文章编号:1004-0609(2008)02-0237-06

AZ91镁合金的热压缩行为(Ⅰ)——EBSP分析

刘六法1,丁汉林1,鎌土重晴2,丁文江1,小島陽2

(1. 上海交通大学 轻合金精密成型国家工程研究中心,上海 200030;

2. 長岡技術科学大学 機械系,新潟 940-2188,日本)

摘 要:

采用背散射电子衍射技术(EBSP)分析AZ91镁合金在热压缩变形过程中的流变行为及组织演变特征。研究表明,该合金在热压缩实验中通过动态再结晶过程细化基体晶粒。随应变速率降低,稳态组织的平均晶粒尺寸增大,大尺寸晶粒比例和大边数晶粒比例增加。流变曲线的峰值应力随Zener-Hollomon参数的增大而增大。

关键词:

中图分类号:TG 146.2 文献标识码:A

Hot compression behavior of AZ91 alloy(Ⅰ)——EBSP analysis

LIU Liu-fa1, DING Han-lin1, KAMADO S2, DING Wen-jiang1, KOJIMA Y 2

(1. National Engineering Research Center of Light Alloy Net Forming,

Shanghai Jiao Tong University, Shanghai 200030, China;

2. Department of Mechanical Engineering, Nagaoka University of Technology, Niigata 940-2188, Japan)

Abstract: The deformation behavior and microstructure evolution characteristics of the AZ91 magnesium alloy during hot compression process is studied by the electron back-scattered diffraction pattern (EBSP) approach. The results suggest that dynamic recrystalliztion (DRX) occurs during the compression process. The DRX in turn refines the grains. When the strain rate is decreased, the average grain size, the fractions of large-size grains and the fraction of large-side grains in the final microstructures are increased. The peak stress of the flow stress curve increases along with the increase of the Zener-Hollomon parameter.

Key words: AZ91 alloy; dynamic recrystallization; flow behavior; microstructure evolution

由于镁是密排六方结构,滑移系少,因此以镁为基的合金一般室温变形能力比较差,使其塑性加工性能和市场应用与传统的铝合金相比受到很大限制。与铝合金相比,镁合金因为层错能低,塑性变形过程中更容易发生动态再结晶(以下简称DRX)[1-5],因而有利于细化晶粒,提高强度和延伸率。近年来,除挤压、轧制、冲压等传统变形方法外,等径角挤压[6-9]、大比率挤压[10]等大变形方法也在镁合金中塑性变形研究和应用中得到重视和开展。

与交通工具轻量化以降低能耗和环境污染等需求相比,目前常用的AZ31和AZ61等变形镁合金由于强度低等原因难以实现与铝合金同等的应用程度。而ZK60合金由于成本高,其常规工业应用受到很大限制。

本研究在平衡性能和价格的基础上,选取AZ91合金作为研究对象,利用实验和计算两种手段,通过比较验证的方法,研究其塑性变形特性。同时,本研究尝试将元胞自动机数值模拟方法应用于研究镁合金塑性变形行为,特别是动态再结晶行为。

本文作者分析了AZ91合金变形过程中的流变行为,并通过背散射电子衍射(以下简称EBSP)技术分析了合金热压缩过程中的组织演变。

1 实验

实验所用AZ91镁合金的化学成分(质量分数,%)为:9.3Al,0.8Zn,0.13Mn,0.003Cu,余量为Mg。压缩试样的加工制作方法为:采用电阻炉中熔炼,CO2+SF6气体保护,金属型重力浇铸,浇注温度680 ℃,铸锭冷却后经430 ℃,12 h+水淬的方式固溶处理,最后精车至尺寸为d10 mm×15 mm的圆柱体试样。

高温压缩实验在Gleeble 1500热模拟机上进行,压缩过程中动态记录变形量与流动应力的即时值。试样以5 ℃/s的速度加热至变形温度后保温180 s。每次热压缩过程中均保持实验温度及变形速率恒定。本研究所用的实验温度分别为250,300,350和400 ℃,变形速率为0.05,0.1,0.5和1.0 s-1。压缩应变量为0.1,0.2,0.4和0.7。试样压缩至设定应变量后利用液氮激冷至室温。

组织分析用的试样取自压缩试样的中部,观察面垂直于压缩方向。试样由醋酸乙二醇溶液(醋酸20 mL,硝酸1 mL,乙二醇60 mL,蒸馏水19 mL)腐蚀后金相显微镜观察,使用JEOL JSM-5600型扫描电镜的EBSP系统进行微观组织分析。OIM(Orientation Imaging Microscopy,取向成像)分析的扫描范围为300 μm×300 μm,扫描步长为1 μm,加速电压25 kV。

2 结果与讨论

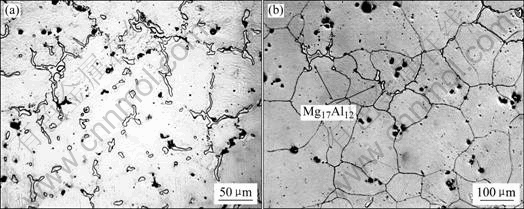

图1(a)和(b)所示分别为实验室制备的铸锭在铸态和固溶处理后的显微组织。由图1可以看出,铸态组织由α-Mg基体和沿晶界连续分布的Mg17Al12相组 成[11],固溶处理后,基体晶粒的平均尺寸约120 μm,Mg17Al12相则基本溶入基体,只有少量的Mg17Al12相不连续地分布于晶界处。

图1 AZ91镁合金的显微组织

Fig.1 Microstructures of AZ91 magnesium alloy: (a) As-cast; (b) 430 ℃, 12 h+water quenching

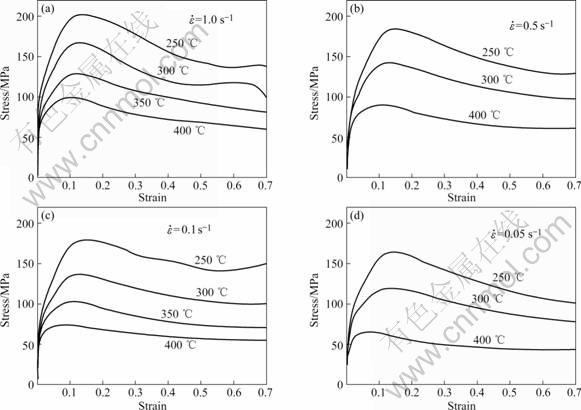

图2示出了不同变形条件下AZ91镁合金热压缩过程中的流动应力—应变曲线。如图1中曲线所示,流变应力随变形程度的增加而不断增大,至某一峰值后平缓下降,最后降至某一稳态值,表现出明显的动态再结晶特征[12]。

图2 热压缩AZ91镁合金的流动应力—应变曲线

Fig.2 Flow stress—strain curves of AZ91 alloy under different deformation conditions

从图中还可以看出,在Z参数(Zener-Hollomon参数![]() )值较大(温度较低或应变速率较高)时,流变曲线所达到的峰值应力越大。在相同的应变速率下,峰值应变(达到峰值应力时的应变值)随着温度的升高而明显减小。

)值较大(温度较低或应变速率较高)时,流变曲线所达到的峰值应力越大。在相同的应变速率下,峰值应变(达到峰值应力时的应变值)随着温度的升高而明显减小。

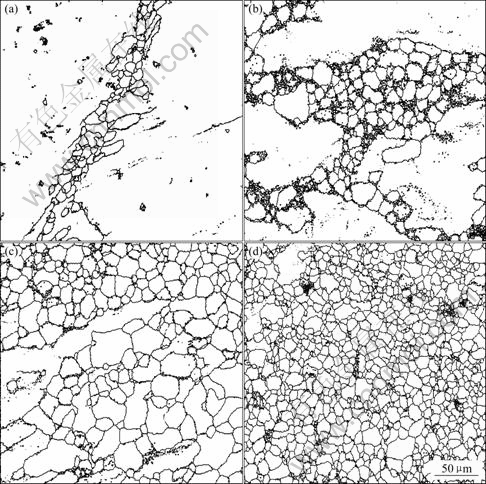

图3给出了试样在400 ℃下经1.0 s-1应变速率压缩至0.1、0.2、0.4和0.7不同应变量时的EBSP分析组织。从图3中可以看出,变形过程中发生了明显的动态再结晶过程,且随着应变量的不断增加,再结晶分数增加。在变形的初始阶段,由于原始晶界对位错运动的阻碍作用,使得晶界附近的位错密度不断升高,当位错密度达到某一临界值时,再结晶晶粒优先在晶界处形核(图3(a))。随着变形的不断进行,再结晶晶粒在晶界处形成项链状组织,并逐步向原始晶粒内部扩展形核并长大(图3(b))。随着应变量的进一步增大,仅有少量的原始晶粒存在于基体中(图3(c))。当基体内应变量为0.7时,再结晶完全,基体达到稳定状态,原始组织完全被等轴晶取代,晶粒平均尺寸约9.0 μm(图3(d))。与试样的原始晶粒尺寸相比,晶粒经动态再结晶得到了显著细化[13-16]。

图3 AZ91合金在400 ℃,1.0 s-1条件下压缩过程中的组织转变

Fig.3 Microstructure evolutions of AZ91 alloy when compressed at 400 ℃ and 1.0 s1 corresponding strains(The microstructures are obtained from EBSP analyses): (a) 0.1; (b) 0.2; (c) 0.4; (d) 0.7

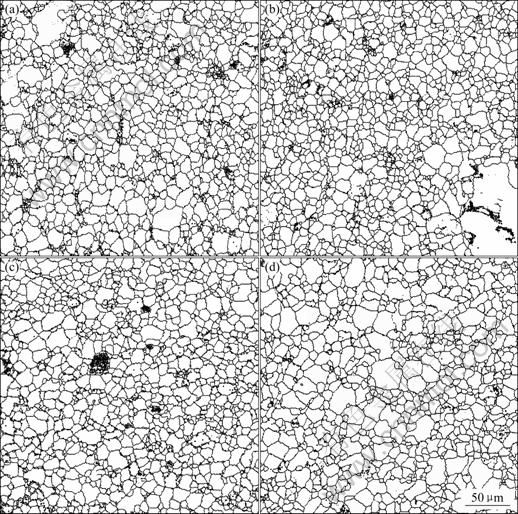

试样在400 ℃下经不同应变速率压缩至稳态(ε=0.7)时的显微组织如图4所示。可以看出,不同应变速率下的稳态显微组织均为等轴晶;应变速率较低时,基体中存在一些尺寸相对较大的晶粒。由EBSP数据结果可知,当应变速率由1.0 s-1降至0.05 s-1时,平均晶粒尺寸由9.0 μm增长至10.4 μm,即稳态组织的平均晶粒尺寸随着应变速率的降低而增加。

由于AZ91合金中Al的含量较高,变形过程中易于析出Mg17Al12相[17]。这些细小的析出相粒子有可能作为形核质点而促进动态再结晶形核,故变形组织中存在少许十分细小的晶粒。但是由于这部分晶粒所占的体积分数很小,其对组织转变及晶粒分布的影响在本文中予以忽略。

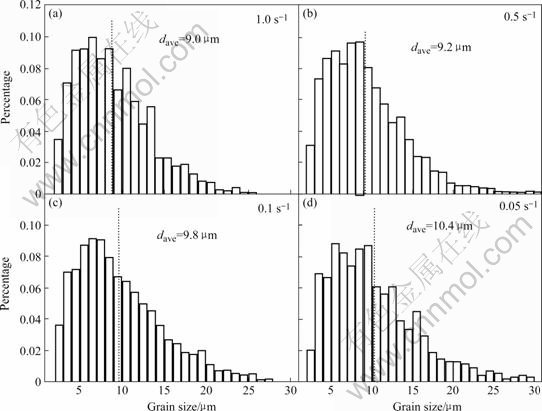

图4中不同应变速率下获得的稳态组织中晶粒的尺寸分布如图5所示,图中虚线所示为平均晶粒尺寸。可以看出,不同应变速率下晶粒尺寸的分布基本相同(类似于正态分布),即与平均晶粒尺寸接近的晶粒的分数最多,而尺寸很小或很大的晶粒分数很少。实验结果中,尺寸小于平均晶粒尺寸的晶粒所占分数相对较多(约占60%),且组织中大尺寸的晶粒随着应变速率的降低而增多,尤其是在应变速率0.05 s-1下的压缩组织出现了尺寸约为30 μm的大晶粒,这与图4中的组织观察结果相一致。

图4 试样在400 ℃下压缩至0.7应变量时的显微组织

Fig.4 Compressed microstructures of samples compressed to strain of 0.7 at 400 ℃ and different strain rates (The microstructures are obtained from EBSP data): (a) 1.0 s-1; (b) 0.5 s-1; (c) 0.1 s-1; (d) 0.05 s-1

图5 不同应变速率下稳态组织中晶粒尺寸的分布

Fig.5 Distributions of grain size in deformed microstructures at strain of 0.7(The average grain sizes are illustrated by the vertical dot lines in the plots)

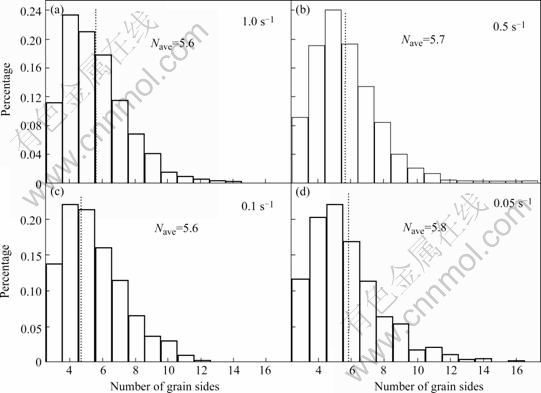

稳态组织中晶粒分布的均匀性,除了可以从晶粒尺寸的分布进行判断外,也可以从晶粒的形状出发通过晶粒边数分布进行判断。图6示出了400 ℃下不同应变速率下压缩稳态组织中晶粒边数的分布情况。可见,组织中晶粒边数的分布基本不随应变速率的变化而发生明显变化,各试样均以四边、五边和六边形晶粒居多,平均晶粒边数(虚线所示)接近理想值6。此外,边数较少的晶粒明显多于边数较多的晶粒,且多边数晶粒的分数随着应变速率的降低而增加,这与大尺寸晶粒增多(图4和图5)是相对应的。

图6 不同应变速率下稳态组织中的晶粒边数分布

Fig.6 Grain sides distributions developed in compressed microstructures based on EBSP data(Nave represents the average number of grain sides, average number of grain sides is illustrated by the vertical dot lines in the plots)

3 结论

1) AZ91镁合金热压缩过程中,应力值随着应变量的增加而迅速增加至某一峰值后平缓下降至某一稳态值,峰值应力随着Z参数的增加而增大。

2) 压缩过程中,AZ91镁合金发生明显的动态再结晶现象,晶粒得到显著细化,再结晶晶粒优先在原始晶界处形核,并逐步向原始晶粒内部扩展形核并长大。

3) 随着应变速率的降低,稳态组织的平均晶粒尺寸增加,试样中大尺寸及大边数晶粒分数增加。

REFERENCES

[1] MOHRI T, MABUCHI M, NAKAMURA M, et al. Microstructural evolution and superplasticity of rolled Mg-9Al-1Zn[J]. Mater Sci Eng A, 2000, 290: 139-144.

[2] ION S E, HUMPHREYS F J, WHITE S H. Dynamic recrystallization and the development of microstructure during the high temperature deformation of magnesium[J]. Acta Metall, 1982, 30: 1909-1919.

[3] KAIBYSHEV R, GALIYEV A. On the possibility of superplasticity enhanced by recrystallization[J]. Materials Science Forum, 1997, 243/245: 131-136.

[4] 刘楚明, 刘子娟, 朱秀荣, 周海涛. 镁及镁合金动态再结晶研究进展[J]. 中国有色金属学报, 2006, 16(1): 1-12.

LIU Chu-ming, LIU Zi-juan, ZHU Xiu-rong, ZHOU Hai-tao. Research and development progress of dynamic recrystallization in pure magnesium and its alloys[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(1): 1-12.

[5] 汪凌云, 黄光胜, 范永革, 黄光杰. 变形AZ31镁合金的晶粒细化[J]. 中国有色金属学报, 2003, 13(3): 594-598.

WANG Ling-yun, HUANG Guang-sheng, FAN Yong-ge, HUANG Guang-jie. Grain refinement of wrought AZ31 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(3): 594-598.

[6] MABUCHI M, IWASAKI H, YANASE K, et al. Low temperature superplasticity in an AZ91 magnesium alloy processed by ECAE[J].Scripta Mater, 1997, 36: 681-686.

[7] 罗 蓬, 夏巨谌, 胡侨丹, 王新云. 基于等径角挤压(ECAP)的超细晶铸造镁合金制备研究[J]. 稀有金属材料与工程, 2005, 34(9): 1493-1496.

LUO Peng, XIA Ju-chen, HU Qiao-dan, WANG Xin-yun. Preparation of ultra-fine grained cast magnesium alloy by equal channel angular pressing[J]. Rare Metal Materials and Engineering, 2005, 34(9): 1493-1496.

[8] YOSHIDA Y, ARAI K, ITOH S, et al. Realization of high strength and high ductility for AZ61 magnesium alloy by severe warm working[J].Sci Tech Adv Mater, 2005, 6: 185-194.

[9] 陈勇军, 王渠东, 翟春泉, 丁文江. 大塑性变形制备高强镁合金的研究与展望[J]. 机械工程材料, 2006, 30(3): 1-3.

CHEN Yong-jun, WANG Qu-dong, ZHAI Chun-quan, DING Wen-jiang. Research and development prospects of high strength mg alloys fabricated by severe plastic deformation[J]. Materials For Mechanical Engineering, 2006, 30(3): 1-3.

[10] LIN H K, HUANG J C. Fabrication of low temperature superplastic AZ91 Mg alloys using simple high-ratio extrusion method[J]. Key Eng Mater, 2002, 233/236: 875-880.

[11] CERRI E, LEO P, DE MARCO P P. Hot compression behavior of the AZ91 magnesium alloy produced by high pressure die casting[J]. J Mater Proc Techn, 2007, 189(1/3): 97-106.

[12] SAKAI T, JONAS J J. Dynamic recrystallization: Mechanical and microstructural considerations[J].Acta Metall, 1984, 32: 189-209.

[13] TAN J C, TAN M J. Dynamic continuous recrystallization characteristics in two stage deformation of Mg-3Al-1Zn alloy sheet[J]. Mater Sci Eng A, 2003, 339: 124-132.

[14] GALIYEV A, KAIBYSHEV R, GOTTSTEIN G. Correlation of plastic deformation and dynamic recrystallization in magnesium alloy ZK60[J].Acta Mater, 2001, 49: 1199-1207.

[15] 张 娅, 马春江, 卢 晨. 变形镁合金的塑性变形机制与动态再结晶[J]. 轻合金加工技术, 2003, 7: 35-39.

ZHANG Ya, MA Chun-Jiang, LU Chen. Plastic strain mechanism and dynamic recrystallization (DRX) of magnesium alloy[J]. Light Alloy Fabrication Technology, 2003, 7: 35-39.

[16] 曹 磊, 丁汉林, 刘六法. 镁合金超塑性研究[J]. 轻合金加工技术, 2005, 33(10): 8-12.

CAO Lei, DING Han-lin, LIU Liu-fa. Superplasticity of magnesium alloys[J]. Light Alloy Fabrication Technology, 2005, 33(10): 8-12.

[17] CELOTTO S. TEM study of continuous precipitation in Mg-9%Al-1%Zn alloy[J]. Acta Mater, 2000, 48: 1775-1787.

基金项目:国家自然科学基金资助项目(50505026);上海市自然科学基金资助项目(05ZR14075)

收稿日期:2007-04-19;修订日期:2007-11-08

通讯作者:丁汉林,博士;电话:021-62932113;E-mail: hanlinding@yahoo.com