Comparison of as-cast microstructure, tensile and creep properties

for Mg-3Sn-1Ca and Mg-3Sn-2Ca magnesium alloys

YANG Ming-bo(杨明波)1, 2, CHENG Liang(程 亮)1, PAN Fu-sheng(潘复生)2

1. Materials Science and Engineering College, Chongqing University of Technology, Chongqing 400050, China;

2. National Engineering Research Center for Magnesium Alloys, Chongqing University, Chongqing 400045, China

Received 3 April 2009; accepted 13 September 2009

Abstract:

The as-cast microstructure, tensile and creep properties of Mg-3Sn-1Ca and Mg-3Sn-2Ca magnesium alloys were investigated and compared by using optical microscopy and scanning electron microscopy, X-ray diffraction analysis and tensile tests. The results indicate that the as-cast microstructures of Mg-3Sn-1Ca and Mg-3Sn-2Ca alloys are different. The former is mainly composed of a-Mg, eutectic CaMgSn and solid state precipitation of Mg2Sn, whereas the latter is mainly composed of a-Mg, primary CaMgSn, eutectic CaMgSn and Mg2Ca phases. As a result, the two alloys obtain different tensile and creep properties. Mg-3Sn-1Ca alloy shows relatively higher ultimate tensile strength and elongation at room temperature and 150 ℃ than Mg-3Sn-2Ca alloy, however, the yield strengths of Mg-3Sn-1Ca alloy at room temperature and 150 ℃ are relatively low. In addition, the creep properties of Mg-3Sn-1Ca alloy at 150 ℃ and 70 MPa for 100 h are obviously lower than those of the Mg-3Sn-2Ca alloy.

Key words:

magnesium alloy; CaMgSn phase; Sn; Ca; mechanical properties;

1 Introduction

Magnesium alloys are the lightest commercially available structural alloys and have great potential for applications in automotive, aerospace industries and others. In recent years, improving the elevated temperature properties has become a critical issue for possible application of magnesium alloys in heat- resistant components[1-3]. It is well known that Sn not only can improve corrosion resistance but also can form a stable Mg2Sn compound with Mg, and Ca can improve creep resistance by forming stable Mg2Ca intermetallic particles with Mg[4-5]. In addition, Sn, Ca and Mg can form the CaMgSn phase which has higher thermal stability[6-7]. Therefore, a new corrosion- and creep- resistant magnesium alloys based on Mg-Sn-Ca system have received much global attention and some research about Mg-3Sn-1Ca and Mg-3Sn-2Ca alloys which are regarded as two potential magnesium alloys is being pursued[8-9].

Based on the Calphad method and combined some key experiments, KOZLOV et al[10-11] predicted the solidification microstructure of the Mg-3Sn-1Ca and Mg-3Sn-2Ca alloys, and found that the solidification structures of the two alloys are different. The former is mainly composed of α-Mg, CaMgSn and Mg2Sn phases, while the latter is mainly composed of α-Mg, CaMgSn and Mg2Ca phases. Obviously, different solidification structures of Mg-3Sn-1Ca and Mg-3Sn-2Ca alloys result in different mechanical and corrosion-resistant properties. LEIL et al[12-13] investigated the corrosion behavior of the as-cast and extruded Mg-3Sn-1Ca and Mg-3Sn-2Ca alloys, and found that the corrosion-resistant properties of the as-cast and extruded Mg-3Sn-1Ca alloys are higher than those of the as-cast and extruded Mg-3Sn-2Ca alloys. The mechanism is considered to be mainly related to the present phases in the two alloys, with Mg2Sn being the most compatible, followed by CaMgSn and finally Mg2Ca. Though the difference of corrosion-resistant properties for the Mg-3Sn-1Ca and Mg-3Sn-2Ca alloys was researched in the above work, the investigation about the effect of microstructural difference on the tensile and creep properties of the two alloys was very scarce. Up to now, only LEIL et al[14] gave a preliminary result that the Mg-3Sn-2Ca alloy has relatively high creep properties as compared to the Mg-3Sn-1Ca alloy. However, the corresponding reason is not reported. In order to provide a theoretical guide for the development of Mg-Sn-Ca based magnesium alloys, the present work investigates and compares the as-cast microstructure, tensile and creep properties of the Mg-3Sn-1Ca and Mg-3Sn-2Ca alloys, and the mechanism for the difference in tensile and creep properties is also analyzed.

2 Experimental

The experimental alloys were prepared from pure Mg and Sn (>99.9%), and Mg-19%Ca (mass fraction) master alloys. The experimental alloys were melted in a crucible resistance furnace and protected by a flux addition. After the Mg-Ca master alloy was added to the melt at 740 ℃, the melt was mixed by mechanical stirring, then held at 740 ℃ for 20 min and poured into a preheated permanent mould. After that, the samples of the experimental alloy were subjected to a solution heat treatment (500 ℃, 6 h, water cooled) in order to examine the microstructural stability at high temperatures. The specimens whose size has been reported in Ref.[15] were fabricated from the casting for tensile and creep tests. The actual chemical compositions of the experimental alloys are listed in Table 1.

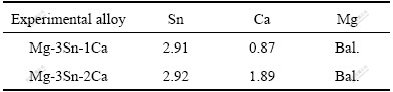

Table 1 Actual composition of experimental alloys (mass fraction, %)

The samples were etched with an 8% nitric acid distilled water solution, and then were examined using an Olympus optical microscope and JEOL/JSM-6460LV type scanning electron microscope (SEM) equipped with Oxford energy dispersive spectrometer (EDS) with an operating voltage of 20 kV. The phases in the experimental alloys were analyzed by D/Max-1200X type X-ray diffractometer (XRD) operated at 40 kV and 30 mA. The tensile properties of the experimental alloys at room temperature and 150 ℃ were determined from a complete stress-strain curve. The ultimate tensile strength (UTS), yield strength (YS) and elongation to failure were obtained based on the average of three tests. The constant-load tensile creep tests were performed at 150 ℃ and 70 MPa for creep extension up to 100 h. The total creep strain and minimum creep rates of the experimental alloys were respectively measured from elongation—time curve and the results were averaged over three tests.

3 Results and discussion

3.1 As-cast microstructure

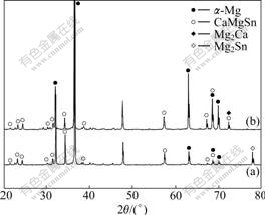

Fig.1 shows the XRD patterns of the as-cast experimental alloys. According to the XRD results, the Mg2Sn and Mg2Ca phases are respectively detected besides the CaMgSn phase in both the Mg-3Sn-1Ca and Mg-3Sn-2Ca alloys. Similar results were reported in the previous study[11]. It is proposed that in the Mg-3Sn-1Ca and Mg-3Sn-2Ca alloys, existing Ca and Sn are first used to develop the CaMgSn particles and the remaining amounts of Sn and Ca eventually form the Mg2Sn and Mg2Ca phases. The formation of Mg2Sn and Mg2Ca phases can be expected on the basis of the respective binary phase diagrams of Mg-Sn and Mg-Ca systems depending on the amount of alloying elements added. Further discussion will be carried out in the following section.

Fig.1 XRD patterns of as-cast alloys: (a) Mg-3Sn-1Ca; (b) Mg- 3Sn-2Ca

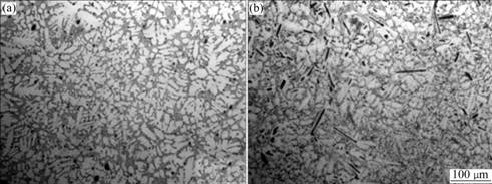

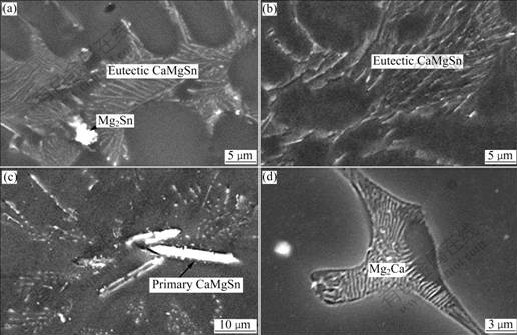

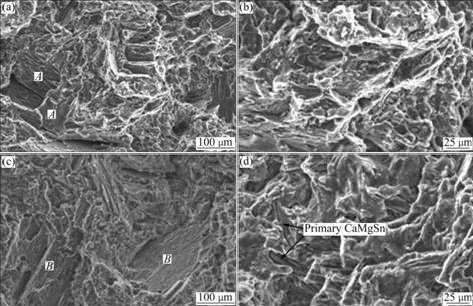

Figs.2 and 3 show the optical and SEM images of the as-cast experimental alloys, respectively. It is found from Fig.2 that the experimental alloys are composed of α-Mg and secondary solidification phases (grey and black precipitates). The black secondary phases in the Mg-3Sn-1Ca alloy mainly exhibit a fine particle-like morphology, while the black secondary phases in the Mg-3Sn-2Ca alloy mainly exhibit a coarse needle-like morphology. Combined XRD and EDS results, the grey second phases that are the major secondary phase in the two alloys are identified as feather-like eutectic CaMgSn (Figs.3(a) and (b)), the black phases with a small amount in the Mg-3Sn-1Ca and Mg-3Sn-2Ca alloys are Mg2Sn and primary CaMgSn (Figs.3(a) and (c)), respectively. In addition, the Mg2Ca phases with a small amount in the Mg-3Sn-2Ca alloy mainly exhibit a lamellar morphology (Fig.3(d)).

Fig.2 Optical images of as-cast alloys: (a) Mg-3Sn-1Ca alloy; (b) Mg-3Sn-2Ca alloy

Fig.3 SEM images of as-cast alloys: (a) Mg-3Sn-1Ca alloy; (b)-(d) Mg-3Sn-2Ca alloy

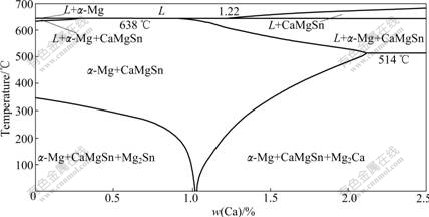

The above results indicate that the as-cast microstructures of Mg-3Sn-1Ca and Mg-3Sn-2Ca alloys are different. In the Mg-3Sn-2Ca alloy, besides Mg2Ca phase the feather-like eutectic and needle-like primary CaMgSn phases are present. However, in the Mg-3Sn-1Ca alloy only the feather-like eutectic CaMgSn phase besides Mg2Sn phase is observed. Since the critical low limit for the primary CaMgSn crystallization in the Mg-3Sn-xCa alloys is at 1.22% Ca (mass fraction)[11], the microstructural difference between the two alloys may be easily explained according to the phase diagrams of the two alloys. Based on the calculated vertical phase diagram section of the Mg-Sn-Ca alloys with a constant Ca content of 2.0% (mass fraction) (Fig.4), the needle-like CaMgSn phase in the Mg-3Sn-2Ca alloy forms as a primary solidification phase when passing through L+CaMgSn region during solidification. Then, at the later stage of solidification, the pseudo binary eutectic reaction (L→a-Mg+CaMgSn) and ternary eutectic reaction (L→a-Mg+CaMgSn+Mg2Ca) occur at about 638 ℃ and 514 ℃, respectively, resulting in the formation of the feather-like CaMgSn phase and Mg2Ca phase. However, it is observed from Fig.4 that in the Mg-3Sn-1Ca alloy only the binary eutectic reaction (L→a-Mg+CaMgSn ) occurs at about 638 ℃, which results in the formation of the feather-like CaMgSn phase. Then, along with the temperature decreasing the solid solubility of Sn in the a-Mg solid solution decreases, which results in the solid state precipitation of the particle-like Mg2Sn from the two-phase a-Mg+CaMgSn below 118 ℃.

Fig.4 Calculated vertical phase diagram sections of Mg-3Sn-Ca alloys [11]

3.2 Tensile properties

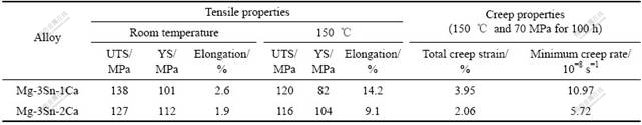

The tensile properties including ultimate tensile strength (UTS), yield strength (YS), elongation and creep properties of the as-cast experimental alloys are listed in Table 2. It is observed from Table 2 that the Mg-3Sn-1Ca alloy has relatively higher ultimate tensile strength and elongation at room temperature and 150 ℃ than the Mg-3Sn-2Ca alloy. This is possibly related to the detrimental effect of the coarse needle-like primary CaMgSn phase in the Mg-3Sn-2Ca alloy on the mechanical properties. Actually, the above results may be further confirmed by the tensile fracture surfaces of the as-cast alloys. Fig.5 shows the SEM images of the tensile fracture surfaces for the as-cast alloys tested at room temperature. As shown in Fig.5, cleavage planes and steps are present and some minute lacerated ridges can also be observed in the local areas of tensile fracture surfaces. Obviously, the tensile fracture surfaces of the two alloys have mixed characteristics of cleavage and quasi- cleavage fractures, indicating the fracture mechanism of the two alloys is similar. However, the fracture surface of Mg-3Sn-2Ca alloy exhibits relatively large cleavage-type facets (arrow ‘B’ in Fig.5(c)), and the cleavage-type facets in the fracture surface of Mg-3Sn-1Ca alloy are relatively small (arrow ‘A’ in Fig.5(a)). Furthermore, it is observed from Fig.5(d) that the fracture surface of Mg-3Sn-2Ca alloy shows some small cracks possibly resulting from primary CaMgSn phase.

Fig.5 SEM images of tensile fractographs for as-cast alloys tested at room temperature: (a, b) Mg-3Sn-1Ca alloy; (c, d) Mg-3Sn-2Ca alloy

Table 2 Tensile and creep properties of as-cast alloys

Furthermore, it is observed from Table 2 that the yield strength of Mg-3Sn-1Ca alloy at room temperature is lower than that of Mg-3Sn-2Ca alloy, and the former exhibits a significant decrease of yield strength as compared to the latter at 150 ℃. However, the reason for the difference in the yield strength for the two alloys is not completely clear. Further investigation needs to be carried out.

3.3 Creep properties

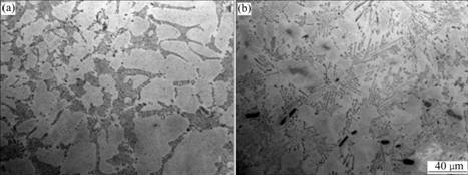

It is observed from Table 2 that the Mg-3Sn-1Ca and Mg-3Sn-2Ca alloys exhibit relatively high creep properties. Since the creep properties of magnesium alloys are mainly related to the structure stability at high temperatures, the solutionized microstructures of Mg-3Sn-1Ca and Mg-3Sn-2Ca alloys are examined (Fig.6). Compared with Figs.2 and 6, it is found that the solutionized microstructures of the two alloys seem to be similar to their as-cast microstructures. The CaMgSn phases in the two solutionized alloys are still observed clearly, indicating that the phase does not dissolve into the matrix after the solid solution heat treatment. Obviously, the high creep properties for the Mg-3Sn-1Ca and Mg-3Sn-2Ca alloys are mainly attributed to the CaMgSn phases due to their high thermal stability.

Fig.6 Optical images of solutionized alloys: (a) Mg-3Sn-1Ca alloy; (b) Mg-3Sn-2Ca alloy

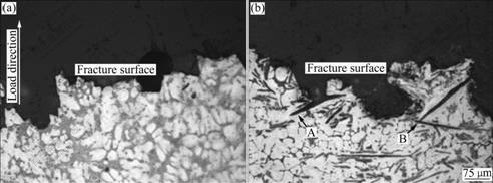

In addition, it is further found from Table 2 that the creep properties of Mg-3Sn-1Ca alloy at 150 ℃ and 70 MPa for 100 h are obviously lower than those of the Mg-3Sn-2Ca alloy. This is also possibly related to the microstructural difference of the two alloys. KIM et al [16] investigated the difference of creep properties between Mg-5Sn-1Ca and Mg-5Sn-2Ca alloys (the former is mainly composed of a-Mg, primary CaMgSn, eutectic CaMgSn and Mg2Sn, the latter is mainly composed of a-Mg, primary CaMgSn, eutectic CaMgSn and Mg2Ca), and found that the eutectic Mg2Ca phase in Mg-5Sn-2Ca alloy is more effective to inhibit grain boundary sliding during creep deformation than Mg2Sn phase in Mg-5Sn-1Ca alloy. Therefore, it is inferred that the higher creep properties of Mg-3Sn-2Ca alloy than those of the Mg-3Sn-1Ca alloy are possibly related to the different boundary strengthening mechanism of Mg2Sn and Mg2Ca phases in the two alloys. In addition, the high creep properties of Mg-3Sn-2Ca alloy are possibly related to the primary CaMgSn phases in the alloy because the coarse primary CaMgSn phases seem to inhibit grain rotation and crack extension during creep deformation (see arrows ‘A’ and ‘B’ in Fig.7(b)). However, this needs further confirmation. In spite of the above analysis, the exact reason for the difference in the creep properties for the Mg-3Sn-1Ca and Mg-3Sn-2Ca alloys is not completely clear. Further investigation still needs to be considered.

Fig.7 Optical images of as-cast alloys after creep rupture at 150 ℃ and 70 MPa: (a) Mg-3Sn-1Ca alloy; (b) Mg-3Sn-2Ca alloy

4 Conclusions

1) The as-cast microstructures of Mg-3Sn-1Ca and Mg-3Sn-2Ca alloys are different. The former is mainly composed of a-Mg, eutectic CaMgSn and solid precipitation of Mg2Sn, whereas the latter is mainly composed of a-Mg, primary CaMgSn, eutectic CaMgSn and Mg2Ca phases.

2) Mg-3Sn-1Ca alloy shows higher ultimate tensile strength and elongation at room temperature and 150 ℃ than Mg-3Sn-2Ca alloy. However, the yield strength of the Mg-3Sn-1Ca alloy at room temperature and 150 ℃ is lower than that of Mg-3Sn-2Ca alloy. In addition, the creep properties of Mg-3Sn-1Ca alloy at 150 ℃ and 70 MPa for 100 h are also obviously lower than those of Mg-3Sn-2Ca alloy. The different tensile and creep properties of the two alloys are possibly related to the microstructural difference of them.

3) Mg-3Sn-2Ca alloy has more potential as elevated temperature magnesium alloy due to its higher creep properties as compared to Mg-3Sn-1Ca alloy. However, the modification and refinement of primary CaMgSn phase in Mg-3Sn-2Ca alloy must be first considered in order to develop the alloy.

References

[1] LUO A, PEKGULERYUZ O. Review: Cast magnesium alloys for elevated temperature applications [J]. J Mater Sci, 1994, 29: 5259-5271.

[2] BAMBERGER M, DEHM G. Trends in the development of new Mg alloys [J]. Annual Review of Materials Research, 2008, 38: 505-533.

[3] YANG M B, PAN F S, ZHANG J, ZHANG J. An analysis of the development and applications of current and new Mg-Al based elevated temperature magnesium alloys [J]. Mater Sci Forum, 2005, 488/489: 923-926.

[4] HORT N, HUANG Y, KAINER K U. Intermetallics in magnesium alloys [J]. Adv Eng Mater, 2006, 8: 235-240.

[5] HUANG Y, HORT N, ABULEIL T, KAINER K U, LIU Y. Effect of microstructural inhomogeneity on creep response of Mg-Sn alloys [J]. Key Eng Mater, 2007, 345/346: 561-564.

[6] HORT N, HUANG Y, ABULEIL T, MAIER P, KAINER K U. Microstructural investigations of the Mg-Sn-xCa system [J]. Adv Eng Mater, 2006, 8: 359-364.

[7] RAO K P, PRASAD Y V, HORT N, HUANG Y, KAINER K U. High temperature deformation behaviour of a new magnesium alloy [J]. Key Eng Mater, 2007, 340/341: 89-94.

[8] PRASAD Y V R K, RAO K P, HORT N, KAINER K U. Optimum parameters and rate-controlling mechanisms for hot working of extruded Mg-3Sn-1Ca alloy [J]. Mater Sci Eng A, 2009, 502: 25-31.

[9] YANG Ming-bo, MA Yan-long, PAN Fu-sheng. Effects of little Ce addition on as-cast microstructure and creep properties of Mg-3Sn-2Ca magnesium alloy [J]. Transactions of Nonferrous Metals Society of China, 2009, 19(5): 1087-1092.

[10] KOZLOV A, OHNO M, ARROYAVE R, LIU Z K, SCHMID-FETZER R. Phase equilibria, thermodynamics and solidification microstructures of Mg-Sn-Ca alloys (Part 1): Experimental investigation and thermodynamic modeling of the ternary Mg-Sn-Ca system[ J]. Intermetallics, 2008, 16: 299-315.

[11] KOZLOV A, OHNO M, ABULEIL T, HORT N, KAINER K U, SCHMID-FETZER R. Phase equilibria, thermodynamics and solidification microstructures of Mg-Sn-Ca alloys (Part 2): Prediction of phase formation in Mg-rich Mg-Sn-Ca cast alloys [J]. Intermetallics, 2008, 16: 316-321.

[12] A B U LEIL T, HORT N, DIETZEL W, BLAWERT C, HUANG Y, KAINER K U, RAO K P. Microstructure and corrosion behavior of Mg-Sn-Ca alloys after extrusion [J]. Transactions of Nonferrous Metals Society of China, 2009, 19: 40-44.

[13] PRASAD Y V R K, RAO K P, HORT N, KAINER K U. Hot working parameters and mechanisms in as-cast Mg-3Sn-1Ca alloy [J]. Mater Letters, 2008, 62: 4207-4209.

[14] A B U LEILL T, HUANG Y, DIERING H, HORT N, KAINER KU, BURSIK J, JIRASKOVA Y, RAO K P. Effect of heat treatment on the microstructure and creep behavior of Mg-Sn-Ca alloys [J]. Mater Sci Forum, 2007, 546/549: 69-72.

[15] YANG M B, CHENG L, Pan F S. Comparison about effects of Ce, Sn and Gd additions on as-cast microstructure and mechanical properties of Mg-3.8Zn-2.2Ca(wt%) magnesium alloy [J]. J Mater Sci, 2009, 44: 4577-4586.

[16] KIM D H, LEE J Y, LIM H K, KYEONG J S, KIM W T, KIM D H. The effect of microstructure evolution on the elevated temperature mechanical properties in Mg-Sn-Ca system [J]. Mater Trans, 2008, 49: 2405-2413.

Foundation item: Project(50725413) supported by the National Natural Science Foundation of China; Project (2007CB613704) supported by the National Basic Research Program of China; Projects(2007BB4400 and KJ090628) supported by the Chongqing Science and Technology Commission and Education Commission of China

Corresponding author: YANG Ming-bo; Tel: +86-23-68667455; E-mail: yangmingbo@cqut.edu.cn

DOI: 10.1016/S1003-6326(09)60182-5

Abstract: The as-cast microstructure, tensile and creep properties of Mg-3Sn-1Ca and Mg-3Sn-2Ca magnesium alloys were investigated and compared by using optical microscopy and scanning electron microscopy, X-ray diffraction analysis and tensile tests. The results indicate that the as-cast microstructures of Mg-3Sn-1Ca and Mg-3Sn-2Ca alloys are different. The former is mainly composed of a-Mg, eutectic CaMgSn and solid state precipitation of Mg2Sn, whereas the latter is mainly composed of a-Mg, primary CaMgSn, eutectic CaMgSn and Mg2Ca phases. As a result, the two alloys obtain different tensile and creep properties. Mg-3Sn-1Ca alloy shows relatively higher ultimate tensile strength and elongation at room temperature and 150 ℃ than Mg-3Sn-2Ca alloy, however, the yield strengths of Mg-3Sn-1Ca alloy at room temperature and 150 ℃ are relatively low. In addition, the creep properties of Mg-3Sn-1Ca alloy at 150 ℃ and 70 MPa for 100 h are obviously lower than those of the Mg-3Sn-2Ca alloy.