DOI: 10.11817/j.issn.1672-7207.2020.11.019

在线加热轧制Mg-6Al-1Sn-Mn板材显微组织及力学性能

刘强1, 2,宋江凤1, 2,赵华1, 2,肖毕权1, 2,潘复生1, 2

(1. 重庆大学 材料科学与工程学院,重庆,400044;

2. 重庆大学 国家镁合金工程技术研究中心,重庆,401123)

摘 要:

g-6Al-1Sn-Mn合金(AT61M)板材进行在线加热轧制,研究150,200和250 °C这3种温度下轧制板材显微组织和力学性能的变化规律。研究结果表明:在线加热轧制能够提高AT61M板材的轧制性能,轧制温度升高,能促进柱面及锥面等非基面滑移更多地激活,板材塑性增强,且促进再结晶而使组织均匀细化,平均晶粒粒径从8.1 μm减小到5.9 μm;板材沿轧制方向的屈服强度及抗拉强度随着轧制温度升高而增加,在较高温度下,轧板沿着横向(TD)的屈服强度、抗拉强度及伸长率都比轧向(RD)的高;在250 °C轧制后,板材横向(TD)的屈服强度约为222.1 MPa,抗拉强度约为342.2 MPa,伸长率约为8.8%,表现出最优的综合力学性能。

关键词:

中图分类号:TG146.2+2 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2020)11-3159-10

Microstructure and mechanical properties of Mg-6Al-1Sn-Mn sheets prepared by on-line heating rolling

LIU Qiang1, 2, SONG Jiangfeng1, 2, ZHAO Hua1, 2, XIAO Biquan1, 2, PAN Fusheng1, 2

(1. College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China;

2. National Engineering Research Center for Magnesium Alloy, Chongqing University, Chongqing 401123, China)

Abstract: The microstructure and mechanical properties of on-line heating rolled of extruded Mg-6Al-1Sn-Mn alloy(AT61M) sheets were investigated at 150, 200 and 250 °C. The results show that the on-line heating rolling technology can effectively improve the rolling ability of AT61M sheets. With the increase of the rolling temperature, the non-basal slips such as prismatic and pyramidal slip are activated greatly, leading to the enhanced plasticity. Meanwhile, the recrystallization is promoted due to the operation of non-basal slips, and the average grain size reduces from 8.1 μm to 5.9 μm. The yield strength and ultimate tensile strength of rolled sheets along the rolling direction increase with the increase of the rolling temperature, and the yield strength, ultimate strength and elongation along the transverse direction(TD) are better than those in the rolling direction(RD) at relative high temperature. After rolling at 250 °C, the yield strength, ultimate tensile strength and elongation in TD are 222.1 MPa, 342.2 MPa and 8.8%, respectively, displaying the best comprehensive mechanical properties.

Key words: AT61M magnesium alloy plate; on-line heating rolling; microstructure; mechanical properties

镁合金作为金属结构材料,因其具有密度低、比强度高以及较强的导热导电性、电磁屏蔽性以及阻尼减震性等优点,在交通、3C通讯、国防军工等诸多领域具有广阔的应用前景[1-5]。随着社会经济的发展,人们对变形镁合金板材的需求日趋增加。轧制是生产镁合金板材的主要方法之一,目前,制备镁合金薄板主要依靠传统轧制方式。由于镁合金散热系数大,板材与轧辊以及周围环境存在热交换,因此,传统轧制时温降快,不利于成形,易引起边裂等缺陷。每道次轧完后需将板材放回炉内进行加热保温退火,以消除加工硬化,如此反复多次,工序繁琐且所需时间较长,导致生产效率低,镁合金板材生产成本高[6-8]。为了增加板材轧制成形性能,人们致力于开发各种新型轧制工艺,以提高镁合金的生产效率。新型轧制工艺包括等径角轧制[9]、交叉轧制[10]、异步轧制[11]、叠合轧制[12]以及在线加热轧制[13]等。在线加热轧制工艺近年来成为研究热点之一,其利用电流加热轧板、热油加热轧辊,在板材轧制过程中无需中间回炉退火,大大节约了时间,提高了效率;此外,通过两端夹头夹住板材实现来回可逆轧制,增加了板材的轧制成形性,确保板材轧制完后拥有较好的板形[14]。近年来,开发新型具有较高强度的无稀土变形镁合金受到人们广泛关注,已有研究表明,Mg-Al-Sn-MnATM系合金是一种具有较好综合力学性能和潜在应用前景的镁合金。SHE等[15]研究了Mg-Al-Sn-Mn系合金在Al和Sn这2种元素质量分数不同时铸态和挤压态组织和性能的变化,在350 ℃时获得了平均晶粒粒径约为9.9 μm的ATM610系挤压棒材,具有良好的综合力学性能,其屈服强度和抗拉强度分别为199 MPa和313 MPa,伸长率达到13.0%。然而,目前尚未见关于在线加热轧制Mg-Al-Sn-Mn系合金板材的研究报道。为此,本文作者通过实验研究在线加热轧制技术对Mg-6Al-1Sn-Mn合金挤压板材进行轧制变形,分析不同轧制温度对合金显微组织和力学性能的影响规律。

1 实验材料与方法

实验采用常规电阻炉熔炼镁合金。先将纯镁块加入铁坩埚中,待温度升高到740 ℃,纯镁融化后依次加入纯Al、纯Sn、纯Zn以及Mg-5%Mn中间合金,并持续地向坩埚中通入保护性气体(SF6+CO2)。保温20 min后,将熔体浇入预热温度为350 ℃的模具并空冷至室温,获得直径约为90 mm、高度约为220 mm的铸锭。随后,将AT61M铸锭在500 ℃下进行24 h固溶处理[15],并进行水冷。对固溶后的铸锭通过X线荧光光谱(X-ray fluorescence, XRF)进行分析,并测定合金成分,其合金化学成分如表1所示。将固溶后的铸锭在370 ℃下挤压成宽度为60 mm、厚度为3 mm的板材,挤压比为28:1,挤压后板材的微观组织如图1所示。由图1可知:AT61M挤压板材组织较均匀,再结晶度高达96.4%,其平均晶粒粒径约为12.6 μm。

表1 合金化学成分( 质量分数)

Table 1 Chemical composition of alloy %

采用在线加热轧机将挤压后的板材分别在150,200和250 ℃下进行轧制,经过4个道次将板材从厚度3 mm轧制到约1 mm,单道次压下量约为25%,轧制速度为0.05 m/s,轧辊预热温度约为180 ℃,轧制两端张力设置为1.5 kN。本次实验采用半自动轧制,手动装载板材后,对镁合金板材进行通电加热,并用热电偶测定温度。加热到设定温度(时间大约为60 s),停止加热并开始轧制。每道次轧制完成后,再次对镁合金板材通电加热到设定的轧制温度,如此反复,直至轧制完成为止。轧制板材制备流程及轧制设备如图2所示。同时,以相同工艺对AT61M板材进行传统轧制。在传统轧制过程中,轧辊未加热。

图1 AT61M挤压板材微观组织

Fig.1 Microstructures of AT61M extruded sheet

图2 轧制板材制备流程及轧制设备

Fig. 2 Process flow and rolling mill of rolling plate

轧制完成后,取板材边部的试样,再通过光学显微镜(OM)、电子背散射衍射(EBSD)对在线加热轧制样品的微观组织进行表征。在进行电子背散射衍射(EBSD)表征之前,先用砂纸将试样进行打磨,再在温度为-20 ℃的AC2溶液中电解抛光90 s。本实验沿轧制方向(RD)与横向(TD)切取标准长度×宽度为10.0 mm×3.5 mm的骨头状拉伸试样,在室温下以0.3 min/s的拉伸速率在电子万能试验机上测量不同温度下轧制板材的力学性能。

2 实验结果

图3所示为不同温度下在线加热轧制以及传统轧制后板材的宏观形貌。从图3可以看出:在150 ℃在线加热轧制时,板材边部出现了1个开口宽度及长度都较大的边裂,还有一系列粒径较小的边裂(图3(a));随着轧制温度升高,在线加热轧制中产生边裂的现象明显减弱;在250 ℃轧制后只发现极少可见的边裂(图3(c)),表明板材的轧制性能提高,而在传统轧制条件下,在150~250 ℃轧制时,轧后板材都呈现出贯穿横向TD的裂纹,表明板材已经失效断裂;当轧制温度为150 ℃时(图3(d)),传统轧制的板材经过2个道次就发生了严重失效断裂,说明在线加热轧制工艺显著提高了AT61M板材的轧制性能,在250 ℃轧制时可获得质量好且表面平整、光洁的轧板,轧板表面边裂等缺陷减少,表明轧制温度是产生边裂的重要影响因素。

图3 不同温度下AT61M轧制板材宏观形貌

Fig. 3 Macromorphology of AT61M rolled sheet at different temperatures

图4 不同温度下AT61M在线轧制板材显微组织

Fig. 4 Microstructures of AT61M rolled sheet at different temperatures

图4所示为不同温度下在线加热轧制板材板面的金相显微组织。由图4可知:板材在150 ℃轧制后的显微组织不均匀,呈现出不同粒径的晶粒共存的特征,且观察到较多孪晶(图4(a));随着轧制温度增加到250 ℃,原始大晶粒粒径逐渐变小,组织较均匀,细晶粒内仍然可观察到较多孪晶(图4(c))。

图5所示为不同温度下轧制板材局部EBSD晶粒取向图以及对应温度的晶粒粒径分布图和极图。由图5可知:在150 ℃轧制后的板材组织仍保留大块的原始晶粒,且在大晶粒周围存在细小的晶粒,原始晶粒内部产生了许多小角度晶界(白色线条所示,见图5(a));温度升高促进了位错滑移。当变形位错滑移到小角度晶界处时,小角度晶界进一步吸收位错,使晶界偏转并变成大角度晶界(见图5(a),(b)和(c)),表现出明显连续再结晶的特征,轧板组织得到细化,平均晶粒粒径从8.1 μm减小到5.9 μm(见图5(d),(e)和(f);轧板在150 ℃轧制后表现出较强基面显微织构(见图5(g)),最大织构强度为28.17;随着轧制温度升高,极密度(织构组分)变得离散,显微织构弱化;在250 ℃轧制后,最大织构强度为14.29(见图5(i))。

图5 不同温度下AT61M轧制板材局部EBSD晶粒取向图

Fig. 5 Local EBSD orientation map of AT61M rolled sheet at different temperatures

图6所示为图5(a)中原始大晶粒EBSD取向图及对应的极图。从图6(a)可见轧制后保留的原始大晶粒因发生变形而晶粒取向略微发生偏转。从图6(b)可见原始大晶粒的基面织构强度很大,最大织构强度达到41.01,且极图织构形状与图5(a)中极图织构相似,表明150 ℃轧制后织构略微偏转且最高极密度未处于中心主要是导致原始大晶粒体积较大的原因。

图7所示为不同温度下轧制板材生成的孪晶以及对应温度下3种类型孪晶的占比(体积分数),其中,绿色代表二次孪晶,蓝色代表压缩孪晶,红色代表拉伸孪晶。从图7(a)和图7(b)可知:在150 ℃以及200 ℃轧制后,3种孪晶中二次孪晶占比最高,在孪晶中的占比分别达到55.8%和55.6%;而在250 ℃轧制后,3种孪晶中拉伸孪晶占比最高,在孪晶中的占比达53.9%。拉伸孪晶的产生可以容纳应变,进一步协调组织变形。

图6 AT61M轧制板材在150 ℃时的EBSD晶粒取向图内大晶粒、取向及大晶粒对应的织构

Fig. 6 Large grains and its orientation in EBSD map of AT61M rolled sheet at 150 ℃ and corresponding texture

图7 不同温度下AT61M轧制板材生成的孪晶

Fig.7 Twins generated by AT61M rolled sheet at different temperatures

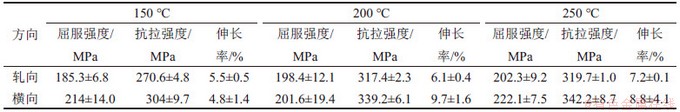

图8所示为不同温度下在线轧制板材的力学性能以及加工硬化率与真应变曲线。由图8(a)可知:随着轧制温度升高,沿着轧制方向的屈服强度略微增加。不同温度下轧制板材轧制方向与横向的力学性能见表2。由表2可知,当温度从150 ℃提高到250 ℃时,抗拉强度从270.6 MPa增加到319.7 MPa,提高约18%;伸长率从5.5%增加到7.2%,提高约31%。而在较高温度下,轧板沿着横向的强度及伸长率都比轧制方向的高,其具体力学性能如表2所示。由图8(c)可知:在150 ℃轧制后加工硬化率较低,而随着温度升高,横向与轧制方向的加工硬化率都明显增大,说明板材成形性能提高,且在较高温度下横向加工硬化率也比轧制方向的高,其中,250 ℃轧制后AT61M板材TD方向的加工硬化率最高,也表现出最优的综合力学性能,其屈服强度、抗拉强度以及伸长率分别约为222.1 MPa,342.2 MPa和8.8%。

图8 不同温度下AT61M轧制板材轧制方向和横向的力学性能

Fig. 8 Mechanical properties of AT61M rolled sheet in rolling direction and transverse direction at different temperatures

3 分析与讨论

表2 不同温度下轧制板材轧制方向与横向力学性能

Table 2 Mechanical properties of rolled sheets in rolling direction and transverse direction at different temperatures

通过对比在线加热轧制与传统轧制后板材的形貌可知在线加热轧制工艺使镁合金板材具有更好的轧制成形性能,这可能与温度场分布和施加张力有关。在线加热轧制工艺中,轧辊在轧制前进行了加热保温,且板材在轧机上通过电阻进行了快速加热,板材温降较慢。而传统轧制工艺中,一方面,轧辊未加热,另一方面,板材从加热炉中预热完成转移到轧机耗时较长,板材温降较大,因此,导致轧制过程中板材中部和边部温度差异大,轧制性能降低。在轧制过程中,施加张力可以显著提高轧制板材的外观质量,板材平整度较高。AFONJA等[16]认为轧制过程中前后施加张力(特别是后张力)有利于减少边裂纹,进而增加成形性。也有研究表明,轧制边裂纹随着张力增加而增加[17]。

在线加热轧制工艺中,边裂程度随着轧制温度升高而逐渐降低。轧制温度对板材边裂的主要影响因素有再结晶程度、孪晶和应变分布。随着轧制温度升高,再结晶程度增加,晶粒分布更加均匀,晶粒粒径减小,因此,在较高温度轧制时大角度晶界多,小角度晶界少。而轧制过程中的再结晶极大地影响了板材的轧制性能,再结晶程度越高,板材轧制性能越好。在轧制过程中,再结晶主要是由于在轧制力作用下,合金板材产生变形,组织内生成了大量的位错、层错和孪晶等。随着变形程度增加,位错密度增加,且相互塞积导致位错胞及亚晶界形成,亚晶界不断吸收位错转变成小角度晶界,小角度晶界进一步吸收位错形成大角度晶界,从而导致大块的原始晶粒细化为动态再结晶晶粒[18],表现出典型的连续再结晶特征。

孪生是密排六方金属中协调晶体塑性变形的主要机制之一[19-20]。一般地,当产生较大变形时,晶界周围因位错累积而引发较大应力集中,促进孪生形核,进而缓解局部应力协调塑性变形。在低温下轧制时,大多数晶粒由于基面滑移使基面逐渐偏转至与轧制平面平行,进而形成较强的基面织构(见图5(g)),此时,大部分晶粒c轴受到压应力而易生成压缩孪晶,进一步生成二次孪晶。而随着温度升高,更多的非基面滑移(柱面以及锥面滑移)激活开启,产生更多的位错而促进再结晶,弱化了织构[21],致使在250 °C轧制时织构组分分布的离散度增加(见图5(i));而散漫的基面分布有利于拉伸孪晶的生成[22](见图7(c))。因此,AT61M镁合金板材在线加热轧制中,250 °C轧制时的拉伸孪晶占比最高。

图9所示为板材在最低和最高轧制温度下的应变分布(KAM)。由图9可知:在低温下轧制时,应变主要集中在大晶粒中,表明应变分布不均匀,易产生裂纹;随着轧制温度升高,应变分布逐渐均匀(见图9(b)),减少了裂纹形成的可能性,进而增加了板材的成形性。应变分布也表明较高的轧制温度有利于板材轧制。

图9 AT61M板材在不同轧制温度下的局部取向差图(应变分布KAM图)

Fig. 9 Local misorientation map of AT61M plate at different rolling temperatures (KAM map)

随着板材轧制温度升高,其屈服强度以及抗拉强度都呈现出增大趋势,这可能与板材晶粒细化有关。根据霍尔-佩奇公式σ=σ0+kd-1/2(其中,σ为材料屈服强度,σ0为多晶体材料变形时所需应力,k为与材料有关的常数,d为晶粒直径),晶粒粒径越小,合金的强度越高[23-24]。图10所示为不同温度下轧制板材沿轧制方向(RD)基面的斯密特(Schmid)因子分布。由图10可知轧制后板材基面滑移平均斯密特(Schmid)因子随着温度升高而升高,在250 ℃轧制后平均Schmid因子达到最大,基面滑移较容易(见图10(f)),因此,轧板沿轧制方向的伸长率与温度呈正相关,即轧板塑性沿着轧制方向呈增强趋势,这主要是由于温度升高引起非基面滑移大量激活,促进再结晶而弱化了显微织构。

图10 不同温度下AT61M轧制板材沿RD方向的基面斯密特因子分布

Fig. 10 Schmid factor along RD direction of AT61M rolled plate at different temperatures

4 结论

1) 与传统轧制相比,在线加热轧制工艺可以提高板材的轧制性能,经过在线加热轧制的轧板其表面质量更好。随着轧制温度升高,板材塑性增加,在线加热轧制后的轧板边部裂纹逐渐减少。

2) 低温下在线加热轧制后的板材组织不均匀,表现出不同粒径的晶粒共存。随着在线加热轧制温度升高,更多的非基面滑移(柱面和锥面滑移)激活开动,促进再结晶而使轧板组织均匀细化,平均晶粒粒径从8.1 μm减小到5.9 μm。

3) 挤压态的Mg-6Al-1Sn-Mn板材经过在线加热轧制后,板材沿轧制方向的屈服强度和抗拉强度随着轧制温度升高而增大。在250 ℃轧后横向表现出最优的综合力学性能,其屈服强度、抗拉强度以及伸长率分别约为222.1 MPa,342.2 MPa和8.8%。

参考文献:

[1] KUMAR A, KUMAR S, MUKHOPADHYAY N K.Introduction to magnesium alloy processing technology and development of low-cost stir casting process for magnesium alloy and its composites[J]. Journal of Magnesium and Alloys, 2018, 6(3): 245-254.

[2] YANG Z, LI J, ZHANG J, et al.Review on research and development of magnesium alloys[J]. Acta Metallurgica Sinica, 2008, 21(5): 313-328.

[3] PEKGULERYUZ M O. Current developments in wrought magnesium alloys[J]. Advances in Wrought Magnesium Alloys, 2012, 3: 3-62.

[4] XU Tiancai, YANG Yan, PENG Xiaodong, et al. Overview of advancement and development trend on magnesium alloy[J]. Journal of Magnesium and Alloys, 2019, 7(3): 536-544.

[5] SONG Jiangfeng, SHE Jia, CHEN Daolun, et al. Latest research advances on magnesium and magnesium alloys worldwide[J]. Journal of Magnesium and Alloys, 2020, 8(1): 1-41.

[6] 马立峰, 庞志宁, 黄庆学, 等. AZ31B镁合金板材轧制边裂与温度场研究[J]. 稀有金属材料与工程, 2014, 43(S1): 387-392.

MA Lifeng, PANG Zhining, HUANG Qingxue, et al. Edge cracks and temperature field of AZ31B magnesium alloy sheet[J]. Rare Metal Materials and Engineering, 2014, 43(S1): 387-392.

[7] ZHI Chenchen, MA Lifeng, HUANG Qingxue, et al. Improvement of magnesium alloy edge cracks by multi-cross rolling[J]. Journal of Materials Processing Technology, 2018, 255: 333-339.

[8] 刘子健, 赵红阳, 胡小东, 等. 轧制温度对AZ31B镁合金薄带轧制的边裂及显微组织的影响[J]. 热加工工艺, 2016, 45(21): 34-38.

LIU Zijian, ZHAO Hongyang, HU Xiaodong, et al. Effects of rolling temperature on edge crack and microstructure of AZ31B magnesium alloy thin strip[J]. Hot Working Technology, 2016, 45(21): 34-38.

[9] XU Qiong, MA Aibin, LI Yuhua, et al. Microstructure evolution of AZ91 alloy processed by a combination method of equal channel angular pressing and rolling[J]. Journal of Magnesium and Alloys, 2020, 8(1): 192-198.

[10] LIM H K, LEE J Y, KIM D H, et al. Enhancement of mechanical properties and formability of Mg-MM-Sn-Al-Zn alloy sheets fabricated by cross-rolling method[J]. Materials Science and Engineering: A, 2009, 506(1/2): 63-70.

[11] ZHU Suqin, YAN Hongge, XIA Weijun, et al. Study on the microstructures and mechanical properties of AZ31 magnesium alloy sheets processed by asymmetrical rolling[J]. Journal of Hunan University Natural Sciences, 2008, 35(8): 51-54.

[12] WANG Qingfeng, XIAO Xinping, HU Jie, et al. An ultrafine-grained AZ31 magnesium alloy sheet with enhanced superplasticity prepared by accumulative roll bonding[J]. Journal of Iron and Steel Research, International, 2007, 14(5): 167-172.

[13] PAN Fusheng, ZENG Bin, JIANG Bin, et al. Enhanced mechanical properties of AZ31B magnesium alloy thin sheets processed by on-line heating rolling[J]. Journal of Alloys and Compounds, 2017, 693: 414-420.

[14] LIU Qiang, SONG Jiangfeng, PAN Fusheng, et al. The edge crack, texture evolution, and mechanical properties of Mg-1Al-1Sn-Mn alloy sheets prepared using on-line heating rolling[J]. Metals, 2018, 8(10): 860.

[15] SHE Jia, PAN Fusheng, et al. Microstructure and mechanical properties of Mg-Al-Sn extruded alloys[J]. Journal of Alloys and Compounds, 2016, 657: 893-905.

[16] AFONJA A A, SANSOME D H. Edge cracking in sandwich rolling[J]. Journal of Mechanical Working Technology, 1979, 3(1): 77-83.

[17] HUANG Yuchen, XIAO Biquan, SONG Jiangfeng, et al. Effect of tension on edge crack of on-line heating rolled AZ31B magnesium alloy sheet[J]. Journal of Materials Research and Technology, 2020, 9(2): 1988-1997.

[18] ZHAO Dongqing, ZHOU Jixue, LIU Yunteng, et al. Microstructure and mechanical properties of Mg-4Zn-2Al-2Sn alloys extruded at low temperatures[J]. Acta Metallurgica Sinica, 2014, 50(1): 41-48.

[19] PARK J H, KIM H L, JUNG J E, et al. Role of tension twins on warm deformation behavior of AZ31 Mg alloy[J]. Metals and Materials International, 2013, 19(3): 389-398.

[20] XIN Yunchang, WANG Maoyin, ZENG Zhen, et al. Tailoring the texture of magnesium alloy by twinning deformation to improve the rolling capability[J]. Scripta Materialia, 2011, 64(10): 986-989.

[21] MA Ru, ZHAO Yiquan, WANG Yinong. Grain refinement and mechanical properties improvement of AZ31 Mg alloy sheet obtained by two-stage rolling[J]. Materials Science and Engineering: A, 2017, 691: 81-87.

[22] 王文珂. ZK60镁合金板材降温轧制及织构对其成形性影响研究[D]. 哈尔滨: 哈尔滨工业大学材料科学与工程学院, 2019: 30-35.

WANG Wenke. Research on lowered temperature rolling of ZK60 plates and the effect of texture on formability[D]. Harbin:Harbin Institute of Technology.School of Materials Science and Engineering, 2019: 30-35.

[23] YUAN W, PANIGRAHI S K, SU J Q, et al. Influence of grain size and texture on Hall-Petch relationship for a magnesium alloy[J]. Scripta Materialia, 2011, 65(11): 994-997.

[24] WANG Pengqi, GUO Enyu, WANG Xuejian, et al. The influence of Sc addition on microstructure and tensile mechanical properties of Mg-4.5Sn-5Zn alloys[J]. Journal of Magnesium and Alloys, 2019, 7(3): 456-465.

(编辑 陈灿华)

收稿日期: 2020 -08 -31; 修回日期: 2020 -10 -22

基金项目(Foundation item):国家自然科学基金资助项目(52071036, 51701027);国家重点研发计划项目(2017YFF0209100, 2016YFB0101700, 2016YFB0301100);中央高校基本科研专项资金资助项目(2020CDJQY-A002) (Projects(52071036, 51701027) supported by the National Natural Science Foundation of China; Projects(2017YFF0209100, 2016YFB0101700, 2016YFB0301100) supported by the National Key Research and Development Program of China; Project(2020CDJQY-A002) supported by the Fundamental Research Funds for the Central Universities)

通信作者:宋江凤,博士,副教授,从事镁合金铸造热裂纹和轧制边裂研究;E-mail: jiangfeng.song@cqu.edu.cn

摘要:通过对挤压态Mg-6Al-1Sn-Mn合金(AT61M)板材进行在线加热轧制,研究150,200和250 °C这3种温度下轧制板材显微组织和力学性能的变化规律。研究结果表明:在线加热轧制能够提高AT61M板材的轧制性能,轧制温度升高,能促进柱面及锥面等非基面滑移更多地激活,板材塑性增强,且促进再结晶而使组织均匀细化,平均晶粒粒径从8.1 μm减小到5.9 μm;板材沿轧制方向的屈服强度及抗拉强度随着轧制温度升高而增加,在较高温度下,轧板沿着横向(TD)的屈服强度、抗拉强度及伸长率都比轧向(RD)的高;在250 °C轧制后,板材横向(TD)的屈服强度约为222.1 MPa,抗拉强度约为342.2 MPa,伸长率约为8.8%,表现出最优的综合力学性能。