Influence of interstitial content on mechanical properties of new type of

near α titanium alloy at cryogenic temperature

LIU Wei(刘伟), DU Yu(杜宇), YANG Guan-jun(杨冠军)

Northwest Institute for Nonferrous Metal Research, Xi’an 710016, China

Received 15 July 2007; accepted 10 September 2007

Abstract:

The influence of interstitial content on mechanical properties of a new type of near α titanium alloy (Ti-Zr-Mo-Nb-Sn) at cryogenic temperature was studied. The results show that interstitial content affects the mechanical properties of the alloy at cryogenic temperature. Interstitial element atoms solving into lattice causes the increasing of degree of distortion, which limits the sliding and twinning of dislocations. Reducing interstitial content is beneficial to generation of dislocation sliding and deformation twins. With interstitial element content reducing, the impact toughness and the elongation of the alloy decrease rapidly while the strength decreases weakly. To obtain good over-all properties at cryogenic temperature, the interstitial element content in this alloy must be controlled to extra low grade.

Key words:

interstitial content; oxygen equivalent; α titanium alloy; mechanical properties; cryogenic temperature ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ; ;;

1 Introduction

Titanium alloys are ideal structural materials for aerospace applications because of their high specific strength and good performance at cryogenic temperature. There are two methods commonly used by local and foreign researchers to improve the performance of the materials at cryogenic temperature: reducing the content of oxygen or Al in the alloys[1-3]. Low Al content has negative effects on solution strengthening, therefore, reducing O and other interstitials becomes the leading method to improve the properties.

The content of interstitials has negative effects on the impact toughness and elongation of the alloys at cryogenic temperature[4], so it is very important to study the relations between the mechanical properties and the interstitials content for further application of a new alloy in engineering. The authors focused on the influence of interstitial content on mechanical properties of a new type of near α titanium alloy (Ti-Zr-Mo-Ni-Sn) at cryogenic temperature.

2 Experimental

2.1 Oxygen equivalent

Alloys can be strengthened by solution treatment of interstitials and strengthening degree/effect gradually increases by the turn of C, O, N. Conversing in atomic mass, the strengthening effect of C is equivalent to 3/4 O and N is about 2 Oxygen. Therefore, it is convenient to take a combination consideration of interstitials by oxygen equivalent[5-6]. Oxygen equivalent can be calculated by the following formula:

Oxygen equivalent=w(O)+3/4w(C)+2w(N) (1)

2.2 Materials and Methods

Zero level sponge titanium particulate, atomic energy level sponge Zr, pure power Mo, Ni-Ti and Ti-Sn inter-alloys, power TiO2 with slight difference in amount are used to produce 3 ingots by VAR remelting and the ingots are different in interstitial content. Table 1 lists the oxygen equivalent of the ingots calculated by Eqn.(1).

After forged and hot rolled, the ingots became 13 mm thickness plates. The plates annealed at 750 ℃ were made into impact sample of 77 K along transverse direction and longitudinal direction by GB6397—86. Impacting tests were finished on Charpy impact machine tester and JSM5800 and S-2700 HITACHI SEM were adapted to analyze fracture after impacting experiment. Tensile samples at cryogenic temperature with 3 mm diameter were manufactured according to GB6397—86. Tensile experiment at 20 K took liquid helium as refrigerating medium and was finished on WD-10A tester. Analysis to fracture and microstructure was completed by TSM5800 SEM and Philips M400T TEM, respectively.

Table 1 Interstitial element contents and oxygen equivalents in ingots (mass fraction, %)

3 Results and discussion

3.1 Mechanical properties at cryogenic temperature

Table 2 lists tensile properties of the alloy with different oxygen equivalents at 20 K, and the impact properties at ambient temperature and 77 K are shown in Fig.1.

Table 2 Tensile properties at 20 K of alloys with various oxygen equivalents

With the oxygen equivalent reducing from 0.23% to 0.20%, the strength decreases by 3% while elongation increases by 9%. Especially when the oxygen equivalent is reduced from 0.20% to 0.15%, the strength just decreases by 1.57% while the elongation increases by 51.2%. Obviously, the interstitial content has active effect on elongation while a little influence on strength of the alloy, especially when the oxygen equivalent is low. So, favorable elongation could be got at cryogenic temperature when the interstitial content of the alloy is low.

In Fig.1, LS, LT, TS and TL represent surface impact in longitudinal direction, transverse impact in longitudinal direction, surface impact in transverse direction and longitudinal direction respectively. Alpha-texture of hexagonal-close-packed of the alloy results in anisotropic impact toughness at ambient temperature. Impact load direction of LS makes it easiest to generate sliding strain for hcp crystals than the others, especially the impact load direction of LT. This explains why impact toughness value of LS is the highest while that of LT is the lowest. The oxygen equivalent affects much more on impact toughness at 77 K than it does at ambient temperature, increasing tendency of impact toughness is smooth while drastically at 77 K. In this connection, with temperature coming down, it becomes difficult for sliding strain to get further expansion because the force is an impediment to dislocation sliding rapidly, which results in plastic deformation localization under the rapid loading condition and makes brittle fracture possible. Therefore, the impact toughness of the alloy is susceptible to interstitial content at cryogenic temperature.

Fig.1 Impact properties of alloys with various oxygen equivalents at room temperature (a) and 77 K (b)

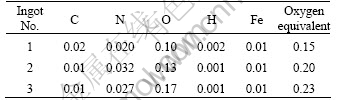

3.2 Fracture analysis

Fig.2 shows the fractures of specimen after impacting at 77 K. Macro-fracture is rough and second- cracks exist when the oxygen equivalent is low. Fracture gets smooth and all-over blink facets emerge with oxygen equivalent increasing. Micro-fracture is featured with quasi-cleavage. Energy is needed for crack initiation and expansion, and the existence of second-crack indicates that the materials absorb a large number of energy in cracking process, so the value of impact toughness is high. Analysis of fractures shows that the impact toughness is high when the oxygen equivalent of alloy is low.

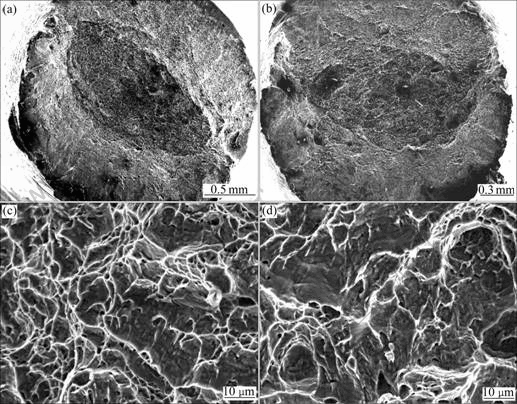

Fig.3 shows the fractures after tensile test at 20 K.

Fig.2 SEM micrographs of fracture surface of alloy after impacting with different oxygen equivalents at 77 K: (a) and (b) Oxygen equivalent 0.15%; (c) and (d) Oxygen equivalent 0.23%

Fig.3 SEM micrographs of fracture surface of alloy after tensile test with different oxygen equivalents at 20 K: (a), (c) Oxygen equivalent 0.15%; (b), (d) Oxygen equivalent 0.23%

When the oxygen equivalent is low, necking is evident and macro-fracture is oval-shaped and rough. There are lots of dimples and second cracks at bottom of dimple, and the alloy has favorable performance at elongation. With oxygen equivalent increasing, degree of necking becomes slight and amount of blink facet increases. The dimples are various in dimensions and fractures locally are characterized with quasi-cleavage, elongation gets deterioration as well.

3.3 Behavior of cryogenic strain

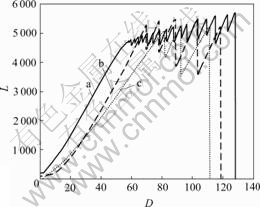

Fig.4 shows tensile load—displacement curves of alloy with different oxygen equivalents at 20 K. The curves go like teeth. With the oxygen equivalent reducing, the amount of the teeth increases while fluctuating amplitude decreases and several shear bands and thin necks emerge in the deformation zone. Cornet dimension between shear band and tensile direction is 45? and cracking finally takes place at thin-neck or shear band. This multi-neck case is described in Ref.[8]. The results[7, 9] show that twinning deformation starts at some area where the cornet dimension between maximum shear stress and tensile axis is 45? because it is difficult to slide deformation for high critical shear strain at 20 K. Low specific heat content of the alloy results in temperature up at local area of shear deformation zone and starting slide. Alternating work between twinning and sliding makes thin necks emerging that can not further develop for the work-hardening and thermal feedback disappearing, and this gives a chance for generating new necking. The multi-necking makes elongation of the alloy unstable and every necking is corresponding to a tooth of the curve.

Fig.4 Tensile load (L) vs displacement(D) curves of alloy with different oxygen equivalents at 20 K: (a) Oxygen equivalent 0.15%; (b) Oxygen equivalent 0.20%; (c) Oxygen equivalent 0.23%

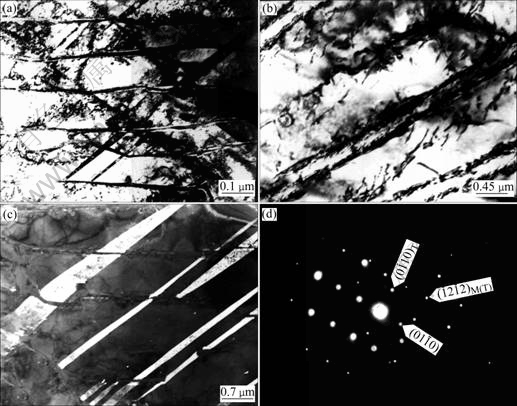

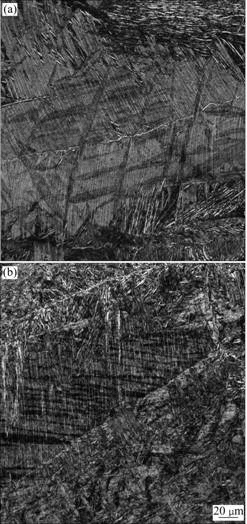

Fig.5 shows the tensioned deformation micro- structure of the alloy with different oxygen equivalents at 20 K.

Fig.5 Microstructures and SAED pattern of alloy after tensioned deformation with different oxygen equivalents at 20 K: (a), (c), (d) Oxygen equivalent 0.15%; (b) Oxygen equivalent 0.23%

Dislocation density in tensioned deformation microstructure of the alloy with high oxygen equivalent is lower than that with low oxygen equivalent, and there is no twin observed in the alloy with high oxygen equivalent while a large number of {1122} twins exist in low oxygen equivalent alloy. Twin is observed in both of microstructures at 77 K (Fig.6) and twins interact obviously. Difference between the twins is just appearance and twins in microstructure of the alloy with high oxygen equivalent are slim because its development is limited. Interstitials such as O, C and N solve into lattice[10], c/a is up and degree of distortion gets added, which limits sliding and twinning of dislocation. Just as Ref.[10] describes: high strain rate has the same effect as low deformation temperature does and twinning is more susceptible to strain rate, and this explains why twinning is observed in microstructure at 77 K.

Fig.6 Microstructures of alloys after impacting with different oxygen equivalents at 77 K: (a) Oxygen equivalent 0.15%; (b) Oxygen equivalent 0.23%

The results in Refs.[11-14] show, as for multi-crystal metal with hcp structure, twins can supply some strain by themselves, release stress concentrations, adjust grain orientation and delay crack initiations so as to make the sliding continue. Elongation of one alloy improves drastically at cryogenic temperature by twins helping deformation.

4 Conclusions

1) With interstitial element content reducing, the strength of the alloy decreases weakly, while the elongation and the impact toughness increase obviously.

2) Interstitials result in the distortion of lattice, so reducing its content is beneficial to the generation of dislocation sliding and deformation twins.

3) To obtain favorable properties at cryogenic temperature, the interstitial content in the alloy must be controlled to extra low grade.

References

[1] WOOD R A, FAVOR R J. Titanium alloys handbook [M]. New York: Plenum Press, 1972.

[2] PU Zheng-li, ZHANG Ting-jie, et al. Rare Metal Materials and Engineering, 1996, 25(4): 25. (in Chinese)

[3] CHEN Ding, HUANG Pei-yun. Mining And Metallurgical Engineering, 2002, 22(3): 111-114.

[4] ZHENG Gui-ju, TANG Jin-biao, QIAN Dong-fan. A Collection of the 4th National Conference on Titanium Alloy [C]. 1981.

[5] BOYER R, WELSCH G, COLLINGS E W. Materials properties handbook: Titanium alloys [M]. ASM International: The Materials Info Society, 1994.

[6] SEEGER A. Dislocation and mechanical property of crystals [M]. New York: Wiley,1957.

[7] CAI Xue-zhang, YANG Guan-jun, DU Yu. Stress-strain and fracture of Ti-3Al-2.5Zr alloy at cryogenic temperature [C]// Proceedings of Xi’an Iinternational Titanium Conference. 1998: 699.

[8] KAWABATA T, MORITA S, IZUMI O, KIMURA H, IZUMI O. Proc 4th International Conference on Titanium [C]. Warrendale, PA: AIME, 1980: 801.

[9] YANG Guan-jun, CAI Xue-zhang. Acta Metall, 1999, 35(s1): 475-478.

[10] WASZ M W, BROTZEN F R. International Materials Reviews, 1996, 41(1): 1-5.

[11] SEEGER A. Dislocation and mechanical property of crystals [M]. New York: Wiley, 1957, 243-250.

[12] FRIEDEL J. Electron microscopy and strength of crystals [M]. THOMAS G, WASHBURN J, ed. New York: Int Science Pub, 1963.

[13] SUN Q Y, SONG X P, GU H C. Trans Nonferrous Met Soc China, 2001, 11(1): 132-134.

[14] SUN Q Y, YU Z T, ZHU R H, et al. Materials Science and Engineering A, 2004, 364(112): 159-165.

Foundation item: Project(2007CB613807) supported by National Basic Research Program of China

Corresponding author: LIU Wei; Tel: +86-29-86231078; E-mail: neuanakin@126.com

(Edited by PENG Chao-qun)

[1] WOOD R A, FAVOR R J. Titanium alloys handbook [M]. New York: Plenum Press, 1972.

[3] CHEN Ding, HUANG Pei-yun. Mining And Metallurgical Engineering, 2002, 22(3): 111-114.

[6] SEEGER A. Dislocation and mechanical property of crystals [M]. New York: Wiley,1957.

[9] YANG Guan-jun, CAI Xue-zhang. Acta Metall, 1999, 35(s1): 475-478.

[10] WASZ M W, BROTZEN F R. International Materials Reviews, 1996, 41(1): 1-5.

[11] SEEGER A. Dislocation and mechanical property of crystals [M]. New York: Wiley, 1957, 243-250.

[13] SUN Q Y, SONG X P, GU H C. Trans Nonferrous Met Soc China, 2001, 11(1): 132-134.

[14] SUN Q Y, YU Z T, ZHU R H, et al. Materials Science and Engineering A, 2004, 364(112): 159-165.