DOI:10.19476/j.ysxb.1004.0609.2017.10.17

微观相场模拟弹性畸变能对L12相沉淀全过程的影响

郑晓娟,赵宇宏,侯 华,靳玉春,马庆爽,田晋忠

(中北大学 材料科学与工程学院,太原 030051)

摘 要:

基于微观相场法研究不同弹性畸变能对Ni75Al5V20合金中L12相沉淀过程的影响。结果表明:虽然弹性畸变能不同,Ni75Al5V20合金在温度为1250 K下沉淀时的显微组织演化过程都可大概分为4个阶段,但也有不同之处;在早期沉淀析出的L12相中,V原子的占位要远大于Al原子的占位,最终,随着弹性畸变能的增大,在L12相中Al原子的占位概率降低,V原子的占位概率增大。在生成化学计量比的L12有序相时,Al原子由L12相边界逐渐向其内部扩散,而V原子则与之相反,且各原子越靠近L12相的边界扩散速度越快,反之越慢。

关键词:

Ni75Al5V20合金;微观相场;弹性畸变能;占位概率;L12相;

文章编号:1004-0609(2017)-10-2098-07 中图分类号:TG111.5 文献标志码:A

镍基合金被广泛应用在高温环境中[1],如在燃气涡轮发动机和航天先进发动机中发挥着很重要的作 用[2-4]。其中镍铝钒合金因其优越的高温性能而备受关注,其相变过程的显微组织演化规律被广泛研究,但通过实验手段难以分析沉淀的整个过程,在以往的实验中大多只讨论了沉淀后期的沉淀相的调制结构形貌等现象[5]。而计算机模拟具有其独特的优势,是因为它可通过利用微观相场动力学模型处理合金沉淀过程中的高度非线性、高度非平衡状态等问题,从而获得直观清晰的有序相原子层次的瞬时形貌。由于合金在沉淀时因应变时效状态不同及合金本身缺陷和造成的过饱和度的差异,在沉淀早期就会有应变能的形成,从而会对预析出相的析出过程产生影响,进而会直接影响到析出相的形核长大、组织形貌、数量分布原子扩散及其占位概率等[6-8]。因此,在研究镍基合金沉淀过程时,通过温度与弹性畸变能的耦合进行模拟更加具有实际意义。

在以往的模拟中,刘芳等[6]和LU等[9]研究过不同弹性畸变能、成分等对L12相和DO22相沉淀序列及其最终原子占位的影响;陈引平等[7]研究了弹性畸变能对L12相预析出相的影响。张明义等[10-18]研究了在Ni-Al-V相变过程中DO22相中合金元素占位概率变化和L12相长大之间的联系,以及L12相之间、DO22相之间、L12相与DO22相异相间的各原子的扩散规律。

以上只是重点分析了L12相在某一阶段的沉淀规律。因此,本文作者研究了在弹性畸变能影响下Ni75Al5V20合金的L12相在整个沉淀过程中的沉淀规律。

1 微观相场法理论模型

在利用计算机模拟合金沉淀时所采用的三元微观相场模型是由KHAUCHATURYAN创建[19],CHEN等[20-21]对此模型进行了补充和修改,在三元合金体系下,用PA(r,t)、PB(r,t)、PC(r,t) 分别表示A、B、C原子在t时刻、占据晶格位置r的概率,由于PA(r,t)+ PB(r,t)+PC(r,t)=1,所以每个格点上只有两个方程是独立的。假设以A和B原子的占位概率为两个独立变量,为了描述形核过程,需要添加随机项来模拟热起伏,使之成为随机方程,即得到微观Langevin方程:

(1)

(1)

式中: 是与单位时间内一对

是与单位时间内一对 和

和 原子在格点位置r和r'上的交换概率有关的常数(

原子在格点位置r和r'上的交换概率有关的常数( 、

、 =A、B或C);T为温度;kB为波尔兹曼常数;F为系统的总自由能;t为时间;

=A、B或C);T为温度;kB为波尔兹曼常数;F为系统的总自由能;t为时间; 为热起伏项。

为热起伏项。

在平均场近似下,系统的总自由能为

(2)

(2)

式中: 为原子间有效作用能(

为原子间有效作用能( 、

、 =A、B或C),它由化学相互作用能

=A、B或C),它由化学相互作用能 、弹性相互作用能

、弹性相互作用能 组成。从而可获得倒易空间中的微扩散方程:

组成。从而可获得倒易空间中的微扩散方程:

(3)

(3)

式中: ,

, ,

, ,

, ,

, 分别是相应函数的傅立叶变换。

分别是相应函数的傅立叶变换。

2 结果与讨论

Ni75Al5V20合金在温度为1250 K下沉淀时位于γ′(Ni3Al,L12) +θ (Ni3V, DO22)两相区,因此在以下分别模拟的不同弹性畸变能(B=200,400,600,800)的沉淀过程中,L12相和DO22相均从无序基体中析出。在模拟时采用128×128 格点,以及在每个方向上都使用周期性边界条件,无序过饱和固溶作为合金的初始状态,时间步数t代表模拟时间,其中时间步长Δt=0.0002。在以下模拟得到的Ni75Al5V20合金显微组织演化图中,以Ni原子作为黑色基体,Al原子在某个点占位越高,该格点灰度越高,而V原子在某个格点占位越高,则该格点白度越高。

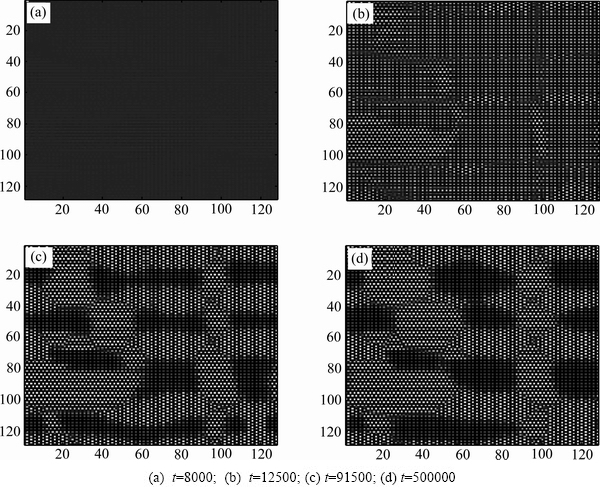

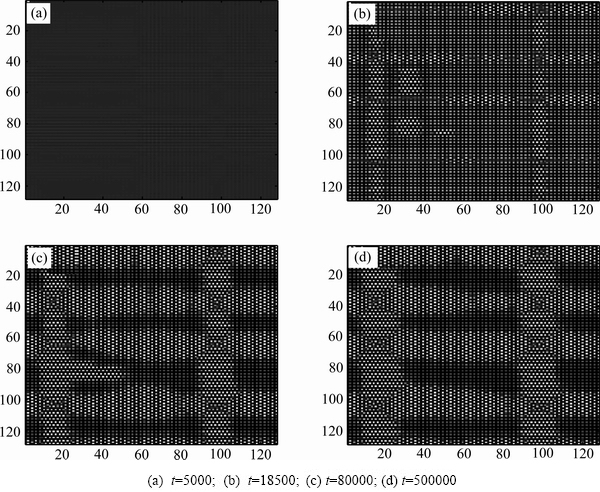

在不同弹性畸变能下,Ni75Al5V20合金沉淀时的原子演化过程类似,因此,如图1和2所示(图中数值为模拟的格点位置),只选取了两组弹性畸变能(B=200和600)下的显微组织演化过程来进行分析。由图1和2可看出,当B为200和600时,Ni75Al5V20合金在沉淀过程中的显微组织演化均可大致分为4个阶段:首先基体由无序状态转化为短程有序相(见图1(a)和2(a));然后是L12相和DO22相由短程由有序相转化或者由基体相直接转化而析出,形成非化学计量比有序相(见图1(b)和2(b));再随着时间的演化,在沉淀早期析出较多的L12相部分转化为了DO22相(见图1(c)和2(c));最终L12相和DO22相通过相互碰撞、融合而沿着[100]方向共同长大粗化,形成了化学计量比有序相(见图1(d)和2(d))。不同弹性畸变能下的微观组织演化也有不同之处,在B=200时(见图1(a)),当t=8000时,Ni75Al5V20合金的短程有序相析出;而B=600时(见图2(a)),当t=5000时,其短程有序相就已析出。由此可见,随着弹性畸变能的增加,短程有序相提前析出。且由图1和2还可看到,随着弹性畸变能的增加,L12相和DO22相从析出到粗化一直具有方向性(沿着[100]方向),两相更加细化且形貌也更加规则,趋于长方形。

图1 温度为1250 K和B为200时Ni75Al5V20合金沉淀过程的微观组织演化过程

Fig. 1 Process of microscopic morphology evolution of alloy Ni75Al5V20 at 1250 K and B=200

图2 温度为1250 K和B为600时Ni75Al5V20合金沉淀过程的微观组织演化过程

Fig. 2 Process of microscopic morphology evolution of Ni75Al5V20 alloy at 1250 K and B=600

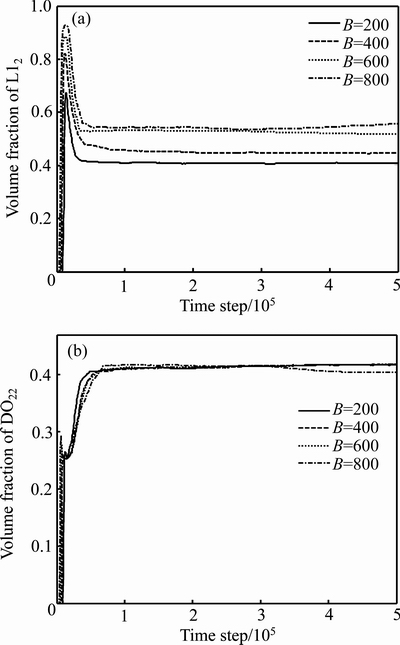

为了更加清楚地了解不同弹性畸变能对Ni75Al5V20合金沉淀过程的影响,对比了在不同弹性畸变能下L12相和DO22相体积分数的变化。图3所示为Ni75Al5V20合金在不同弹性畸变能下的体积分数变化曲线。由图3可知,在各个弹性畸变能下,L12相的体积分数先增加到一最大值,然后降低,向DO22相进行转化,与以上模拟出的合金的微观组织演化过程相一致;而DO22相的体积分数先快速增加,后缓慢增加,然后到达其平衡值,其原因是当DO22相由基体直接析出时,其沉淀速度较快,而由L12相进行转化时,其沉淀速度较慢[10]。通过对比图3中各个弹性畸变能下两相体积分数的变化可观察出,随着弹性畸变能的增大,L12相和DO22相的析出时间均越来越早,即两相的孕育期缩短;L12相在早期沉淀中的析出量越来越多;L12相的最终析出量也是增多的,而DO22相最终析出量变化不大,稍有减少。由此可见,在Ni75Al5V20合金沉淀过程的整个中,随着弹性畸变能的增加,都有利于L12相的析出。

图3 Ni75Al5V20合金在不同弹性畸变能下的体积分数变化曲线

Fig. 3 Volume fraction variation of L12(a) and DO22(b) phase of Ni75Al5V20 alloy at different elastic strain energy

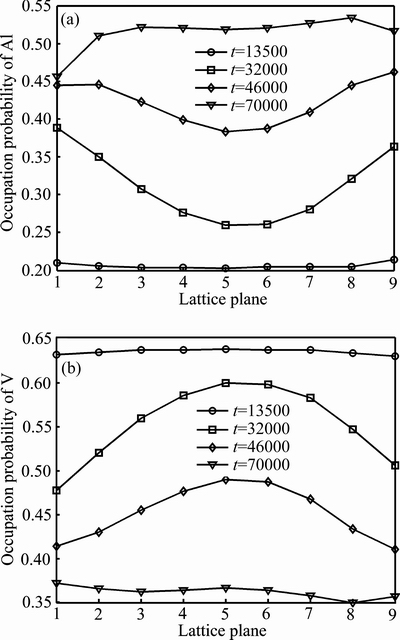

为了清楚地了解Ni75Al5V20合金的L12相的早期扩散情况,首先分析了在早期沉淀出的L12相中Al、V原子由边界到中心的占位概率变化,如图4格点1到格点5、6及格点9到格点5、6的曲线变化。由于在各个弹性畸变能下Al、V原子的占位变化趋势在早期沉淀出的L12相中类似,因此只分析了B=600时Al、V原子在早期沉淀出的L12相内扩散变化。

综合图4(a)、图4(b)可知,在时间步数t=13500时,在L12相内,Al原子的占位很小,大约在0.2左右,而V原子的占位较高,大约在0.64左右,由此可见,在早期生成的L12相内V原子占位较高。随着时间步数的增加,当t=32000时,Al原子在越靠近L12相的边界的地方占位较高,内部占位较低,而V原子与之相反,其是在越靠近L12相的边界的地方占位较低,内部占位较高,由此可见,生成化学计量比的L12相时,Al原子从其边界向内扩散,而V原子是从其内部向边界扩散。还可观察到在Al、V原子在L12相边界扩散较快,而越接近内部,它们的扩散速度越慢,这是因为溶质原子在相边界的扩散速度比相内要快。当时间步数增加到46000时,由于随着溶质原子的扩散,L12相内部与边界浓度差减小,使得相变驱动力减小,Al、V原子的扩散速度降低,从而它们的扩散曲线的斜率降低,但扩散趋势与t=32000时类似。再随着时间步数的增加,Al、V原子的扩散速度更加缓慢,且由于Al原子扩散到了L12相内部,V原子扩散到了L12相外部即DO22相内,如t=70000时,Al原子在最靠近L12相的边界处的占位概率小于内部,而V原子与之相反。

图4 Ni75Al5V20合金在B=600时早期沉淀出的L12相内Al原子与V原子的占位变化

Fig. 4 Occupation probability evolution of Al atom(a) and V atom(b) in L12 phase when early precipitation in Ni75Al5V20 alloy at B=600

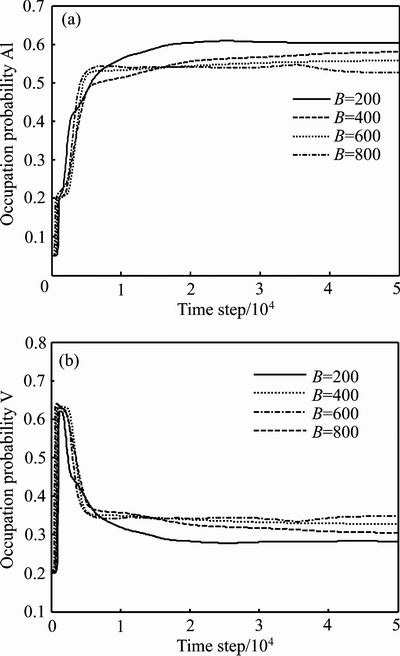

图5所示为Al、V原子在整个沉淀过程占位概率变化,结果与图4所示一致,在早期的沉淀出的L12相内V原子占位较大;而随着时间的演化Al原子的占位概率逐渐升高,V原子的占位概率逐渐下降;最终Al、V原子的扩散均达到了各自的动态平衡状态,且V原子在L12相内有一定的占位。综合图5(a)和(b)可知,随着弹性畸变能的增大,Al原子的占位概率降低,V原子的占位概率增大。结合以上关于L12相和DO22相体积分数的分析可知,弹性畸变能增大,L12相的体积分数增多,Al原子需要为多余的L12相提供溶质原子,因此Al原子在L12相的占位下降;而DO22相与L12相相反,随弹性畸变能增大,DO22相的体积分数稍有减少,因此V原子有较多的剩余,最终V原子在L12相的占位有所上升。

图5 Ni75Al5V20合金不同弹性畸变能下L12相中Al原子与V原子的占位概率变化

Fig. 5 Variation of atomic occupation probability in L12 phase Al atom(a) and V atom(b) of Ni75Al5V20 alloy at different elastic strain energy

3 结论

1) 当温度为1250 K、不同弹性畸变能时,Ni75Al5V20合金沉淀过程的显微组织演化过程都可大致分为4个阶段:无序基体→短程有序相析出→L12相和DO22相由短程由有序相转化或者由基体相直接转化而析出→部分L12相转化为DO22相→L12相和DO22相沿着[100]方向共同长大粗化。

2) 随着弹性畸变能的增大,合金的孕育期缩短,L12相和DO22相从析出到粗化一直具有方向性,两相更加细化且形状也更加规则,趋于长方形;而且在沉淀过程的整个过程中都有利于L12相的析出,而对DO22相的析出量影响不大。

3) 当弹性畸变能存在时,在早期沉淀析出的L12相中,V原子的占位要远大于Al原子的占位概率;随着时间的演化,Al原子的占位概率逐渐升高,V原子的占位概率逐渐降低,最终均达到各自的平衡状态,且V原子在L12相中也有一定的占位。随着弹性畸变能的增大,在L12相中Al原子的占位概率降低,V原子的占位概率下降。

4) 在生成化学计量比的L12有序相时,Al原子由L12相边界逐渐向其内部扩散,而V原子则由其内部向边界扩散。各原子越靠近在L12相的边界扩散速度越快,反之,扩散速度越慢。

REFERENCES

[1] REN X D, ZHAN Q B, YUAN S, ZHOU J Z, WANG Y, REN N F, SUN G F, ZHENG L M, DAI F Z, YANG H M, DAI W J. A finite element analysis of thermal relaxation of residual stress in laser shock processing Ni-based alloy GH4169[J]. Materials and Design, 2014, 54: 708-711.

[2] JIANG R, EVERITT S, LEWANDOWSKI M, GAO N, REED P A. Grain size effects in a Ni-based turbine disc alloy in the time and cycle dependent crack growth regimes[J]. International Journal of Fatigue, 2014, 62: 217-227.

[3] XIAO Feng, YANG Ren-hui, LIU Lan-xiao, ZHAO Hong-kai, FANG Liang, ZHANG Chi. Density and molar volume of molten Ni-based commercial alloys measured by modified sessile drop method[J]. Rare Metal Materials and Engineering, 2009, 38(5): 770-773.

[4] 王新然, 赵宇宏, 侯 华, 杨东然, 王 锟, 李海峰. Ni74.6AlxMo25.4-x合金早期沉淀过程的微观相场模拟[J]. 中国有色金属学报, 2014, 24(7): 1730-1735.

WANG Xin-ran, ZHAO Yu-hong, HOU Hua, YANG Dong-ran, WANG Kun, LI Hai-feng. Microscopic phase-field simulation for early precipitation process of Ni74.6AlxMo25.4-x alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(7): 1730-1735.

[5] 霍进良, 王永欣, 陈 铮, 张 静, 赵 彦, 张利鹏. 应变能对Ni75Cr16.4Al8.6合金沉淀过程影响的微观相场研究[J]. 稀有金属材料与工程, 2008, 37(10): 1723-1727.

HUO Jin-liang, WANG Yong-xin, CHEN Zheng, ZHANG Jing, ZHAO Yan, ZHANG Li-peng. The phase-field model study with the elastic energy for the effect on the precipitation in Ni75Cr16.4Al8.6 alloy[J]. Rare Metal Materials and Engineering, 2008, 37(10): 1723-1727.

[6] 刘 芳, 王永欣, 陈 铮, 王晓鹏, 陈 阡, 唐洪奎. 微观相场法研究应变能对Ni68.2Al22.7V9.1合金中两相沉淀及原子占位的影响[J]. 稀有金属材料与工程, 2012, 41(6): 973-977.

LIU Fang, WANG Yong-xin, CHEN Zheng, WANG Xiao-peng, CHEN Qian, TANG Hong-kui. Study for the effect of strain energy on two-phase precipitation and atoms occupying in Ni68.2Al22.7V9.1 alloy using the microscopic phase-field method [J]. Rare Metal Materials and Engineering, 2012, 41(6): 973-977.

[7] 陈引平, 王永欣, 卢艳丽, 郭 舒, 杨 坤, 陈 铮. 应变能对Ni75Al15V10合金预析出相影响的微观相场研究[J]. 稀有金属材料与工程, 2011, 40(8): 1361-1366.

CHEN Yin-ping, WANG Yong-xin, LU Yan-li, GUO Shu, YANG Kun, CHEN Zheng. Study for the effect of strain energy on pre-precipitation phase in Ni75Al15V10 alloy using the microscopic phase-field method[J]. Rare Metal Materials and Engineering, 2011, 40(8): 1361-1366.

[8] 马庆爽, 靳玉春, 赵宇宏, 侯 华, 王欣然, 王 锟. Ni-Al间作用势对Ni75Al14Mo11合金原子有序化影响的微观相场模 拟[J]. 中国有色金属学报, 2015, 25(6): 1450-1457.

MA Qing-shuang, JIN Yu-chun, ZHAO Yu-hong, HOU Hua, WANG Xin-ran, WANG Kun. Microscopic phase-field simulation for influence of Ni-Al interaction energy on ordering behavior of Ni75Al14Mo11 alloy atoms[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(6): 1450-1457.

[9] LU Yan-li, LU Guang-ming, JIA De-wei, CHEN Zheng. Phase-field study on competition precipitation process of Ni-Al-V alloy[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(2): 544-551.

[10] ZHANG Ming-yi, LI Zhi-gang, ZHANG Jin-ling, ZHANG Hui-zhan, CHEN Zhen, ZHANG Jia-zhen. Site occupation evolution of alloying elements in Ni3V phase during phase transformation in Ni75Al4.2V20.8[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(5): 1599-1604.

[11] 张明义, 杨 坤, 陈 铮, 王永欣, 张嘉振. L12相间有序畴界成分的微观相场研究[J]. 稀有金属材料与工程, 2013, 42(6): 1194-1198.

ZHANG Ming-yi, YANG Kun, CHEN Zheng, WANG Yong-xin, ZHANG Jia-zhen. Microscopic phase-field Study on the compositions of ordered domain interfaces formed between L12 phases[J]. Rare Metal Materials and Engineering, 2013, 42(6): 1194-1198.

[12] ZHANG Ming-yi, CHEN Zheng, WANG Yong-xin, MA Guang, LU Yan-li, FAN Xiao-li. Effect of atomic structure on migration characteristic and solute segregation ofordered domain interfaces formed in Ni75AlxV25-x[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(3): 604-611.

[13] 张明义, 陈 铮, 王永欣, 卢艳丽, 张 静, 范晓丽. Ni75AlxV25-x合金DO22到L12相变过程异相界面的结构及其迁移特征[J]. 金属学报, 2009, 45(8): 930-936.

ZHANG Ming-yi, CHEN Zheng, WANG Yong-xin, LU Yan-li, ZHANG Jing, FAN Xiao-li. Structure and migration characteristic of hetero interfaces during the phase transforrmation from DO22 to L12 phase in Ni75AlxV25-x alloys[J]. Acta Metallurgica Sinica, 2009, 45(8): 930-936.

[14] 张明义, 杨 坤, 陈 铮, 王永欣, 张嘉振. DO22相间反相畴界成分演化的微观相场模拟[J]. 有色金属工程, 2012, 2(4): 21-27.

ZHANG Ming-yi, YANGH Kun, CHEN Zheng, WANG Yong-xin, ZHANG Jia-zhen. Microscopic phase-field study on the compositions of ordered domain interfaces formed between DO22 phases[J]. Nonferrous Metals Engineering, 2012, 2(4): 21-27

[15] 赵宇宏. 合金早期沉淀过程的原子尺度计算机模拟[D]. 西安: 西北工业大学, 2003.

ZHAO Yu-hong. Atomic-scale computer simulation for alloy during early precipitation process[D]. Xi’an: Northwestern Polytechnical University, 2003..

[16] 赵宇宏. 材料相变过程微观组织模拟[M]. 北京: 国防工业出版社, 2010.

ZHAO Yu-hong. Simulation for the materials microstructure evolution in phase transformation process[M]. Beijing: National Defend Industry Press, 2010.

[17] HOU Hua, WEN Zhi-qin, ZHAO Yu-hong. First-principles investigations on structural, elastic, thermodynamic and electronic properties of Ni3X (X=Al, Ga and Ge) under pressure[J]. Intermetallics, 2014, 44: 110-115.

[18] QI Lei, JIN Yu-chun, ZHAO Yu-hong. HOU Hua. The structural, elastic, electronic properties and Debye temperature of Ni3Mo under pressure form first-principles[J]. Journal of Alloys and Compounds, 2015, 621: 383-388.

[19] KHACHATURYAN A G. Theory of structural transformations in solids[M]. New York: Wiley, 1983, 41(2): 208.

[20] PODRUI R, CHEN L Q. Computer simulation of atomic ordering and compositional clustering in the pseudobinary Ni3Al-Ni3V system[J]. Acta Materialia, 1998, 46(5): 1719-1729.

[21] CHEN L Q. A computer simulation technique for spinodal decomposition and ordering in ternary systems[J]. Scr Metall Mater, 1993, 29(5): 683-688.

Effect of elastic strain energy on L12 phase precipitation simulated by using microscopic phase-field method

ZHENG Xiao-juan, ZHAO Yu-hong, HOU Hua, JIN Yu-chun, MA Qing-shuang, TIAN Jin-zhong

(College of Materials Science and Engineering, North University of China, Taiyuan 030051, China)

Abstract: The precipitation process of L12 phase in Ni75Al5V20 alloy was mainly simulated by using the microscopic phase-field kinetic mode. The results demonstrate that the process of microscopic morphology evolution can be divided into four stages for Ni75Al5V20 alloy at 1250 K on different elastic strain energy, but there also are some different points. The occupation probability of Al atom is greater than V atom in early precipitation of L12 phase when the elastic strain energy is existent. Eventually, with increasing the elastic strain energy, the occupation probability of Al atom reduces and the occupation probability of V atom increases in L12 phase. When stoichiometric L12 ordered phase generates, the Al atoms gradually diffuse from L12 phase boundaries to its internal, meanwhile, the V atoms gradually diffuse from L12 phase internal to its boundaries, and the atoms in L12 phase are more closer to boundary, their diffusion speed becomes more faster, conversely becomes more slowly.

Key words: Ni75Al5V20 alloy; microscopic phase-field; elastic strain energy; occupation probability; L12 phase

Foundation item: Projects(51774254, 51774253, 51701187, U1610123, 51574207, 51574206, 51574226) supported by the National Natural Science Foundation of China; Project(MC2016-06) supported by the Science and Technology Major Project of Shanxi Province, China

Received date: 2016-08-15; Accepted date: 2016-11-02

Corresponding author: ZHAO Yu-hong; Tel: +86-15035172958; E-mail: zyh388@sina.com

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51774254,51774253,51701187,U1610123,51574207,51574206,51574226);山西省科技重大专项 (MC2016-06)

收稿日期:2016-08-15;修订日期:2016-11-02

通信作者:赵宇宏,教授,博士;电话:15035172958;E-mail: zyh388@sina.com

摘 要:基于微观相场法研究不同弹性畸变能对Ni75Al5V20合金中L12相沉淀过程的影响。结果表明:虽然弹性畸变能不同,Ni75Al5V20合金在温度为1250 K下沉淀时的显微组织演化过程都可大概分为4个阶段,但也有不同之处;在早期沉淀析出的L12相中,V原子的占位要远大于Al原子的占位,最终,随着弹性畸变能的增大,在L12相中Al原子的占位概率降低,V原子的占位概率增大。在生成化学计量比的L12有序相时,Al原子由L12相边界逐渐向其内部扩散,而V原子则与之相反,且各原子越靠近L12相的边界扩散速度越快,反之越慢。