J. Cent. South Univ. (2016) 23: 685-700

DOI: 10.1007/s11771-016-3114-0

Numerical analysis of soil-rock mixture’s meso-mechanics based on biaxial test

ZHANG Hai-yang(张海洋), XU Wen-jie(徐文杰), YU Yu-zhen(于玉贞)

State Key Laboratory of Hydroscience and Hydraulic Engineering, Department of Hydraulic Engineering,

Tsinghua University, Beijing 100084, China

Central South University Press and Springer-Verlag Berlin Heidelberg 2016

Central South University Press and Springer-Verlag Berlin Heidelberg 2016

Abstract:

Soil-rock mixture(S-RM)is a widely distributed geotechnical medium composed of “soil” and “rock block” different both in size and strength. Internal rock blocks form special and variable meso-structural characteristics of S-RM. The objective of this work was to study the control mechanism of meso-structural characteristics on mechanical properties of S-RM. For S-RM containing randomly generated polygonal rock blocks, a series of biaxial tests based on DEM were conducted. On the basis of research on the effects of rock blocks’ breakability and sample lateral boundary type (rigid, flexible) on macroscopic mechanical behavior of S-RM, an expanded Mohr-Coulomb criterion in power function form was proposed to represent the strength envelop. At the mesoscopic level, the variations of meso-structure such as rotation of rock block, and the formation mechanism and evolution process of the shear band during tests were investigated. The results show that for S-RM with a high content of rock block, translation, rotating and breakage of rock blocks have crucial effects on mechanical behavior of S-RM. The formation and location of the shear band inside S-RM sample are also controlled by breakability and arrangement of rock blocks.

Key words:

1 Introduction

As a special kind of geotechnical material, soil-rock mixture(S-RM) is common in human engineering activities. It is similar to the block-in-matrix rocks (or bimrock) that was defined as mixtures of relatively large, competent blocks within a bonded matrix of finer and weaker texture by Medley [1], but there are also some differences. Xu and Hu [2] pointed that S-RM is a kind of extreme inhomogeneous geotechnical materials which is formed in Quaternary period and composed of certain percentage of large rock blocks, fine grained soil and pores. Because of its special material composition, S-RM also shows nonlinear, heterogeneity and other complex physical and mechanical properties. The meso-structure of S-RM, such as shape, size and distribution of rock blocks, has good self-organization in the statistical level [3], and it has much more obvious effect on the macroscopic mechanical behavior and strength parameters compared with homogeneous soil or rock in previous research. Sometimes, the structural characteristics of S-RM would control its overall mechanical properties.

Due to restrictions of experiment apparatus, researchers try to develop some empirical methods to predict the strength of this kind of farrago. Sonmez et al [4] proposed an empirical approach to determine the UCS for a volcaniclastic rock. Hamidi et al [5] investigated the empirical relationship between the shear strength of sand-gravel mixture and that of the sandy fraction of soil considering the particle breakage in high confinements. However, there are too many factors affecting the mechanical properties of S-RM for empirical formulas to fully take into account. Xu et al [6] and Coli et al [7] carried out large-scale in-situ tests, respectively. The results show that the mixture has higher internal friction angle and lower cohesion compared with the soil matrix. Besides, the friction angle has a positive correlation with rock block content while the cohesion changes little after the rock content exceeds a critical threshold (25%-30%). When it comes to more detailed influence factors such as the particle shape, size and orientation, laboratory tests and DEM numerical tests show greater advantages. The content, shape, size, arrangement of rock blocks and the inherent anisotropy have different degrees of influence on the overall mechanical properties of S-RM, which have been confirmed through various related laboratory and numerical tests [8-13]. When the rock block content is between the scope of 25% to 70%, soil and rock block control the mechanical properties of S-RM jointly. Moreover, angularity rock blocks lead to a higher internal friction angle and more obvious dilatancy compared with circular smooth one. In recent years, image processing technology has also been introduced into the model reconstruction of S-RM in order to reflect the internal structural characteristics of S-RM [14-16].

In the study of the meso-mechanical properties of S-RM, laboratory experiments also show some shortcomings. It is difficult to observe the evolution of the internal meso-structure, such as rotation and breakage of rock blocks and formation of shear bands, during the loading process. The test apparatus also limits the particles’ size in the S-RM sample. Therefore, carrying out numerical tests to reveal the mesoscopic mechanism of S-RM’s mechanical behavior is of great significance. In Ref. [17], YADE, an open-source discrete element software, is adopted for two- dimensional numerical simulation of the biaxial compression test with typical S-RM from Tangjiashan barrier dam formed in the Wenchuan earthquake, 2008. To reveal the role of rock block in mesoscopic structure evolution and failure mechanism of S-RM, a random generation algorithm was applied to generate polygonal rock blocks in S-RM numerical sample according to the given grading curve. Compared with elliptical rock block usually adopted, polygonal rock block could simulate the interlocking effect of natural rock blocks produced in the colluvial accumulation much better. In addition, instead of a single rigid box boundary which provides a strong constraint, a series of little boxes with relatively independent movements were designed to simulate the flexible membrane lateral boundary in laboratory. For the strength of different types of rock varies widely, they show different fractured natures in the experiment, and further affect the meso-structural characteristic of S-RM. Both the effects of two kinds of lateral boundary types and the fractured nature of rock block on meso-structural evolution process and macroscopic mechanical properties of S-RM were investigated. During the biaxial numerical tests, locations of particles were recorded and rotations of rock blocks were calculated to reveal the formation and evolution of shear band in S-RM. On this basis, the preliminary control mechanism of meso-structure on the macroscopic mechanical properties was brought to light.

2 Numerical simulation of biaxial tests for S-RM

2.1 Numerical model for S-RM

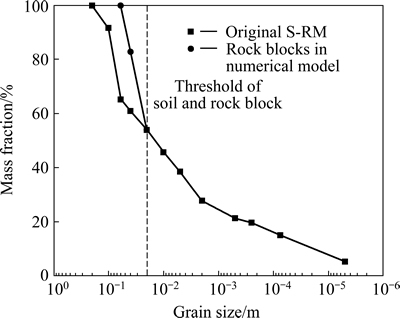

Biaxial test is similar to a simplified two-dimensional triaxial test. It not only reflects the main mechanical characteristics such as stress-strain relationship and volumetric change of geotechnical materials, but also is convenient for observing the internal meso-structural features of specimen clearly. The samples in all conditions have the same dimensions with 0.4 m width and 0.8 m height. Besides the size, particle constitutions of all samples are the same. That is to say, all samples have exactly the same initial internal structure. In order to obtain conclusions of general applicability, a moderate rock block content of 46.16% according to the in-site sieving test results was selected for numerical sample. The oversized rock blocks were handled using equivalent weight replacement method to control the maximum rock block size as 0.06 m, below one sixth of the sample width. The threshold between soil and rock block (dS/RT) was set as 0.05 times the sample width, i.e. 0.02 m. Both the particle size distribution curves of original S-RM in-site and numerical model are shown in Fig. 1.

Fig. 1 Grain size distributions for original S-RM and rock blocks in numerical model

The S-RM numerical model was composed of “soil particles”, “rock blocks” and box boundaries. “Soil particles” were simplified to spheres with radii distributing in the block [0.8 mm, 1.2 mm] randomly, while “rock block” was simulated with an assembly of orderly arranged spheres. Previous research shows that compared with regular round rock block, the angularity of polygonal rock block results in more obvious bite and crushing at the corner, which is more representative of natural S-RM. Therefore, the shapes of rock block in numerical models used in this work are randomly generated polygons. The radii of spheres are directly proportional to size of the corresponding polygon. There are 20450 soil particles in one sample while the total number of particles is 28647.

In order to investigate the influence of rock blocks’ breakability on mechanical behavior of S-RM, two kinds of samples with breakable and unbreakable rock blocks respectively were generated. The object “clump” in YADE was used to simulate unbreakable rock block particles assembly. In the other case, the spheres of breakable rock block were set much stronger bond than that between “soil particles” instead of being bounded as a “clump”, so this kind of rock block will break under certain pressure.

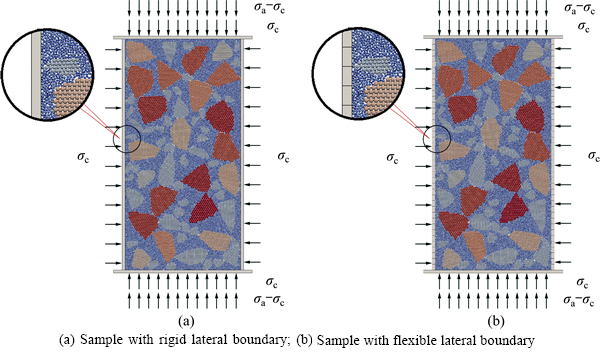

The influence of boundary type was considered as well. Laboratory triaxial test always has lateral membrane boundary, which can deform more flexibly. However, the boundary objects in DEM simulation are rigid usually. In this work, a series of little rigid boxes with 0.02 m height was used to simulate the flexible boundary. There is no interaction between the rigid boxes and their movements are relatively independent, so they could reflect the deformation of flexible lateral boundary. The numerical models of different lateral boundaries are shown in Fig. 2.

2.2 Experimental procedure

Similar to the triaxial test, a predefined confining pressure was applied to the sample in both horizontal and vertical directions for consolidation. To achieve this goal, the lateral boundary boxes kept adjusting their positions in horizontal direction while the top and bottom boxes kept adjusting positions in vertical direction until stress of each box maintained at the predetermined constant value to the end of the test.

When the adjustment of sample deformation finished, namely, after consolidation, axial loading took place under the condition of constant confining pressure, the strain controlled axial loading was simulated through setting an opposite speed of top box and bottom box as 2 mm/s. The stress of each lateral box was monitored. According to the size relationship between this and predefined confining pressure, the direction of lateral box’s motion was adjusted to maintain constant lateral pressure during the axial loading process. The test stopped when the axial strain of sample received 20%. The relationship of deviatoric stress and volume strain along with the change of axial strain was recorded.

3 Meso-mechanical parameters of S-RM

3.1 Meso-mechanical parameters of “soil”

3.1.1 Direct shear tests of “soil”

In order to obtain the meso-mechanical parameters of “soil particles” in DEM simulation, a series of direct shear tests for “soil” with particle size less than 5 mm in the natural S-RM from Tangjiashan barrier dam was conducted. Four vertical pressures from 100 kPa to 400 kPa with an interval equaled 100 kPa were chosen. The soil sample was placed in a standard shear box of 6.18 cm in diameter and 2 cm in height. The moisture content of sample was controlled to be 10.4%. At the same time, the dry density and wet density of sample were 1.73×103 kg/m3 and 1.90×103 kg/m3, respectively. After installation of the shear box, the specified vertical pressure from the vertical condensation framework was applied to the sample through the pressure roof and steel ball. When the vertical deformation of sample became stable after the consolidation completed, shearing of sample with 1.2 mm/min rate took place. The test finished when the shear strain reached 10%.

In addition, a similar two-dimensional direct shear numerical model with 0.2 m length and 0.2 m height was established. Heights of both up and down shear boxes were 0.1 m. The soil particles had the same gradation of that used in the biaxial numerical tests with porosity equaled 0.18. The total number of soil particles was 4640. The shear boxes were set as ideal smooth material while the soil particles were set as cohesive friction material. The test process was consistent with the laboratory direct shear test. At first the rated vertical pressure was applied to the top of sample, and then shearing with 1 mm/s speed began after the consolidation completing until received 10% shear strain.

Fig. 2 Schematic diagram of S-RM numerical model with different lateral boundaries:

3.1.2 Results analysis

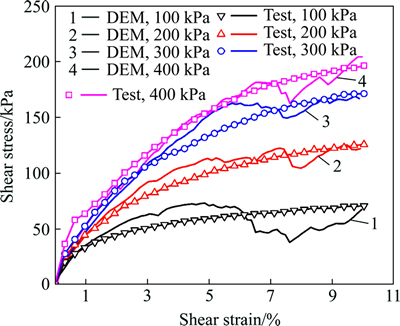

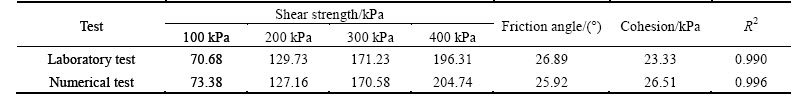

The shear stress-shear strain relationship curves of numerical tests under different vertical stresses agree well with the laboratory tests results when the elastic modulus of soil particle is 7×106 kPa, fraction angle takes 30°, and normal and tangential cohesion are both 100 kPa (Fig. 3). As can be seen from Fig. 3, the elastic portion of numerical simulation curve is nearly coincident with that of laboratory test under each vertical pressure. Moreover, they present the same trend that the shear stress increases with the increase of shear strain, and the shear stress has achieved the maximum value and tended to be stabilized at 10% shear strain. The corresponding stabilized shear strength under difference normal pressures and the macro-mechanical parameters such as friction angle and cohesion of soil sample calculated based on Molar Coulomb’s law in laboratory tests and numerical tests are listed in Table 1. Both results are similar, the internal friction angles are 26.89° and 25.92° while the cohesions are 23.33 kPa and 26.51 kPa, respectively. It can thus be seen that this group of meso-mechanical parameters in numerical tests can simulate the macro-mechanical properties of soil sample.

Fig. 3 Relationship curves of shear stress and shear strain in laboratory and numerical direct shear tests

3.2 Meso-mechanical parameters of rock block particles

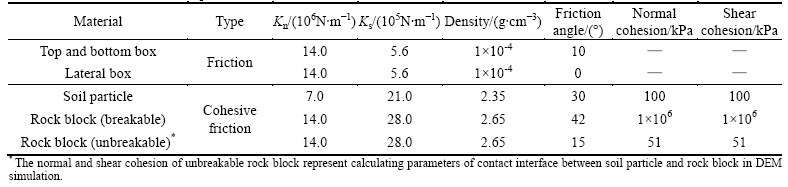

There are certain degree of cementations both inside the rock block and between the rock block and soil, thus rock block in the biaxial compression numerical simulation was also set as cohesive friction material. But the strength is greater and the Poisson ratio is smaller compared with soil particle. In addition, two kinds of rock blocks with different breakability have different parameters. The rock block which can be broken under high stress level is bounded through internal strong cementation, so the friction angle and cohesion are much greater than those of soil particle. When it comes to the rock block set to “clump” and couldn’t be broken, the inter-particle interaction is ignored during the calculation. Therefore, the stress concentrates at the interlocked angular of rock blocks and contact surface between rock block and soil. As the weak portion in S-RM, the contact surface had low mechanical parameters, so the friction angle and cohesion of unbreakable rock block were set smaller than those of soil particle. In order to reflect the end constraint of sample posed by loading apparatus, the top and bottom boundary boxes were set to frictional material while the lateral boxes were smooth. All these materials’ parameters used in the DEM simulation are listed in Table 2.

4 results analysis of S-RM Biaxial tests

4.1 Effect of confining pressure on mechanical behavior of S-RM

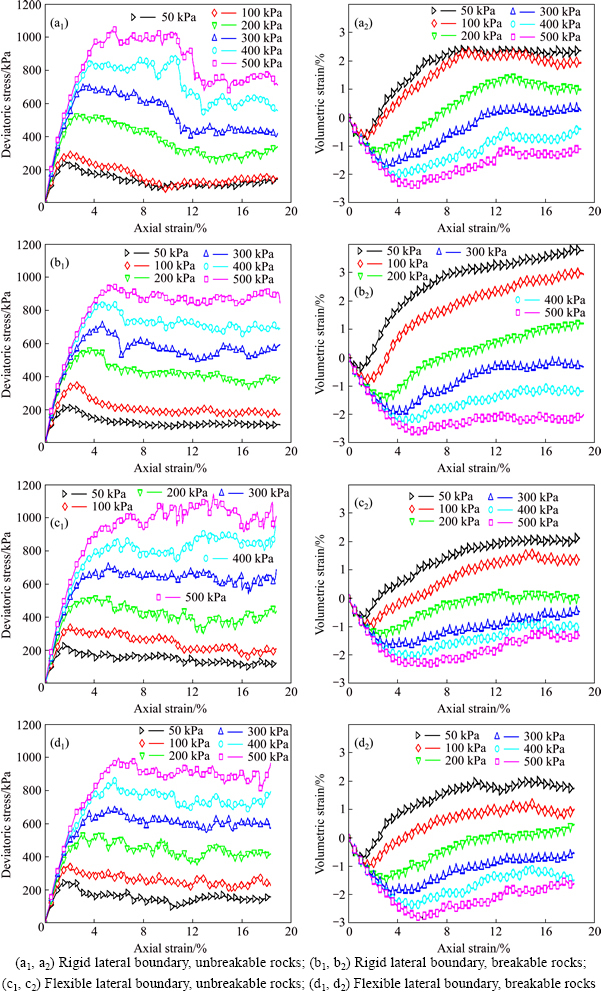

There are four kinds of S-RM samples with two types of lateral boundary (rigid, flexible) and two kinds of rock blocks with different breakability natures (unbreakable, breakable) in this work. The variations of deviatoric stress and volumetric strain with axial strain for four kinds of S-RM samples under 50, 100, 200, 300, 400, 500 kPa confining pressures are drawn in Fig. 4.

Table 1 Comparison of soil sample shear strength parameters in laboratory direct shear tests and DEM Numerical tests

Table 2 Numerical calculation parameters of materials used in DEM model

Fig. 4 Variation of deviatoric stress and volumetric strain with axial strain for four kinds of S-RM samples under 50, 100, 200, 300, 400, 500 kPa confining pressures:

The deviatoric stress variations of four kinds of samples show that both the peak intensity and its corresponding axial strain increase as confining pressure increases, and the initial elastic modulus also increases similar to the compressive hardening of soil. The softening phenomenon of stress-strain relationship curves for S-RM samples with rigid boundary is more obvious under lower confining pressure. For sample with breakable rock blocks, the deviatoric stress has a slow downward trend after the peak strength. But when it comes to the S-RM sample with unbreakable rock blocks, a platform on the stress-strain curve appears which means that the deviatoric stress keeps at peak strength level for some time before dropping down especially under high confining pressure. Due to the joint action of rigid boundary and high confining pressure, movements of internal particles in S-RM sample, especially rock blocks, are under strong constraints. The adjustment of S-RM internal structure mainly through rock blocks’ rotation and dislocation is difficult. The stress will fall down after the platform when rock blocks at the hinge position rotate a big angle. In the other case of flexible boundary or breakable rock blocks, the adjustment of internal structure is more flexible so there is no mutation on the deviatoric stress curve while the occlusion and dislocation of internal particles cause more dramatic fluctuations compared with sample with rigid lateral boundary. They perform stress softening under low confining pressure and show stress hardening under high confining pressure. And the stress hardening for sample of unbreakable rock blocks is more apparent than that for samples containing breakable rock blocks.

The volumetric strain variations of four kinds of samples show that S-RM sample has apparent volume expansion followed a small amount volume contraction at the beginning of biaxial compression process. Furthermore, the initial shear shrank and the axial strain corresponding to the start point of dilatancy decrease while the subsequent dilatancy increases with decreasing of confining pressure. That is to say, the dilatancy of S-RM is more likely to happen under low confining pressure which offers smaller constraints. The volumetric strain curve flattens out gradually corresponding to the stability deviatoric stress level.

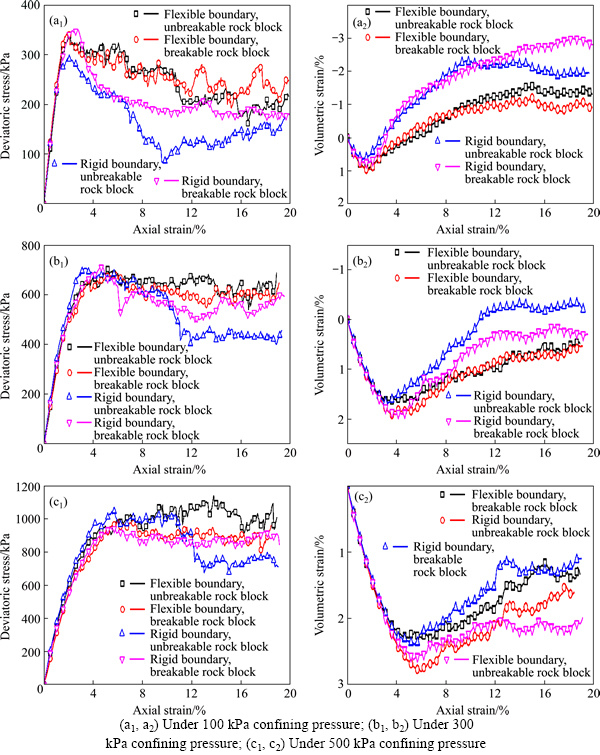

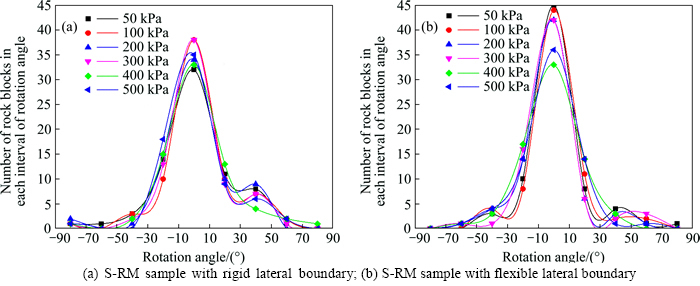

4.2 Effects of rock blocks’ breakability and lateral boundary on mechanical behavior of S-RM

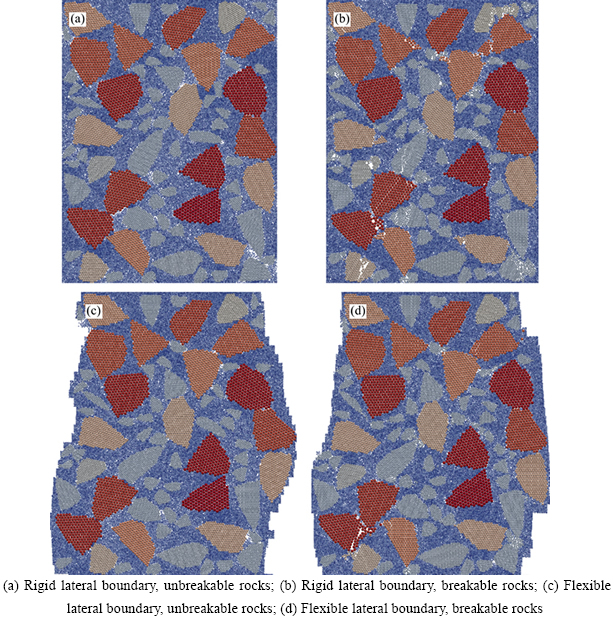

The variations of deviatoric stress and volumetric strain with axial strain for S-RM samples with unbreakable, breakable rock blocks and rigid, flexible lateral boundary under 100, 300 and 500 kPa confining pressure are shown in Fig. 5. Deformations of four kinds of S-RM numerical samples at 18.7% axial strain under 400 kPa confining pressure are shown in Fig. 6.

From an overall perspective, the deviatoric stress for sample of flexible boundary is greater than that of rigid boundary. For S-RM sample of flexible boundary, the deviatoric stress for sample containing unbreakable rock blocks is higher than that of sample containing breakable rock blocks and the difference between them is more obvious along with confining pressure increasing. At early stage of the test, the S-RM sample of rigid boundary and unbreakable rock blocks has the maximum deviatoric stress. But the stress has significantly drop with the increase of axial strain and becomes the lowest residual strength at the end of deformation. The reason for this phenomenon has been expounded in section 4.1. It’s worth noting that the effects of lateral boundary condition and rock blocks’ breakability on the mechanical properties of S-RM sample are not the same under different confining pressure levels. Under low confining pressure (100 kPa), the initial elastic segment of deviatoric stress curve for four kinds of samples are almost overlap, and the difference of residual stress is small. With the increasing of confining pressure, four elastic segments of deviatoric stress curves separated gradually. For specific performance, the rigid boundary sample and unbreakable rock blocks sample have greater initial elastic modulus. This conclusion is consistent with the fact that a larger elastic modulus reflects larger stiffness of material. Under lower confining pressure, the status of S-RM sample after consolidation is more loose and its constraints is smaller compared with the high confining pressure. As a result, the adjustment of internal structure is easier and the deviatoric stress curve rises and falls more severe. So, the deviatoric stress-axial strain curve could not display the influence of boundary types and rock block breakability on the mechanical properties of S-RM sample clearly. On the contrast, these effects are more obvious under high confining pressure.

Through comparison of volumetric strain-axial strain curves for four kinds of S-RM samples under the same confining pressure, it can be found that with the same lateral boundary condition, breakage of rock blocks produces more small particles and a better particle size distribution which makes sample be compacted to a denser situation with porosity filled by rock clastics. A larger body shrinkage thus occurs in the sample containing breakable rock blocks. When the S-RM samples have rock blocks with the same breakability, their body shrinkage are almost the same despite of different lateral boundary types. But the dilatancy of rigid lateral boundary sample is greater than that of flexible lateral boundary sample, and the difference reduces along with the confining pressure increasing. When the S-RM sample is compressed at both ends, its central region will has a ballooning trend, which is also the area with the biggest deformation. With the constraints of flexible lateral boundary, the lateral deformation of S-RM sample could occur relatively free and the internal stress is more uniform. But with the rigid lateral boundary, the central region of sample where has stress concentration will have a denser arrangement of particles compared with both ends. So, the dilatancy quantity for S-RM sample of rigid lateral boundary is bigger when inspecting the whole volumetric strain.

Fig. 5 Variation of deviatoric stress and volumetric strain with axial strain for S-RM samples with rigid, flexible lateral boundary and unbreakable, breakable rock blocks under different confining pressures:

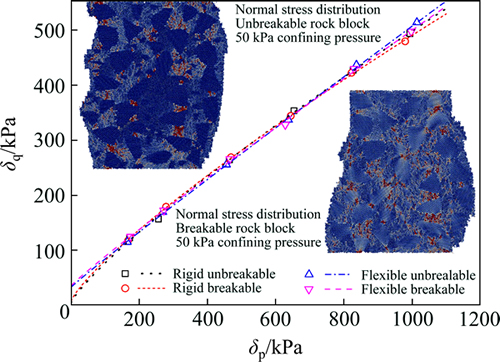

4.3 Effects of rock blocks’ breakability and lateral boundary on macro mechanical parameters of S-RM

S-RM does not fully comfort to the Mohr-Coulomb criterion for its strength envelope is not a straight line but a curve with decreasing slope. Figure 7 shows the relationship between shear stress dq and average stress dp at the first peak of stress-strain curve under different confining pressures, the meanings of dp and dq are as follows:

Fig. 6 Deformation of S-RM numerical models with different lateral boundaries and unbreakable, breakable rock blocks at 18.7% axial strain under 400 kPa:

Fig. 7 Relationship between shear stress dq=(sa-sc)/2 and average stress dp=(sa+sc)/2 for different kinds of S-RM samples

dp=(sa+sc)/2 (1)

dq=(sa-sc)/2 (2)

where sa is axial stress and sc is confining pressure.

For these four kinds of S-RM samples, an expanded form of Mohr-Coulomb criterion as eq. (3) was proposed to fit the discrete data under different confining pressures, and the excellent fitting results are listed in Table 3.

dq=fdpe+c (3)

Table 3 Fitting parameters of expanded Mohr-Coulomb criterion

The intercept c on the y axis is corresponding to the cohesion while the basic slope f is corresponding to the friction angle of S-RM sample. The exponent e which determines the change of curve slope has a relationship with rock blocks’ breakability. And it is less than or equal to 1. When e equals 1, this criterion in power function form degenerates to the linear Mohr-coulomb criterion. With confining pressure increasing, breakage of rock blocks becomes more obvious and the strength slightly decreases, which results in the strength envelop deviating the straight line and bend downward. Therefore, under the same boundary condition, the exponent e of S-RM sample containing breakable rock blocks is less than that of sample with unbreakable rock blocks, meaning that the slope of strength envelop decreases with a higher rate. Furthermore, the contribution of rock blocks’ interlocking and breakage on loading capacity performs as a part of cohesion and friction angle. As a result, the cohesion and friction angle of S-RM sample with breakable rock blocks are higher. Taking sample with flexible lateral boundary as an example, the normal stress distribution of S-RM sample containing different kinds of rock blocks is shown in Fig. 7. for S-RM sample with unbreakable rock blocks, the stress concentrates at the angles where rock blocks interlocked while it distributes more uniformly in S-RM sample with breakable rock blocks. Due to the strong constraint of rigid boundary, the interlock effect of rock blocks is more strongly and the adjustment extent of sample internal structure is larger, which leads to a higher friction angle and lower exponent e compared with flexible boundary sample.

5 Characteristics of meso-mechanical behavior of S-RM

In granular material, the formation of shear band which has discontinuous strain at its boundary is related to strain localization and is often accompanied by rotations of particles and change of void ratio. Masson and Martinez [18] marked the shear band of granular materials formed in the direct shear process with particle displacement and rotary. Rochter et al [19] pointed that the elastic energy rate in the unloaded area between the shear bands tends to a minimum. There have been a lot of research achievements about the spherical particles’ motion both inside and outside the shear zone for homogeneous dense particulate matter such as sandy soil. The discrete element numerical method was widely used to simulate the direct shear tests [20-22] or biaxial tests [23-24] and investigate the translation and rotation of particles, the coordination number and void ratio in shear band, width of shear band, the relationship between strain localization and the corresponding stress soften. Image processing and analysis technologies, such as three-dimensional CT scanning and X-ray imaging are also used to track the movement of particles in shear zone and study the strain distribution and dilatancy phenomenon near the shear zone [25-28]. For the breakage of granular materials, breakage of rock block reduces the anisotropy coefficients of the sample and therefore its strength and dilation behavior were reported [29-31]. Lobo et al [32] reported that the rock block breakage does not develop uniformly throughout the sample, but rather concentrates in certain regions.

But for S-RM, research of rock block rotation and broken, formation of shear zone during the loading process is scarce. Graziani et al [33] carried out DEM simulation of direct shear and biaxial tests for bimrock in site of a gravity dam and studied the relationship between material constitutive parameters of whole and its microscopic characteristics. Estrada et al [34] compared the effect of rolling resistance at the contacts in disks granular systems with that of angularity in granular systems composed of regular polygonal particles using contact dynamics simulation. The results indicated that the resistance of angularity particles’ rotation is a main factor affecting the mechanics behavior of particle system consisting of noncircular particles. Cheng et al [35] simulated two-dimensional direct shear test of crushable agglomerates with PFC and found that friction angle and dilatancy reduce while the thickness of the shear band defined by relative rotation increases with the existence of particle crushing. In the following sections, the unique microstructure evolution characteristic of S-RM was analyzed from two aspects of rock block rotation and shear band formation respectively.

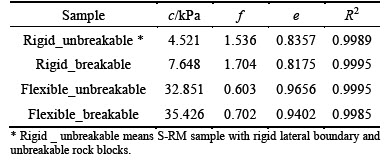

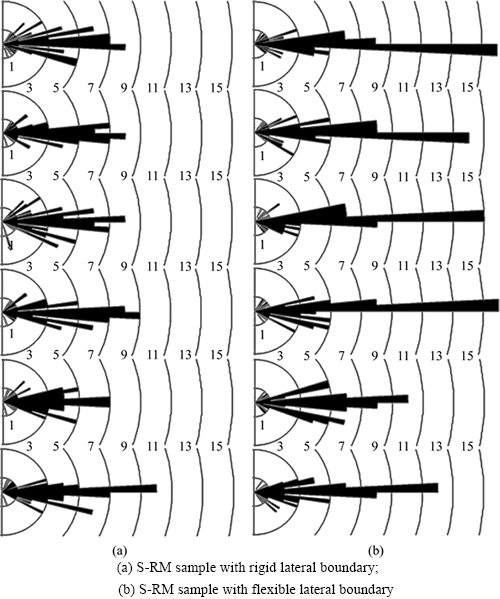

5.1 Rotation of rock block in S-RM

The mesoscopic structure of S-RM keeps adjusting to adapt to the current stress field during the loading process. Such adjustments including the dislocation and rearrangement of internal particles, and corresponding rotations of rock blocks also occur in S-RM under the action of surrounding soil particles. Rock blocks’ rotation controls the evolution of mesoscopic structure due to their large sizes. In addition, the rotation quantities of rock blocks also can be used as an index of the internal shear zone in S-RM.

For unbreakable rock block, the line connecting two points of the longest distance over rock block’s outline is taken as the long axis of this rock block, and the rotation quantity of each rock block is represented by the change of angle between the long axis and horizontal direction. The counterclockwise rotation is defined as positive and clockwise rotation is negative. Because the whole S-RM sample is relatively compact, the rotation angles of internal rock blocks are limited in the interval of [-90°, 90°]. Rotational process of every rock block was obtained by extracting the boundary balls of all rock blocks and recording their positions in the whole loading process.

The rotation angles of rock blocks inside the sample at 18.7% axial strain were shown in the rose chart with 3° interval of angle range. From top to bottom in Fig. 8(a), the rose chart of rock block rotation angles in sample with rigid lateral boundary is under confining pressure from 50 kPa to 500 kPa. Figure 8(b) shows rock blocks’ rotation in sample with flexible lateral boundary. The diagram shows that in the S-RM sample with flexible lateral boundary, vast majority of rock blocks’ rotation angles are small. There are 30% of rock blocks’ rotation angles concentrated within the scope of [-3°, 3°] because the sample can deform more flexible and adjusting of internal structure is easier. In the other side, the same deformation along the height of sample is forced by rigid lateral boundary, so most of the rock blocks need to rotate for larger angle in the internal structure adjusting process. The number of rock blocks distributing in every rotation angle interval is relatively uniform instead of concentrating in a scope of small angle. But the difference caused by different lateral boundaries gets smaller with the increase of confining pressure.

The frequency distribution of unbreakable rock blocks with different rotation angles in S-RM samples of rigid and flexible lateral boundary at 18.7% axial strain under 50, 100, 200, 300, 400, 500 kPa confining pressure is shown in Fig. 9. The rotation angle interval is 20°. The frequency distribution of rock blocks concentrates in the small angle range under all kinds of conditions. Compared with rigid lateral boundary, confining pressure affects the rock blocks’ rotation angle more obvious for flexible lateral boundary sample. With the increase of confining pressure, the lateral inhomogeneous deformation of S-RM sample with flexible boundary is bigger, and more rock blocks rotate a big angle. As a result, the peak of rock blocks’ rotation frequency distribution curve decreases.

5.2 Formation of shear band in S-RM

The displacement vector diagram of particles in S-RM sample helps to express the movement of particles and mesostructure change within the S-RM sample intuitively. In addition, the rotation of rock blocks was also considered to explore the formation mechanism and characteristics of the shear band inside S-RM.

Fig. 8 Rose chart of unbreakable rock blocks’ rotation angle in S-RM samples with different lateral boundary types at 18.7% axial strain under 50, 100, 200, 300, 400, 500 kPa from top to bottom:

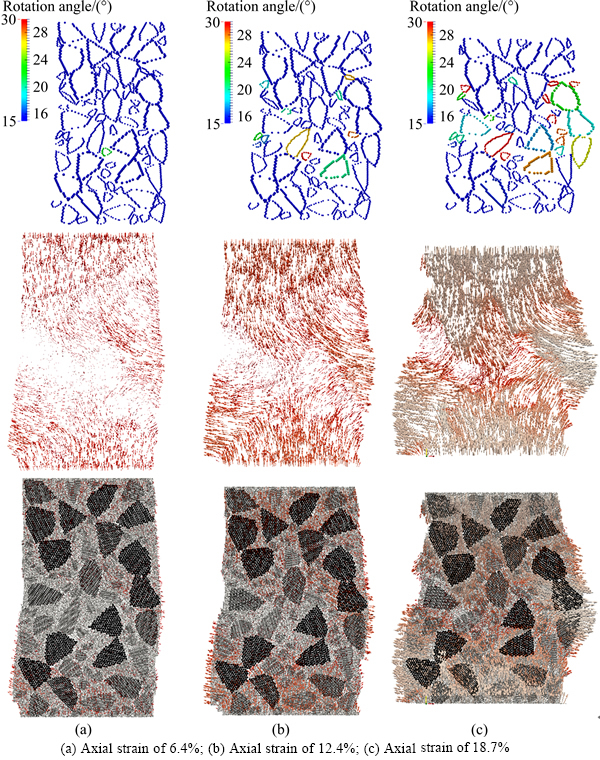

The variation of rock block rotation diagram and internal particle displacement vector diagram for the S-RM sample with unbreakable rock blocks and flexible lateral boundary during the test with 400 kPa confining pressure are shown in Fig. 10.

Fig. 9 Frequency distribution of unbreakable rock blocks in different rotation angle intervals in S-RM samples with different lateral boundaries at 18.7% axial strain under 50, 100, 200, 300, 400, 500 kPa confining pressures:

Fig. 10 Variation of unbreakable rock blocks’ rotation and displacement vector of internal particles in S-RM sample with flexible lateral boundary during test process under 400 kPa confining pressure:

The corresponding axial strain values are 6.4%, 12.4%, 18.7%, respectively. The formation of shear bands in S-RM sample can be seen clearly, where the displacement vector having high gradient is boundary of shear zone. The directions of displacement vectors within shear band are scattered and swirl appears, corresponding to the phenomenon that rock blocks in this area rotates large angles.

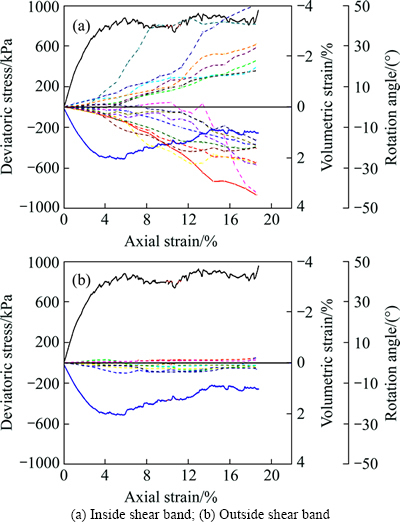

Some representative rock blocks have been chosen from the internal shear band and external shear band respectively. The variation curves of their rotation angles during the axial compression process were drawn as shown in Fig. 11.

Fig. 11 Comparison of rotation angles’ changes for unbreakable rock blocks inside and outside shear band in S-RM sample with flexible lateral boundary during test under 400 kPa confining pressure:

It can be seen that the rock blocks outside shear band have comparatively small amount of rotation angles which are mainly concentrated in the range of [-5°, 5°] during the whole test. On the contrary, the rock blocks inside shear band have the same change trend that the amount of rotation increases significantly with the increase of axial strain. Most rock blocks rotate more than 10° at the end of test. Furthermore, corresponding to the variation curve of deviatoric stress, the whole change process of rock blocks rotation can be divided into four parts, the elastic section, the elastic-plastic section before peak stress, the after-peak stable section and the second peak section. In the elastic section, the amount of rock blocks’ rotation is very small and the growth is rather slow. Rock blocks’ rotation started to get larger but the growth is still low in the elastic-plastic section before peak stress. After the deviatoric stress reaches the first peak, the growth of rock blocks’ rotation becomes bigger. Rotation angles increase significantly with varying degree in this stress stable stage, most of the rotation angles are in the range of [10°, 20°]. When the deviatoric stress rises again after the first peak, the rotation amount of most rock blocks inside shear band increases linearly with a greater speed. A few of rock blocks even rotate more than 30°. During the elastic deformation stage, the S-RM sample is compressed and becomes dense while the arrangement of internal particles has almost no change. But the elastic-plastic deformation is accompanied by the adjustment of structure inside the shear band, including rearrangement of particles and rotation of rock blocks.

Moreover, the formation of shear bands is controlled by the arrangement of rock blocks in S-RM. When a few of rocks aggregate, a strong integrity forms due to mutual restriction, so the main motion of this part will be united translation and shear band will not appear in this place. For example, in the lower left and upper left of the S-RM sample, there are a few of rock blocks constituting triangular rock clusters. Such local structure has strong stability with small rotation, so it was not be penetrated by the shear band. In contrast, rock blocks suspended in the soil matrix are easier to rotate. These sites are relatively weak areas in S-RM and are more likely to develop to shear band.

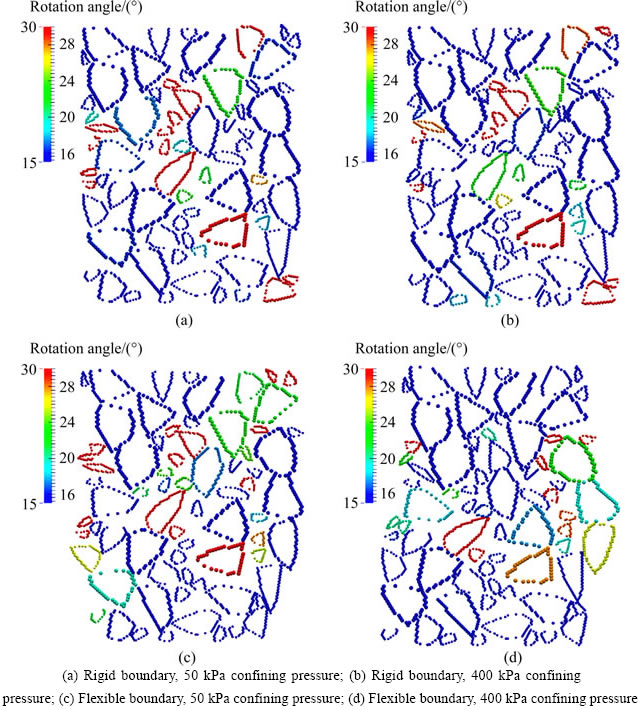

Figure 12 shows the unbreakable rock blocks’ rotation in S-RM samples with rigid and flexible lateral boundaries at 18.7% axial strain under 50 kPa and 400 kPa, respectively. As mentioned above, the rock blocks located in the shear zone of S-RM sample rotate big angles in the loading process, so the amount of rock block rotation can be used to characterize the shear band. For S-RM sample with rigid boundary, the position of shear band is consistent under low and high confining pressure and both shear bands are sickle shaped. The shear bands expend to the internal region from the top right and bottom right of the sample respectively and intersect at the left central area inside the sample. But for the flexible boundary sample, the shear band under high confining pressure has a distinctly difference from the one under low confining pressure. The location and shape of shear band inside S-RM sample under low confining pressure are similar to those of the rigid boundary sample but a little wider. under high confining pressure, the main shear band expends to the bottom right from the left middle portion of sample, forming a short shear band through the sample.

Fig. 12 Schematic diagram of unbreakable rock blocks’ rotation in S-RM samples with different lateral boundaries at 18.7% axial strain under different confining pressures:

For sample of rigid lateral boundary, the constraints enhance and rotation angles of some rock blocks become smaller with the increase of confining pressure. But in the case of large rock block content, these rock blocks constitute the skeleton of the S-RM sample. The confining pressure will not change the relative position of internal rock blocks. Therefore, location of the shear band is almost not affected by the confining pressure. On the other side, the S-RM sample of flexible lateral boundary has a relative uniform deformation along the sample height under low confining pressure, so the location of shear band is similar to that of rigid lateral boundary sample. Nevertheless, the movement of soil particles and rotation of rock blocks are much easier for less constraint of flexible lateral boundary, which leads to a wider shear band. It can be seen from fig. 12(d) that under the joint action of high confining pressure and end constraints, both the deformation and rock blocks’ rotation angles are small in ends of sample while an obvious ballooning phenomenon occurs in the center portion. In addition, the rock blocks near the right lateral flexible boundary of sample rotate large angles. The strain localization inside the S-RM sample performs as inhomogeneous macroscopic deformation and the shear band appears in the corresponding position.

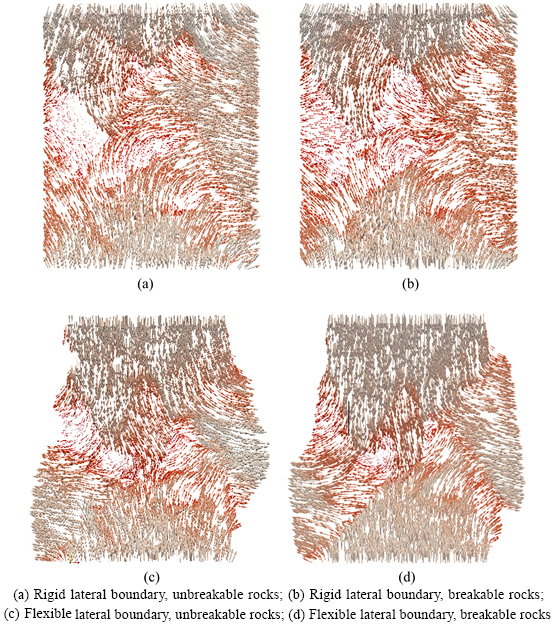

Figure 13 shows the displacement vector of internal particles in four kinds of S-RM samples at 18.7% axial strain under 400 kPa confining pressure. It can be seen that the lateral boundary types have a great impact on the formation of S-RM shear band. The pattern of shear band in the sample of unbreakable rock blocks is described in the preceding part. The rock blocks’ breakage concentrates in a place where the stress concentrates, such as the edges and corners of rock blocks. As a result, the strain in sample with breakable rock blocks is more uneven. The displacement vector gradient increases at the broken corner of the rock block, forming a number of local strain areas of small scope. The effect is more evident under flexible lateral boundary condition. Due to more flexible deformation of flexible lateral boundary sample, besides the main shear band extending throughout the sample from upper left to lower right, a secondary shear band penetrates throughout the sample from upper right to lower left, which constitutes “X” shape with the main shear band.

Fig. 13 Schematic diagram of displacement vector of internal particles in four kinds of S-RM samples at 18.7% axial strain under 400 kPa confining pressure:

6 Conclusions

1) S-RM has a nature of compressive hardening like soil that initial elastic modulus increases with the increase of confining pressure. The stress softening of S-RM under low confining pressure also transforms to stress hardening gradually with confining pressure increasing. Shear dilatancy occurs during the axial loading process, and the amount of dilatancy increases with the decrease of confining pressure.

2) As a whole, the stable deviatoric stress after peak stress of flexible boundary S-RM sample is higher than that of rigid boundary sample, and the stress of S-RM with unbreakable rock blocks is higher than that of samples with breakable rock blocks under flexible boundary condition. Both rigid lateral boundary and unbreakable rock blocks can enhance the stiffness and elastic modulus of S-RM. For deformation of S-RM samples, the shear contract of sample volume is mainly affected by the sample inherent nature, but the dilatancy could be affected by lateral boundary condition. The influence degrees of lateral boundary type and rock blocks’ breakability on the mechanical properties of S-RM are sensitive to confining pressure. As a result, an expanded Mohr-Coulomb criterion in power function form can fit the strength envelop very well. Its exponent index can reflect the rock blocks’ breakability. The S-RM sample with breakable rock blocks has higher cohesion and friction angle and lower exponent index.

3) The rock blocks constitute the skeleton for S-RM containing a high percentage of rock blocks. During loading process, the internal meso-structure of S-RM includes arrangement of rock blocks and location of particles adjusting slowly toward a more stable situation, which is suitable for bearing the load. These adjustments, such as translation, rotation and breakage of rock blocks, directly affect the internal stress and strain field, and reflect the macroscopic mechanical properties of the S-RM sample ultimately.

4) The lateral boundary condition of S-RM sample also is one of the important influence factors of meso- structure. Compared with flexible lateral boundary under the same condition, rigid boundary provides strong constraints on lateral deformation of S-RM sample, which forces the deformation uniform with large adjustment of the internal structure, such as containing more rock blocks of large amount rotation. In addition, breakage of rock blocks produces more medium and small-sized blocks, making the grain gradation of S-RM sample better and increasing the number of small shear zones inside the sample. Its influence is more obvious in the S-RM sample of flexible lateral boundary which deforms more flexible.

5) The shear band in S-RM can be characterized by displacement vector of particles and rotation of rock blocks. Formation and location of the shear band are mainly controlled by the arrangement of rock blocks in S-RM. In addition to the lateral boundary condition, confining pressure and breakability of rock block have different degrees of influence on the pattern and location of shear band.

References

[1] MEDLEY E W. The engineering characterization of melanges and similar block-in-matrix rocks (bimrocks) [D]. California: University of California, Berkeley, 1994.

[2] XU Wen-jie, HU Rui-lin. Conception, classification and significations of soil-rock mixture [J]. Hydrogeology & Engineering Geology, 2009, 36(4): 50-56. (in Chinese)

[3] XU Wen-jie, XU Qiang. Study of quantitative description methods of geomaterial meso-structure taking soil rock mixture for example [J]. Chinese Journal of Rock Mechanics and Engineering, 2012, 31(3): 499-506. (in Chinese)

[4] SONMEZ H, GOKCEOGLU C, MEDLEY E W, TUNCAY E, NEFESLIOGLU H A. Estimating the uniaxial compressive strength of a volcanic bimrock [J]. International Journal of Rock Mechanics and Mining Sciences, 2006, 43: 554-561.

[5] HAMIDI A, ALIZADEH M, SOLEIMANI S M. Effect of particle crushing on shear strength and dilation characteristics of sand-gravel mixtures [J]. International Journal of Civil Engineering, 2009, 7(1): 61-71.

[6] XU Wen-jie, XU Qiang, HU Rui-lin. Study on the shear strength of soil-rock mixture by large scale direct shear test [J]. International Journal of Rock Mechanics and Mining Sciences, 2011, 48(8): 1235-1247.

[7] COLI

[8] PENA A A, GARCIA-ROJO R, HERRMANN H J. Influence of particle shape on sheared dense granular media [J]. Granular Matter, 2007, 9(3/4): 279-291.

[9] CHENG Guo-wen, HE Jian-min, LI Xiao, DI Bang-rang, LI Shou-ding. Particle flow simulation for soil-rock mixtures under biaxial pressure [J]. Mining and Metallurgical Engineering, 2010, 30(4): 1-4. (in Chinese)

[10] OUYANG Zhen-hua, LI Shi-hai, DAI Zhi-sheng. On the influence factors of mechanical properties for soil-rock mixture [J]. Journal of Experimental Mechanics, 2010, 25(1): 61-67. (in Chinese)

[11] MAHMOOD Z, IWASHITA K. A simulation study of microstructure evolution inside the shear band in biaxial compression test [J]. International Journal for Numerical and Analytical Methods in Geomechanics, 2011, 35(6): 652-667.

[12] PIETRUSZCZAK S, GUO P. Description of deformation process in inherently anisotropic granular materials [J]. International Journal for Numerical and Analytical Methods in Geomechanics, 2013, 37(5): 478-490.

[13] AFIFIPOUR M, MOAREFVAND P. Experimental study of post-peak behavior of bimrocks with high rock block proportions [J]. Journal of Central South University, 2014, 21(2): 761-767.

[14] COLI

[15] SHI Chong, WANG Sheng-nian, LIU Lin, CHEN Hong-jie. Structure modeling and mechanical parameters research of outwash deposits based on digital image analysis [J]. Rock and Soil Mechanics, 2012, 33(11): 3393-3399. (in Chinese)

[16] WANG Sheng-nian, XU Wei-ya, SHI Chong, ZHANG Qiang. Numerical simulation of direct shear tests on mechanical properties of talus deposits based on self-adaptive PCNN digital image processing [J]. Journal of Central South University, 2014, 21(7): 2904-2914.

[17] KOZICKI J, DONZ F V. Yade-open dem: an open-source software using a discrete element method to simulate granular material [J]. Engineering Computations, 2009, 26(7): 786-805.

F V. Yade-open dem: an open-source software using a discrete element method to simulate granular material [J]. Engineering Computations, 2009, 26(7): 786-805.

[18] MASSON S, MARTINEZ J. Micromechanical analysis of the shear behavior of a granular material [J]. Journal of Engineering Mechanics-Asce, 2001, 127(10): 1007-1016.

[19] ROCHTER L, KONIG D, SCHANZ T, NIEMUNIS A, TRIANTAFYLLIDIS T. Shear band systems in plane strain extension: analytical solution and comparison with experimental results [J]. Granular Matter, 2011, 13(5): 553-563.

[20] WANG J, DOVE J E, GUTIERREZ M S. Discrete-continuum analysis of shear banding in the direct shear test [J]. Géotechnique, 2007, 57(6): 513-526.

[21] ZHOU Q, HELENBROOK B T, SHEN H H. A computational study of the micromechanics under pre- and post- failure in a 2-D direct shear test [C]// Nakagawa M, Luding S. Powders and Grains. Melville: Amer Inst Physics, 2009: 405-408.

[22] ZHOU Q, SHEN H H, HELENBROOK B T, ZHANG H W. Scale dependence of direct shear tests [J]. Chinese Science Bulletin, 2009, 54(23): 4337-4348.

[23] BI Zhong-wei, SUN Qi-cheng, LIU Jian-guo, JIN Feng, ZHANG Chu-han. Development of shear band in a granular material in biaxial tests [J]. Acta Physica Sinica, 2011, 60(3): 451-454. (in Chinese)

[24] JIANG M J, YAN H B, ZHU H H, UTILI S. Modeling shear behavior and strain localization in cemented sands by two-dimensional distinct element method analyses [J]. Computers and Geotechnics, 2011, 38(1): 14-29.

[25] ALSHIBLI K A, ALRAMAHI B A. Microscopic evaluation of strain distribution in granular materials during shear [J]. Journal of Geotechnical and Geoenvironmental Engineering, 2006, 132(1): 80-91.

[26] YAMAMOTO H. Application of digital image analysis to displacement measurements of sand particles in shear zone [C]// Burns S E, Mayne P W, Santamarina J C. Deformation Characteristics of Geomaterials. Amsterdam: IOS Press, 2008: 377-382.

[27] CHUPIN O, RECHENMACHER A L, ABEDI S. Finite strain analysis of nonuniform deformation inside shear bands in sands [J]. International Journal for Numerical and Analytical Methods in Geomechanics, 2012, 36(14): 1651-1666.

[28] HASAN A, ALSHIBLI K. Three dimensional fabric evolution of sheared sand [J]. Granular Matter, 2012, 14(4): 469-482.

[29] BAGHERZADEH-KHALKHALI A, MIRGHASEMI A A, MOHAMMADI S. Micromechanics of breakage in sharp-edge particles using combined DEM and FEM [J]. Particuology, 2008, 6(5): 347-361.

[30] BAGHERZADEH-KHALKHALI A, MIRGHASEMI A A, MOHAMMADI S. Numerical simulation of particle breakage of angular particles using combined DEM and FEM [J]. Powder Technology, 2011, 205(1): 15-29.

[31] SEYEDI H E, MIRGHASEMI A. Numerical simulation of breakage of two-dimensional polygon-shaped particles using discrete element method [J]. Powder Technology, 2006, 166(2): 100-112.

[32] LOBO G S, VALLEJO L E, VESGA L F. Visualization of crushing evolution in granular materials under compression using DEM [J]. International Journal of geomechanics, 2006, 6(3): 195-200.

[33] GRAZIANI A, ROSSINI C, ROTONDA T. Characterization and DEM modeling of shear zones at a large dam foundation [J]. International Journal of Geomechanics, 2012, 12(6): 648-664.

[34] ESTRADA N, AZEMA E, RADJAI F, TABOADA A. Identification of rolling resistance as a shape parameter in sheared granular media [J]. Physical Review E, 2011, 84(1): 1-4.

[35] CHENG Y P, PENG Q, HUGHES L. Shear band and strength of crushable agglomerates in direct shear box simulations of discrete element method [C]// Burns S E, Mayne P W, Santamarina J C. Deformation Characteristics of Geomaterials. Amsterdam: IOS Press, 2008: 357-364.

(Edited by YANG Hua)

Foundation item: Projects(51323014, 51479095) supported by the National Natural Science Foundation of China; Project(20111081125) supported by Independent research plan of Tsinghua university, China; Project(2013-KY-4) supported by the State Key Laboratory of Hydroscience and Engineering Project, China

Received date: 2014-12-29; Accepted date: 2015-04-20

Corresponding author: XU Wen-jie, PhD, Associate Professor; Tel: +86-10-62789319; Cell: +86-13522279843; Fax: +86-10-62782301; E-mail: wenjiexu@tsinghua.edu.cn

Abstract: Soil-rock mixture(S-RM)is a widely distributed geotechnical medium composed of “soil” and “rock block” different both in size and strength. Internal rock blocks form special and variable meso-structural characteristics of S-RM. The objective of this work was to study the control mechanism of meso-structural characteristics on mechanical properties of S-RM. For S-RM containing randomly generated polygonal rock blocks, a series of biaxial tests based on DEM were conducted. On the basis of research on the effects of rock blocks’ breakability and sample lateral boundary type (rigid, flexible) on macroscopic mechanical behavior of S-RM, an expanded Mohr-Coulomb criterion in power function form was proposed to represent the strength envelop. At the mesoscopic level, the variations of meso-structure such as rotation of rock block, and the formation mechanism and evolution process of the shear band during tests were investigated. The results show that for S-RM with a high content of rock block, translation, rotating and breakage of rock blocks have crucial effects on mechanical behavior of S-RM. The formation and location of the shear band inside S-RM sample are also controlled by breakability and arrangement of rock blocks.