文章编号:1004-0609(2012)10-2756-06

冷镦紧固件用Ti-3Al-5Mo-4.5V钛合金的微观组织及性能

张青来1,匡雁锐1,韩寅奔2,韩伟东3,冯甜甜1

(1. 江苏大学 材料科学与工程学院,镇江 212013;

2. 东北大学 材料与冶金学院,沈阳 110004;

3. 宝鸡市博信金属材料有限公司,宝鸡 721013)

摘 要:

摘 要:通过透射电镜、扫描电镜和光学显微镜等手段,研究丝材制备过程中BT16钛合金的组织结构演变。结果表明:BT16合金退火态丝材具有良好的力学性能,断面收缩率Ψ为62%~65%,冷镦变形量达到80%;退火后的合金组织由初生等轴α相、少量短条状α相及晶间β相组成的;固溶时效后合金组织由不规则的等轴状初生α相和析出针状α′相的β相组成,其中淬火时效合金中的针状α′相更细小。

关键词:

BT16钛合金;冷镦紧固件;微观组织;固溶;时效;力学性能;

中图分类号:TG146.4 文献标志码:A

Microstructures and mechanical properties of

Ti-3Al-5Mo-4.5V titanium alloy for cold upsetting fasteners

ZHANG Qing-lai1, KUANG Yan-rui1, HAN Yin-ben2, HAN Wei-dong3, FENG Tian-tian1

(1. School of Materials Science and Engineering, Jiangsu University, Zhenjiang 212013, China;

2. School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China;

3. Baoji Boxin Metal Materials Co., Ltd., Baoji 721013, China)

Abstract: The microstructure evolution of titanium alloy BT16 during the preparation wires were investigated by transmission electron microscopy, scanning electronic microscopy and optical microscopy. The results show that BT16 alloy annealed wires have excellent mechanical properties with area reduction (Ψ) of 62%-65% and cold heading deformation amount of 80%. After annealing, the alloy microstructure consists of primary equiaxial α phases, a few short-bar α′ phases and intergranular β phases. The microstructure of solid-aged alloy is composed of irregularl equiaxial primary α phases and β phases which precipitate needle α′ phases, while the needle α′ phases in the quench-aged alloy are smaller.

Key words: BT16 titanium alloy; microstructure; cold upsetting fasteners; solution; aging; mechanical properties

Ti-3Al-5Mo-4.5V钛合金(BT16)由全俄轻合金研究院研制,是一种高强、新型的典型α+β两相钛合金,具有优良的力学性能和冷镦成形,该合金的主要半成品是轧制态和拉拔态直径为4~10 mm的丝材和棒 材,通过冷镦可以制作螺钉、螺栓和铆钉等航空紧固 件[1-2]。

BT16钛合金特点如下:含少量的Al,更多的β稳定元素(Mo),β相稳定系数Kβ高达0.8,β相含量约为25%~30%,退火或淬火状态下都具有较高的塑性,而固溶+时效合金具有更高的强度,而塑性降低不明 显[3]。钛合金在热处理过程中出现的主要过渡相有α′相、α″相和淬火时效β相[4-5]。俄罗斯采用退火态BT16合金丝材冷镦制作航空紧固件[6]。国内外学者[7-11]对BT16钛合金退火工艺、微观组织、相结构和力学性能

基金项目:国家自然科学基金资助项目(51175231)

收稿日期:2011-03-06;修订日期:2012-09-22

通信作者:张青来,教授,博士;电话:051-188797324;E-mail: zhangql196210@163.com

进行了大量研究。WANG等[12]和张庆玲等[13]研究冷变形过程形成的绝热剪切带相转变。采用BT16合金制造冷变形强化紧固件,其工时和成本最低,可在160 ℃以下无限期使用;采用固溶时效BT16合金制造的紧固件,其工作温度可达350 ℃。

因此,本文作者将利用光学显微镜(OM)、扫描电镜(SEM)和透射电镜(TEM)手段研究BT16钛合金在生产过程中组织结构演变及热处理工艺对合金丝材力学性能的影响,为进一步研究和优化BT16钛合金及应用提供理论依据和实验数据,具有重要的应用价值和研究意义。

1 实验

在本实验中,使用直径为6.5 mm的BT16钛合金丝材,其化学成分如表1所列。合金丝材的制备过程如下:铸锭→开坯→锻造→轧制。首先,利用两次真空自耗电极熔化炉获得直径为210 mm的BT16钛合金铸锭,然后开坯,开始温度为1 150 ℃,结束温度控制在800 ℃左右,之后热锻成直径为7.5 mm的丝材,最后进行退火处理:780 ℃保温2 h,炉冷至550 ℃,再空冷。退火后的丝材进行表面磨光,以备冷镦实验用。

利用LEICA DM2500M型正置透反射光学显微镜

表1 BT16钛合金化学成分

Table 1 Chemical composition of BT16 alloy (mass fraction, %)

Type

Al

Mo

V

C

Fe

Test

2.8

5.2

4.5

0.02

0.05

Standard

1.8-3.8

4.5-5.5

4.0-5.0

≤0.10

≤0.25

Type

Si

Zr

O

N

H

Test

0.08

0.10

0.08

0.02

0.001

Standard

≤0.15

≤0.30

≤0.15

≤0.05

≤0.015

(OM)、JEOL JEM-2100型透射电镜(TEM)和JEOL JSEM-7001F 型高分辨扫描电镜(SEM)对BT16钛合金丝材和冷镦试样进行观察和分析。化学腐蚀剂配比为2.5 mL Hf+3 mL HNO3+5 mL HCl+89.5 mL H2O。

2 结果与分析

2.1 铸锭和热锻棒微观组织

图1所示为BT16钛合金铸锭和热锻棒的微观组织。BT16钛合金铸锭是α+β两相组织,粗大β晶内α相以树枝状形式存在,部分α相沿粗大β晶界分布(见图1(a)和(b));BT16合金的再结晶温度范围为840~ 860 ℃[2],因此,开坯开始温度选为1 150 ℃,终了温

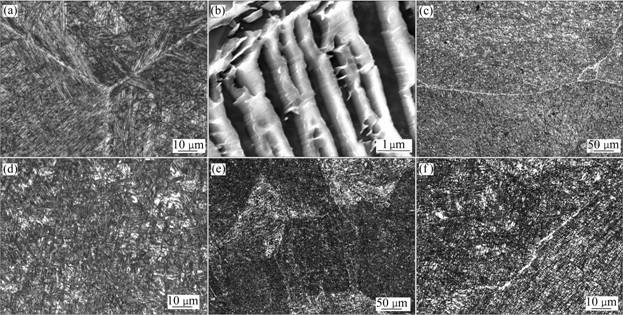

图1 BT16钛合金铸锭和热锻棒的微观组织

Fig. 1 Micrographs of ingot and hot-forged BT16 alloy rods: (a), (b) OM, SEM images of ingot, respectively; (c), (d) OM images of hot-forged billet; (e), (f) OM images of forged and annealed rods with 55 mm diameter

度控制在800 ℃左右,之后空冷,锻坯含有粗大β晶粒,在其晶内和边界均有细小片状α相不均匀析出(见图1(c)和(d));直径为55 mm的热锻棒材中,形成等轴的β晶粒,其平均尺寸为150 μm,在其边界和晶内均有细小α相不均匀析出,如图1(e)和(f)所示。

2.2 丝材微观组织和力学性能

表2所列为BT16钛合金丝材的力学性能如表2所列。从表2可见,退火态BT16钛合金丝材(d 6.5 mm)的拉伸性能为σb为870~935 MPa,δ为22%~25%,ψ为62%~ 65%,均满足俄罗斯ГОСТ1497—84标准对BT16钛合金紧固件冷镦成形性能要求。经780 ℃、 2 h+550 ℃、AC退火处理的BT16合金丝材冷镦变形量达到80%,和文献[13]中冷镦极限值一致,试样形状完整,未见任何开裂和表面微裂纹,如图2所示。

图3所示为BT16钛合金丝材的微观组织。在丝材热轧过程中,如果加热温度在Tα~Tβ之间,那么片状α晶粒将发生球化,形成细等轴晶粒,因此,热轧

图2 BT16钛合金丝材冷镦试样照片

Fig. 2 Photos of cold upsetting specimen of BT16 alloy: (a) Without deformation; (b) With 80% deformation

表2 BT16钛合金丝材的力学性能

Table 2 Mechanical properties of titanium alloy BT16 wires

Sample No.

Diameter/mm

Annealing

σb/MPa

σs/MPa

δ/%

ψ/%

1

6.5

(760 ℃, 2 h)+(550 ℃, AC)

935

880

22

65

2

6.5

(780 ℃, 2 h)+(550 ℃, AC)

870

835

24

64

3

6.5

(800 ℃, 2 h)+(550 ℃, AC)

895

855

25

62

Standard

4-10

(770-790 ℃, 2 h)+(550 ℃, AC)

830-950

≥14

≥60

图3 直径6.5 mm BT16钛合金丝材的微观组织

Fig. 3 Microstructures of 6.5 mm-diameter rolled wires: (a), (b) OM and SEM images of samples annealed at 780 ℃, 2 h+550 ℃, AC, respectively; (c) TEM image; (d) SEM image of tensile fracture

终了温度应控制在α+β两相区间。在合金丝材磨光前进行退火处理,由于BT16合金的再结晶温度范围为840~860 ℃,本实验选用热处理工艺制度如下:760~800 ℃保温2 h, 炉冷至550 ℃,再空冷。退火丝材是由均匀分布的细小近等轴α和β两相组成,其晶粒大小为1~3 μm,如图3(a)~3(c)所示。拉伸断口具有典型的分布均匀的细小韧窝,呈韧性断裂,具有良好的塑性(见图3(d))。

2.3 固溶时效处理和显微组织

由文献[3]可知,与退火态相比,固溶+时效后的BT16合金的性能得到强化,其抗拉强度可达到 1 000~1 200 MPa,尽管伸长率降为12%~16%,其断面收缩率仍大于60%。由于钼和钒的含量相当高,BT16合金在固溶+时效过程中可有效地强化,因此,本文作者将研究该合金固溶+时效后的组织结构特征。实验中固溶时效工艺制度如下:

1) 空冷+时效制度:随炉加热到800 ℃、保温2 h,空冷,500 ℃、6 h,空冷,即800 ℃、2 h、AC+500 ℃、6 h、AC;

2) 淬火+时效制度:随炉加热到800 ℃保温2 h,水冷,550 ℃、6 h,空冷,即800 ℃、2 h、WQ+550 ℃、6 h、AC。

图4(a)~(c)所示为固溶(空冷)+时效BT16合金的微观组织。合金由均匀分布的α相和β相组成的双态等轴组织组成(见图4(a))。空冷+时效后,合金中仍保持细小片状和不规则的等轴初生α相,同时β相内析出大量细小分布的不均匀针状次生α′相,如图4(b)和(c)所示。一方面,加热到800 ℃时(近α+β区域),合金中仍保留大部分的初生α相;另一方面,在时效过程中,β相内析出大量细小的针状次生α′相,即发生如下转变:β→β+α′。

图4(d)~(f)所示为淬火(固溶)+时效BT16合金的微观组织。固溶时效后合金由等轴α相和晶间β相构成的双态组织组成,即由初生α相、晶间β相和β相内析出的针状α′相组成。此时,析出的次生α′相比空冷+时效过程中析出的更加细小(见图4(c)和(f))。其原因如下:1) α+β相区淬火时,部分β相分解成针状马氏体α′相,α′相分布在初生α相间的中间层(即β相内),发生无扩散型相变形成的合金元素处于六方结构α中的过饱和固溶体;2)时效过程中马氏体分解成细小的α′相和β相。

3 讨论

钛合金BT16是一种高强、新型的马氏体型α+β钛合金,退火或淬火状态下都具有较高的塑性,即在退火状态下强度低,塑性特别好;在固溶+时效状态下,强度较高,塑性降低不明显[3],如表2和3所列。

将BT16和TC4两种钛合金分别在750~800 ℃和780~820 ℃温度区间进行淬火处理[14-15],即在α+β区

图4 固溶时效后BT16合金丝材显微组织

Fig. 4 Microstructures of BT16 alloy wires after solution and aging: (a), (b), (c) OM and TEM images for (800 ℃, 2 h, AC)+ (500 ℃, 6 h, AC), respectively; (d), (e), (f) OM and TEM images for (800 ℃, 2 h, WQ)+(550 ℃, 6 h, AC), respectively

图5 (800 ℃, 2 h, AC)+(500 ℃, 6 h, AC)固溶时效后BT16合金的SEM像及EDS谱

Fig. 5 SEM images((a), (b)) and EDS spectra((a′), (b′)) of BT16 alloy after solution and aged under (800 ℃, 2 h, AC)+(500 ℃, 6 h, AC): (a), (a′) β phase; (b), (b′) α phase

淬火处理,组织中含有大量α″马氏体和亚稳β相,但没有发现ω相的存在,含α″相淬火钛合金具有较低的屈服强度,其原因是合金中的亚稳β相导致剪切模量降低,当β稳定元素(5%~9% Mo)含量增加时,针状α′相数量减少,板状α″相数量增加。本实验中两种固溶+时效处理后合金中均未发现板状α″相(见图4)。固溶时效合金EDS分析表明,β稳定元素(Mo)存在于β相中,而α相中未发现Mo的存在(见图5)。

表3 不同热处理BT16合金力学性能[3]

Table 3 Mechanical properties of BT16 alloy after different heat treatments[3]

Heat treatment

σb/MPa

σs/MPa

δ/%

ψ/%

Quenching in water from

800 ℃

910

730

18

61

Quenching in water from 800 ℃+aging at 550 ℃ for 5 h

955

760

16

67

Quenching in water from 800 ℃ + aging at 550 ℃ for 10 h

1075

860

12

60

4 结论

1) BT16合金丝材退火制度如下:760~830 ◦C、2 h+ 550 ℃、空冷。所得丝材的力学性能如下:σb为870~ 935 MPa,δ为22%~25%,ψ为62%~65%,其冷镦变形量达到80%,退火后合金组织由初生等轴α相、少量短条状α相及晶间β相组成。

2) 固溶(空冷)+时效后,合金组织由不规则的等轴状初生α相和析出针状α′相的β相组成;固溶(淬火)+时效后,合金由等轴α相和晶间β相构成的双态组织,即由初生α相、晶间β相及β相内析出的针状α′相组成。

REFERENCES

[1] FERRERO J G. Candidate materials for high-strength fastener applications in both the aerospace and automotive industries[J]. J Mater Eng Perform, 2005, 14(6): 691-696.

[2] SKVORTSOV A A, KHABAROV V P. Effect of the regimes of strengthening heat treatment on the properties of blanks made of alloy VT16[J]. Metalloved Term Obrab Met, 1988, 10: 56-57.

[3] KOLACHEV B A, MOISEEV V N, RYNDENKOV D V. Structure and mechanical properties of alloys Ti-2.2%Al-2.2%V- 2.2%Mo-2.5%Fe and Ti-2.2%Al-5%Fe equivalent to alloy VT16[J]. Metal Science and Heat Treatment, 2006, 48(5/6): 240-243.

[4] MALITSEV M V, VOKOVA T N, SKUDNOV VA. Effect of cooling rate on the phase composition and mechanical properties of alloy VT16[J]. Metalloved Term Obrab Met, 1973, 9: 49-52.

[5] 辛社伟, 赵永庆. 关于钛合金热处理和析出相的讨论[J]. 金属热处理, 2006, 31(9): 39-42.

XIN She-wei, ZHAN Yong-qing. Discussion about the heat treatment and precipitated phases of titanium alloy[J]. Heat Treatment of Metals, 2006, 31(9): 39-42.

[6] 沙爱学, 王庆如, 李光无. BT16钛合金紧固件加工工艺分析[J]. 稀有金属材料与工程, 2006, 35(3): 455-458.

SHA Ai-xue, WANG Qing-ru, LI Xing-wu. Process analysis of BT16 titanium alloy fastener[J]. Rare Metal Materials and Engineering, 2006, 35(3): 455-458.

[7] LI X W, LU M X, SHA Ai X, ZHANG L. The tensile deformation behavior of Ti-3Al-4.5V-5Mo titanium alloy[J]. Mater Sci Eng A, 2008, 490: 193-197.

[8] MALTSEV M V, KASHNIKOV N I. Shape recovery during the reverse martensitic transformation in quenched and deformed titanium alloy VT16[J]. Metalloved Term Obrab Met, 1983(9): 25-26.

[9] URKHANOV YU A, RAKHSHTADT A G. Processes of dynamic aging of VT16 titanium alloy[J]. Metalloved Term Obrab Met, 1996, 7: 16-20.

[10] ZONG Y Y, SHAN D B, LU Y. Microstructural evolution of a Ti-4.5Al-3Mo-1V alloy during hot working[J]. J Mater Sci 2006, 41(12): 3753-3760.

[11] ZHANG Z G, WU G Q, SONG H, CUI D, HUANG Z. Relationships between microstructure and mechanical properties of Ti-3Al-5Mo-5V alloy[J]. Mater Sci Eng A, 2008, 487: 488-494.

[12] WANG B F, YANG Y. Microstructure evolution in adiabatic shear band in fine-grain-sized Ti-3Al-5Mo-4.5V alloy[J]. Mater Sci Eng A, 2008, 473: 306-311.

[13] 张庆玲, 王庆如, 李兴无. 航空用钛合金紧固件选材分析[J]. 材料工程, 2007, 1: 11-14.

ZHANG Qing-ling, WANG Qing-ru, LI Xing-wu. Materials selection analysis for titanium alloy fasteners in aviation industry[J]. Materials Engineering, 2007, 1: 11-14.

[14] KOLACHEV B A, MAMONOVA F S. Characteristics of the structure and properties of quenched titanium alloys[J]. Metalloved Term Obrab Met, 1975, 8: 52-56.

[15] LUZHNIKOV L P, NOVIKOVA V M, MAREEV V M. Hardenability of industrial titanium alloy[J]. Metalloved Term Obrab Met, 1965, 5: 53-56.

(编辑 龙怀中)