption peaks related to phosphate and SiO2 in Figure 10(c) reveal the stable existence of hybrid phosphate-silica coating after annealing.

Figure 8 DSC curves of Fe-6.5Si powders (a), Fe-6.5Si powders coated with phosphate (b), silica (c) and hybrid phosphate-silica (d) layer

Figure 9 XRD patterns of Fe-6.5Si powders coated with phosphate, silica and hybrid phosphate-silica layer before (a) and after (b) annealing

Figure 10 FTIR curves of Fe-6.5Si powders coated with phosphate (a), silica (b) and hybrid phosphate-silica (c) layer before and after annealing

Physical and AC magnetic performance (effective permeability and core loss) comparison of Fe-6.5Si SMCs coated by single phosphate, single silica and hybrid phosphate-silica is listed in Table 3. With a very low density of 0.65-0.85 g/cm3 for FePO4 [43], Fe-6.5Si SMCs coated with hybrid phosphate-silica show the minimum value of ρ and Bs. Fe-6.5Si SMCs coated by single phosphate show effective permeability of 29 and relatively high core loss of 3097 mW/cm3 at 50 mT and 100 kHz. Magnetic performance of Fe-6.5Si SMCs coated with single phosphate deteriorates after annealing treatment. The crystallization for FePO4 at 576 °C decreases its electrical resistivity. Further temperature rise causes the reduction reaction of FePO4 and the reduzate (Fe2P) is of high conductivity. Fe2O3originates from the oxidation of Fe2P and it shows lower electrical resistivity comparing to FePO4. Thus during the annealing treatment process, whether crystallization or decomposition of FePO4, is harmful for blocking eddy current and reducing core loss. And there is no obvious improvement for Fe-6.5Si SMCs coated with single silica. Although single silica coating shows better thermal stability than single phosphate coating, effective coating is not formed because of the poor adhesion of SiO2 on Fe-6.5Si particles. Thus incomplete insulation causes a high eddy current loss. Fe-6.5Si SMCs coated with hybrid phosphate-silica exhibit much higher μ and lower core loss compared with Fe-6.5Si SMCs coated by single phosphate and single silica. Especially, the core loss value is 627 mW/cm3 and the decrease amplitude is as much as 80% in comparison to Fe-6.5Si SMCs coated with single phosphate. Effective adhesion on the surface of Fe-6.5Si powders by chemical conversion, inner phosphate layer is beneficial for a complete and dense coating. With excellent thermotolerance and three-dimensional random network structure, external silica prevents the inner phosphate from decomposition and fracture under high temperature and high pressure. Introduction of SiO2 can enhance the density of composites so as to improve the permeability. Eddy current is blocked by hybrid phosphate-silica layer composed with high electrical resistivity materials, guaranteeing the effective insulation between conductive ferromagnetic particles.

Table 3 Performance comparison of Fe-6.5Si SMCs coated with phosphate, silica and hybrid phosphate-silica

4 Conclusions

Fe-6.5Si soft magnetic composites with hybrid phosphate-silica insulation coatings have been successfully prepared and investigated in this paper. Hybrid phosphate-silica insulation coating shows good heat resistance even if the temperature reaches to 600 °C. When the silica content is 0.04, the density and Ms of the Fe-6.5Si SMCs with hybrid phosphate-silica coatings are similar with those of the Fe-6.5Si SMCs with single silica coating. And the density and Ms of the Fe-6.5Si SMCs with hybrid phosphate-silica coatings decrease slightly with the increasing silica content. The μ of the SMCs decreases with the increase of silica content, which is much higher than that of the SMCs with single silica coating except for the sample with silica content of 0.12. The core loss rises first and then drops as the silica content increases. Magnetic properties of Fe-6.5Si SMCs with hybrid phosphate-silica is optimal with effective permeability of 36 and core loss of 627 mW/cm3 when the phosphate concentration is 0.004 and silica content is 0.04. Compared with single phosphate or silica coating, the hybrid phosphate-silica coating can remarkably improve the effective permeability and core loss of Fe-6.5Si SMCs while saturation magnetic induction does not deteriorate.

Contributors

WANG Jian conducted the literature review and wrote the first draft of the manuscript. LIU Xin provided the concept and edited the draft of manuscript. LI La and MAO Xin-hua provided the measured experimental data, and analyzed the measured data. WANG Jian and LIU Xin replied to reviewers’ comments and revised the final version.

Conflict of interest

WANG Jian, LIU Xin, LI La and MAO Xin-hua declare that they have no conflict of interest.

References

[1] SUNDAY K J, TAHERI M L. Soft magnetic composites: Recent advancements in the technology [J]. Metal Powder Report, 2017, 72(6): 425-429. DOI: 10.1016/j.mprp.2016.08. 003.

[2] SILVEYRA J M, FERRARA E, HUBER D L, MONSON T C. Soft magnetic materials for a sustainable and electrified world [J]. Science, 2018, 362(6413): eaao0195. DOI: 10.1126/ science.aao0195.

[3] GRANDE M A, FERRARIS L, FRANCHINI F, POSKOVIC E. New SMC materials for small electrical machine with very good mechanical properties [J]. IEEE Transactions on Industry Applications, 2017, 54(1): 195-203. DOI: 10.1109/ TIA.2017.2756593.

[4] SHOKROLLAHI H, JANGHORBAN K. Soft magnetic composite materials (SMCs) [J]. Journal of Materials Processing Technology, 2007, 189: 1-12. DOI: 10.1016/ j.jmatprotec.2007.02.034.

[5] GUO Y, ZHU J G, WATTERSON P A, WU W. Comparative study of 3-D flux electrical machines with soft magnetic composite cores [J]. IEEE Transactions on Industry Applications,2003, 39(6): 1696-1703. DOI: 10.1109/TIA. 2003.818990.

[6] FAN X A, WU Z Y, LI G Q, WANG J, XIANG Z D, GAN Z H. High resistivity and low core loss of intergranular insulated Fe-6.5wt.%Si/SiO2 composite compacts [J]. Materials & Design,2016, 89: 1251-1258. DOI: 10.1016/j.matdes.2015. 10.087.

[7] MENG Q S, YANG F Y, WU X Y, XU T T, ZHOU M M, GUAN W W, SU H L, DU Y W. Magnetic spectra of soft magnetic composites based on Fe-Si-Cr-B amorphous and carbonyl-iron powders [J].Journal of Superconductivity and Novel Magnetism, 2019, 32: 2987-2994. DOI: 10.1007/ s10948-019-5078-4.

[8] WU S, SUN A, ZHAI F, WANG J, ZHANG Q, XU W, LOGAN P, VOLINSKY A A. Annealing effects on magnetic properties of silicone-coated iron-based soft magnetic composites [J]. Journal of Magnetism and Magnetic Materials, 2012, 324: 818-822. DOI: 10.1016/j.jmmm.2011.09.026.

[9] STRECKOVA M, MEDVECKY L, FUZER J, KOLLAR P,BURES R, FABEROVA M. Design of novel soft magnetic composites based on Fe/resin modified with silica [J]. Materials Letters, 2013, 101: 37-40. DOI: 10.1016/j.matlet. 2013.03.067.

[10] SUN H, ZHANG L, CHEN Y, CHEN F, QU X, XIE C, ZHANG L. Magnetic properties of iron-based soft magnetic composites prepared by utilizing polyimide insulating layer [J].Journal of Magnetism and Magnetic Materials, 2019, 486: 165287. DOI: 10.1016/j.jmmm.2019.165287.

[11] KIM Y B, JANG D H, SEOK H K, KIM K Y. Fabrication of Fe-Si-B based amorphous powder cores by cold pressing and their magnetic properties [J]. Materials Science and Engineering, 2007, 449-451: 389-393. DOI: 10.1016/j.msea. 2006.02.394.

[12] XIA C, PENG Y, YI Y, DENG H, ZHU Y, HU G. The magnetic properties and microstructure of phosphated amorphous FeSiCr/silane soft magnetic composite [J].Journal of Magnetism and Magnetic Materials,2019, 474: 424-433. DOI: 10.1016/j.jmmm.2018.11.058.

[13] LIU L, YUE Q, LI G Q, XU K, WANG J, WU Z Y, FAN X A. Influence of SiO2 insulation layers thickness distribution on magnetic behaviors of Fe-Si@SiO2 soft magnetic composites [J].Journal of Physics and Chemistry ofSolids,2019, 132: 76-82. DOI: 10.1016/j.jpcs.2019.04.016.

[14] WANG J, FAN X A, WU Z Y, LI G Q. Synthesis, microstructure and magnetic properties of Fe3Si0.7Al0.3@SiO2 core-shell particles and Fe3Si/Al2O3 soft magnetic composite core [J]. Journal ofSolidStateChemistry, 2015, 23: 152-158. DOI: 10.1016/j.jssc.2015.08.016.

[15] ZHOU B, DONG Y, LIU L, CHANG L, BI F, WANG X. Enhanced soft magnetic properties of the Fe-based amorphous powder cores with novel TiO2 insulation coating layer [J].Journal of Magnetism and Magnetic Materials, 2019, 474: 1-8. DOI: 10.1016/j.jmmm.2018.11.014.

[16] LEI J, ZHENG J, ZHENG H, QIAO L, YING Y, CAI W, LI W, CHE S. Effects of heat treatment and lubricant on magnetic properties of iron-based soft magnetic composites with Al2O3 insulating layer by one-pot synthesis method [J].Journal of Magnetism and Magnetic Materials,2019, 472: 7-13. DOI: 10.1016/j.jmmm.2018.09.125.

[17] PENG Y, YI Y, LI L, YI J, NIE J, BAO C. Iron-based soft magnetic composites with Al2O3 insulation coating produced using sol-gel method [J]. Materials & Design,2016, 109: 390-395. DOI: 10.1016/j.matdes.2016.07.097.

[18] QIAN L, PENG J, XIANG Z, PAN Y, LU W. Effect of annealing on magnetic properties of Fe/Fe3O4 soft magnetic composites prepared by in-situ oxidation and hydrogen reduction methods [J]. Journal of Alloys and Compounds, 2019, 778: 712-720. DOI: 10.1016/j.jallcom.2018.11.184.

[19] ZHOU M M, HAN Y, GUAN W W, HAN S J, MENG Q S, XU T T, SU H L, GUO X, ZOU Z Q, YANG F Y, DU Y W. Magnetic properties and loss mechanism of Fe-6.5Si powder core insulated with magnetic Mn-Zn ferrite nanoparticles [J].Journal of Magnetism and Magnetic Materials,2019, 482: 148-154. DOI: 10.1016/j.jmmm.2019.03.062.

[20] YI Y, PENG Y, XIA C, WU L, KE X, NIE J. Influence of heat treatment on microstructures and magnetic properties of Fe-based soft magnetic composites prepared by co-precipitation method [J].Journal of Magnetism and Magnetic Material,2019, 476: 100-105. DOI: 10.1016/j.jmmm.2018. 12.049.

[21] LI L, CHEN Q, GAO Z, GE Y, YI J. Fe@SiO2@(MnZn)Fe2O4 soft magnetic composites with enhanced permeability and low core loss for high-frequency applications [J]. Journal ofAlloysand Compounds,2019, 805: 609-616. DOI: 10. 1016/j.jallcom.2019.07.016.

[22] PANG Y X, HODGSON S N B, WEGLINSKI B, GAWORSKA D. Investigations into sol-gel silica and silica hybrid coatings for dielectromagnetic soft magnetic composite applications [J]. Journal of Materials Science,2006, 41(18): 5926-5936. DOI: 10.1007/s10853-006-0360-9.

[23] LIU D, WU C, YAN M. Investigation on sol-gel Al2O3 and hybrid phosphate-alumina insulation coatings for FeSiAl soft magnetic composites [J].Journal of Materials Science, 2015, 50(20): 6559-6566. DOI: 10.1007/s10853-015-9189-4.

[24] ZHONG X, CHEN J, WANG L, LI B, LI L. Properties of FeSiAl-based soft magnetic composites with AlN/Al2O3 and hybrid phosphate-silane insulation coatings [J]. Journal ofAlloysand Compounds,2018, 735: 1603-1610. DOI: 10. 1016/j.jallcom.2017.11.312.

[25] LI L, CAI Y, LIU X, MAO X, YI J. Effects of phosphate concentration on the structure and magnetic properties of Fe-6.5%Si magnetic powder cores [J]. Materials Science and Engineering of Powder Metallurgy, 2016, 21(6): 899-906. DOI: 10.3969/j.issn.1673-0224.2016.06.012.

[26] MUELLER J, RANEY J R, SHEA K, LEWIS J A. Architected lattices with high stiffness and toughness via multicor-shell 3D printing [J]. Advanced Materials, 2018, 30: 1705001. DOI: 10.1002/adma.201705001.

[27] FRATZL P, GUPTA H S, FISCHER F D, KOLEDNIK O. Hindered crack propagation in materials with periodically varying Young’s modulus-lessons from biological materials [J]. Advanced Materials, 2007, 19(18): 2657-2661. DOI: 10. 1002/adma.200602394.

[28] FAN X A, WANG J, WU Z Y, LI G Q. Core-shell structured FeSiAl/SiO2 particles and Fe3Si/Al2O3 soft magnetic composite cores with tunable insulating layer thicknesses [J]. Materials Science and Engineering B, 2015, 201: 79-86. DOI: 10.1016/j. mseb.2015.08.009.

[29] REBEYRAT S, GROSSEAUPOUSSARD J, RENAULT P, PANICUD B, DINHUT J F. Structural characterisation of phosphated α-iron oxidised at 400 °C [J]. Surface & Coatings Technology, 2002, 161(2): 144-149. DOI: 10.1016/S0257-8972(02)00361-4.

[30] WANG J, FAN X A, WU Z, LI G. Synthesis, microstructure and magnetic properties of Fe3Si0.7Al0.3@SiO2 core-shell particles and Fe3Si/Al2O3 soft magnetic composite core [J].Journal of Solid StateChemistry, 2015, 231: 152-158. DOI: 10.1016/j.jssc.2015.08.016.

[31] RAGHAVAIAH B V, LAXMIKANTYH C, VEERAIAH N. Spectroscopic studies of titanium ions in PbO-Sb2O3-As2O3 glass system [J]. Optics Communications, 2004, 235(4-6): 341-349. DOI: 10.1016/j.optcom.2004.02.082.

[32] PAL R, KUNDU D. Sol-gel synthesis of porous and dense silica microspheres [J]. JournalofNon-CrystallineSolids, 2009, 355(1): 76-78. DOI: 10.1016/j.jnoncrysol.2008.03.052.

[33] GOTIC M, DRAZIC G, MUSIC S. Hydrothermal synthesis of α-Fe2O3 nanorings with the help of divalent metal cations, Mn2+, Cu2+, Zn2+ and Ni2+ [J]. Journal of Molecular Structure, 2011, 993(1-3): 167-176. DOI: 10.1016/j.molstruc.2010.12. 063.

[34] LI Z W, CHEN L, ONG C K, YANG Z. Static and dynamic magnetic properties of Co2Z barium ferrite nanoparticle composites [J].Journal of Materials Science,2005, 40(3): 719-723. DOI: 10.1007/s10853-005-6312-y.

[35] XIAO Y, PU W, WAN W, CUI Y. Preparation and performance of the cathode precursor ferric phosphate for Li-ion battery facilitated by impinging stream [J]. International Journal of Electrochemical Science, 2013, 8: 938-948. DOI: 10.1016/j. jelechem.2013.02.009.

[36] KIRYANOV Y G, ZAVINA T A, SYRKIN V G. Kinetics of the Phosphatizing reaction of carbonyl iron powders [J].Powder Metallurgy and Metal Ceramics, 1978, 17(2): 110-112. DOI: 10.1007/BF00796338.

[37] HUANG M, WU C, JIANG Y, YAN M. Evolution of phosphate coatings during high-temperature annealing and its influence on the Fe and FeSiAl soft magnetic composites [J]. Journal ofAlloysand Compounds, 2015, 644: 124-130. DOI: 10.1016/j.jallcom.2015.04.201.

[38] XU Y, LU Y, YAN L, YANG Z, YANG R. Synthesis and effect of forming Fe2P phase on the physics and electrochemical properties of LiFePO4/C materials [J]. Journal of Power Sources, 2006, 160(1): 570-576. DOI: 10.1016/j.jpowsour. 2006.01.042.

[39] LAI Y, LIANG X, YANG S, LIU P, ZENG Y, HU C. Raman and FTIR spectra of CeO2 and Gd2O3 in iron phosphate glasses [J].Journal ofAlloysand Compounds,2014, 617: 597-601. DOI: 10.1016/j.jallcom.2014.08.051.

[40] SHI M, LIANG Y, CHAI L, MIN X, ZHAO Z, YANG S. Raman and FTIR spectra of modified iron phosphate glasses containing arsenic [J].Journal of Molecular Structure, 2015, 1081: 389-394. DOI: 10.1016/j.molstruc.2014.10.061.

[41] LAI Y, LIANG X, YANG S, WANG J, CAO L H, DAI B. Raman and FTIR spectra of iron phosphate glasses containing cerium [J].J Mol Struct, 2011, 992(1): 84-88. DOI: 10.1016/j. molstruc.2011.02.049.

[42] STOCH P, STOCH A, CIECINSKA M, KRAKOWIAK I, SITARZ M. Structure of phosphate and iron-phosphate glasses by DFT calculations and FTIR/Raman spectroscopy [J]. Journal of Non-crystallineSolids, 2016, 450: 48-60. DOI: 10.1016/j.jnoncrysol.2016.07.027.

[43] GAO Q, XIAO C, ZHANG Z, LIU C, SHANG F, YANG H. Effect of phosphate processing on the properties of soft magnetic iron powder [J]. Journal of Wuhan University of Technology, 2014, 36(2): 7-11. DOI: 10.3963/j.issn.1671-4431.2014.01.002.

(Edited by HE Yun-bin)

中文导读

磷酸盐/二氧化硅复合包覆Fe-6.5Si软磁复合材料的性能改善

摘要:本文通过磷酸盐/二氧化硅复合绝缘包覆而改善Fe-6.5Si软磁复合材料的综合性能,复合绝缘包覆结构由化学包覆结合溶胶凝胶法制备而成。研究了复合绝缘包覆的Fe-6.5Si软磁复合材料的微观结构及磁性能。结果发现,在Fe-6.5Si软磁合金粉末表面形成的复合绝缘包层具有良好的热稳定性和耐压性。相比于单层磷酸盐及二氧化硅包覆的Fe-6.5Si软磁复合材料,复合绝缘包覆的Fe-6.5Si软磁复合材料具有更高的磁导率及更低的损耗。因此,本文提供了一种优化软磁复合材料性能的新思路。

关键词:软磁复合材料;磷酸盐/二氧化硅绝缘包覆;热稳定性;磁性能

Foundation item: Projects(2020GDSYL-20200402008, 2018GDASCX-0117) supported by GDAS’ Project of Science and Technology Development, China; Projects(2015B010136004, 2019A1515010886) supported by Science and Technology Planning Project of Guangdong Province of China; Project(1920001001392) supported by Key Technology Project of Foshan, China

Received date: 2020-12-27; Accepted date: 2021-03-18

Corresponding author: LIU Xin, PhD, Professor; Tel: +86-20-61086128; E-mail: liuxin@gimp.gd.cn; ORCID: https://orcid.org/0000-0001-6169-4921

Abstract: Fe-6.5Si soft magnetic composites (SMCs) with hybrid phosphate-silica insulation coatings have been designed to improve their comprehensive property via chemical coating combining sol-gel method in this work. The microstructure and magnetic performance of the Fe-6.5Si SMCs with hybrid phosphate-silica insulation coatings were investigated. The hybrid phosphate-silica coatings with high heat resistance and high withstand pressure, formed on the surface of the Fe-6.5Si ferromagnetic powders, were found stable in the composites. Compared with Fe-6.5Si SMCs coated by single phosphate or single silica, Fe-6.5Si SMCs with hybrid phosphate-silica show much higher permeability and lower core loss. The work provides a new way to optimize the magnetic performance of soft magnetic composites.