Fracture behaviors of AZ80 magnesium alloy during multiple forging processes

GUO Qiang(郭 强), YAN Hong-ge(严红革), CHEN Zhen-hua(陈振华), ZHANG Hui(张 辉)

School of Materials Science and Engineering, Hunan University, Changsha 410082, China

Received 20 October 2005; accepted 20 March 2006

Abstract:

The initiation, propagation and the accompanied dislocation structures of the cracks in AZ80 magnesium alloy during multiple forging processes were investigated. The results show that the cracks firstly initiate at the Mg/Mg17Al12 interface under the hoop tensile stress on equatorial free surface. On further deformation, the cracks in the Mg17Al12 particles tend to propagate along the grain boundaries(GBs) in a zigzag pattern and link with adjacent cracks in other Mg17Al12 particles to form one whole crack, leading to the fracture surface. Low deformation temperature and too many forging passes during the deformation will promote the nucleation of interfacial microcrack inside the specimens due to the strong plastic strain incompatibility and the high internal stresses near the GBs. The loading axis rotating during the process can change the stress field at the tip of cracks, leading to the change of the crack propagating path and assisting in inhabiting microcracking development.

Key words:

AZ80 magnesium alloy; multiple forging; cracks; fracture behaviors;

1 IntroductionPure magnesium and magnesium alloys are the lowest density metals used as structural materials and have excellent specific strength and stiffness, machinability, dimensional stability, and excellent recycling capability. They are, therefore, very attractive in such applications as automobile, aviation, electronic and communication industry in the past few years[1]. As a consequence of their hexagonal closed packed (hcp) structure, magnesium alloys exhibit only limited formability at ambient temperatures and cracking easily occurs during their deformation process[2,3]. Cracking may nucleate during the processing either at inhomogeneities (e.g. inclusions, grain boundary impurities, second phases) or at pre-existing defects (e.g. triple junctions, pores)[4]. WANG et al[5] reported that fatigue crack initiation of cast AM50 alloy generally occurs on the boundary of α-Mg grains at the vicinal notch root because of stress concentration. LU et al[6] revealed the cleavage fracture of tensile tested AZ91 alloy and explained that the Mg/Mg17Al12 interface served as a crack initiation source. YUAN et al[7] also found that the creep microcracks of permanent casting AZ91 alloy without Sb addition initiated preferentially in the interface between discontinuous precipitation and the α-Mg grains. However, direct reports on observations of the microprocess of fracture in magnesium alloys during severe plastic deformation are rare. Further studies are needed to clarify the micromechanism of fracture, especially the initiation and propagation of microcracks and their interaction with the microstructure.

For this purpose, the fracture behaviors in AZ80 magnesium alloy during multiple forging processes were studied. OM, SEM and TEM were used to investigate the initiation, propagation and the accompanied dislocation structures of the cracks in the present study.

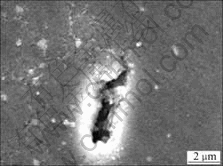

2 ExperimentalThe alloy used in the present study was Mg-Al-Zn alloy, AZ80, with the measured composition (mass fraction) of 8.5%Al, 0.5%Zn, and 0.12%Mn. Before deformation the cast ingot of the alloy was homogenized at 673 K for 15 h in order to reduce segregation. After solution treatment, the brittle eutectic phase Mg17Al12, which distributed continuously along the α grain bound- aries in alloys[8], was almost dissolved and minimum remained (Fig.1). Subsequent work consisted of sequen-

Fig.1 Microstructures of alloys: (a) Initial as-cast; (b) After heat treatment

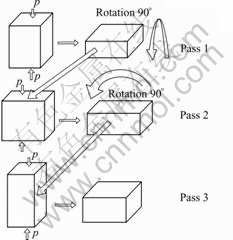

tial deformation of prismatic samples (110 mm×70 mm×60 mm) along three orthogonal directions on a 3.15 MN hydraulic press, which is shown in Fig.2. Machine oil mingled with graphite powder was used as lubricant between the interface of the anvil and the specimens. After deformation the samples were water quenched immediately to keep the microstructure. The initial press speed and the true strain per deformation step were 12.5 mm/s and about 0.4, respectively. The true strain was calculated as ln(h0/h), where h0 and h are the initial and final height, respectively.

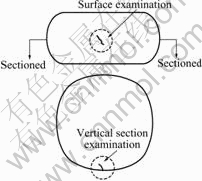

The fracture surface and metallographic sections perpendicular to the failure surface (vertical sections) of the rupture specimens (Fig.3) and at least 4 different regions of the deformed microstructures inside per specimen (Fig.4) were examined with MM-6 metallo- graphic microscope(OM), JSM-5610LV scanning electron microscopy(SEM) and H-800 transmission electron microscope(TEM), respectively.

3 Results and discussion

3.1 β-phase (Mg17Al12)-matrix interface cracking on surface

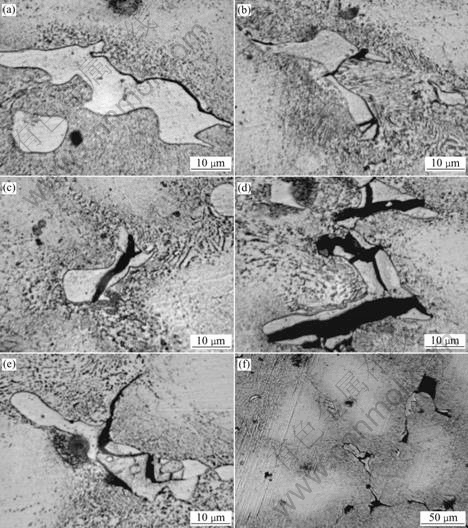

In the present study, the microcracks are observed to initiate firstly near the Mg/Mg17Al12 interface under the hoop stress at equatorial free surface of the samples during the deformation. The OM images from Fig.5 show a typical process of surface crack initiation and propagation. For the selected alloy, the body centered

Fig.2 Multiple forging deformation of AZ80 magnesium alloy

Fig.3 Microstructure examination of fracture surface

Fig.4 Microstructure examination at different regions labeled by × in specimen

cubic (bcc) structure of the intermetallic compound Mg17Al12 is incompatible with the hcp structure of magnesium matrix, which leads to the fragility of the Mg/Mg17Al12 interface during the deformation[6]. In addition, due to the limited slip systems in hcp magnesium alloys, the local stress concentration in the magnesium alloys can not be easily relaxed by plastic deformation compared with aluminum alloys[9]. There- fore, the separation occurs at the stress concentration sites in the Mg/Mg17Al12 interface, as shown in Fig.5(a). This separation usually takes place nearly perpendi- cularly to the maximum tensile stress axis when the applied stress exceeds the poor adhesion strength in the Mg/Mg17Al12 interface[10]. As the forging test proceeds, the separation becomes more and more intensive, and

Fig.5 Formation and propagation of cracks at β phase-matrix interface on surface: (a) Separation occurring at Mg/Mg17Al12 interface; (b) Cracks nucleating at separation sites; (c) Cracks propagating at Mg17Al12 particles; (d) Cracks intercrossing in Mg17Al12 particles; (e) Crack propagating along grain boundaries in matrix; (f) Cracking coalescencing

with the increasing of applied stress, the cracks initiate at the separation sites (Fig.5(b)). Crack nucleation is the primary deformation mechanism by which the interfacial stress concentration is relieved[11]. At the same time, Mg17Al12 itself is relatively soft and has poor strength[12]. Therefore, the cracks propagate first in the Mg17Al12 particles (Fig.5(c)). It is noted that due to the characterization of multiple forging (the loading axis rotating), there easily occurs the intercrossing cracking in the Mg17Al12 particles (the detail will be discussed in the following part), as shown in Fig.5(d). On further deformation, the cracking in the Mg17Al12 particles tends to propagate along the grain boundaries(GBs) in a zigzag pattern (Fig.5(e)) and links with adjacent cracking in other Mg17Al12 particles to form one whole cracking (Fig.5(f)), leading to the fracture surface.

3.2 Cracking inside specimens

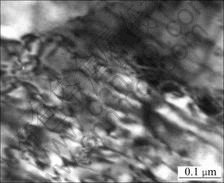

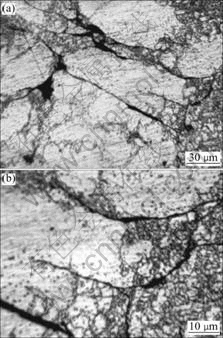

If the deformation temperature is low or the number of forging pass is too large (its effect is equivalent to decreasing deformation temperature) during the deformation, there will likely exist cracking inside the specimens. The mechanism of the cracking inside the specimens is different from that on the surface, and crack does not nucleate near the Mg/Mg17Al12 interface. Fig.6 shows the morphologies of the second phase Mg17Al12 inside the specimens during the deformation. Although there also exist some separations at the Mg/Mg17Al12 interface, these separations cannot develop into cracks due to the local high hydrostatic pressure. However, under the present deformation conditions of large strain, the misorientation of the GBs increases with increasing strain[13,14], leading to a large difference in the slip directions of two adjacent grains and the dislocation will be blocked at the interface between different grains effectively (Fig.7). The piling-up of dislocations at the GBs indicates that strong plastic strain incompatibility and higher stress concentration near the GBs may exist [15]. Upon further deformation, the internal stresses produced by the inhomogeneously distributed grain boundary dislocations will strengthen the local distortion [16,17]. In addition, there is lack of enough slip systems to accommodate the strain incompatibility between the grains in magnesium alloys[5]. Therefore, the nucleation of interfacial crack is possible when the distortion degree at a site exceeds a critical value, as shown in Fig.8. After initiation, the interfacial crack goes through its propagated process along the serrated α-Mg GBs (Fig.9(a)) and even extends into the inner of grains during the deformation (Fig.9 (b)).

Fig.6 Morphologies of Mg17Al12 particle inside specimens with different passes and strain values (Arrows indicate separations existed at Mg/Mg17Al12 interface): (a) 4 passes, ε=1.82; (b) 7 passes, ε=3.2

Fig.7 TEM image of dislocation piling-up at grain boundary

Fig.8 Secondary electron image of nucleation of interfacial crack

Fig.9 Propagating path of interfacial cracks: (a) Cracks propagating along serrated α-Mg GBs; (b) High magnification image of cracks extending into grain interiors

3.3 Cracking characterization of multiple forging materials

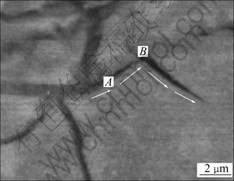

Multiple forging, as one of severe plastic deformation(SPD) methods, assumes multiple repeats of a free forging operations: setting-drawing. Compared with other deformation processings such as rolling or uniaxial compression, the principle of multiple forging is a change of the axis of the applied load during the process, which not only has a great influence on the refinement of microstructure[17-19] but also assists in inhabiting cracking development. It is known that the fracture behavior is usually caused by the tensile stress and cracks propagate in a direction approximately perpendicular to the maximum tensile stress[9, 20]. Once the applied loading axis rotates during the deformation, the stress field at the tip of cracks will change, leading to the change of the crack propagating direction. Fig.10 shows a crack propagating path changing with the load axis rotation. Crack A initially propagates along the GBs ahead. When its tip arrives at position B, the crack transforms its path and propagates in a direction nearly perpendicular to the original one designated by the arrows due to the change of maximum tensile stress caused by the loading axis rotating. Therefore, there are some cracks with different orientations in a local area and these cracks easily encounter each other. When a crack (Ⅰ) encounters another one (Ⅱ) with a different orientation, it would be blocked by the other crack and stop propagating, as shown in Fig.11.

Fig.10 Backscattered electron image of crack propagating path changing with load axis rotation

Fig.11 Backscattered electron image of encountering cracks each other

4 Conclusions

The fracture behaviors in AZ80 magnesium alloy during multiple forging processes have been studied. The mechanisms of cracking on the surface and inside the specimens are different. For the former, the cracks firstly initiate in the Mg/Mg17Al12 interface under the hoop tensile stress on equatorial free surface during the deformation. But in the case of the latter, the strong plastic strain incompatibility and the high internal stresses near the GBs strengthen the local distortion and promote the nucleation of interfacial crack upon further deformation. The loading axis rotating during defor- mation process changes the stress field at the tip of cracks, leading to the change of the crack propagating path and assisting in inhabiting cracking development.

References[1] MORDIKE B L, EBERT T. Magnesium properties-applications- potential [J]. Mater Sci Eng A, 2001, A302: 37-45.

[2] KOIKE J, OHYAMA R. Geometrical criterion for the activation of prismatic slip in AZ61 Mg alloy sheets deformed at room temperature [J]. Acta Mater, 2005, 53: 1963-1972.

[3] OGAWA N, SHIOMI M, OSAKADA K. Forming limit of magnesium alloy at elevated temperatures for precision forging [J]. Int J Mach Tool Manu, 2002, 42(5): 607-614.

[4] STAEHLER J M, PREDEBON W W. Micromechanisms of deformation in high-purity hot-pressed alumina [J]. Mater Sci Eng A, 2000, A291: 37-45.

[5] WANG X S, LU X, WANG D H. Investigation of surface fatigue microcrack growth behavior of cast Mg-Al alloy [J]. Mater Sci Eng A, 2004, A364: 11-16.

[6] LU Y Z, WANG Q D, DING W J. Fracture behavior of AZ91 magnesium alloy [J]. Mater Lett, 2000, 44: 265-268.

[7] YUAN G Y, WANG Q D, DING W J. High temperature deformation behavior of permanent casting AZ91 alloy with and without Sb addition [J]. J Mater Sci, 2002, 37: 127-132.

[8] KLEINER S, BEFFORT O, UGGOWITZER P J. Microstructure evolution during reheating of an extruded Mg-Al-Zn alloy into the semisolid state [J]. Scripta Mater, 2004, 51: 405-410.

[9] ZHENG M Y, ZHANG W C, WU K, YAO C K. The deformation and fracture behavior of SiCw/AZ91 magnesium matrix composite during in-situ TEM straining [J]. J Mater Sci, 2003, 38: 2647-2654.

[10] KLEINER S, BEFFORT O, WAHLEN A, UGGOWITZER P J. Microstructure and mechanical properties of squeeze cast and semi-solid cast Mg-Al alloys [J]. J Light Met, 2002, 2: 277-280.

[11] YOO M H, ZOU J, FU C L. Mechanistic modeling of deformation and fracture behavior in TiAl and Ti3Al [J]. Mater Sci Eng A, 1995, A192/193: 14-23.

[12] POLMEAR I J. Recent developments in light alloys [J]. Mater Trans, JIM, 1996, 37: 12-31.

[13] KIM H K, KIM W J. Microstructural instability and strength of an AZ31 Mg alloy after severe plastic deformation [J]. Mater Sci Eng A, 2004, A385: 300-308.

[14] VALIEV R Z, ISLAMGALIEV R K, ALEXANDROV I V. Bulk nanostructured materials from severe plastic deformation [J]. Prog Mater Sci, 2000, 45: 103-189.

[15] JIANG H, ZHU Y T, BUTT D P. Microstructural evolution, microhardness and thermal stability of HPT-processed Cu [J]. Mater Sci Eng A, 2000, A290: 128-138.

[16] LI Y, LI S X, LI G Y. The dislocation structure evolution of deformation band and crack formation in a copper bicrystal with a perpendicular grain boundary [J]. Mater Sci Eng A, 2004, A372: 221-228.

[17] BELYAKOV A, SAKAI T, MIURA H, KAIBYSHEV R. Substruc- tures and internal stress developed under warm severe deformation of austenitic stainless steel [J]. Scripta Mater, 2000, 42: 319-325.

[18] BELYAKOV A, SAKAI T, MIURA H, TSUZAKI K. Grain refinement in copper under large strain deformation [J]. Philo Mag A, 2001, 18(11): 2629-2643.

[19] BELYAKOV A, GAO W, MIURA H, SAKAI T. Strain-induced grain evolution in polycrystalline copper during warm deformation [J]. Metall Mater Trans A, 1998, 29A: 2957-2965.

[20] CHENG W C, LIN Y C, LIU C F. The fracture behaviors in an Fe-Mn-Al alloy during quenching processes [J]. Mater Sci Eng A, 2003, A343: 28-35.

Foundation item: Project(04GK1008-1) supported by the Major Program of Science and Technology of Hunan Province; Project(03JKY1016) supported by the Key Program of Science and Technology of Hunan Province

Corresponding author: YAN Hong-ge; Tel/Fax: +86-731-8821648; E-mail: yanhg68@163.com