J. Cent. South Univ. (2018) 25: 1501-1512

DOI: https://doi.org/10.1007/s11771-018-3843-3

Edge and texture detection of metal image under high temperature and dynamic solidification condition

CHEN Zu-guo(陈祖国), LI Yong-gang(李勇刚), CHEN Xiao-fang(陈晓方),YANG Chun-hua(阳春华), GUI Wei-hua(桂卫华)

School of Information Science and Engineering, Central South University, Changsha 410083, China

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2018

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2018

Abstract:

The zinc casting is a complicated process with high temperature, high dust content and dynamic solidification. To accurately detect the edge and texture of metal image under this condition, a sub-pixel detection based on gradient entropy and adaptive four-order cubic convolution interpolation (GEAF-CCI) algorithm is proposed. This method mainly involves three procedures. Firstly, the gradient image is generated from the grey images by using gradient operator. Then, a dynamic threshold based on the maximum local gradient entropy (DTMLGE) algorithm is applied to distinguishing the edge and texture pixels from gradient images. Finally, the adaptive four-order cubic convolution interpolation (AF-CCI) algorithm is proposed for interpolating calculation of the target edges and textures according to their variation differences in different directions. The experimental result shows that the proposed algorithm can remove the jag and blur of the edges and textures, improve the edge positioning precision and reduce the false or missing detection rate.

Key words:

edge and texture detection; GEAF-CCI algorithm; DTMLGE algorithm; metal image;

Cite this article as:

CHEN Zu-guo, LI Yong-gang, CHEN Xiao-fang, YANG Chun-hua, GUI Wei-hua. Edge and texture detection of metal image under high temperature and dynamic solidification condition [J]. Journal of Central South University, 2018, 25(6): 1501–1512.

DOI:https://dx.doi.org/https://doi.org/10.1007/s11771-018-3843-31 Introduction

Currently, over 80% of the world’s zinc metal is produced through zinc hydrometallurgy due to its advantages [1]. Zinc hydrometallurgy involves five processes [2–4]: grinding, leaching, purifying, electro-winning and casting. During casting, some of the zinc on the liquid surface will be oxidized, which seriously affects the quality of the zinc ingot. Thus, when the zinc liquid is injected into the mould cavity, the oxidizing slag floating on the surface must be removed in time. To remove the floating oxidizing slag, different types of deslagging machines are designed. As for the molten iron deslagging process, there are many typical types of deslagging machines, such as pneumatic wheel deslagging machine [5] and hydraulic vehicle walking type [6]. The pneumatic wheel deslagging machine is not stable to operate and cannot remove iron slag completely. The hydraulic telescopic arm type has a high requirement on hydraulic equipment in which the oil can be easily affected by the temperature and its complex telescopic arm is hard to control. Meanwhile, only a few scholars did some researches which are far from enough on the zinc deslagging machine. Besides, although some automatic deslagging machines are designed [7–9], in the control of some deslagging machines, there is a main difficulty that is very hard to align the deslagging actuator with the moving mould cavity, which will make the application effects of the deslagging machines mentioned above unsatisfactory. Later, PROPERZI [10] designed an improved automatic deslagging machine that employs a pre-set method to align the deslagging actuator with the moving mould cavity. However, the agility and reliability of the automatic deslagging machine are relatively poor.

To improve the agility and reliability of automatic deslagging machine, a visual technology is applied to the automatic deslagging machine. During zinc liquid deslagging, obtaining accurate edge and texture feature information of mould cavity surface is very important for positioning deslagging actuator and identifying oxidizing slag. The edge feature plays a dominant role during aligning the deslagging actuator with the moving mould, and so does the texture feature in identifying oxidizing slag. So, it is of great significance to find a good detection method of the edge and texture. Up to now, quite a few classical detection algorithms have been proposed, such as the Rebort algorithm, the Sobel algorithm and the Canny algorithm [11–15]. They are easy to operate because their calculation amount is small. But they also have many deficiencies, such as being more sensitive to noise, and unable to discriminate edges and textures. To overcome the above- mentioned deficiencies, DOLL R et al [16] proposed fast detection algorithm based on structured forests. In the algorithm, a morphological gradient technique is proposed to detect the ideal edge model and it can obtain good effect. But it is difficult to be applied to the complex industrial image. To obtain better edge detection effect, an alpha planes theory is used to obtain generalized type-2 fuzzy logic [17]. The heights and approximation methods are applied to the defuzzification process and it is good for restraining noise. But the fuzzy processing will lead to poor detection precision. A novel edge detection method based on traditional Canny and multiplicative gradient operator is proposed [18]. The method combines a new multiplicative gradient operator of non-Newtonian type with the traditional Canny operator to generate the initial edge map and it is subsequently optimized by the following edge tracing steps. However, the accuracy of the method is not satisfactory because the traditional Canny operator is easy to be affected by environment noise. A sub-pixel detection based on non-linear fourth-order interpolation algorithm was proposed [19]. The algorithm combines the benefits of classical Canny operator and nonlinear fourth-order interpolation. But it depends on complex models and its computation speed is low. AMSTUTZ et al [20] proposed edge detection based on topological gradients. The edge is detected by a new edge detector based on the maximization variance of image, which will raise the localization accuracy of edges. But the algorithm is still not ideal for edge detection of high noise image.

R et al [16] proposed fast detection algorithm based on structured forests. In the algorithm, a morphological gradient technique is proposed to detect the ideal edge model and it can obtain good effect. But it is difficult to be applied to the complex industrial image. To obtain better edge detection effect, an alpha planes theory is used to obtain generalized type-2 fuzzy logic [17]. The heights and approximation methods are applied to the defuzzification process and it is good for restraining noise. But the fuzzy processing will lead to poor detection precision. A novel edge detection method based on traditional Canny and multiplicative gradient operator is proposed [18]. The method combines a new multiplicative gradient operator of non-Newtonian type with the traditional Canny operator to generate the initial edge map and it is subsequently optimized by the following edge tracing steps. However, the accuracy of the method is not satisfactory because the traditional Canny operator is easy to be affected by environment noise. A sub-pixel detection based on non-linear fourth-order interpolation algorithm was proposed [19]. The algorithm combines the benefits of classical Canny operator and nonlinear fourth-order interpolation. But it depends on complex models and its computation speed is low. AMSTUTZ et al [20] proposed edge detection based on topological gradients. The edge is detected by a new edge detector based on the maximization variance of image, which will raise the localization accuracy of edges. But the algorithm is still not ideal for edge detection of high noise image.

As is mentioned before, the zinc casting is a complicated process with high temperature, high dust content and dynamic solidification condition. With the above methods, it is difficult to obtain accurate edge feature information of moving mould cavity and texture feature information of zinc liquid surface, and these will cause the deslagging actuator positioning and the oxidizing slag identification to fail. To solve the problems, a sub-pixel detection based on gradient entropy and adaptive four-order cubic convolution interpolation (GEAF-CCI) algorithm is proposed. In the algorithm, the grey image is processed into gradient images by the classical gradient operator. Then, the dynamic threshold based on the maximum local gradient entropy (DTMLGE) is applied to distinguishing pixel point of the edge and texture in gradient images. The gradient images are divided into two types: edge-and-texture gradient images, non-edge and non-texture gradient images. The threshold selection method can not only extract effectively the edge and texture of images with features of dynamic solidification and light-spots’ uneven distribution but also improve the accuracy and processing speed. Finally, the adaptive four-order cubic convolution interpolation (AF-CCI) algorithm is applied in the gradient direction of target edges and textures, and then sub-pixel subdivision computation is performed to obtain accurate sub-pixel locations of target edges and textures, which can largely enhance the edges and textures of images.

The proposed method combines the advantages of the gradient changes of target edges and textures, the DTMLGE algorithm and the AF-CCI algorithm. So, it can keep fine details of images, restrain the noise from background and improve the precision of edge detection. It can also effectively reduce the false or missing detection rate and the positioning errors during the detection process.

The rest of the paper is organized as follows. In Section 2, the importance of edge and texture detection is described and its difficulties are analyzed. In Section 3, calculation process of the GEAF-CCI algorithm is presented and the DTMLGE algorithm is analyzed and the AF-CCI algorithm is proposed.

2 Problem descriptions

Some zinc will be oxidized during casting and the oxidizing slag will be floating on the zinc liquid until the zinc liquid solidifies, as shown in Figure 1. It seriously affects the quality of zinc ingot. So, the oxidizing slag floating on the zinc liquid surface must be removed in a timely manner. To ensure the automatic deslagging machine to complete successfully the operation of automatic deslagging, the deslagging actuator must be aligned with the mould cavity, and the oxidizing slag must be well distinguished by deslagging machine. If the deslagging actuator is unable to align with the mould cavity, it cannot be inserted into the zinc liquid, and the deslagging task cannot be completed. If the deslagging machine cannot distinguish the oxidizing slag on the surface of zinc liquid, it cannot ensure the quality of deslagging. Thus, the two factors are critical for the whole process of the automatic deslagging.

To solve the above problems, a visual technology is used to control the alignment of the shovel and the mould cavity, and to distinguish the oxidizing slag on the surface of zinc liquid. The technology mainly lies in the fact that the edge feature of mould cavity and the texture feature of zinc liquid surface are detected through an improved sub-pixel detection algorithm. The edge feature is used to locate mould cavity, and the texture feature is used to locate and distinguish the oxidizing slag on the surface of zinc liquid. Obviously, obtaining accurate edge and texture feature information is the primary job in the process of automatic deslagging. However, the zinc casting is a complicated process with high temperature, high dust content and dynamic solidification condition. When the visual system of automatic deslagging machine detects the edge feature of mould cavity and the texture feature of zinc liquid surface, it needs to overcome many difficulties. Firstly, the high-temperature thermal radiation with continuous spectrum will increase brightness of the images, reduce the contrast of the images and produce high temperature background noise [21]. Secondly, the dust will absorb and scatter the incoming light and this influence will weaken the colour and contrast of images [22]. Besides, the dynamic solidification process of liquid metal will generate some phenomena, such as volume change, gas desolventizing and element segregation [23]. So, the resolution of images may become low, and the structure information of images may become unstable. Finally, the oxidizing slag is not evenly distributed and it mixes with zinc liquid, which makes it difficult to be distinguished from the surface of zinc liquid. So the detection algorithm is required to be insensitive to noise and its output cannot be affected by illumination variations and the nonlinear. To overcome the above difficulties, the GEAF-CCI algorithm is proposed. The method combines the advantages among gradient change of the target edges and target textures, the DTMLGE algorithm and the AF-CCI algorithm, which can keep fine details of images, restrain the noise of background and improve the edge and texture precision of detection.

Figure 1 Image detection during zinc casting

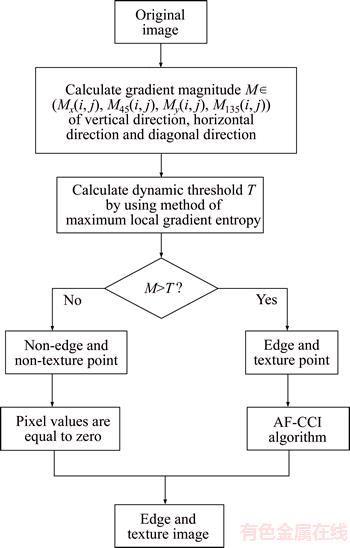

3 Sub-pixel feature detection of mould cavity

To ensure that the automatic deslagging machine completes successfully the automatic deslagging, the deslagging actuator must be aligned with the mould cavity, and the automatic deslagging machine can distinguish the oxidizing slag on the surface of zinc liquid. But before that, the edge and texture feature information of the mould cavity surface must be detected accurately. To solve the above problem, the GEAF-CCI algorithm is proposed to detect edge and texture feature information of the mould cavity and its calculation process is shown in Figure 2. Its calculation steps are shown below.

1) The algorithm calculates gradient magnitude (Mx(i, j), M45(i, j), My(i, j), M135(i, j)) of the x-axis, the 45°, the y-axis and the 135° direction using the classical gradient operator, respectively. Gradient images will be obtained.

2) Then, the threshold is calculated by the maximum local gradient entropy and it is applied to distinguishing the pixel point of the edge and texture in gradient images. The gradient images are divided into two parts: gradient images of the edge and texture and gradient images of the non-edge and non-texture.

3) Next, the AF-CCI algorithm is applied in the gradient direction of the target edges and target textures.

Figure 2 Calculation process of GEAF-CCI algorithm

4) Finally, the sub-pixel subdivision computation is performed to obtain accurately the sub-pixel locations of the target edges and target textures, and the image of edges and textures is generated.

3.1 Calculate histogram of local gradient

Each pixel has four edge detection directions in the digital image. When an edge is perpendicular to edge detection directions, the edge point can be good detected [24]. In theory, each edge can be detected just by the horizontal and vertical direction. But it will show obvious missing detection for the edge and texture detection of metal images. To accurately detect the edge and texture of metal images and reduce errors, every pixel relative to the gradient magnitude in the image is calculated respectively by the finite difference mean of first order partial derivative for the x-axis, the 45°, the y-axis and the 135° direction in the 5×5 window. The formula is shown as the following [24],

(1)

(1)

(2)

(2)

(3)

(3)

(4)

(4)

(5)

(5)

where i and j are the horizontal and vertical coordinates of pixel, respectively; n and m are the horizontal and vertical coordinates variation of pixel, respectively; I(i, j) is the pixel value of central pixel(i, j) in the 5×5 window; M(i, j) is the gradient magnitude of central pixel(i, j) in the 5×5 window; Mx(i, j), M45(i, j), My(i, j) and M135(i, j) are the finite difference mean of first order partial derivative for the x-axis, 45°, y-axis and 135° direction, respectively. The detection image is divided into small blocks using the non-overlap strategy before calculating local gradient histogram [25].

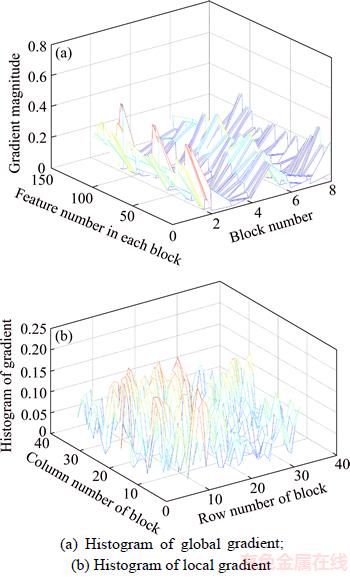

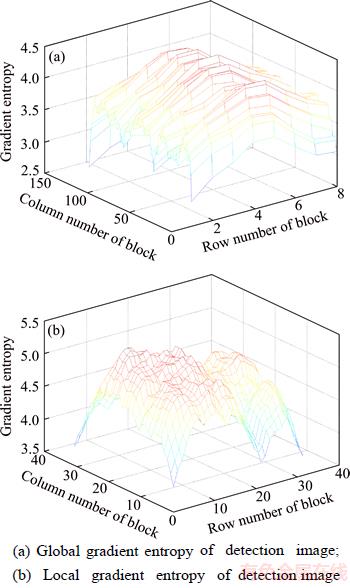

The histogram of the global gradient and local gradient of the detection image is obtained, as shown in Figure 3. Through comparing the gradient magnitude (Mx(i, j), M45(i, j), My(i, j) and M135(i, j)) of four directions with the threshold T, if one of these four gradient magnitudes is greater than the threshold T, the pixel point is judged as the edge and texture point. Otherwise, the pixel point isn’t the edge and texture point. The calculation method of threshold T will be given in detail in Section 3.2.

Figure 3 Global gradient histogram and local gradient histogram of detection image:

3.2 DTMLGE algorithm

The choice of threshold is very critical during detection of the edge and texture. If the threshold is too big, some edge and texture may be regarded as noise and be removed. What’s worse, noise may produce some false edge and texture [26]. Besides, during zinc liquid deslagging, the mould cavity will move continuously one after another. Pixel intensity of image varies a lot on different blocks of different mould cavities. If a unified threshold is used to detect the edge and texture of image, the detection results will be inaccurate. And the edge and texture will be discontinuous because the output values of detectors fluctuate around the threshold. To eliminate the influence of the objective conditions and interference factors, the DTMLGE algorithm is proposed. In the algorithm, the optimal edge and texture information in every local area is obtained according to pixel distribution of images. It can ensure the differences between the edge and texture feature and the background information. It not only decreases information loss but also enhances detection ability.

The gradient entropy is introduced to detect edge and texture. That is, the gradient magnitude of image is split into two parts: gradient amplitude of the edge and texture and gradient amplitude of the non-edge and non-texture, using the entropy to ensure a threshold. The method can make the information amounts of image reach its maximum value. Moreover, the local gradient entropy can reflect the dispersion degree of the grey image change. The dispersion degree is relatively large in the different objects of images. So, its local gradient entropy is also relatively large, and the region of the maximum local gradient entropy lies at the edge and texture.

The gradient histogram should be obtained before selecting threshold using the maximum local gradient entropy method. Assuming that gradient histogram of the S×F local image is Pl(l=1, 2, 3, …, L–1 and L is total amount of the gradient levels of the S×F local image), probability distribution of the gradient amplitude of the non-edge and non-texture is PN and probability distribution of the gradient amplitude of the edge and texture is PE.

(6)

(6)

According to the definition of entropy, the gradient entropy of the non-edge and non-texture HN(T) can be obtained by

(7)

(7)

The gradient entropy of edge and texture HE(T) can be obtained by

(8)

(8)

The entropy of gradient histogram is:

(9)

(9)

The global gradient entropy and the local gradient entropy of the detection image are shown in Figure 4. According to the principle of the maximum entropy, when H(T) achieves the maximum value, T is threshold. The gradient histogram of the M×N local image can be reasonably divided into two parts: gradient amplitude of the edge and texture and gradient amplitude of the non-edge and non-texture using the threshold. T can be obtained by

(10)

(10)

Figure 4 Global gradient entropy and local gradient entropy of detection image:

3.3 AF-CCI algorithm

To detect more clearly the edge and texture at the sub-pixel level, the grey image of the edge and texture is processed by an interpolation algorithm. An interpolation function is a special type of approximating function. The fundamental property of interpolation functions is that they must coincide with the sampled data at the interpolation nodes, such as the sample points [27]. If f is a sampled function and g is the corresponding interpolation function, then g(xb)=f(xb), where xb is an interpolation node. The interpolation kernel in the four-order cubic convolution interpolation (F-CCI) algorithm is composed by piecewise cubic polynomials defined on the subintervals [x0, x1], [x1, x2], …, [xb–1, xb] [30]. Outside the interval [x0, xb], the interpolation kernel is zero. The interpolation kernel must be symmetric in the algorithm. Coupled with the previous condition, this means that R(x) must have the following form:

(11)

(11)

The kernel function must be continuous and differentiable in the cubic convolution interpolation algorithm [28]. In addition, R(0)=1, and when n= (±1, ±2, ±3), R(b)=0. Thus, the relation equations are as follows:

(12)

(12)

There are 12 undetermined coefficients in the relation equations. However, the equation set has only ten relation equations above. So, it is an under-constrained problem. According to the three-bending moment algorithm [29], the kernel function can achieve the highest interpolation precision when A2=–7/12 and A3=1/12. This so-called fourth-order cubic convolution kernel is defined as:

(13)

(13)

In the algorithm, the pixel value of adjacent points is selected for interpolation, which can increase interpolation accuracy [30]. But the F-CCI algorithm ignores many factors, such as the local features of image and the variations of the edge and texture in different directions. Besides, when it is used to detect the edge and texture feature of metal image under special conditions, it may cause the “error processing” problems, such as false detection, leak detection and multi-pixel width edge. Because metal images under the special condition contain a large number of impurities and noises, it may result in easy rich details loss of the image during detection. To improve interpolation accuracy, an AF-CCI algorithm is proposed. The interpolation equation can be obtained by

(14)

(14)

where f1(x) is results of the F-CCI algorithm in the horizontal direction or the 45° diagonal direction; a0, which can be obtained by experience method, is weight; f2(x) is results of the F-CCI algorithm in the vertical direction or the 135° diagonal direction.

In AF-CCI algorithm, the edge direction is divided into strong and weak edge directions. These two types of edge directions can be used to measure correlation between neighbouring pixels point and edge pixel point. However, the influence degree of the strong and the weak edge directions on pixel value is different. So, when calculating interpolation pixel, pixels information in the strong edge direction should increase calculation weight. It can reduce error accumulation, suppress noise while preserving edge and detail element, and enhance visual effect effectively.

To consider the local features of image, the pixel points of image are divided into the points of the edge and texture and the non-edge and non- texture according to a local threshold value T. Then, different interpolation strategies are adopted for two types of pixel points, respectively. If the difference between the pixels is smaller than the threshold value T, these pixel points are classified as the point of the non-edge and non-texture, and they are assigned zero. Whereas, these pixel points are classified as the point of the edge and texture on which the interpolating calculation can be done by the AF-CCI algorithm.

4 Experimental results and discussion

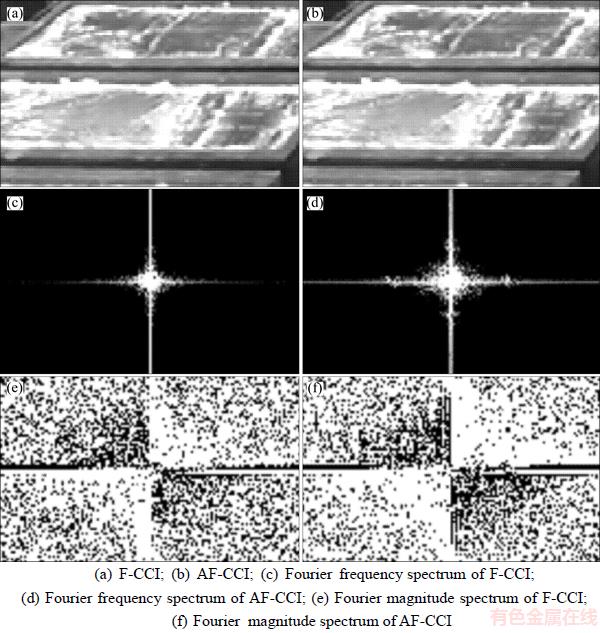

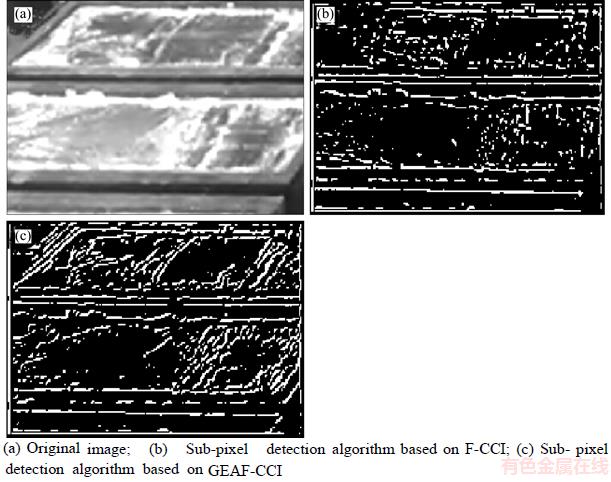

During the experiment, to prove the validity and superiority of the AF-CCI algorithm, the same image is processed by the F-CCI algorithm [29, 30] and AF-CCI algorithm, respectively. In Figure 5, the two pictures in the first line are processing results using the F-CCI algorithm and AF-CCI algorithm.

The two pictures in the second line are the spectral images of the pictures in the first line using the two-dimensional Fourier transforming. As shown in Figure 5, there are differences in the size of the area covered by the bright spot. The size of bright spot processed by the AF-CCI algorithm is greater than that of the image processed by the F-CCI algorithm. Likewise, the high-frequency components of image processed by the AF-CCI algorithm are much more. And the images processed by the AF-CCI algorithm contain more information.

The two pictures in the third line are the spectral images of the pictures in the first line using Fourier magnitude spectrum transforming. As can be seen from the pictures, the resolution of image processed by the AF-CCI algorithm is clearly higher. Therefore, the results obtained through comparing the two groups of images indicate that the interpolating calculation can be done much better on images by the AF-CCI algorithm.

Figure 6 shows the experimental results of the edge and texture detection obtained by the GEAF-CCI and F-CCI algorithms, respectively. We can see from Figure 6 that the effect of the edge and texture detection by GEAF-CCI algorithm is better, and its superiority mainly lies in the following two aspects: First, there is an obvious decrease in the breakpoint of edge and the missing detection of texture. Second, the edge contour of mould cavity becomes clearer. To further analyze its superiority, the evaluation methods based on local pixel intensity distribution and local pixel entropy are used to evaluate the results of the edge and texture detection during the experiment.

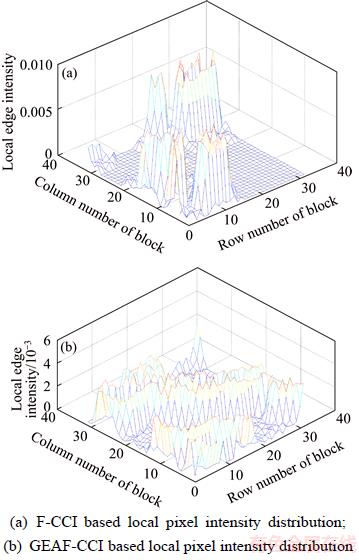

The local pixel intensity distributions of detection results are calculated and visualized in Figure 7. Figures 7(a) and (b) show local pixel intensity distributions which are obtained by the F-CCI and GEAF-CCI algorithms, respectively. We can see from the picture that a few pixel intensity of the edge and texture in Figure 7(a) is bigger, which means that the detection capability of the F-CCI algorithm in detecting edges with typical spatial layout feature is slightly stronger than that of the GEAF-CCI algorithm. But these bigger pixel intensity values are mainly distributed in edge area and most of the other values tend to be zero, which reflects well that many edges and textures are missed in the process of detection. So, the GEAF-CCI is more practical in obtaining the entire feature information and the intensity distribution obtained by GEAF-CCI is more uniform. Thus, it can conclude that the GEAF-CCI algorithm has stronger detection capability for structure and non-structure feature information and it is good for obtaining the entire feature information.

Figure 5 Same image processed by F-CCI and AF-CCI algorithms:

Figure 6 Experimental results of edge and texture detection obtained by GEAF-CCI algorithm and F-CCI algorithm, respectively:

Figure 7 Experimental results of evaluation method based on local pixel intensity distribution:

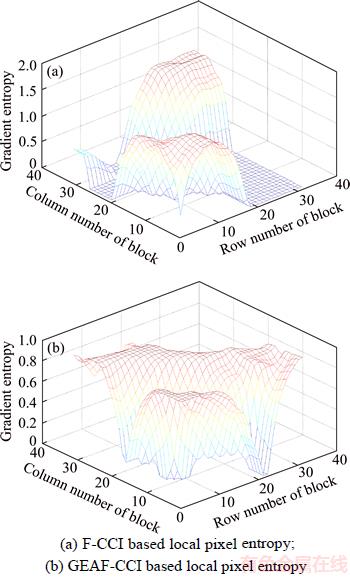

The local pixel entropy of detection result is calculated and visualized in Figure 8. Figures 8(a) and (b) are obtained by the F-CCI algorithm and GEAF-CCI algorithm, respectively. We can see from the picture that some local pixel entropy of the edge and texture in Figure 8(a) is bigger, but most of these intensity values are distributed at the edge area. So, the image of the edge and texture in Figure 8(a) has more chaotic pixel distribution than that in Figure 8(b) at the edge area. However, the image of the edge and texture obtained by using the GEAF-CCI algorithm is clear.

Figure 8 Experimental results of evaluation method based on local pixel entropy:

Besides, a large part of local pixel entropy of the edges and textures obtained by the F-CCI algorithm tends to zero. It can be seen that many edges and textures are missed in the process of detection. So, the F-CCI algorithm is less practical in obtaining the entire feature information. However, the intensity distribution obtained by GEAF-CCI is more uniform. It can be seen that the GEAF-CCI algorithm has stronger detection capability for structure and non-structure feature information. The conclusion of Figure 8 is similar to that of Figure 7.

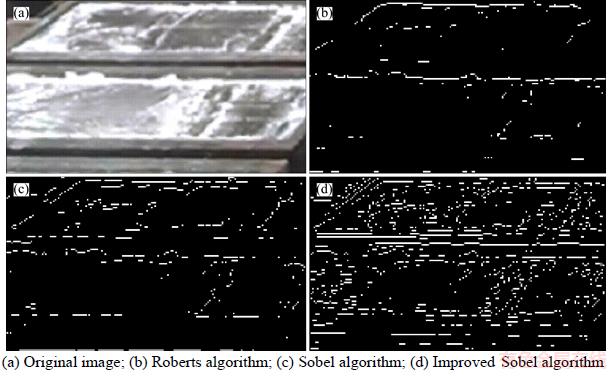

To certify the superiority of the GEAF-CCI algorithm, the edge and texture of an image are directed by other three algorithms (Roberts algorithm [11], Sobel algorithm [12], and improved Sobel algorithm [31]), as shown in Figure 9. We can clearly see from the picture that detective effectiveness of the Roberts algorithm, the Sobel algorithm and the improved Sobel algorithm are all poorer than that of the F-CCI algorithm. And they are all poorer than that of the GEAF-CCI algorithm.

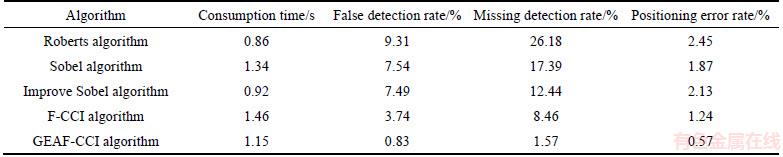

We can see from Table 1 that the consumption time of the GEAF-CCI algorithm during image detection is longer than that of the Roberts algorithm and the improved Sobel algorithm, respectively. But its consumption time is shorter than that of the Sobel algorithm and the F-CCI algorithm, respectively. And the false detection rate, the missing detection rate and the positioning error rate of the GEAF-CCI algorithm during image detection are all the smallest. Based on the above, we can draw a conclusion that the effect of edge detection using the GEAF-CCI algorithm is the best in these algorithms.

5 Conclusions

As is presented above, this work aims to design a visual deslagging robot, and to improve the flexibility and adaptability of the deslagging robot. But the accuracy of the edge and texture features information on mould cavity surface is of great significance to position the deslagging actuator and identify the oxidizing slag. To obtain accurate features information of the edge and texture, a GEAF-CCI algorithm, which is fit for complicated process with high temperature, high dust content and dynamic solidification condition, is proposed in the work.

The GEAF-CCI algorithm combines the advantages of the gradient changes of target edges and textures, the DTMLGE algorithm and the AF-CCI algorithm. So, it can keep fine details of image and avoid saw tooth and smoothing effects of the edge and texture. It can get a better visual effect,remove the jag and blur of the edge and texture, and reduce the noise interference efficiently. Thus it can, to a great extent, decrease the false detection rate, the missing detection rate and the positioning error rate during the detection. However, there are still much subsequent work needed to be done, such as feature matching, visual positioning, oxidation slag identifying based on texture feature. They are supposed to be completed in subsequent research.

Figure 9 Experimental results of edge detection obtained using other three algorithms (Roberts algorithm, Sobel algorithm, and improved Sobel algorithm):

Table 1 Performance index of different algorithms

References

[1] LI Yong-gang, GUI Wei-hua, TEO K L, ZHU Hong-qiu, CHAI Qin-qin. Optimal control for zinc solution purification based on interacting CSTR models [J]. Journal of Process Control, 2012, 22(10): 1878–1889.

[2] XIE Yong-fang, XIE Shi-wen, CHEN Xiao-Fang, GUI Wei-hua, YANG Chun-hua, CACCETTA L. An integrated predictive model with an on-line updating strategy for iron precipitation in zinc hydrometallurgy [J]. Hydrometallurgy, 2015, 15(25): 62–72.

[3] SUN Bei, GUI Wei-hua, WU Tie-bin, WANG Ya-lin, YANG Chun-hua. An integrated prediction model of cobalt ion concentration based on oxidation-reduction potential [J]. Hydrometallurgy, 2013, 140(11): 102–110.

[4] SUN Bei, GUI Wei-hua, WANG Ya-lin, YANG Chun-hua. Intelligent optimal setting control of a cobalt removal process [J]. Journal of Process Control, 2014, 24(5): 586–599.

[5] HU Ming-qian. Study and productive practice for improving the quality of casting slab in Benxi steel [D]. Shenyang: School of Material and Metallurgy, Northeastern University, 2010. (in Chinese)

[6] TAN Peng-fu. Modeling and control of copper loss in smelting slag [J]. JOM, 2011, 63(12): 51–57.

[7] SHENG Fu-chun. Device for implementing a high efficiency method of scooping-up slag from liquid iron: US, 8153050 [P]. 2012–10–04.

[8] TAN R B H, KHOO H H. Zinc casting and recycling [J]. The International Journal of Life Cycle Assessment, 2005, 10(3): 211–218.

[9] HE Di-qiu, ZHANG Zhi-yong, ZHAO Xiao-ling, YI You-ping. Automatic cinder scraping technique in aluminium ingot casting [J]. Journal of Central South University: Science and Technology, 1999, 30(5): 530–532. (in Chinese)

[10] PROPERZI G. Apparatus for melting and refining impure nonferrous metals, particularly scraps of copper and/or impure copper originating from the processing of minerals: US, 8961866 [P]. 2015–12–09.

[11] GAO Zan, JIANG Wei, ZHU Kong-feng, WANG Chao. Auto-focusing algorithm based on Roberts gradient [J]. Infrared and Laser Engineering, 2006, 35(1): 117–121. (in Chinese)

[12] SUN Qiu-cheng, HOU Yue-qian, TAN Qing-chang, LI Chun-jing, LIU Ming. A robust edge detection method with sub-pixel accuracy [J]. Optik - International Journal for Light and Electron Optics, 2014, 125(14): 3449–3453.

[13] MALIK J, DAHIYA R, GIRDHAR D, SAINARAYANAN G. Finger knuckle print authentication using Canny edge detection method [J]. International Journal of Signal and Imaging Systems Engineering, 2016, 9(6): 333–341.

[14] SHIVAKUMARA P, SREEDHAR R P, PHAN T Q, LU S J, TAN C L. Multioriented video scene text detection through Bayesian classification and boundary growing [J]. IEEE Transactions on Circuits and Systems for Video Technology, 2012, 22(8): 1227–1235.

[15] LEE J S, WEN Kai-rui, LI Bo. Renovating contaminative image archives based on patch propagation and adaptive confidence collation [J]. IEEE Transactions on Circuits and Systems for Video Technology, 2016, 26(5): 1004–1011.

[16] DOLL R P, ZITNICK C L. Fast edge detection using structured forests [J]. IEEE Transactions on Pattern Analysis and Machine Intelligence, 2015, 37(8): 1558–1570.

R P, ZITNICK C L. Fast edge detection using structured forests [J]. IEEE Transactions on Pattern Analysis and Machine Intelligence, 2015, 37(8): 1558–1570.

[17] APAMELIN P, GONZALEZ C I, CASTRO J R, MENDOZA O. Edge-detection method for image processing based on generalized type-2 fuzzy logic [J]. IEEE Transactions on Fuzzy Systems, 2014, 22(6): 1515–1525.

[18] GONG Xiao-hong, ZHOU Ya-li, ZHOU Hao, ZHENG Yin-fei. Ultrasound image edge detection based on a novel multiplicative gradient and Canny operator [J]. Ultrasonic Imaging, 2015, 37(3): 238–250.

[19] WU Peng, LI Wen-lin, SONG Wen-long, CAO Jun. An image sub-pixel edge detection algorithm of plant roots based on non-linear fourth-order interpolation method [J]. International Journal of Hybrid Information Technology, 2014, 7(3): 275–284.

[20] AMSTUTZ S, FEHRENBACH J. Edge detection using topological gradients: A scale-space approach [J]. Journal of Mathematical Imaging and Vision, 2015, 52(2): 249–266.

[21] CHEN X, YANG L X, XU N, XIE X, SIA B, XU R. Cluster approach based multi-camera digital image correlation: Methodology and its application in large area high temperature measurement [J]. Optics and Laser Technology, 2014, 57(7): 318–326.

[22] TING Yan, WANG Lie-jun, WANG Jia-xing. Method to enhance degraded image in dust environment [J]. Journal of Software, 2014, 9(10): 2672–2677.

[23] BANOUNI H, FAIZ B, IZNAIM D, AYAOU T, OUACHA E, BOUTAIB M, ABOUDAOUD I. Determination of the flight time of the acoustic waves transmitted by the cement paste in solidification by the image processing [J]. Physics Procedia, 2015, 70: 442–446.

[24] ZUO Yi-fan, WU Qiang, ZHANG Jian, AN Ping. Explicit edge inconsistency evaluation model for color-guided depth map enhancement [J]. IEEE Transactions on Circuits and Systems for Video Technology, 2018, 28(2): 439–453. DOI: 10.1109/TCSVT. 2016. 2609438.

[25] YOU Xin-ge, LI Qiang, TAO Da-cheng, OU Wei-hua, GONG Ming-ming. Local metric learning for exemplar- based object detection [J]. IEEE Transactions on Circuits and Systems for Video Technology, 2014, 24(8): 1265–1276.

[26] CHEN Li-ping, CHEN Xiang-yang, WANG Si-le, YANG Wen-zhu, LU Su-kui. Foreign fiber image segmentation based on maximum entropy and genetic algorithm [J]. Journal of Computer and Communications, 2015, 03(11): 1–7.

[27] SU Yong, ZHANG Qing-chuan, GAO Ze-ren, XU Xiao-hai. Noise-induced bias for convolution-based interpolation in digital image correlation [J]. Optics Express, 2016, 24(2): 1175–1195.

[28] MEIJERING E, UNSER M. A note on cubic convolution interpolation [J]. IEEE Transactions on Image Processing, 2003, 12(4): 477–479.

[29] WANG Lei, JEON G. Bayer pattern CFA demosaicking based on multi-directional weighted interpolation and guided filter [J]. IEEE Signal Processing Letters, 2015, 22(11): 2083–2087.

[30] WANG L J, SHU C T. An efficient fractional-pixel motion compensation based on cubic convolution interpolation [J]. Journal of Electrical and Electronic Engineering, 2014, 2(4): 52–59.

[31] GONZALEZ C I, MELIN P, CASTRO J R, MENDOZA O, CASTILLO O. An improved Sobel edge detection method based on generalized type-2 fuzzy logic [J]. Soft Computing, 2016, 20(2): 773–784.

(Edited by YANG Hua)

中文导读

高温和动态凝固条件下金属图像的纹理和边缘检测

摘要:锌锭铸造是一个高温、高粉尘和动态凝固的复杂过程。为了准确地检测该条件下金属图像的边缘和纹理特征,提出了一种基于梯度熵和自适应四阶立方卷积插值的亚像素检测算法(GEAF-CCI)。该方法主要包含3个过程:首先,采用梯度算子从灰度图像中生成梯度图像;然后,采用基于最大局部梯度熵的动态阈值(DTMLGE)算法去区分梯度图像中的边缘和纹理的像素;最后,使用AF-CCI 算法根据目标边缘和纹理在不同方向的变化差异对其进行插值计算。实验结果表明,该算法可以减少细节模糊和边缘锯齿现象的产生,提高边缘的定位精度和降低误检率和失检率。

关键词:边缘与纹理检测;GEAF-CCI算法;DTMLGE算法;金属图像

Foundation item: Project(61673400) supported by the National Natural Science Foundation of China; Project(61590923) supported by the Major Program of the National Natural Science Foundation of China; Project(61621062) supported by the Foundation for Innovative Research Groups of the National Natural Science Foundation of China; Project(61533020) supported by the State Key Program of National Natural Science of China; Project(502221709) supported by the Fundamental Research Funds for the Central Universities, China

Received date: 2017-03-30; Accepted date: 2017-09-24

Corresponding author: LI Yong-gang, PhD; Tel/Fax: +86–731–88836876; E-mail: liyonggang@csu.edu.cn; ORCID: 0000-0002- 5029-8875

Abstract: The zinc casting is a complicated process with high temperature, high dust content and dynamic solidification. To accurately detect the edge and texture of metal image under this condition, a sub-pixel detection based on gradient entropy and adaptive four-order cubic convolution interpolation (GEAF-CCI) algorithm is proposed. This method mainly involves three procedures. Firstly, the gradient image is generated from the grey images by using gradient operator. Then, a dynamic threshold based on the maximum local gradient entropy (DTMLGE) algorithm is applied to distinguishing the edge and texture pixels from gradient images. Finally, the adaptive four-order cubic convolution interpolation (AF-CCI) algorithm is proposed for interpolating calculation of the target edges and textures according to their variation differences in different directions. The experimental result shows that the proposed algorithm can remove the jag and blur of the edges and textures, improve the edge positioning precision and reduce the false or missing detection rate.