Creep properties and controlled creep mechanism of as-cast Mg-5Zn-2.5Er alloy

LI Han(李 晗), DU Wen-bo(杜文博), LI Jian-hui(李建辉), LI Shu-bo(李淑波), WANG Zhao-hui(王朝辉)

School of Materials Science and Engineering, Beijing University of Technology, Beijing 100124, China

Received 23 September 2009; accepted 30 January 2010

Abstract:

The creep behaviors of as-cast Mg-5Zn-2.5Er alloy (mass fraction, %), under various applied stresses (50-70 MPa) and creep temperatures (150-200 ?C) for 100 h, were investigated. The stress exponent n is in the range of 1.5-5.8, and the activation energy Qc is in the range of 28.3-77.1 kJ/mol. With respect to the calculated n and Qc as well as the microstructures after creep, it is suggested that there is a transition region between grain boundary sliding(GBS) dominated creep to dislocation creep mechanism (from n<3 to n>3), arising in the steady-stage creep rate value of 2.89×10-9 s-1.

Key words:

magnesium alloy; as-cast magnesium alloy; creep mechanism; erbium;

1 Introduction

Magnesium alloys have many advanced properties such as low density, high specific strength and rigidity, good damping capacity and electromagnetic shielding, so their application in automobile, aerospace and electronic industries becomes more and more extensive. However, magnesium alloys have low strength and poor creep resistant at elevated temperatures, which restrict their further application as structural material. Recently, many researches have focused on magnesium alloys reinforced by the icosahedral quasicrystalline phase (I-phase)[1-3]. Stable I-phase in Mg-Zn-Y alloys was first reported by LUO et al[4]. It has been reported that Mg-Zn-Y alloys containing a thermally stable I-phase, exhibit significantly high level of yield strength and elongation at room temperature[5]. Compared with the AZ91D alloy, the mechanical property of AZ91D alloy strengthened by the quasicrystalline has been improved[6]. YUAN et al[7] reported that Mg-Zn-Gd-based alloy strengthened by quasicrystalline exhibited much better creep properties compared with AE42 alloy. LI et al[8] discovered that I-phase with face-centered icosahedral quasicrystalline structure, and the W-phase with face-centered cubic structure presented in the as-cast Mg-Zn-Er alloy. Since stress exponent n and activation energy Qc obtained from creep tests are important parameters for evaluating the performance of heat resistant materials, the creep properties of the new alloys must be investigated[9]. The present work is designed to investigate the creep behaviors of as-cast Mg-5Zn-2.5Er alloy and discuss the controlled creep mechanism of this alloy.

2 Experimental

The tested alloy with the nominal composition of Mg-5%Zn-2.5%Er (mass fraction) was prepared using magnesium (99.9%), zinc (99.9%) and binary Mg-14.6%Er master alloy. Melting was conducted in ordinary electric resistance furnace (melting temperature of 780 ?C) under an anti-oxidizing flux with the purpose of preventing the oxidation and burning of magnesium alloy.

Constant-load tensile creep tests were carried out on CSS-3902 creep machine at temperatures of 150, 175 and 200 ?C, under applied stresses of 50, 60 and 70 MPa, and the creep time of 100 h. For these tests, cylindrical specimens with a gauge length of 25 mm and a gauge diameter of 5 mm (see in Fig.1) were machined from the as-cast ingot.

The microstructures of specimens with different applied-stresses/temperatures were studied by scanning electron microscopy (SEM, HATACHI S3400N) and transmission electron microscopy (TEM, JEOL JEM 2000FX). The SEM specimens were mechanically

Fig.1 Specimen for creep tests used in this study (Unit: mm)

ground, polished and then etched with 4 % nitric acid and 96 % ethanol (to obtain the SEM image, volume fraction) for several seconds. The TEM specimens were prepared by a combination of mechanical and ion thinning techniques. Discs with a diameter of 3 mm produced by wet grinding were further prepared by twin-jet polishing in a solution of 80% methanol and 20% nitric acid (volume fraction) at ~20 V and 243 K. Final thinning was performed on an ion beam etching machine with an incident angle less than 10?.

3 Results and discussion

3.1 Microstructure

The microstructures of the as-cast and the post-crept are compared, as shown in Fig.2. The microstructure of the as-cast Mg-5Zn-2.5Er alloy consists of grey α-Mg matrix, eutectoid-lamellar phases distributing along grain boundaries and white granular phases in grains, as shown in Fig.2(a). The microstructures of post-crept Mg-5Zn- 2.5Er alloy performed at 150 ?C, 50 MPa; 175 ?C, 50 MPa and 200 ?C, 50 MPa are shown in Figs.2(b), (c) and (d), respectively. Sections of grain boundaries are also covered by the eutectoid-lamellar phases, and some fine granular phases are distributed within the grains. No significant difference in microstructure of the as-cast and the post-crept alloys is observed.

3.2 Creep properties

Figs.3(a)-(c) show the tensile creep strain—time curves that exhibit the creep strain as a function of time conducted under constant applied stresses of 50, 60 and 70 MPa and various temperatures of 150, 175 and 200 ?C for 100 h. These curves exhibit two stages: a short primary creep stage which shows an instantaneous strain after being loaded, followed by a prolonged steady-state creep which extends to the end of the creep. However, the third creep stage is not observed in all creep curves during creep time of 100 h, which implies excellent creep resistant of as-cast Mg-5Zn-2.5Er alloy. As shown in Fig.3(a), tensile steady-state creep rate and total creep strain increase with the increasing creep temperatures under applied stress of 50 MPa. It can be found that there is similar tendency of tensile steady-state creep rate and creep strain under the applied stress of 60 and 70 MPa in Figs.3(b) and (c). From Fig.3(c), the elevation of the stress level up to 70 MPa results in a great increase of steady-stage creep rate and total creep strain at the creep temperature of 200 ?C. It can be attributed to the extreme creep test condition. The values of steady-stage creep rate and total creep strain at 70 MPa and 200 ?C are much higher, which are 1.42×10-8 s-1 and 0.85%, respectively.

In order to investigate the controlled creep

Fig.2 SEM images of as-cast Mg-5Zn-2.5Er alloy (a) and Mg-5Zn-2.5Er alloy crept under 50 MPa for 100 h at different temperatures: (b) 150 ?C; (c) 175 ?C; (d) 200 ?C

Fig.3 Creep curves of as-cast Mg-5Zn-2.5Er alloy under 50 MPa (a), 60 MPa (b) and 70 MPa (c)

mechanism of as-cast Mg-5Zn-2.5Er alloy, the stress exponent n and activation energy Qc were calculated. The relationship among steady-stage creep rate, applied stress and creep temperature, is given by power-law creep equation[11]:

![]() (1)

(1)

where ![]() is the steady-stage creep rate, A is the constant, σ is the applied stress and R is the gas constant. By plotting logarithmically the steady-stage creep rate

is the steady-stage creep rate, A is the constant, σ is the applied stress and R is the gas constant. By plotting logarithmically the steady-stage creep rate ![]() versus the applied stress σ, the stress exponent n can be determined. And plotting lg

versus the applied stress σ, the stress exponent n can be determined. And plotting lg![]() versus T -1 will yield the apparent activation energy Qc. Various n and Qc give an indication of the controlled mechanism for creep.

versus T -1 will yield the apparent activation energy Qc. Various n and Qc give an indication of the controlled mechanism for creep.

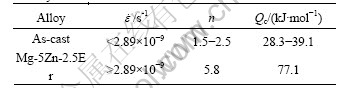

Fig.4 shows the logarithmic applied stress versus the steady-stage creep rate for as-cast Mg-5Zn-2.5Er alloy at 150, 175 and 200 ?C. Within the investigated stress range, there is a linear relationship between the logarithmic steady-stage creep rate and the applied stress. The stress exponent n calculated from the slope in Fig.4 is 1.5, 2.5, 5.8, respectively, as summarized in Table 1. It can be concluded from Table 1 that the values of n in the whole applied stress regime slightly increase with increasing creep temperature. A set of values of n were used to fit the experimental data points, since they are usually associated with several creep mechanisms such as grain boundary sliding, dislocation viscous glide and dislocation climb[12]. The best linear fits of the experimental data are obtained in low steady-stage creep rate regime (![]() <2.89×10-9 s-1) where the measured value of n≈2, corresponding to the grain boundary sliding(GBS) mechanism[13]. The data points obtained in high steady-stage creep rate regime (

<2.89×10-9 s-1) where the measured value of n≈2, corresponding to the grain boundary sliding(GBS) mechanism[13]. The data points obtained in high steady-stage creep rate regime (![]() >2.89×10-9 s-1) form approximately a linear curve with a slope of n=5.8, implying dislocation creep mechanism[9].

>2.89×10-9 s-1) form approximately a linear curve with a slope of n=5.8, implying dislocation creep mechanism[9].

Fig.4 Logarithmic steady-stage creep rate vs applied stress of as-cast Mg-5Zn-2.5Er alloy

Table 1 Apparent activation energies for creep stress exponents of alloys

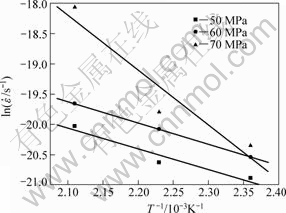

As shown in Fig.5, there is also a linear relationship between the reciprocal of test temperature and the logarithmic steady-stage creep rate. For the creep tests carried out at applied stresses of 50, 60 and 70 MPa, the activation energy for creep of as-cast Mg-5Zn-2.5Er alloy is calculated from Arrhenius plot (ln![]() versus T -1), reaching 28.3, 39.1 and 77.1 kJ/mol, respectively, as

versus T -1), reaching 28.3, 39.1 and 77.1 kJ/mol, respectively, as

Fig.5 Reciprocal of test temperature dependences of steady-stage creep rate of as-cast Mg-5Zn-2.5Er alloy

summarized in Table 1. In the present work, the activation energy for creep exhibits an obvious increase with increasing applied stresses. In the low steady-stage creep rate regime (![]() <2.89×10-9 s-1), the determined activation energy achieves at the value of 28.3 kJ/mol and 39.1 kJ/mol, respectively. In the high steady-stage creep rate regime (

<2.89×10-9 s-1), the determined activation energy achieves at the value of 28.3 kJ/mol and 39.1 kJ/mol, respectively. In the high steady-stage creep rate regime (![]() >2.89×10-9 s-1), the determined n value is 5.8 for as-cast Mg-5Zn-2.5Er alloy, and the activation energy of the alloy(77.1 kJ/mol) is found to be also lower than that of grain boundary diffusion for pure magnesium (92 kJ/mol[14]) and lattice self-diffusion for pure magnesium (135 kJ/mol[14]). Thus, it can be suggested that dislocation creep is the controlled creep mechanism of the as-cast Mg-5Zn-2.5Er alloy at the high steady-stage creep rate. By summarizing, there is a transition region between GBS dominated creep mechanism and dislocation creep mechanism (from n<3 to n>3), arising in the steady-stage creep rate of 2.89×10-9 s-1.

>2.89×10-9 s-1), the determined n value is 5.8 for as-cast Mg-5Zn-2.5Er alloy, and the activation energy of the alloy(77.1 kJ/mol) is found to be also lower than that of grain boundary diffusion for pure magnesium (92 kJ/mol[14]) and lattice self-diffusion for pure magnesium (135 kJ/mol[14]). Thus, it can be suggested that dislocation creep is the controlled creep mechanism of the as-cast Mg-5Zn-2.5Er alloy at the high steady-stage creep rate. By summarizing, there is a transition region between GBS dominated creep mechanism and dislocation creep mechanism (from n<3 to n>3), arising in the steady-stage creep rate of 2.89×10-9 s-1.

The determination of activation energies and exponents is an useful guide to the operative mechanism but, without microstructure studies, it is insufficient to choose the most effective alloying elements[15]. The TEM micrograph of Mg-5Zn-2.5Er alloy post-crept at 70 MPa, 175?C for 100 h is presented in Fig.6. Fine particle-like precipitates (dark area, as indicated by arrows) in α-Mg matrix can be observed on the dislocation line. Dislocations are pinned by these precipitates which can effectively obstruct dislocation motion, thereby, improving the creep resistance of the alloy. These fine precipitates are thermally stable at 175 ?C, and growth of these precipitates has not been observed after 100 h creep exposure[10]. It is reported[16] that rod-like MgZn2 phase emerged during creep deformation can act as an effective barrier to basal slide systems, consequently, the movement of basal dislocation system is impeded, leading to the pile-up of a-type dislocation in Mg-5%Zn-2%Al(-2%Y) alloy.

Fig.6 TEM micrograph of fine particle-like precipitates obstructing dislocation motion of as-cast Mg-5Zn-2.5Er alloy

4 Conclusions

1) Elevated temperature creep properties and the controlled creep mechanism of as-cast Mg-5Zn-2.5Er alloy were investigated within the applied stress range of 50-70 MPa and creep temperature of 150-200 ?C. No significant difference in microstructure of as-cast and the post-crept alloys is observed.

2) The stress exponent of n varies from 1.5 to 5.8, and the activation energy varies from 28.3 to 77.1 kJ/mol, which both exhibit an obvious increase with increasing creep temperature and applied stress. There is a transition region between GBS dominated creep mechanism and dislocation creep mechanism (from n<3 to n>3), arising in the steady-stage creep rate value of 2.89×10-9 s-1.

3) Fine precipitates in α-Mg matrix can play the role in hindering the dislocation movement.

References

[1] SINGH A, WATANABE M, KATO A, TSAI A P. Strengthening in magnesium alloys by icosahedral phase [J]. Science and Technology of Advanced Materials, 2005, 6(8): 895-901.

[2] KIM I J, BAE D H, KIM KH. Precipitates in a Mg-Zn-Y alloy reinforced by an icosahedral quasicrystalline phase [J]. Materials Science and Engineering A, 2003, 359: 313-318.

[3] BAE D H, KIM Y, KIM I J. Thermally stable quasicrystalline phase in a superplastic Mg-Zn-Y-Zr alloy [J]. Materials Letters, 2006, 60: 2190-2193.

[4] LUO Z P, ZHANG S Q, TANG Y L, ZhAO D S. Quasicrystal in as-cast Mg-Zn-RE alloys [J]. Scripta Metallurgica et Materialia, 1993, 28(12): 1513-1518.

[5] PARK E S, Yi S, OK J B, BAE D H, KIM W T, KIM D H. Solidification and microstructure control of Mg-rich alloys in the Mg-Zn-Y ternary system [C]//Proceedings of the MRS Fall Meeting. Boston: MA, 2000: 251-258.

[6] WAN D Q, YANG G C, ZHU M. Microstructure formation and mechanical property involving icosahedral quasicrystal phase of Y rich Mg-Zn-Y quasicrystal alloy [J]. Acta Metallurgica Sinica (English Letters), 2007, 20(6): 429-433.

[7] YUAN G Y, KATO H, AMIYA K, INOUE A. Excellent creep properties of Mg-Zn-Cu-Gd-based alloy strengthened by quasicrystals and Laves phases [J]. Journal of Materials Research, 2005, 20 (5): 1278-1286.

[8] LI Jian-hui, DU Wen-bo, LI Shu-bo, WANG Zhao-hui. Icosahedral quasicrystalline phase in an as-cast Mg-Zn-Er alloy [J]. Rare Metals, 2009, 28(3): 297-301.

[9] ANYANWU I A, KAMADO S, KOJIMA Y. Creep properties of Mg-Gd-Y-Zr alloys [J]. Materials Transactions, 2001, 42: 1212-1218.

[10] LI Jian-hui, DU Wen-bo, LI Shu-bo, WANG Zhao-hui. Tensile and creep behaviors of as-cast Mg-5Zn-2.5Er alloy improved by icosahedral quasicrystal [J]. Materials Science and Engineering A, 2010, 527: 1255-1259.

[11] PARK K T, MOHAMED F A. Creep strengthening in a discontinuous SiC-Al composite [J]. Metallurgical and Materials Transactions A, 1995, 26(12): 3119-3129.

[12] ZHANG P. Creep behavior of the die-cast Mg-Al alloy AS21 [J]. Scripta Materialia, 2005, 52: 277-282.

[13] RUANO O A, SHERBY O D. On constitutive equations for various diffusion-controlled creep mechanisms [J]. Rev Phys Appl, 1988, 23(4): 625-638.

[14] FROST H J, ASHBY M F. Deformation mechanism maps [M]. Oxford: Pergamon Press, 1982: 44.

[15] MORDIKE B L. Creep-resistant magnesium alloys [J]. Materials Science and Engineering A, 2002, 324: 103-112.

[16] ZOU Hong-hui. Effects of microstructure on creep behavior of Mg-5%Zn-2%Al(-2%Y) alloy [J]. Transactions of Nonferrous Metals Society of China, 2008, 18(3): 580-587.

(Edited by LI Xiang-qun)

Foundation item: Project(2007CB613706) supported by the National Basic Research Program of China

Corresponding author: DU Wen-bo; Tel: +86-10-67392917; E-mail:duwb@bjut.edu.cn

DOI: 10.1016/S1003-6326(09)60280-6