Precision forging technologies for magnesium alloy bracket and wheel

WANG Qiang(王 强)1, ZHANG Zhi-min(张治民)1, ZHANG Xing(张 星)1, YU Jian-min(于建民)2

1. College of Materials Science and Engineering, North University of China, Taiyuan 030051, China;

2. Engineering Research Center of Magnesium-base Material Processing Technology, Ministry of Education,

Taiyuan 030051, China

Received 12 June 2008; accepted 5 September 2008

Abstract:

Fundamental investigations on precision forging technology of magnesium alloys were studied. As-cast billet prestraining and a new concept of hollow billet were proposed in order to reduce the maximum forming load. A scheme of isothermal forming and the use of combined female dies were adopted, which can improve the die filling capacity and ensure the manufacture of high quality forgings. By means of the developed technique, AZ80 alloy wheel and AZ31 alloy bracket were produced successfully at suitable process parameters and applied in the automotive industries. The results show that the hot compression of AZ80 magnesium alloy has the peak flow stresses of pre-strained alloy with finer grain, which are lower by 20% than those of as-cast alloy under the same deformation conditions. The forming load is related to contact area and average positive stress on interface during forging process.

Key words:

Mg alloy; precision forging; as-cast billet prestraining; hollow billet; isothermal forming;

1 Introduction

Magnesium alloys are promising structural light metals because their low densities, good recyclical potential and abundant resources, which are expected to become next-generation materials[1-3]. Recently magnesium alloy manufacturing processes have been adopted for use in casting, die casting and thixotropic molding[4-6]. Although casting processes offer good near net shape solutions, the material properties of these parts often cannot meet the requirements concerning mechanical properties (e.g. endurance strength and ductility). Casting defects such as porosity and inclusions restrict the use of common cast magnesium components to light duty [7].

To achieve improved material properties forging is an alternative production technology for mass production of Mg parts. The parts manufactured by this technology were characterized by advantageous mechanical properties and fine-grained microstructure without pores[8-9]. Especially components for the aerospace and automotive industry, which have to meet high requirements concerning safety and lightweight construction aspects, offer a wide field for the use of Mg-forging products [10-11]. Precision forging can produce complex-shaped forgings with high precision, good flow lines and improved load-bearing capacity. It is a new technique developed on the basis of traditional forging processes [12-13].

In order to have a widespread use of precision forging for the processing of magnesium alloys, it is necessary to have sufficient knowledge about the forming technology and suitable process parameters that have to be applied. Hence, the precision forging process of magnesium alloys was investigated. As-cast billet prestraining and a new concept of hollow billet were proposed to reduce the maximum forming load. The die and process parameters were determined and optimized by experiment for AZ80 wheel and AZ31 bracket.

2 Methods of reducing forming force

2.1 As-cast billet prestraining

The AZ80 (Mg-8.9%Al-0.53%Zn) alloy used in the present investigation was produced by electromagnetic casting method. The billets were machined in order to remove the effect of the surface layer of the ingot and homogenized (355 ℃, 16 h, air cooled) before deformation (hereafter, denoted as as-cast material). The pre-strained material was attained by as-cast billet upsetting with the reduction in height of 50% at 300 ℃ (hereafter, denoted as pre-strained material). Specimens with 15 mm in length and 10 mm in diameter of as-cast and pre-strained AZ80 magnesium alloy were deformed respectively in compression on Gleeble 3 800 to investigate the effect of initial grain on hot working stresses. The experiment temperature was ranged in 200-400 ℃ and various strain rates of 0.01 and 1.0 s-1 under maximum strain of 60%.

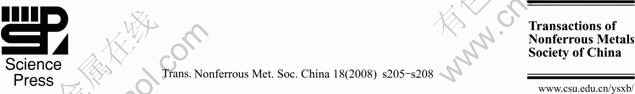

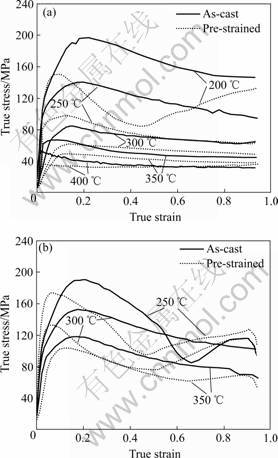

The true stress—true strain curves in Fig.1 show that the initial grain has significant effect on flow stress except strain rate and temperature. Under the same deformation conditions, the flow stresses of pre-strained alloy with finer grain are lower than those of as-cast alloy, i.e., the flow stress increases with the increase of grain size. The effect diminishes with the increase of strain and temperature. It is also evident that the strain to the peak stress also increases with the increase of grain size. The peak flow stresses of pre-strained alloy are lower by about 20% than those of as-cast alloy, as shown

Fig.1 True stress—true strain curves of AZ80 alloy: (a) 0.01 s-1; (b) 1.0 s-1

in Fig.2. The results are the same with BARNETT’s investigation results for AZ31 alloy [14-15]. This indicates initial grain size influences proceeding of work hardening and dynamic recrystallization during hot compression.

Fig.2 Comparison of peak stress

The method of reducing forming force using as-cast billet pre-straining was put forward during magnesium alloy extrusion. Pre-straining was given for as-cast magnesium alloy without restraining metal flow and then extrusion was attained with a low flow stress.

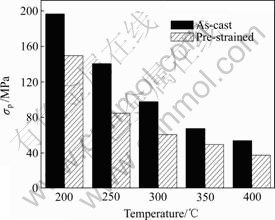

2.2 Extrusion from hollow billet

The maximum load was chosen as the extrusion load during extrusion process. A new concept of hollow billet was proposed and a method of extrusion from hollow billet was developed in order to reduce the maximum forming load. The schematic diagram of extrusion from hollow billet is shown in Fig.3.

Fig.3 Schematic diagram of extrusion from hollow billet

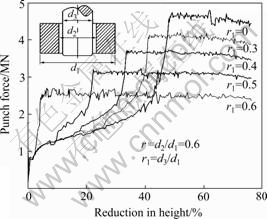

To investigate the press force during extrusion from hollow billet, the finite element simulation was conducted using an implicit FE code MSC/Autoforge. The data on AZ80 alloy flow stress as function of strain, strain rate and temperature established based on above compression experiment were introduced into the FE package. Fig.4 presents the calculational force- displacement curve during extrusion from hollow billet at different r1. The load—displacement curve can be divided into two stages and identical behavior of change in slope is observed. The results show that forming force decreases enormously during extrusion from hollow billet, because of not only the decrease of contact area but also the decrease of average positive stress at interface. At the same time, the hole is formed directly and reduces cutting process for the parts with center hole such as wheel by extrusion from hollow billet.

Fig.4 Calculational force—displacement curves

3 Investigation of forging process

3.1 Isothermal forming

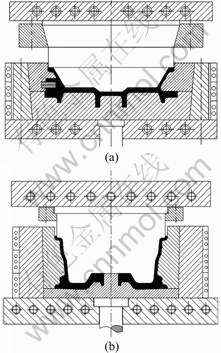

Magnesium alloy with HCP structure shows a limited formability at room temperature. The forging temperatures range is very narrow. The thermal conductivity of Mg alloy is about 2 times that of die steel. The temperature of billet will decrease quickly, the deformation resistance will increase and the plasticity will decrease during hot forging process. The bracket has two ears, conical wall and flange, and the wheel has top and bottom flange, as shown in Fig.6. The geometrical shapes are complicated and the deformation is large. The two ears, conical wall and the flange can not accomplish in a single pass by conventional hot forging. Considering above-mentioned reasons, isothermal forming process was adopted for the magnesium alloy wheel and bracket.

3.2 Combined female die design

The die structure should fulfill the forming requirements and be convenient for die releasing and manufacture. Female die should not be integral for the sake of the ears and the bottom flange, otherwise the forging cannot be removed from the dies after forging. Hence the female die is divided into two pieces. The lateral punch is employed to extrude the ear hole and to decrease inhomogeneous straining. Forward extrusion ears, backward extrusion cone, forging flange can be achieved in a single-step process for bracket forging. During wheel forging, extrusion from hollow billet was used.

To obtain isothermal conditions, the tool system was heated by electric heating elements, integrated into top plate, punch, base plate and die. Insulation layers prevent the heat transmission from these elements into tool frame and the press machine. A thermocouple inserted into the die was used to monitor the die temperature during forging deformation. The die devices for the bracket and wheel are shown in Fig.5.

Fig.5 Schematic diagram of die device for bracket(a) and wheel(b)

3.3 Experiment and results

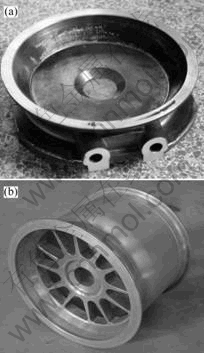

The AZ31 alloy (Mg-3.20%Al-1.1%Zn) prepared for the bracket was produced by the semi-continuous direct chill casting method. The billets were machined from the ingot and homogenized (12 h, 400 ℃, air cooled). The AZ80 alloy was prepared for the wheel with above-mentioned method. As-cast alloy were pre- strained in upsetting before forging. Forging were conducted under isothermal conditions in which the die temperatures were varied depending on the billet temperature. The billet was heated to 360-400 ℃ in a resistance furnace without using protective gas. The equipment employed was oil-hydraulic press of capacity 6.3 MN and average forming speed of 16 mm/s. A graphite coating was used to lubricate billet and punch surface. The AZ31 alloy bracket is forged successfully by a single-step process. The one-piece AZ80 alloy wheel was produced by hot forging (as shown in Fig.6).

Fig.6 Magnesium alloy forgings: (a) AZ31 bracket; (b) AZ80 wheel

The standard tensile specimens with a diameter of 5 mm were machined from the forgings respectively. Tension tests were performed at ambient temperature according to the specifications GB/T 228—2002. The mechanical properties are significantly improved. For AZ31 alloy bracket and AZ80 alloy wheel, the ultimate tensile strength is 260-270 MPa and 320-330 MPa, respectively. The elongation is 10%-12%.

The forming temperature was chosen to be 360- 400 ℃, which is suitable for forging of AZ31 and AZ80 magnesium alloy without cracks and unstable deformation. The forming force was decreased by as-cast billet prestraining and extrusion from hollow billet. The forging of 10J×13 wheels is achieved on the 6.3 MN oil-hydraulic press. The technology and dies designed have many advantages such as better filling for flange, high production precision, low surface roughness and convenient mould unloading for near-net shape forming.

4 Conclusions

1) The hot compression results of AZ80 alloy show that the peak flow stresses of prestraining alloy are lower by about 20% than those of as-cast alloy. As-cast billet prestraining is proposed in order to reduce the maximum forming load, in which pre-straining is given without restraining metal flow and then extrusion is attained with a low flow stress.

2) The FEA results indicate that extrusion from hollow billet can reduce the maximum forming load because of the decrease of contact area and average positive stress at interface.

3) The AZ80 alloy wheel and AZ31 alloy bracket are forged successfully for near-net shape forming by means of the developed technique. The improved mechanical properties of common wrought magnesium components can expand the use of Mg alloy.

References

[1] YOSHIHARA S, NISHIMURA H, YAMAMOTO H, MANABE K I. Formability enhancement in magnesium alloy stamping using a local heating and cooling technique: Circular cup deep drawing process [J]. J of Mat Proc Tech, 2003, 142(3): 609-613.

[2] Gray J E, Luan B. Protective coatings on magnesium and its alloys: A critical review [J]. Journal of Alloys and Compounds, 2002, 336(1/2): 88-113.

[3] MA Chun-jiang, LIU Man-ping, WU Guo-hua, DING Wen-jiang, ZHU Yan-ping. Tensile properties of extruded ZK60/RE alloys [J]. Materials Science and Engineering, 2003, A349(1/2): 207-212.

[4] MURAI T, MATSUOKA S I, MIYAMOTO S, OKI Y. Effects of extrusion conditions on microstructure and mechanical properties of AZ31B magnesium alloy extrusions [J]. J of Mat Proc Tech, 2003, 141(2): 207-212.

[5] YIN D L, ZHANG K F, WANG G F, HAN W B. Warm deformation behavior of hot-rolled AZ31 Mg alloy [J]. Mater Sci Eng, 2005, A392(1/2): 320-325.

[6] ZHANG P, LINDEMANN J. Influence of shot peening on high cycle fatigue properties of the high-strength wrought magnesium alloy AZ80 [J]. Scripta Materialia, 2005, 52(6): 485-490.

[7] KLEINER S, UGGOWITZER P J. Mechanical anisotropy of extruded Mg-6%Al-1%Zn alloy [J]. Mater Sci Eng, 2004, A379(1/2): 258-263.

[8] LAWRENCE C, YU Y, SHIGEHARU K, YO K, FUKASHI W. Microstructures and tensile properties of ECAE-processed and forged AZ31 magnesium alloy [J]. Materials Transactions, 2003, 44: 476-483.

[9] DOEGE E, DRO¨DER K. Sheet metal forming of magnesium wrought alloys—formability and process technology [J]. J of Mat Proc Tech, 2001, 115(1): 14-19.

[10] BEHRENS B A, SCHMIDT I. Improving the properties of forged magnesium parts by optimized process parameters [J]. J of Mat Proc Tech, 2007, 187/188: 761-765.

[11] WANG Ling-yun, FAN Yong-ge, HUANG Guang-jie, HUANG Guang-sheng. Flow stress and softening behavior of wrought magnesium alloy AZ31B at elevated temperature [J]. Trans Nonferrous Met Soc China, 2003, 13(2): 335-338.

[12] SHAN D B, XU W C, LU Y. Study on precision forging technology for a complex-shaped light alloy forging [J]. J of Mat Proc Tech, 2004, 151(1/3): 289-293.

[13] OGAWA N, SHIOMI M, OSAKADA K. Forming limit of magnesium alloy at elevated temperatures for precision forging [J]. International Journal of Machine Tools & Manufacture, 2002, 42(5): 607-614.

[14] BARNETT M R, BEER A G, ATWELL D, OUDIN A. Influence of grain size on hot working stresses and microstructures in Mg-3Al-1Zn [J]. Scripta Mater, 2004, 51(1): 19-24.

[15] BARNETT M R. Influence of deformation conditions and texture on the high temperature flow stress of magnesium AZ31 [J]. Journal of Light Metals, 2001, 1(3): 167-177.

(Edited by CHEN Can-hua)

Foundation item: Project(50575213) supported by the National Natural Science Foundation of China

Corresponding author: WANG Qiang; Tel: +86-351-3921398; E-mail: ncustwangq@nuc.edu.cn