J. Cent. South Univ. (2012) 19: 1673-1678

DOI: 10.1007/s11771-012-1192-1![]()

Pretreatment of hypersaline mustard wastewater with integrated bioreactor

HE Qiang(何强), ZHANG Ting-ting(张婷婷), CHAI Hong-xiang(柴宏祥),

YANG Shi-wei(杨士伟), ZHOU jian(周健), DU Guo-jun(杜国军)

Key Laboratory of Three Gorges Reservoir Region’s Eco-Environment (Chongqing University),

Ministry of Education, Chongqing 400045, China

? Central South University Press and Springer-Verlag Berlin Heidelberg 2012

Abstract:

A full-scale experimental study of treating mustard wastewater by the integrated bioreactor with designed scale of 1 000 m3/d is conducted combined with a demonstration project. The systematical researches on the efficiency of combined operation conditions of anaerobic-aerobic and anaerobic-aerobic-flocculation as well as chemical phosphorus removal of hypersaline mustard wastewater are conducted. The optimal operation condition and parameters in pretreatment of mustard wastewater in winter (the water temperature ranges 8-15 ℃) are determined: the anaerobic load is 3.0 kg (COD)/(m3·d), the average COD and phosphate concentration of the inflow are respectively 3 883 mg/L and 35.53 mg/L and the dosage of flocculent (PAC) is 400 mg/L. The anaerobic-aerobic-flocculation combined operation condition and postpositive phosphorous removal with ferrous sulfate are employed. After treatment, the COD of the effluent is 470 mg/L and the average phosphate concentration is 5.09 mg/L. The effluent could achieve the third-level of Integrated Wastewater Discharge Standard (GB 8978—1996).

Key words:

1 Introduction

In the process of biological treatment for hypersaline wastewater, high salinity may lower the microbial metabolism, leading to the death of microorganism due to cell rupture and deterioration of biochemical treatment effects [1]. In addition, it will also lead to a bad influence on microbial flocculation and lower the sedimentation performance of sludge [2]. High salinity will also have negative impacts on the efficiency of organics removal, nitrification, denitrification and biological phosphorous removal [3] and the change of salinity will destroy the stability of biological treatment system [4].

At present, biological treatment processes of hypersaline wastewater mainly include aerobic and anaerobic processes. CRISTINA et al [5] used constructed wetland to treat tannery wastewater with variable concentrations of organic pollutants (COD 68- 425 mg/L) and high salinity (2.2-2.6 g Cl-/L-1). By using the salt tolerant plant species, the removal efficiency of COD could reach 80% and the removal efficiency of total P and total Kjeldahl nitrogen could reach 93% and 90% at most. BORAN et al [6] inoculated halophilic bacteria in SBR to treat wastewater with salinity of 3%. After the reactor reached quasisteady state, the degradation rate of organics increased by 67% and the nitrification rate increased by 39%. The research of WINDEY et al [7] demonstrated that nitrification efficiency could be enhanced when the salinity was lower than 4.12 g/L NaCl. Exceeding this limit, the nitrification rate would decrease dramatically.

In the anaerobic biological treatment processes, the adaptation of anaerobic microorganisms to salinity and the antagonism existing among different ions will mitigate the toxicity of salt on microorganisms. Compared to aerobic biological treatment, the anaerobic treatments are characterized with low energy consumption, low yield of sludge and generation of clean energy. Therefore, the anaerobic treatment technology is one of the most important methods in treating wastewater with high salinity and high organics concentration at present. Researchers have done many experimental studies on treating saliferous wastewater by various anaerobic processes. GUERRERO et al [8] used mesothermal anaerobic filter chamber to treat wastewater produced by manufacturing marine products and the results demonstrated that the duration of domestication stage had a crucial effect on the steady systematic operation. MONHAN et al [9] studied the influence of recirculation on the performance of ASBBR treated hypersaline composite chemical wastewater and the results showed that the maximum COD removal efficiency was observed at recirculation-to-feed (R/F) ratio of 2. ZHOU et al [10] adopted ASBBR reactor to treat mustard wastewater with high salinity and high organics concentration and the results showed that increasing biofilm density and adding betaine could improve the COD removal efficiency in winter.

Mustard wastewater is a kind of composite wastewater which is featured by high chloride content of 1%-4%, high organics concentration and high nitrogen and phosphorus concentrations. District Fuling of Chongqing is the biggest manufacture area and market of mustard in China. The manufacture processes produce about five million ton wastewater every year. If the wastewater discharges without any treatment, the high organics concentration will accelerate eutrophication of Three Gorges Reservoir and high salinity will destroy the edaphic physiological activity and will lead to the collapse of edaphic ecosystem [11-12]. At present, the main technologies for treating mustard wastewater in China include ASBBR [10], UASB-aerobic-coagulation process [13], and hydrolytic acidification-SBR- coagulation process [14] etc. FENG et al [15] proved by experiments that Fenton-like reagents oxidation process for treating hypersaline mustard wastewater had a high COD removal efficiency.

However, most of the technologies remain in the stage of laboratory research and are not fit for engineering application. This full-scale experimental study combined with a demonstrative project is carried out on the early basis of lab-scale and pilot-scale experimental researches [16-18] of mustard wastewater treatment. The integrated bioreactor with designed scale of 1 000 m3/d in Lidu Industrial Estate in District Fuling of Chongqing is constructed to accomplish the full-scale experimental research.

2 Materials and methods

2.1 Regulating tank and integrated bio-reactor

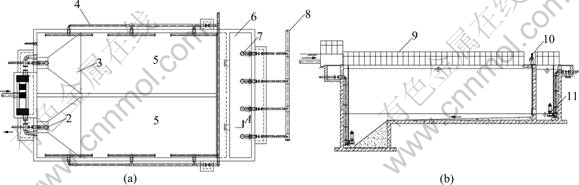

The structure of regulating tank is shown in Fig. 1 with designed volume of 1 000 m3. It is divided into two tanks which can be used alternately. Each tank is set up with a strengthened pretreatment macro-bubble aeration system and spherical suspended combined filler with the packing ratio of 20%. The aeration system can improve dissolved oxygen (DO) of the regulating tank and develop an aerobic condition inside the tank, improving the microbial degradation of the substrate. The filler can increase the amount of attached biomass and realize a better homogenization of water quantity and quality.

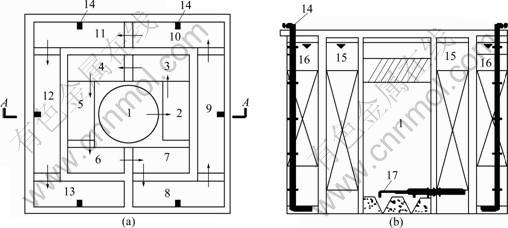

The integrated bio-reactor has a unique series hierarchical structure, which consists of three parts: central area, inner area and outer area. The inner area and outer area are both constituted by six reaction zones in series. The upper part and under part of every adjacent reaction areas are connected alternately. Semi-soft filler is added inside every reaction zone and aeration pipes are set up inside the reaction zones of outer areas. The integrated bioreactor is a new type of reactor combing different wastewater treatment processes. It is characterized with the advantages of AFB reactor and ABR reactor: effective mass transfer, high concentrations of microorganisms, strong resistance to organic load impact, good hydraulics conditions, strong retention of biological solids and strong resistance to toxic and hazardous substances. Moreover, the reactor is improved on the basis of the traditional treatment process of mustard wastewater. Integrated bio-reactor organically integrates aerobic and anaerobic treatment processes. The series reaction at all levels can not only develop plug-flow state, but also adjust the operation conditions according to ambient temperature and the quality of mustard wastewater, to improve the flexibility of reactor operation and reduce the cost of operation and management. The structure of integrated bioreactor is shown in Fig. 2.

2.2 Experimental water quality

This demonstrative project is constructed to treat the manufacturers in Lidu Industrial Estate, District Fuling, Chongqing City, China. The water quality is presented in Table 1.

Fig. 1 Structure of regulating tank: (a) Lay-out plan of regulating tank; (b) Cross-section drawing of regulating tank (1- Inlet pipe; 2-Sludge pump; 3-Sludge-collecting hopper; 4-Aeration pipe; 5-Regulating tank; 6-Catch basin; 7-Sewage pump; 8- Outlet pipe; 9-Railing; 10-Hoist; 11-Suction pipe)

2.3 Experiment design

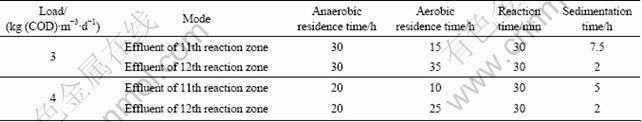

Based on the former lab-scale and pilot-scale experiments, the effluent of anaerobic and anaerobic- flocculation treatment processes could not meet the discharge standards. Therefore, the full-scale experimental study employed anaerobic-aerobic and anaerobic-aerobic-flocculation operation conditions and through testing and analyzing indicators such as COD, pH, temperature, salinity, DO, PO43--P, comparing the treatment efficiency under those two different operation conditions and determining the optimal parameters of the integrated bioreactor to run in winter. According to the quantity and quality of the experimental water, the anaerobic organic load of the integrated bioreactor was determined as follows: 2.0, 3.0 and 4.0 kg (COD)/(m3·d).

Anaerobic-aerobic operation condition was to set the inside reaction zones to be anaerobic while the outside reaction zones to be aerobic (DO is 6 mg/L), then increase the anaerobic organic load gradually and test the relevant indicators under different loads.

Anaerobic-aerobic-flocculation operation condition was to add the flocculation to the anaerobic-aerobic operation condition which used poly aluminum chloride as the flocculent. The dosage of flocculent under three different levels of anaerobic organic load was 200, 400 and 600 mg/L, respectively. The temperature ranged between 10 and 15 ℃. The test scheme is given in Table 2.

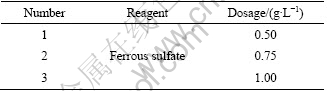

Based on the conclusion of the lab-scale experiments of phosphorous removal, the prepositive phosphorous removal produced a large amount of sedimentation in the regulating tank, which led to the decrease of the effective volume of regulating tank and the decline of regulatory function. Therefore, the postpositive phosphorus removal was adopted in this work, and the point of dosing the reagent was the last reaction zone of the integrated bioreactor and the sedimentation was removed through sedimentation tank. The influence of reaction time on the chemical phosphorous removal efficiency was studied in this work. As it was used for the pretreatment of hypersaline mustard wastewater, the relationship of the reaction time and postpositive phosphorous removal efficiency was tested through parallel experiments. The former experimental results had shown that the ferrous sulfate was the best phosphorous removal reagent. When the dosage of reagent stepped up in an equidifferent way, the reaction time was 5, 10, 15, 20, 25 and 30 min, respectively. The best reaction time could be confirmed by the comparison of the indicators such as PO43--P, COD and so on.

Fig. 2 Structure of integrated bio-reactor: (a) Lay-out plan of bio-reactor; (b) Cross-section drawing of bio-reactor (1-Central area; 2-1st reaction zone; 3-2nd reaction zone; 4-3rd reaction zone; 5-4th reaction zone; 6-5th reaction zone; 7-6th reaction zone; 8-7th reaction zone; 9-8th reaction zone; 10-9th reaction zone; 11-10th reaction zone; 12-11th reaction zone; 13-12th reaction zone/settling zone; 14-Aeration pipe; 15-Inner area; 16-Outer area; 17-Inlet pipe)

Table 1 Water quality of mustard tuber wastewater in Lidu Industrial Estate

![]()

Table 2 Test scheme

Under the optimal reaction time, the optimal dosage of reagent was analyzed through the indicators such as PO43--P. The test scheme is described in Table 3.

Table 3 Reagent and dosage

3 Results

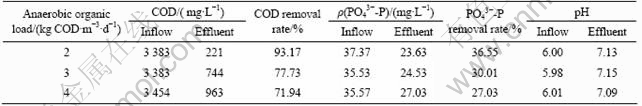

The indicators including COD, PO43--P and pH value were tested after the integrated bioreactor reached a quasisteady state under anaerobic-aerobic operation condition. The experimental data are given in Table 4.

When the anaerobic organic load was set separately at 2.0, 3.0 and 4.0 kg (COD)/(m3·d), the COD removal rate was respectively 93.17%, 77.73% and 71.94%. The COD removal rate tended to decrease with the increase of anaerobic organic load. When the load was 2.0 kg (COD)/(m3·d), the effluent could reach the third- level of “Integrated Wastewater Discharge Standard” (GB 8978—1996), however, the effluent under the anaerobic organic load of 3.0 kg (COD)/(m3·d) and 4.0 kg (COD)/(m3·d) could not reach the standard. The tendency of SS and PO43--P was in conformity with COD. The influence of anaerobic organic load on the pH of the effluent was not significant. Under the three levels of anaerobic load, the pH of the inflow and effluent was relatively steady without significant change.

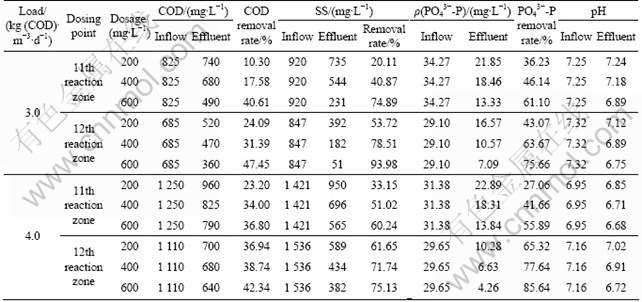

The experimental results indicated that under anaerobic-aerobic operation condition, when the anaerobic organic load was 2.0 kg (COD)/(m3·d), the COD and pH of the effluent could reach the third-level of “Integrated Wastewater Discharge Standard” (GB 8978—1996) and the treatment efficiency was optimal. However, since the designed scale of the reactor was 1 000 m3/d, the anaerobic-aerobic operation condition still couldn’t meet the requirements of the standard. In order to enhance treatment efficiency, the reactor was operated under anaerobic-aerobic-flocculation operation condition. The relevant indicators were tested after the system came into stability. The experimental data are presented in Table 5. Under the condition that the anaerobic organic load was 3.0 kg (COD)/(m3·d), when using the first dosing scheme with the dosage of 600 mg/L, the COD of effluent was 490 mg/L which was up to the discharge standard; when using the second dosing scheme with the dosage of 400 mg/L, the COD of effluent was 470 mg/L and the wastewater could be discharged within the requirements of the standard. When the anaerobic organic load increased to 4.0 kg (COD)/(m3·d), under the same dosage, the processing performance declined significantly. Under the same organic load and discharge standards, compared with the first scheme, the second dosing scheme could save the consumption of flocculent. And PO43--P and SS removal rates of the first dosing scheme were lower than those of the second dosing scheme. The pH value of effluent increased with the increase of dosage, and the influence of the second dosing scheme on the pH value of effluent was more obvious.

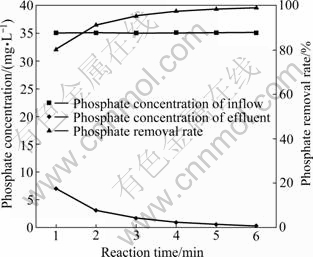

To ensure that the PO43--P concentration of effluent was up to the discharge standard, the chemical phosphorus removal efficiency under different reaction time was studied. The impacts of reaction time on chemical phosphorus removal efficiency are shown in Fig. 3.

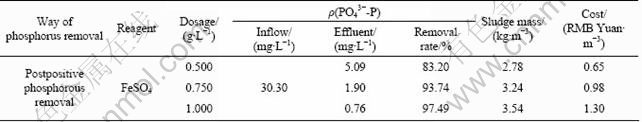

The results showed that with reaction time increasing, PO43--P removal rate presented a rising trend, but the rate of rising slowed down. Therefore, considering the performance of reagents and economic efficiency in engineering application comprehensively, the optimal reaction time of chemical phosphorus removal of mustard wastewater was 25 min. The results of influences of the optimal reaction time under different dosages on chemical phosphorus removal efficiency are given in Table 6.

Table 4 Effects of organic load on treatment efficiency of reactor

Table 5 Effects of dosing point and dosage on reactor treatment efficiency under anaerobic-aerobic-flocculation operation condition

Table 6 Effects of different dosages on phosphorus removal efficiency

Fig. 3 Effects of reaction time on phosphorus removal efficiency

4 Discussion

The removal rates of COD in anaerobic zone under three levels of load are 49.74%, 41.54% and 38.41%, respectively, when the anaerobic-aerobic operation condition is used. The main reasons are as follows. Firstly, the environment temperature during the experiments is 10-15 ℃, and the low temperature reduces the removal rate of organics. Secondly, short flow phenomenon appears when part of filler in anaerobic zone floats upward, which reduces the contact of organics and the attached biomass. This inhibits the maximization of the efficiency of anaerobic zone. Thirdly, the treatment efficiency of regulating tank is restrained due to the low temperature and leads to the increase of the organic load of subsequent biological treatment, and the pH of inflow is slightly low. All these factors have negative impacts on the improvement of the efficiency of integrated bioreactor.

The removal rate of PO43--P under three levels of the load are 36.55%, 30.01% and 27.03%, respectively. The mechanism of PO43--P removal under this operation condition is not through elimination of excess sludge, but through the construction of phosphate reduction system in the reactor.

Under anaerobic-aerobic-flocculation operation condition, with the same organic load and the same dosage of reagent, the treatment efficiency of dosing in the 12th reaction zone is higher than that of dosing in the 11th reaction zone. So the latter dosing scheme is advantageous for the improvement of treatment efficiency.

In the chemical phosphorus removal process, the removal rate of PO43--P increases with the extension of reaction time, but the rate of increase slows down. The reason is that the mechanism of chemical phosphorus removal is that PO43--P and the decentralized reagents contact to form insoluble phosphate flocs, and then the flocs precipitate from the liquid phase. At the preliminary stage of the reaction, a large amount of insoluble phosphate flocs are formed and precipitated to be removed. Along with the extension of reaction time, the process of forming flocs by PO43--P and the decentralized reagent levels is finished, and the removal rate of PO43--P achieves quasisteady state.

Under the optimal reaction time, when dosage is 1.0 g/L, the concentration of PO43--P of effluent is less than 1 mg/L and at this point, the dosing ratio of ferrous sulfate is 3.77:1, which is much higher than the theoretical value. This is because the dosage of reagents is affected by many factors such as pH value, alkalinity, dosing point and mixture conditions, therefore, the actual dosage is often higher than the theoretical value.

5 Conclusions

1) When the temperature ranges between 10 and 15 ℃, the anaerobic organic load is 2.0 kg (COD)/(m3·d), the optimal treatment efficiency is realized under aerobic-anaerobic operation condition. The removal rate of COD is 93.17%, which is up to the third level of Integrated Wastewater Discharge Standard (GB 8978—1996).

2) When the temperature ranges between 10 and 15 ℃, the anaerobic organic load is 3.0 kg (COD)/(m3·d) and the dosage of flocculent is 400 mg/L, the COD concentration of the effluent is 470 mg/L under anaerobic-aerobic-flocculation operation condition, which is up to the standard.

3) The optimal dosage of ferrous sulfate in postpositive chemical phosphorous removal process is 0.5 g/L, at which the phosphorous removal rate could reach 83.20%.

References

[1] LEFEBVRE O, MOLETTA R. Treatment of organic pollution in industrial saline wastewater: A literature review [J]. Water Research, 2006, 40(20): 3671-3682.

[2] UYGUR A, KARGI F. Salt inhibition on biological nutrient removal from saline wastewater in a sequencing batch reactor [J]. Enzyme Microbial Technology, 2004, 34(3/4): 313-318.

[3] FONTENOT Q, BONVILLAIN C, KILGEN M, BOOPATHY R. Effects of temperature, salinity, and carbon:nitrogen ratio on sequencing batch reactor treating shrimp aquaculture wastewater [J]. Bioresource Technology, 2007, 8(9): 1700-1703.

[4] WEN Xiang-hua, ZHAN Xin-ming, WANG Jian-long, QIAN Yi. Review of the biological treatment of salinity wastewater [J]. Environmental Science, 1999, 20(3): 104-106. (in Chinese)

[5] CRISTINA S C C, PAULA V B Q, GABRIELA S, LU?S F C C, HANS B, SANDRA C M, PAULA M L C. Use of constructed wetland systems with Arundo and Sarcocornia for polishing high salinity tannery wastewater [J]. Journal of Environmental Management, 2012, 95(1): 66-71.

[6] KARTAL B I, KOLEVA M, ARSOV R, STAR W V D, JETTEN M S M, SCROUS M. Adaptation of a freshwater anammox population to high salinity wastewater [J]. Journal of Biotechnology, 2006, 126: 546-553.

[7] WINDEY K, BO I D, VERSTRAETE W. Oxygen-limited autotrophic nitrification–denitrification (OLAND) in a rotating biological contactor treating high-salinity wastewater [J]. Water Research, 2005, 39(18): 4512-4520.

[8] GUERRERO L, OMIL F, MENDEZ R, LEMA J M. Treatment of saline wastewater from fish meal factories in an anerobic filter under extreme ammonia concentrations [J]. Bioresource Technology, 1997, 61(1): 69-78.

[9] MONHAN S V, BABU V L, BHASKAR Y V. Influence of recirculation on the performance of anaerobic sequencing batch biofilm reactor (AnSBBR) treating hypersaline composite chemical wastewater [J]. Bioresource Technology, 2007, 98(7): 1373-1379.

[10] ZHOU Jian, GAN Chun-juan, LONG Teng-rui, CHAI Hong-xian. Research on efficiency of anaerobic sequencing batch biofilm reactor for hypersalt mustard tuber wastewater treatment [J]. China Water & Wastewater, 2006, 22(17): 77-79. (in Chinese)

[11] YANG L. Biodegradation of dispersed diesel fuel and high salinity conditions [J]. Water Research, 2000, 34(13): 3303- 3314.

[12] YANG L, LAI C T. Biological treatment of mineral oil in a salty environment [J]. Water Science and Technology, 2005, 42(5): 369-375.

[13] MA Qian, XU Ding-wen, GU Xue-xi. Study on the treatment of mustard tuber wastewater with high salinity by UASB-aerobic- coagulation process [J]. Industrial Water Treatment, 2011, 31(4): 62-65. (in Chinese)

[14] WU Dao-ji, SUN Wei, TAN Feng-xun. Experimental study on the treatment of mustard tuber wastewater by the process of hydrolysis-acidgenesis-SBR-coagulation [J]. Technology of Water Treatment, 2009, 35(6): 60-63. (in Chinese)

[15] FENG Xiang-hua, ZHU Ming-xiong, WEN Liang-qin, DING Shi-ming. Removal of COD from mustard wastewater by Fenton-like reagents oxidation process [J]. Chinese Journal of Environmental Engineering, 2008, 2(11): 1483-1486. (in Chinese)

[16] LI Zhe, ZHOU Jian, ZENG Chao-yin. Nature of the vegetable processing wastewater and its influence on the secondary sedimentation in activated sludge process [J]. Water & Wastewater Engineering, 2005, 31(11): 57-60. (in Chinese)

[17] ZHOU Jian, WU Qi-tao, LONG Teng-rui, WANG Xia-ming. Establishment of microbiological system for treatment of mustard tuber wastewater with high salinity [J]. China Water & Wastewater, 2007, 23(15): 17-20. (in Chinese)

[18] CHEN Yao, ZENG Chao-yin, LONG Teng-rui, LI Xiao-ping. Selection of aerobic biological process for treatment of integrated mustard tuber wastewater [J]. China Water & Wastewater, 2009, 25(15): 21-24. (in Chinese)

(Edited by HE Yun-bin)

Foundation item: Project(20090191120036) supported by the Fund of Doctoral Program of Ministry of Education, China

Received date: 2011-07-26; Accepted date: 2011-11-14

Corresponding author: CHAI Hong-xiang, PhD; Tel: +86-23-65120980; E-mail: chaihx@126.com

Abstract: A full-scale experimental study of treating mustard wastewater by the integrated bioreactor with designed scale of 1 000 m3/d is conducted combined with a demonstration project. The systematical researches on the efficiency of combined operation conditions of anaerobic-aerobic and anaerobic-aerobic-flocculation as well as chemical phosphorus removal of hypersaline mustard wastewater are conducted. The optimal operation condition and parameters in pretreatment of mustard wastewater in winter (the water temperature ranges 8-15 ℃) are determined: the anaerobic load is 3.0 kg (COD)/(m3·d), the average COD and phosphate concentration of the inflow are respectively 3 883 mg/L and 35.53 mg/L and the dosage of flocculent (PAC) is 400 mg/L. The anaerobic-aerobic-flocculation combined operation condition and postpositive phosphorous removal with ferrous sulfate are employed. After treatment, the COD of the effluent is 470 mg/L and the average phosphate concentration is 5.09 mg/L. The effluent could achieve the third-level of Integrated Wastewater Discharge Standard (GB 8978—1996).