- Abstract:

- 1 Introduction▲

- 2 Working mechanisms▲

- 3 Calculation of bearing ...▲

- 4 Model test study▲

- 5 Conclusions▲

- References

- Figure

- Fig.1 Restrictions on pile by geosynthetics

- Fig.2 Distortion of geosynthetics under local additional load

- Fig.3 Calculation model of horizontal reinforcement

- Fig.4 Physical dimension of model test flume (unit: mm)

- Fig.5 Cumulative settlement curves of observation points of test 1

- Fig.6 Cumulative settlement curves of observation points of test 2

- Fig.7 Cumulative settlement curves of observation points of test 3

- Fig.8 Cumulative settlement curves of observation points of test 4

- Fig.9 Q-s curves of point 2 in each test

- Fig.10 Comparison between measured and calculated Δf2

J. Cent. South Univ. Technol. (2007)04-0589-06

DOI: 10.1007/s11771-007-0113-1![]()

Working mechanism of two-direction reinforced composite foundation

ZHANG Ling(张 玲), ZHAO Ming-hua(赵明华), HE Wei(贺 炜)

(Institute of Geotechnical Engineering, Hunan University, Changsha 410082, China)

__________________________________________________________________________________________

Abstract:Based on the discussion about working mechanism of horizontal reinforcement and that of vertical reinforcement, respectively, the working mechanism of two-direction reinforced composite foundation was studied. The enhancing effect of horizontal reinforcement on vertical reinforced composite foundation was analyzed. A simplified calculation method for such two-direction reinforced working system was presented. A model experiment was carried out to validate the proposed method. In the experiment, geocell reinforcement worked as the horizontal reinforcement, while gravel pile composite foundation worked as the vertical reinforcement. The results show that the calculated curve is close to the measured one. The installation of geosynthetic reinforcement can increase the bearing capacity of composite foundation by nearly 68% at normal foundation settlement, which suggests that the enhancing effect by geosynthetic reinforcement should be taken into account in current design/analysis methods.

Key words:

composite foundation; two-direction reinforcement; working mechanism; bearing capacity;

__________________________________________________________________________________________

1 Introduction

In recent years, along with the development of the high way construction, it becomes increasingly necessary to construct infrastructure in districts where previously unsuitable to construct. Construction of road embankment over soft subsoil can result in failure or large, often differential, settlements on the surface of the embankment[1-2]. A variety of techniques including some innovative techniques such as two-direction reinforced composite foundation method referred herein are required to solve these problems[3-5].

Two-direction reinforced composite foundation consists of vertical piles (gravel pile, cement-soil pile), and a geosynthetic reinforced layer that work as horizontal reinforcement. Usually, geosynthetic reinforced layer is installed over the vertical piles. These two directional reinforcements work together to sustain the superstructure loads.

Due to the benefits associated with the use of the horizontal reinforcement and the vertical reinforcement, this new foundation treatment is widely applied to engineering constructions such as high way subgrade improvement, abutment backfilling improvement, widening of existing roads with weak subsoil condition.

However, until now, researches about this two-direction reinforced composite foundation have not been employed widely. Theory about how the load is transferred to subsoil remains poorly understood. In the past decades, much attention has been focused on experimental studies[6-7], but analysis method for this foundation system has been rarely reported[8-10]. In order to popularize this new foundation treatment technique, it is necessary to make an intensive study of its working mechanism and develop its calculation methods as well.

2 Working mechanisms

2.1 Mechanisms of horizontal reinforcement

Due to the installation of geosynthetic reinforcement composed of a single layer of geosynthetic material (such as geofabric, geogrid, geocell) or a multilayer system onto the gravel cushion, the horizontal reinforcement has some special working performances[10-13] as follows.

2.1.1 Stress dispersion effect

The vertical stress from embankment is diffused availably by the geosynthetic reinforcement so as to reduce the total and the differential settlements on the ground surface.

2.1.2 Lateral restricting effect

Due to the differential lateral displacement tendency induced by differential elastic modulus between the geosynthetic and the foundation soil materials, there is a resistance at the interface between the geosynthetic reinforcement and the foundation soil, which can limit the lateral displacement of the foundation soil.

2.1.3 Net sling and isolation effects

As a result of the contribution of the vertical component of reinforcement tension, the vertical stress below the geosynthetic is smaller than that above. In addition, geosynthetic reinforcement also acts as a stiffened platform to isolate the vertical stress and the displacement induced by superstructure loads. Then, the integrity and the continuity of the soil system are improved by such effect indirectly. After all, due to the presence of the geosynthetic reinforcement, the vertical stress of the foundation soil is diffused and uniformed, and its stress and strain fields are altered. Thus, the foundation is strengthened.

2.2 Mechanisms of vertical reinforcement

Generally, piles act as the vertical reinforcements, and their main effects are introduced as follows[13-14].

2.2.1 Replacement effect

When a pile is formed, it usually has a diameter from 40 to 100 cm, and a high density. It works together with the surrounding foundation soil to sustain the embankment loads by following the deformation compatibility conditions. The foundation stress tends to redistribute by differential deformation modulus of materials. The stress concentration increases with an increase in the stiffness difference between pile and soil. That is to say, the pile sustains much greater mass of superstructure loads than the soil. In other words, the reinforced soil can bear more loads than the untreated one. Furthermore, compared with unreinforced case, the stability of the embankment is increased with the enhancement of the shear strength of the composite foundation.

2.2.2 Extruding and compacting effect

Due to the extruding effect or the compacting effect that piles act on the soft foundation soil during the construction, the density of the foundation soil becomes higher and higher, and then its bearing capacity is enhanced accordingly.

Furthermore, piles (such as gravel pile) formed by discrete materials not only have replacement and compaction effects, but also play an important role in accelerating the consolidation of soil drainage. For varied foundation soils with different physical natures, vertical piles play different roles. For example, for saturated soil, the installation of the gravel pile can enhance the bearing capacity of the foundation by replacing a portion of the soft foundation soil and improving soft soil drainage consolidation, while for the unsaturated soil foundation, the installation of the gravel pile can enhance the foundation bearing capacity by replacing the soft foundation soil and extruding (or compacting) the surrounding soft soil.

2.3 Mechanisms of two-direction reinforced composite foundation

By combining the horizontal reinforcement with the vertical reinforcement, a two-direction reinforced composite foundation is formed [10]. In this working system, the geosynthetic reinforcement that acts as a cushion limits the soil lateral displacement and diffuses the loads effectively, while the vertical pile composite foundation strengthens the soil body.

2.3.1 Tensioned membrane effect (or stiffened platform effect) to pile by geosynthetic reinforcement

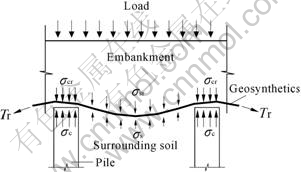

There is differential settlement on the foundation surface and at the elevation of pile head due to the modulus difference between the pile and the soil materials. As a result, stress concentrates from soil to pile by the soil arching which was induced by this differential settlement. Compared with the unreinforced case, the inclusion of geosynthetic reinforcement is able to reduce the differential displacement between the pile and the soil. The tension in geosynthetic material reduces the pressure acting on the surrounding soil but increases the load applied to the pile. Therefore, the load that transfers to the pile by embankment soil arching is reduced. In parallel, the load on the pile may be increased by the vertical components of the tension forces of the geosynthetic reinforcement (Fig.1). Moreover, a single geosynthetic layer acts as a tensioned membrane, while a multilayer geosynthetic system acts as a stiffened platform due to the interlock of reinforcements with the surrounding soil.

Fig.1 Restrictions on pile by geosynthetics

Furthermore, along with the development of foundation settlement, the shallow surrounding soil becomes compact gradually, and its bearing capacity is enhanced accordingly. In parallel, this compact surrounding soil can restrain the lateral movement at the top of the discrete material pile (such as gravel pile) much more effectively. Thus, the discrete material pile can not be destroyed prematurely, and its failure surface gets lower than the composite foundation without geosynthetic reinforcement.

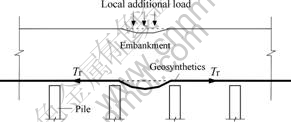

The foundation with the geosynthetic reinforcement also has a stress concentration from soil to pile under the local additional load (such as vehicular load). In addition, the vertical component of the tension forces of the geosynthetic reinforcement can also take an effective part in supporting the embankment loads (Fig.2).

Fig.2 Distortion of geosynthetics under local additional load

2.3.2 Support to geosynthetic reinforcement by vertical pile composite foundation

Throughout the whole loading process, vertical piles always put into full play, and have effects on supporting the geosynthetic reinforcement and preventing the geosynthetic material from greater bending or failure under larger superstructure loads.

3 Calculation of bearing capacity

As previous analysis, the two-direction reinforced composite foundation has its own characteristics, and the geosynthetic reinforced cushion is quite different from the normal one, so the common bearing capacity calculation method is not suitable to calculate this working system. Therefore, a simplified bearing capacity calculating method was presented in this paper. In this method, the bearing capacity of this reinforced composite foundation fcps can be estimated by adding the bearing capacity of vertical pile composite foundation fps and the increased bearing capacity Δf by horizontal reinforcement together.

3.1 Bearing capacity of vertical pile composite foundation

Main methods to determine the bearing capacity of vertical pile composite foundation are as follows: loading test methods, theoretical calculative methods and experience analogism methods. However, for the high cost and the long time of loading test, theoretical calculation methods are used more widely to estimate the bearing capacity fps, with the complex projects excepted. Among the various theoretical methods, area ratio method is the most popular one[15], and its expression is

fps=K1λ1mfp+K2λ2(1-m)fs (1)

where fp,? fs are the bearing capacities of pile and surrounding soil, respectively; K1, K2 are the modified coefficients of the pile and the soil, reflecting their real ultimate bearing capacities, these two coefficients should be evaluated on a concrete engineering, usually K1>1, K2>0; l1 is the ratio of the real bearing capacity of the pile in the failure process to its ultimate bearing capacity, if the pile gets its ultimate bearing capacity earlier than the soil, l1=1, otherwise l1<1; l2 is the ratio of the real bearing capacity of the soil in the failure process to its ultimate bearing capacity. Generally, the pile gets its ultimate value earlier than the soil, so the range of l2 usually varies from 0.4 to 1.0; m is the replacement ratio of the composite foundation.

3.2 Increased bearing capacity by horizontal reinforcement

As discussed above, main effects of the geosynthetic are ‘stress diffusion effect’ and ‘net sling effect’, so the enhancement induced by this reinforcement can be considered from two aspects relatively. Considering that length of the embankment is much greater than its width, a lengthways unit is chosen to analyze.

3.2.1 Calculation of increased bearing capacity by stress dispersion effect of geosynthetic reinforcement Δf1

The increased bearing capacity Δf1 can be calculated as follows:

![]() (2)

(2)

where Ac and A are the dispersion area of the embankment fill below the geosynthetic reinforcement and the area of geosynthetic reinforcement in unite embankment length, respectively. If Ac ≥b+2hctanqc, Ac=b+2hctanqc, or if Ac<b+2hctanqc, Ac=A, in which b is the bottom width of the embankment; hc and qc are the height and the dispersion angle of the geosynthetic reinforcement, respectively.

3.2.2 Calculation of increased bearing capacity by vertical component of tension force of geosynthetic reinforcement Δf2

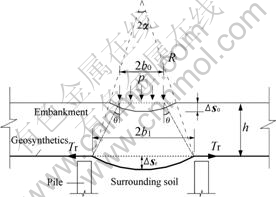

Supposing that when the geosynthetic reinforcement sustains a local additional load p, it will have a distortion whose shape is a circular arc with a radius of R, as shown in Fig.3.

The increased bearing capacity Δf2 can be estimated as follows:

Δf2=2Trsinα (3)

where Tr is the tension force of the geosynthetic reinforcement, and it can be calculated as follows:

Tr=EcΔε (4)

where Ec is the tensile modulus of the geosynthetic material, which can be estimated by an indoor tensile test; Δe is the strain of the geosynthetic material, which can be calculated as follows:

![]() (5)

(5)

where q is the dispersion angle of the embankment material; b1 that is half of the dispersion length shown in Fig.3, has a geometrical relationship with b0, b1=b0+htanq, in which b0 is half of the distributed load’s acting width; h is the height of the embankment; Δsr is the differential settlement at elevation of pile heads. If the embankment isn’t very high, Δsr is close to the differential settlement Δs0 on the embankment surface.

Fig.3 Calculation model of horizontal reinforcement

When the height of the embankment is less than 6 m, especially less than 1.5 m, the bearing capacity of the embankment will be influenced by the vehicular load greatly. So the geosynthetic reinforcement can contribute its potential in enhancing the bearing capacity of embankment foundation.

3.3 Bearing capacity of two-direction reinforced composite foundation

The bearing capacity of the two-direction reinforced composite foundation fcps can be evaluated by adding the bearing capacity of the vertical pile composite foundation fps and the increased bearing capacity Δf by the horizontal reinforcement together:

![]() (6)

(6)

4 Model test study

4.1 Model test

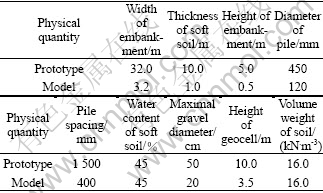

A foundation treatment project in Linchang road, which is a section of Jinzhu highway, was applied as a prototype. According to the similarity theory, four model tests were designed[6]. They are: soft soil foundation (untreated, model test 1), geocell reinforced foundation (model test 2), gravel pile composite foundation (model test 3), and geocell reinforced gravel cushion and gravel pile composite foundation(model test 4). Main parameters of these four model tests were estimated by dimensional method[6], as shown in Table 1.

Table 1 Main parameters of model tests

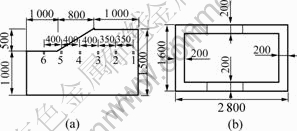

Fig.4 shows the geometrical dimensions of the model test flume. The loading plate with dimensions of 1 160 mm×600 mm was located on the model embankment, and the jack on the upside of the loading plate was emplaced to supply an opposite force.

Fig.4 Physical dimension of model test flume (unit: mm)

(a) Section view; (b) Plan view

In the model test, the load was added step by step. Next step of load wouldn’t be exerted until the system was stable under a certain load. The load wouldn’t be stopped exerting until the settlement on the surface of the model embankment reached its allowable value, or the embankment tended to be slipping or caught its shear failure.

4.2 Experimental data analysis

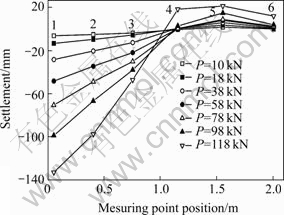

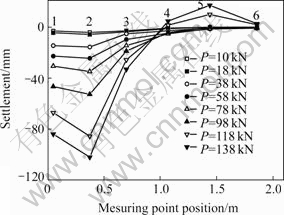

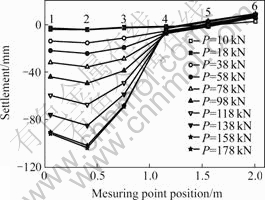

Figs.5-8 show Q-s curves in each test under every step of load. From right to left, measurement points near the midline of the model embankment surface are signed from 1 to 6. Among these 6 points, points 1 to 5 are located under the model embankment as shown in Fig.4.

From Figs.5-8, it is demonstrated that the two-direction reinforced composite foundation formed by geocell reinforced gravel cushion and gravel pile composite foundation can be used to enhance the bearing capacity of the soft soil foundation and reduce its total and differential settlements effectively. Furthermore, the effect induced by the two-direction reinforced composite foundation is much greater either than that induced by single geocell reinforced gravel cushion or than that induced by single gravel pile composite foundation.

Fig.5 Cumulative settlement curves of observation points of test 1

Fig.6 Cumulative settlement curves of observation points of test 2

Fig.7 Cumulative settlement curves of observation points of test 3

Fig.8 Cumulative settlement curves of observation points of test 4

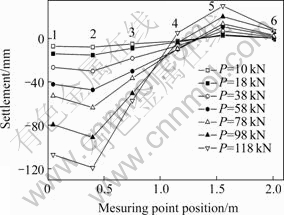

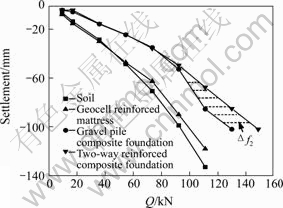

Q-s curves of point 2 in each test in Fig.9 indicate that the bearing capacity enhanced by two-direction reinforced composite foundation is greater than that enhanced by one-direction reinforcement. The bearing capacity of the reinforced foundation (either one-direction reinforced foundation or two-direction reinforced foundation) is much greater than that of the soft soil foundation untreated. As presented in Fig.9, when the settlement is 40 mm, the bearing load of the soft soil foundation is 49.8 kN, while that of the two-direction reinforced composite foundation is 83.5 kN, increased by 67.67 %.

Fig.9 Q-s curves of point 2 in each test

Broken lines in Fig.9 show the difference values of bearing capacities between the two-direction reinforced composite foundation and the single gravel pile composite foundation that reinforced in vertical direction. This difference represents the bearing capacity increased by geocell reinforcement.

It should be noted that the following expressions exist according to the fact of the model test, Ac =Ag≈ A, Δf1≈0, so Δf =Δf2.

4.3 Comparison

As shown in Fig.8, from points 1 to 5, the cumulative settlement at point 2 is the biggest, while that at point 5 is the smallest, and thus the differential displacement between these two points can be treated as the maximal flexure of the geocell material.

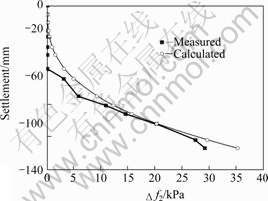

Fig.10 indicates the comparison between the calculated Δf2 and the measured one. When calculating, the diffusion angle of the embankment is assumed be 20?, and tensile yield strength of 8.5 MPa is used for geocell material.

Fig.10 Comparison between measured and calculated Δf2

From Fig.10, the calculated values are much closed to the measured values. Figs.9- 10 show that the vertical component of tension force of geocell reinforcement is limited when the distortion of the geocell reinforcement is small. But in the later load service period, Δf2 increases quickly with the development of the distortion, until the distortion of the geocell reinforcement approaches its ultimate allowable value. Obviously, this enhancing effect should be take into account in engineering design.

5 Conclusions

1) Two-direction reinforced composite foundation, a new type of innovative foundation treatment, has an advantage of enhancing the bearing capacity of the embankment foundation by associating with the use of the horizontal reinforcement and the vertical reinforcement. In parallel, the total and differential settlements on the surface of embankment can be reduced due to the presences of these two directional reinforcements.

2) Based on the discussion about the working mechanism of two-direction reinforced composite foundation, a simplified bearing capacity calculation method considering the distribution of tension in geosynthetic reinforcement was proposed. This method is easy to be applied to engineering practices.

3) When the method presented was applied to analyzing a model test, the calculated curve is closed to the measured one. The distribution of tension in geosynthetic shows that the bearing capacity of foundation can be enhanced by about 68% at a normal displacement. So this enhancing effect by geosynthetic reinforcement should be taken into account in engineering design.

References

[1] ZHAO Ming-hua, LIU Yu, CAO Wen-gui. The developing regularity and forecasting of settlement in soft clay roadbed[J]. Journal of Central South University of Technology: National Science, 2004, 35(1): 157-161. (in Chinese)

[2] LI Yu-feng, HU Rui-ning. The formation and countermeasures to subgrade uneven sedimentation[J]. Journal of Chongqing Jiaotong University, 2006, 25(S1): 85-88.(in Chinese)

[3] CHEN Hong-you, LI Bin. Application of the geosynthetic-reinforced and pile-supported earth platform in Tan-Shao freeway[J]. Central South Highway Engineering, 2002, 27(1): 40-41, 44. (in Chinese)

[4] JIANG Peng-fei, CHEN Chang-fu, ZHAO Ming-hua, et al. Application and research on geocell and gravel pile composite foundation in soft ground treatment in express-way[J]. Highway, 2006, 42(4): 135-139. (in Chinese)

[5] HAN J, AKINS K. Case studies of geogrid-reinforced and pile-supported earth structures on weak foundation soils[C]// O?Neill and Towsend, Proceedings of International Deep Foundation Congress, Orlando, ASCE, 2002: 668-679.

[6] CHEN Yan-ping, ZHAO Ming-hua, CHEN Chang-fu, et al. Similarity model test of geocell reinforced gravel mattress and gravel pile composite foundation[J]. China Journal of Highway and Transport, 2006, 19(1): 17-22. (in Chinese)

[7] CAO Xin-wen, QING San-hui, ZHOU Li-xin. Experimental study on reinforcement effect of geogrid on composite foundation with dry jet mixing piles[J]. Chinese Journal of Rock Mechanics and Engineering, 2006, 25(S1): 3162-3167.(in Chinese)

[8] HAN J, GABR M A. Numerical analysis of geosynthetic reinforced and pile supported earth platforms over soft soil[J]. Journal of Geotechnical and Geoenvironmental Engineering, ASCE, 2002, 128(1): 44-53.

[9] WANG M C, FENG Y X, JAO M. Stability of geosynthetic reinforced soil above a cavity[J]. Geotextiles and Geomembranes, Elsevier, 1996, 14(1): 95-109.

[10] ZHAO Ming-hua, CHEN Yan-ping, CHEN Chang-fu, et al. Stability analysis of geocell + gravel cushion structure[J]. Journal of Hunan University: Natural Science, 2003, 30(2): 68-72. (in Chinese)

[11] LATHA G M, RAJAGOPAL K, KRISHNASWAMY N R. Experimental and theoretical investigations on geocell-supported embankments[J]. International Journal of Geomechanics, ASCE, 2006, 6(1): 30-35.

[12] MICHAEL T A, JAMES G C. Large model spread footing load tests on geosynthetic reinforced soil foundations[J]. Journal of Geotechnical and Geoenvironmental Engineering, ASCE, 1997, 123(1): 66-72.[13] LI Li, FU Jian-feng. The reinforcement mechanism and status in application and study of geocell[J]. Shanxi Science and Technology of Communications, 2003, 31(S1): 63-65. (in Chinese)

[14] GONG Xiao-nan. Design of Composite Foundation and Construction Guide[M]. Beijing: People Traffic Press, 2003: 106-108.(in Chinese)

[15] GONG Xiao-nan. Composite foundation introduction (Ⅱ)[J]. Foundation Treatment, 1991, 2(4): 1-11. (in Chinese)

_______________________

Foundation item: Project (2006AA11Z104) supported by the National High-Tech Research and Development Program(“863” Program)

Received date: 2006-11-18; Accepted date: 2007-03-05

Corresponding author: ZHANG Ling, Doctorial candidate; Tel:+86-731-8821659; E-mail: zhanglhd@163.com

- Working mechanism of two-direction reinforced composite foundation