J. Cent. South Univ. (2018) 25: 3085-3097

DOI: https://doi.org/10.1007/s11771-018-3976-4

Physical simulation test of soil-rock mixture from synthetic transparent soil

DING Xiao-hua(丁小华)1, 2, ZHOU Wei(周伟)1, 2, LU Xiang(陆翔)1, 2, GAO Yan(高岩)1, 2

1. School of Mines, China University of Mining & Technology, Xuzhou 221116, China;

2. State Key Laboratory of Coal Resources and Safe Mining, China University of Mining & Technology, Xuzhou 221116, China

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2018

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2018

Abstract:

The waste dump of open-pit coal mine is remade of soil-rock mixture under the action of gravity, dynamic load of transportation equipment and earthquake, etc. By using artificial synthetic transparent soil, the developing process and migration law for soil-rock mixture are observed in the remade process. The mixture of fused quartz sand, liquid paraffin and n-tridecane is chosen as the material for synthetic transparent soil which is mixed with liquid paraffin and n-tridecane at a mass ratio of 4.4 at room temperature of 17℃. Physical and mechanical properties of transparent soil are determined by physical test and compared with those in natural sandy soil. The results show that transparent soil and sandy soil have high similarity, in other words, transparent soil can be used for similar simulation experiments of soil-rock mixture.

Key words:

transparent soil; waste dump; soil-rock mixture; physical test;

Cite this article as:

DING Xiao-hua, ZHOU Wei, LU Xiang, GAO Yan. Physical simulation test of soil-rock mixture from synthetic transparent soil [J]. Journal of Central South University, 2018, 25(12): 3085–3097.

DOI:https://dx.doi.org/https://doi.org/10.1007/s11771-018-3976-41 Introduction

The essence of open-pit coal mining is to break the rock and soil into loose soil-rock mixture for mining, transportation, dumping and reclamation [1]; the loose soil-rock mixture stacking in the inside and outside waste dump is remolded under the influence of water, temperature, dynamic load of transportation equipment and earthquake, etc. However, due to the concealment of soil-rock mixture, the developing process, migration and final morphology of inside soil-rock cannot be observed directly in the remodeling process. The present method measures the displacement change of earth-rock mixture by installing a sensor inside soil and rock to obtain the migration law of soil-rock mixture in the remodeling process. The above method cannot directly observe the internal deformation of the soil-rock mixture during the process of remodeling, and the accuracy of the collected data is not high due to the influence of the sensor on the movement of the soil-rock mixture.

Transparent soil is made of transparent solid material and transparent liquid material, solid and liquid respectively simulate actual soil particles and water, the mechanical properties of transparent solids should be similar to those of real soils and the liquid materials should be matched with the refractive index of solid materials. Because the refractive index of the two is the same or similar,the light cannot even refract and scatter on the solid-liquid interface, which reduces the energy loss caused by the propagation of light in the solid- liquid mixture, so that the mixture of the two shows a transparent property. The synthesis of transparent soil is closely related to the refractive index of materials. According to the optical theory, the transparent solid particles of the monomer are stacked together, and the internal pores contain air and other impurities, making the substance appear in an opaque state. If the air and impurities in the pores are removed and replaced by liquid that matches the refractive index with the transparent medium, the substance will be transparent. Because of its opaque nature, the natural soil is replaced by solid particles whose properties are similar to those of the natural soil. The water is replaced by the liquid that matches the refractive index of the solid particles, and the liquid is filled in the solid particles and exhausting the air. Because the refractive index of the two solid-liquid mixtures is matched, the light in which the propagation does not occur, such as reflection and refraction, so the transparent soil synthesized by the solid liquid mixture will show the transparency.

From the early study of transparent material, ALLERSMAL et al [2, 3] prepared transparent materials by using broken glass and liquids with the same refractive index as broken glass and studied the stress distribution of transparent materials under uniaxial shear condition and the stress variation of saturated embankment under seismic load; WELKER et al [4] made transparent material from mineral oil and amorphous silicon powder and obtained mechanical parameters of transparent materials by mechanical test, the results showed that the transparent material made of amorphous silicon powder and mineral oil had similar physical and mechanical properties to clay; transparent soil was synthesized by amorphous silicon powder and its mechanical properties were tested [5–13], in addition, amorphous silicon powder obtained by liquid or gaseous silica gel particles was widely used in industrial production because of its wide source and low cost; the research from ISKANDER [14] showed that amorphous silica could absorb liquid and exclude air, and its inner pores were larger than the surface area, similar to the clay properties, so it could be used as a material to simulate the transparent clay.

The research of transparent soil in China has started late than other countries, but in recent years, the technology of artificial transparent soil has developed rapidly. In the synthesis of transparent soils, using amorphous silica powder as solid material and mineral oil as pore fluid, the transparent material of simulated soil was synthesized and the deformation mechanism of soil under transparent material load was studied by SHE [15]. ZHANG et al [16] studied the possibility of calcium bromide solution as pore fluid and determined the refractive index of calcium bromide solution with different temperature and concentration, the results showed the refractive index of calcium bromide solution was positively correlated with temperature and concentration. SUI et al [17] obtained the particle image in transparent soil by laser speckle technique. WU [18] made transparent soil using fused quartz sand as solid material and calcium bromide solution as pore fluid, and did the three axis test of synthetic transparent soil compared with standard sand which showed that properties of transparent soil and sandy soil under certain conditions are similar. Using silica gel as aggregate and the mixture of liquid paraffin and n-tridecane as liquid materials, XU [19] made the similar materials of transparent rock. ZHANG et al [20] prepared the similar material of transparent soft rock by using fused quartz powder and mineral oil and its basic mechanical parameters were determined.

2 Materials and methods

2.1 Solid materials

At present, solid materials for synthetic transparent soil mainly include amorphous silica gel, transparent glass sand and fused quartz sand. Although amorphous silica gel has a certain transparency, it is quite different from the physical properties of sand; transparent glass sand has high transparency, but its cost is high. Therefore, the fused quartz sand is selected as the solid material for the synthesis of transparent soil-rock mixture.

The fused quartz sand produced by Wanhe Mining Co., Ltd. of Xinyi City, Xuzhou City, Jiangsu Province, China, is selected. The parameters of fused quartz sand are shown in Table 1.

To ensure that the transparent soil synthesized by fused quartz sand and natural sand have similar characteristics. According to geotechnical test standard (GB-T50123-1999), main physical and mechanical properties of selected fused quartz sand are determined.

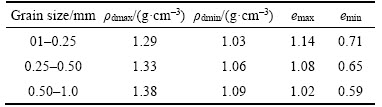

Table 1 Physical indexes of fused quartz sand

1) Grain size

Screening fused quartz sand by vibrating screen, the grain size of selected fused quartz sand is between 0.1 and 1.0 mm. According to the mass ratio, the average grain size distribution of the sample is estimated (see Table 2).

Table 2 Proportional distribution of three kinds of grain size

It is concluded that the content of the size of 0.5–1.0 mm in the fused quartz sand with 0.1–1.0 mm grain size is nearly 50%, while the rest 0.1–0.25 mm size is about half of the 0.25–0.5 mm grain size.

2) Proportion

The soil mass in the drying box is constant at 105–110 °C and the mass ratio of the same volume of 4 °C water is its specific gravity. As the grain size of fused quartz sand is less than 5 mm, with the help of bottle method, the proportion of fused quartz sand is 2.21 by bottle method according to Geotechnical test standard.

3) Natural repose angle

Measuring the natural repose angle of fused quartz sand screened by the repose angle measuring instrument, the natural repose angle of fused quartz sand with 0.1–0.25 mm grain size is 35°; the angle of 0.25–0.5 mm grain size is 36°; and the angle of 0.5–1.0 mm grain size is 37°. With the increase of grain size, the natural repose angle increases, and the grain size can affect the flow of granular materials.

4) Density

The properties of sand are closely related to their compactness and have certain influence on the experiment. In order to measure the density of fused quartz sand, the maximum pore ratio and the minimum pore ratio of different grain sizes are obtained by the relative density meter, shown in Table 3.

Table 3 Density and void ratio of quartz sand with different grain sizes

5) Permeability coefficient

Permeability is an important physical property of sand. According to Geotechnical test standard, the grain size of fused quartz sand is larger than 0.1 mm belonging to coarse-grained sand, and the results from the constant head permeability test are shown on Table 4.

Table 4 Permeability coefficient of fused quartz sand with different grain sizes

It is concluded that the permeability increases gradually with the increasing grain size of fused quartz sand, which indicates that the larger the grain size is, the better the permeability is.

By determining the physical indexes of fused quartz sand such as grain size, proportion, natural repose angle, density and permeability, it is concluded that physical and mechanical properties of fused quartz sand are similar to those of sand, so it can be used as a solid material for synthesizing transparent soil.

2.2 Liquid materials

The liquid in sand soil is water, which requires that the liquid material of synthetic transparent soil should have similar physical and chemical properties to that of water. Under normal temperature and pressure, the density of water is 0.998 g/cm3, the melting point is 0 °C, the boiling point is 100 °C, and the refractive index is 1.333.

Solute dissolved in water with the same index of refraction as fused quartz sand is used to prepare or a mixture of two and more than two liquids. Three target liquids are determined by experiment: sucrose solution, calcium bromide solution, the mixture of liquid paraffin and n-tridecane LN-15 white oil. Three kinds of liquid materials have advantages and disadvantages. The process of sucrose solution and calcium bromide solution is simple and inexpensive, but it is not stable for a long time; there are volatilization and irritating odors for the two solutions in the experiment, so they are not considered. The mixture of liquid paraffin and n-tridecane is relatively stable, and the two will not react with each other; the long position will not affect the refractive index, but it will be affected by temperature and the cost of synthesis is high. Considering the stability of the experiment, the mixture of liquid paraffin and n-tridecane is selected as the liquid material for synthesizing transparent soil.

Mclean’s liquid paraffin and the n-tridecane of Moroke Company are selected, as shown in Figure 1.

The liquid paraffin is a colorless transparent liquid with a density of 0.84–0.86 g/mL, a flash point of 185 °C and a boiling point of more than 300°C; the molecular formula of n-tridecane is C13H28, a colorless transparent liquid with a density of 0.755 g/mL,the melting point of –5.45°C, the flash point of 94°C, and the boiling point of 234°C.

Record the temperature, mix the liquid paraffin and n-tridecane at a certain mass ratio, mix the solution until the two are fully mixed, set it still for 3 min, use Abbe refraction meter to measure, record the refractive index of the mixture with different mass ratio, at different temperatures, the refractive index of the mixture is shown in Table 5.

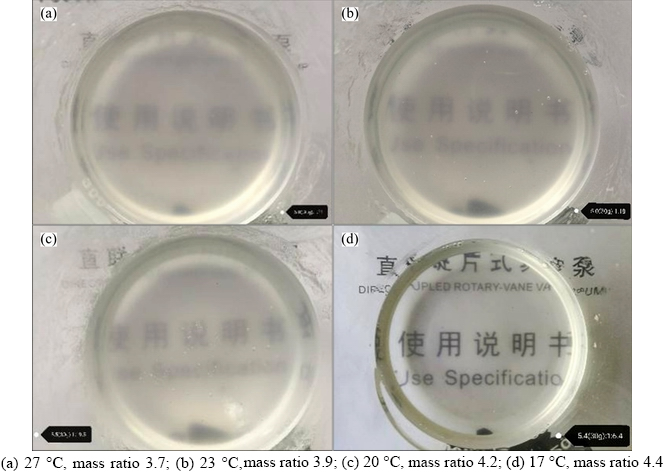

According to the measurement results, the best matching mass ratio of mixed liquid refractive indexes at different temperatures is different. With the decrease of temperature, the mass ratio of the best matching refractive index value increases continuously. The mass ratio of liquid paraffin and n-tridecane at the temperature of 27°C is 4.0; and the mass ratio of the two increases to 4.4 at the temperature of 17°C; So when preparing the mixture, it is of great necessity of ensuring the temperature of the two liquids and the temperature of the laboratory. During the experiment, the temperature of laboratory is controlled at 17 C. The transparent soil with different mixtures is shown in Figure 2.

Figure 1 Liquid paraffin (a) and N-tridecane (b)

2.3 Preparation of transparent soil

At the temperature of 17 °C in the laboratory, the mixture of liquid paraffin and n-tridecane at the mass ratio of 4.4 is configured to be mixed and fully stirred until the mixture is free of flocculent liquid and the liquid becomes transparent. The refractive index of the mixture measured by Abbe refractometer was 1.458. Cover the mixture with a lid to prevent contamination.

Prepare transparent soil according to the mass ratio of solid material to liquid material at 2:1. Wash the fused quartz sand and dry it in the oven.

Table 5 Refractive index of mixture at different temperatures

Place the sieve on an already configured mixing tank and fix it. Divide the dried fused quartz sand into three portions and pour one on the sieve, one by one; use a glass rod to stir the sand, allowing the sand to drop evenly into the mixture to minimize the production of bubbles; unload the sieve when the fused quartz sand falls into the mixture; put the experimental barrel containing the transparent soil in the vacuum box for 10 min, except for the air in the transparent soil to prevent it from affecting the transparency of transparent soil; repeat the above process and dissolve all three pieces of fused quartz sand in the mixture and vacuum, and then set the configured transparent soil to rest.

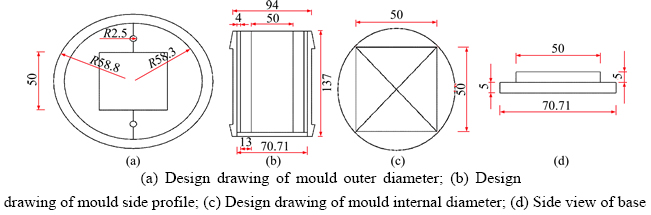

2.4 Consolidation of transparent soil

The conventional consolidation tests are mostly ring knives of various types, with 30, 50, 100 and 200 cm3. According to the test requirements, a consolidation mould is designed, which consists of two valves, clamps and bases. Design drawings and mould physical drawings are as shown in Figures 3 and 4.

The cylinder mould made of stainless steel consists of the base, the flap die and the clamp, mould diameter is 50 mm and height is 140 mm.40 mm is reserved for consolidation test.

There are many factors that affect the consolidation of samples, such as mold removal, transport, material properties, laboratory temperature and humidity, consolidation stress, consolidation time and so on. However, due to the material properties and the relative stability between the temperature and humidity in the laboratory, the main factors affecting the consolidation of the samples are consolidation pressure and consolidation time. According to the main factors affecting the consolidation of samples, the design of consolidation scheme is shown on Table 6.

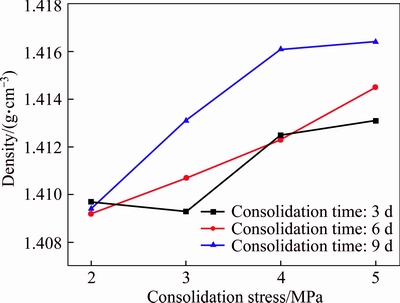

According to the consolidation plan of the transparent soil sample, three consolidation specimens of each consolidation pressure 2, 3, 4 and 5 MPa are set according to different consolidation pressures. The consolidation time of each group of specimens with the same consolidation pressure varied from 3 d, 6 d, to 9 d. Use Vernier caliper and analytical balance to measure the height and mass of the sample, and calculate the density of the consolidated transparent soil based on the data shown on Table 7.

The density change trend presented in Figure 5 shows the greater influence of consolidated stress on the density of transparent soil samples than that of consolidated time. The density of transparent soil samples is concentrated between 1.408 and 1.418 g/cm3. With the increase of consolidation stress, the density of transparent soil samples is increasing. The density of transparent soil samples with different consolidation time under the same consolidation pressure varies slightly.

Figure 2 Transparent soil synthesized by different proportions of mixed liquid:

Figure 3 Design drawing of cylinder mould (Unit: mm):

Figure 4 Physical diagram of cylinder mould:

Table 6 Consolidation scheme of transparent soil sample

3 Test and discussion

3.1 Compression test of transparent soil

The transparent soil sample should be put in the center of the confined plate of the WDW-300 universal machine in sequence; adjusted the indenter of the machine to the horizontal level in order to make sure that the transparent soil sample is contacted with indenter contacted uniformly. Set the initial contact force with 0.01 kN and decreased the upper head of machine until both of them are contacted; destroyed samples by controlling displacement and billet under axial pressure, and the loading speed is 0.05 mm/min.

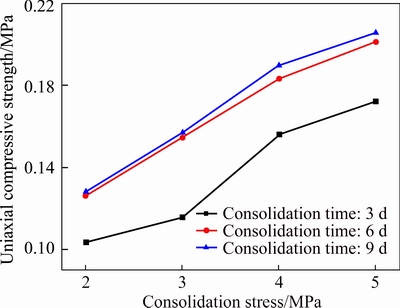

The uniaxial compression test is carried out for the 12 transparent soil samples consolidated successively, and the uniaxial compressive strength is obtained respectively, as shown in Table 8.

Figure 6 shows the changed trend with uniaxial compressive strength of transparent soil samples under the condition of consolidation pressure and time. It demonstrates that the uniaxial compressive strength of the transparent soil samples is within the range of 0.10 to 0.21 MPa, and the uniaxial compressive strength of the samples with 6 d consolidation is similar to that of 9 d. The consolidation with 3 d is lower, and the strength is less than that of the samples with many consolidation days. The strength of the samples with small consolidation time and stress is also lower, so the disturbance has greater impact on them during the test.

The elastic modulus of transparent soil samples with different influence factors of consolidation stress and consolidation time is shown in Table 9.

The changed trend according to the elastic modulus of transparent soil samples under two- factor of different consolidation stress and time is shown in Figure 7, which is different from the density and uniaxial compressive strength. It can be summarized that when the consolidation stress is less than 3 MPa, the modulus increases with the consolidation stress, but the change trend is slower. When the consolidation stress exceeds 3 MPa, the slope becomes larger, which is similar to that of the modulus. The modulus of the transparent soil sample with the consolidation time of 6 and 9 d has the same tendency, and the mechanical properties do not change.

Table 7 Statistical data of height, volume, mass and density of transparent soil sample

Figure 5 Density trend map of transparent soil sample

Table 8 Uniaxial compressive strength of transparent soil samples

Figure 6 Trend chart of uniaxial compressive strength of transparent soil under two-factor

The relationship between compression deformation and loading of transparent soil can be determined by confined compression test.

Table 9 Elastic modulus of transparent soil samples

Figure 7 Elastic modulus under two-factor of transparent soil

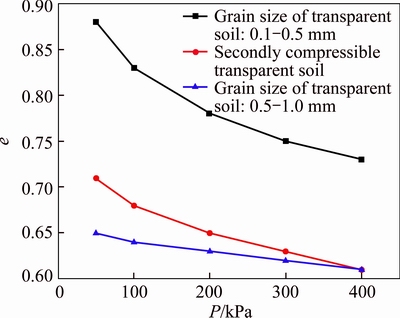

According to the loading ratings of 50, 100, 200, 300 and 400 kPa, the graded loading is performed on 0.1–0.5 mm, 0.5–1.0 mm, the above-mentioned transparent soil with the mass ratio of 1:1 and the ordinary soil with the same grain sizes successively. The relationship between void ratio and loading of transparent soils with different grain sizes were calculated on the basis of time period, as shown in Figure 8.

On the basic of the states, we can conclude that the compressibility between three different grain sizes of transparent soil is different, the largest compressibility is between 0.1 and 0.5 mm. The range of void ratio under different loadings is 0.73–0.88 mm. The compressibility of the secondly compressible transparent soil has been greatly reduced than the smaller size. The void ratio of secondly sand under different loadings is between 0.61 and 0.71 mm; the worst compressibility is 0.5–1.0 mm, but it is similar with the secondly transparent soil, the void ratio under different loadings is 0.61–0.65 mm.

Figure 8 e–P curves of different grain sizes of transparent soil

Curves of void ratio and loading between different grain sizes are shown in Figure 9.

Figure 9 e–P curves of different grain sizes of sandy soil

According to above curve, we can conclude that the compressibility is different between ordinary soils with three different grain sizes. The highest compressibility is the ordinary soil with the grain size of 0.1–0.5 mm, and the void ratio was 0.60–0.73 mm under different loadings. The compressibility of secondly sands is smaller than the small soil and the void ratio under different loadings is 0.51–0.61 mm. The ordinary sand with 0.5–1.0 mm diameter has the least compressibility and the void ratio under different loadings is between 0.48 and 0.52 mm.

The void ratio relationship between different grain sizes of transparent soil and ordinary soil under different vertical loadings is shown in Figure 10.

Figure 10 e–P curves of transparent soil and sandy soil

The curve shows the compressibility is different between transparent soil and soil with different grain sizes. Among them, the compressibility of secondly and the smallest sand is less than that of the transparent soil, and the compressibility is similar between both of them with the size of 0.1–0.5 mm but smaller than transparent soil. The compressibility between transparent soil and soil is similar although both of them have the same tendency.

3.2 Shear tests of transparent soil

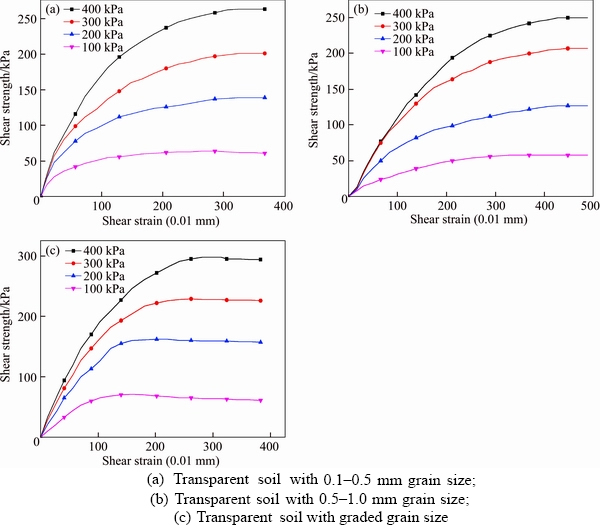

The synthetic transparent soil has a high permeability and direct shear tests are carried out. After vertical pressure, direct fast shearing requires that the sample applies shear forces into the transparent soil quickly and finishes the shear failure within 3–5 min.

Based on the experimental data, shear displacement as abscissa and the shear stress as the ordinate. Curves of relation between stress–strain displacement under different diameters of transparent soil are as shown in Figure 11.

Experiment results show that the same diameters of the fused quartz sand increased with the increment of vertical pressure. There is no obvious peak intensity in the shear stress and shear displacement curves of transparent soil with different grain sizes. There are obvious strains hardening characteristics.

Curves of relation between stress-strain under same vertical pressure in different diameters of transparent soil are as shown in Figure 12.

Results indicate that at the same vertical pressure, the shear strength of the gradation transparent soil is the highest, followed by the transparent soil with the diameter of 0.5–1.0 mm, and the shear strength of the transparent soil with the diameter of 0.1–0.5 mm is the lowest.

Figure 11 Curves of relation between stress–strain under different diameters of transparent soil:

Figure 12 Curves of relation between stress–strain under different vertical pressure of transparent soil:

Curves of relation between stress and strain under different diameters of transparent soil of two different materials are as shown in Figure 13.

Results indicate that the sheer strength of transparent soil and standard sand increases with the raising of vertical pressure, and the pressure fluctuation trend of this operating is similar to that.

Figure 13 Curves of relation between stress–strain under different diameters of transparent soil of two different materials:

The shear strength–strain of transparent soil and sandy soil with the same diameters size of 0.1–0.5 mm under the same vertical pressure has very little differences, and each index is very close. The size of the transparent soil and sandy soil with a grain size of 0.5–1.0 mm, has a certain change compared with the transparent soil with a grain size of 0.1–0.5 mm, but the indexes are also close between transparent soil and sandy soil under the same vertical pressure.

In the shear strength–strain curve, there is no obvious peak intensity and it shows the characteristics of strain hardening. The type of shear strength of the transparent soil and sandy soil is similar, which shows that the ability of the transparent soil resisting shear deformation is similar to that of sand, acting as sand in simulated soil-rock mixture.

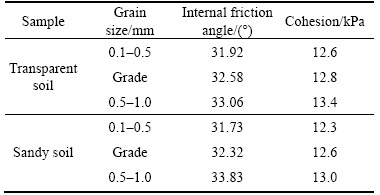

Calculate the internal friction angle φ and cohesion c of transparent soil and sandy soil with different diameters. The results are shown in Table 10.

Table 10 Internal friction angle and cohesion of transparent soil and soil with different diameters

Results indicate that internal friction angles and clay of the transparent soil and sandy soil with the same diameters are closed. The internal friction angles of the transparent soil and sandy soil increase with the increase of grain sizes. The physical and mechanical properties of the transparent soil are similar to those of the sand. Under the same vertical pressure, the indexes of the transparent soil and sandy soil are similar, so the synthetic transparent soil can be used to simulate the soil.

4 Conclusions

On the basis of the optical theory and material transparency principle, we can conclude that configuration of transparent soil must quest for transparent solid materials and liquid materials with the same refractive index. With the steady physical and chemical properties and great transparency, the fused quartz sand has been selected as a solid material for the synthesis of transparent soil; The parameters such as grain sizes, proportions, natural repose angles and densities of fused quartz sand are determined, which are similar to that of soil; the index of fused quartz sand is 1.458. The liquid paraffin and n-tridecane mixed are determined as liquid materials for the synthesis of transparent soil, and the index of the mixture is measured at different concentrations, temperatures and proportions. The mixed index of liquid paraffin and n-tridecane is 1.458 at the ratio of 4.4 at 17 °C. Consolidation is carried out with configuration of transparent soil. The consolidation pressures are 2, 3, 4 and 5 MPa, and the consolidation time is 3, 6 and 9 d, respectively. Under the same consolidation time, the density of the solidified samples increases with the consolidation pressure up, which are similar to that of the density of the solidified sample with the consolidation time.

The uniaxial compressive strength of transparent soil samples is within the range of 0.10 to 0.21 MPa. Because of the consolidation time and pressure, the uniaxial compressive strength and elastic modulus increase with the up of them. The compressibility of transparent soil and ordinary soil has similar change trend with the same grain size, and the compressibility of two materials decrease with the increasing grain size. The compressibility of the transparent soil with grain size of 0.1–0.5 mm is the best. The second is transparent soil, and the worst is 0.5–1.0 mm. The shear strength, internal friction angle and clay of the transparent soil and ordinary soil with the same grain size have similar trends. The shear strength of grading transparent soil is the highest, and the transparent soil with the particle of 0.5–1.0 mm is the next one, the 0.1–0.5 mm grain size is the smallest. The internal friction angle and clay force increase with the up of grain size. Transparent soil and sandy soil have high similarities and both of them can be used for the study of similar simulation test of soil-rock mixture.

References

[1] QIAN Ming-gao, XU Jia-lin. Discussion of several issues concerning the development of coal industry in China [J]. Journal of Mining and Safety Engineering, 2006, 23(2): 127–132.

[2] TAHA M R, SHAVERDI H. Evolution of fabric under the rotation of the principal stress axes in the simple shear test [J]. Mechanics of Materials, 2014, 69(1): 173–184. DOI: 10.1016/j.mechmat.2013.10.003.

[3] HASAN A, ALSHIBLI K. Three dimensional fabric evolution of sheared sand [J]. Granular Matter, 2012, 14(4): 469–482. DOI: 10.1007/s10035-012-0353-0.

[4] ABISALLOUM T Y. Electromagnetically induced transparency and Autler-Townes splitting: Two similar but distinct phenomena in two categories of three-level atomic systems [J]. Physical Review A, 2010, 81(5): 90. DOI: 10.1103/PhysRevA.81.053836.

[5] MAGUED I. Geotechnical properties of transparent silica [J]. Canadian Geotechnical Journal, 2011, 39(1): 111–124. DOI: 10.1139/t01-075.

[6] SADEK S, ISKANDER M G, LIU J. Accuracy of digital image correlation for measuring deformations intransparent media [J]. Journal of Computing in Civil Engineering, 2003, 17(2): 88–96. DOI: 10.1061/(ASCE)0887-3801(2003)17: 2(88).

[7] STANIER S A, BLACK J A, HIRD C C. Enhancing accuracy and precision of transparent synthetic soil modeling [J]. International Journal of Physical Modelling in Geotechnics, 2012, 12(4): 162–175. DOI: 10.1680/ijpmg.12. 00005.

[8] ISKANDER M, LIU J, SADEK S. Transparent amorphous silica to model clay [J]. Journal of Geotechnical & Geoenvironmental Engineering, 2002, 128(3): 262–273. DOI: 10.1061/(ASCE)1090-0241(2002)128:3(262).

[9] MANNHEIMER R J, OSWALD C J. Development of transparent porous media with permeabilities and porosities comparable to soils, aquifers, and petroleum reservoirs [J]. Groundwater, 2010, 31(5): 781–788. DOI: 10.1111/j.1745- 6584.1993.tb00851.x.

[10] ISKANDER M. Transparent soils to image 3D flow and deformations [C]// Imaging Technologies: Techniques and Applications in Civil Engineering, 1998: 255–264.

[11] ABIDEEN A G, AHMAD S A R, MOHD H O. Utilisation of transparent synthetic soil surrogates in geotechnical physical models: A review [J]. Journal of Rock Mechanics and Geotechnical Engineering, 2016, 8(4): 568–576. DOI: 10.1016/j.jrmge.2015.11.009.

[12] LIU J, ISKANDER M, SADEK S. Consolidation and permeability of transparent amorphous silica [J]. Geotechnical Testing Journal, 2003, 26(4): 390–401. DOI: 10.1520/GTJ11257J.

[13] LIU J, ISKANDER M. Modelling capacity of transparent soil [J]. Canadian Geotechnical Journal, 2010, 47(4): 451–460. DOI: 10.1139/T09-116.

[14] ISKANDER M. Modelling with transparent soils [M]. Berlin, Heidelberg: Springer, 2010.

[15] SHE Yue-xin. Research progress in soil deformation measurement using transparent media and particle image velocimetry [J]. Site Investigation Science and Technology, 2005(6): 7–10.

[16] ZHANG Yi-ping, LI Liang, WANG Si-zhao. Experimental study on pore fluid for forming transparent soil [J]. Journal of Zhejiang University (Engineering Science), 2014, 48(10): 1828–1834. DOI: 10.3785/j.issn.1008-973X.2014.10.017.

[17] SUI Wang-hua, GAO Yue, LIU Jin-yuan. Status and prospect of transparent soil experimental technique [J]. Journal of China Coal Society, 2011, 36(4): 577–582. (in Chinese)

[18] WU Ming-xi. Study on transparent synthetic sand and its triaxial test [D]. Dalian: Dalian University of Technology, 2006. (in Chinese)

[19] XU Guo-an. Research on the mechanism and evolution law of rock deformation and cracking around deep tunnels [D]. Xuzhou: China University of Mining and Technology, 2011. (in Chinese)

[20] ZHANG Shun-jin. Study on the development of transparent similar materials for rock mass and its experimental applications [D]. Xuzhou: China University of Mining and Technology, 2014. (in Chinese)

(Edited by HE Yun-bin)

中文导读

利用人工合成透明土的土石混合体物理模拟试验研究

摘要:露天煤矿排土场是松散的土石混合体在重力、运输设备动荷载、地震等作用下重塑形成的。通过人工合成透明土的新方法来观测重塑过程中土-石体的发展过程、运移规律。选择熔融石英砂和液体石蜡与正十三烷的混合液作为合成透明土的材料,在室温17 ℃条件下,将液体石蜡与正十三烷按质量比4.4混合配置透明土。通过物理试验测定透明土的物理力学性质并与普通砂土进行比较,实验结果表明透明土和砂土具有很高的相似性,说明透明土可用于土石混合体相似模拟实验研究。

关键词:透明土;排土场;土石混合体;物理试验

Foundation item: Project(2015QNA40) supported by the Fundamental Research Funds for the Central Universities, China

Received date: 2018-09-04; Accepted date: 2018-11-25

Corresponding author: ZHOU Wei, PhD, Professor; Tel: +86-516-83590567; E-mail: zhw19820624@163.com; ORCID: 0000-0002- 8758-2511

Abstract: The waste dump of open-pit coal mine is remade of soil-rock mixture under the action of gravity, dynamic load of transportation equipment and earthquake, etc. By using artificial synthetic transparent soil, the developing process and migration law for soil-rock mixture are observed in the remade process. The mixture of fused quartz sand, liquid paraffin and n-tridecane is chosen as the material for synthetic transparent soil which is mixed with liquid paraffin and n-tridecane at a mass ratio of 4.4 at room temperature of 17℃. Physical and mechanical properties of transparent soil are determined by physical test and compared with those in natural sandy soil. The results show that transparent soil and sandy soil have high similarity, in other words, transparent soil can be used for similar simulation experiments of soil-rock mixture.