J. Cent. South Univ. (2012) 19: 1125-1131

DOI: 10.1007/s11771-012-1118-y![]()

Stress-strain behavior of plastic concrete using

monotonic triaxial compression tests

Y. Pashang Pisheh, S. M. Mir Mohammad Hosseini

Department of Civil and Environmental Engineering, Amirkabir University of Technology, Tehran 15914, Iran

? Central South University Press and Springer-Verlag Berlin Heidelberg 2012

Abstract:

The mechanical behavior of plastic concrete used in the cut-off walls of earth dams has been studied. Triaxial compression tests on the specimens in various ages and mix designs under different confining pressures have been done and the stress-strain behavior of such materials and their strength parameter changes have been experimentally investigated. It has been observed that increasing the confining pressures applied on the specimens causes the material behavior to be alike the more ductile materials and the compressive strength increases considerably as well. Moreover, a parametric study has been carried out to investigate the influence of essential parameters on the shear strength parameters of these materials. According to the research, increasing the coarse to fine aggregates ratio leads to the increase of compressive strength of the specimens as well as the increase of the cohesion and internal friction angle of the materials. Furthermore, the bentonite content decrease and the cement factor increase result in an increase of the cohesion parameter of plastic concretes and decrease of the internal friction angle of such materials.

Key words:

plastic concrete; stress-strain behavior; triaxial compression test; strength; elastic modulus;

1 Introduction

Water, as one of the most valuable nonrenewable resources, has always attracted the attention of human beings who have all the time made their best to make optimal use of it. One of the most important water resources available all over the world is surface water and throughout the history human beings have always tried to control and use the energy derived of it. The most important tool for controlling surface water is the construction of dams. Earth dams have highly attracted the attention due to their privileges and such characteristics as capability of being constructed upon weak foundations and the possibility of using local materials instead of costly concrete materials. Hence, there have been so many researches done in relation to behavior of this type of dams.

Among the various issues discussing about designing earth dams, the seepage of water into the earth body of dams as well as their foundations has been one of the most important issues being regarded as an effective factor involved in designing such huge constructions. There are different methods for controlling the seepage in the foundation of such dams. One of the most popular methods is to make use of a plastic concrete cut-off wall constructed in weak foundations of earth dams. Among other applications, such walls are effective on stabilizing excavations, and they act as the separator of two environments from each other, e.g. separating environmental palliatives from local waters in order to prevent further pollution [1-5].

Plastic concrete is typically a mixture of sand-gravel aggregates, cement, bentonite and water. This type of concrete has widespread applications in the structure of cut-off walls of the earth dams. This material, due to lower rigidity than normal concrete and its appropriate impermeability, can suitably meet the intended needs for designing cut-off walls of dams [6-8]. Thus, the walls constructed using this type of concrete, in addition to their characteristics of flexibility and low permeability, have a desirable shear strength and as such, their application to the construction of cut-off walls of dams is often more economical than a large number of other methods [1].

Due to the considerable loads applied on the foundation and the cut-off wall, the mechanical properties and behavior of materials used in the construction of such walls are of great significance. Moreover, since there are confining pressures applied on the cut-off walls in the real condition, there will be an urgent requirement for exact investigation of the possible impacts of triaxial pressures on the mechanical behavior of plastic concrete materials because such studies are necessary for numerical modeling used in the analysis of the behavior of wall under loads resulted from the dam.

Although there is a large number of research works on the mechanical behavior of plastic concretes through unconfined pressure experiments [9-11], there have been a limited number of triaxial experiments in this area and the existing findings seem not to be practically desirable. The present work is aimed at studying the behavior of such materials under triaxial pressures as well as investigating the impacts of such parameters as coarse to fine aggregates ratio, the bentonite content, the cement factor, and the age of the specimens on the mechanical behavior of plastic concrete materials.

2 Materials and specimens

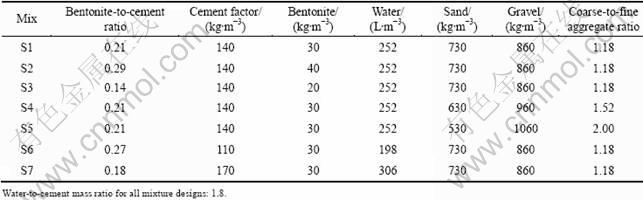

Herein, seven mixtures of plastic concrete have been proportioned and the significance of various parameters such as the ratio of coarse to fine aggregates, bentonite content and cement factor on the properties of plastic concrete has been studied. Mixture designs and material proportions for the plastic concrete specimens are reported in Table 1. Specimens prepared for the triaxial compression tests were compacted in steel molds with 10 cm in diameter and 20 cm in height, and kept under water for curing in saturated conditions to the required age.

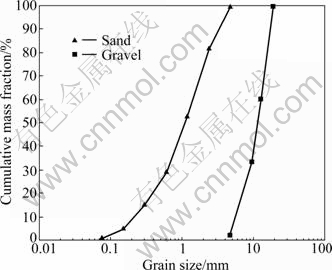

The particle size distribution curves (PSD) of the gravel and sand aggregates incorporated in the plastic concrete specimens are illustrated in Fig. 1. The cement used in the mix designs was Type I-425 from Tehran Cement Company and the bentonite was commercially acquired from Salafchegan. Table 2 presents the specifications of the bentonite used for the current investigation. Owing to the very low permeability and very high water absorption of bentonite material, it was mixed with 90% of the water determined for the mix design 24 h prior to sample preparation. The remaining water content, i.e. 10%, was introduced upon the mixture preparation and adding of cement and aggregates. This scheme ensured that the bentonite particles are uniformly distributed and a homogenous mixture is derived.

3 Triaxial apparatus and tests procedure

A fully automated closed-loop servo controlled triaxial apparatus capable of exerting stress/strain defined stress paths is incorporated. Strain controlled loading is applied under various confiding pressures. Axial displacement is monitored and controlled by a LVDT with the range and accuracy of 254 mm and 0.02 mm, respectively. The air pressure control system and regulator can provide a cell pressure up to 1 000 kPa. Axial load is measured by a 50 kN load cell with the precision of 0.6 kN. Triaxial tests are performed with the constant confining pressures of 0, 200, 350 and 500 kPa. A photograph of the apparatus during testing is depicted in Fig. 2.

According to ASTM D2166 and ASTM D2850 for unconfined and triaxial tests [12-13], soils for which the strain values corresponding to the peak stress range between 0.03 and 0.06 are designated as brittle materials. For such materials, the loading rate in triaxial tests should be 0.003 min-1. For plastic concretes, the peak strength is mobilized at strain range of 0.004-0.009; hence, this material is comparable to very brittle cemented soils where the strain corresponding to the peak strength is 1/6 to 1/10 of the value for brittle soils [13-14]. Based on the foregoing, the shear loading rate for plastic concrete specimens should be adjusted to account for this mechanical behavior. The loading rate in triaxial tests on this very brittle material is determined as 0.000 3 min-1. Therefore, for a cylindrical specimen with height of 200 mm, the loading rate was determined as 0.05 mm/min to minimize the damping effects, to allow the growth of micro cracks, and to provide the static condition requirements throughout the experiments.

4 Various parameters effects on plastic concrete behavior

4.1 Confining pressure

In the current work, the unconfined and triaxial tests on the plastic concrete specimens were conducted at the confining pressures of 0, 200, 350 and 500 kPa. Figure 3 shows the effect of confining pressure on the compressive strength of mix S1 at the age of 28 d. Anticipatively, the compressive strength rises as the confining pressure increases. Moreover, increase in the confining pressure causes changes in the mode of failure for the specimens. At zero or low confining pressures, the failure mode is similar to brittle materials and the specimens fail, showing a distinct peak strength point, accompanied by strain-softening behavior. For higher confining pressures, the behavior is more ductile and the axial strain corresponding to failure tends to higher magnitudes up to 5%-6%. In this condition, the stress- strain curve continues to reach higher strain values as a horizontal plateau. The aforementioned behavior has been observed for similar hardened cemented materials by previous investigators [11-13, 15-16].

Table 1 Mixture designs proportions of plastic concrete mixes

Fig. 1 Particle size distribution curves of gravel and sand aggregates used in mixes

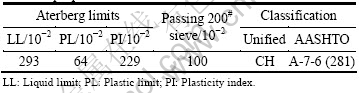

Table 2 Specifications of Salafchegan bentonite used for plastic concrete proportions

Fig. 2 Cell containing plastic concrete specimen during testing

Fig. 3 Variation of deviator stress versus axial strain for unconfined and triaxial compression tests for mix S1 at age of 28 d

It must be noted that, at lower confining pressures, the failure mechanism is governed by the progressive deterioration of cement paste bonds between the aggregates, while for higher confining pressures, the shear strength is controlled by the frictional characteristics of the materials [17-19].

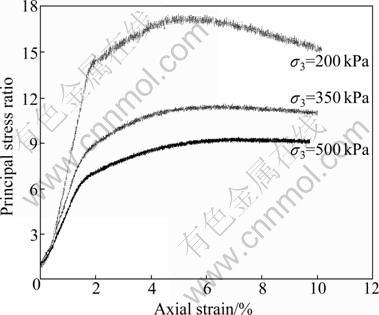

Figure 4 illustrates the effects of confining pressure on the principal stress ratio, σ1/σ3, for mix design S1 at the age of 28 d. Accordingly, as the confining pressure increases, the stress ratio decreases significantly, that is to say, with the increase of confining pressure, the axial strength of the specimens increases with a smaller rate rather than the confining pressures.

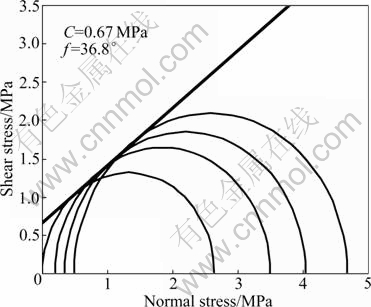

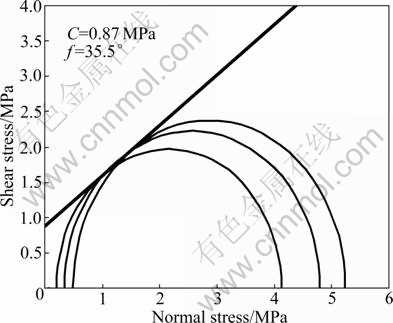

Hard cemented granular materials, such as plastic concretes, are mechanically distinguished from soils and rocks [20-21]. Hence, their mechanical behavior is governed by the interlocking and friction of grains, as well as cohesion resulted from cemented bonds. The mechanical properties of these materials are similar to very hard soils and show generally a coulomb type behavior [19]. Mohr circles and corresponding envelopes for triaxial tests on specimens of mix design S1 at 28 and 90 d are shown in Figs. 5 and 6, respectively. So, by appreciating the Mohr coulomb failure model for plastic concrete material behavior, shear strength parameters such as internal friction angle and cohesion parameter can be determined.

Fig. 4 Principal stress ratio versus axial strain for triaxial compression tests

Fig. 5 Mohr circles and envelope for specimens with mix design S1 at age of 28 d

Fig. 6 Mohr circles and envelope for specimens with mix design S1 at age of 90 d

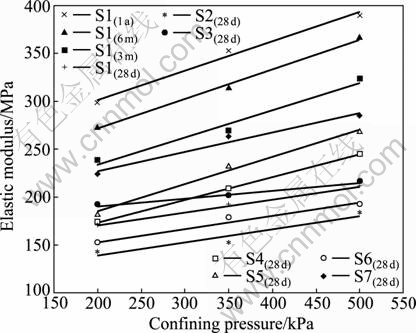

Figure 7 shows the effect of confining pressure on the elastic modulus of plastic concrete materials for different mixture designs. As observed here, with an increase in the confining pressure, the level of elastic modulus of such materials increases. On one hand, the increasing rate for specimens with different proportion mixtures varies depending on the coarse to fine aggregates ratio, cement factor, and bentonite content. On the other hand, the augmentation rates in elastic modulus with the increase in confining pressure are almost equal for specimens with the same mix design but different ages.

Fig. 7 Effect of confining pressure on elastic modulus for specimens with different mix designs and ages

4.2 Specimen age

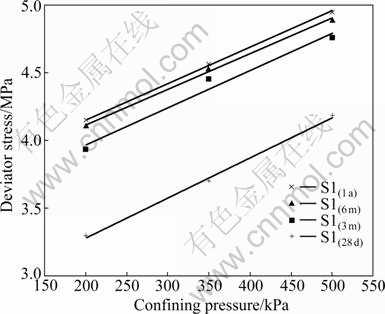

The effects of specimen age on the mechanical behavior of plastic concrete including the elastic modulus and compressive strength are illustrated in Figs. 7 and 8. As can be seen, the elastic modulus and compressive strength of plastic concrete specimens for mix design S1 increase at higher ages. This increasing rate is almost identical for the specimens irrespective of their confining pressures. In addition, the compressive strength of the specimens grows more slowly in higher ages. Therefore, it can be concluded that making use of bentonite material slows down the chemical reaction of cement hydration in the plastic concrete and as such, the rate of strength increase in such kind of materials would be less than that of normal concretes.

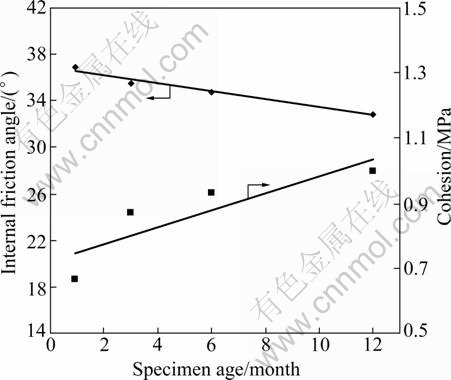

Moreover, the variation of shear strength parameters including internal friction angle, f, and cohesion, C, with respect to specimen age is illustrated in Fig. 9. As the specimen age increases, the cohesion parameter of the material increases although the internal friction angle undergoes a small reduction. It can be concluded that as time elapses the cement hydration process of the material is completed, therefore the cement paste bond between aggregate particles becomes stronger and this influences the shear strength parameters as described above.

Fig. 8 Effect of specimen age on compressive strength of plastic concrete specimens at different confining pressures

Fig. 9 Influence of specimens age on shear strength parameters

4.3 Coarse to fine aggregates ratio

The influence of coarse to fine aggregates ratio on plastic concrete materials is illustrated in Figs. 7 and 10. As can be seen, by increasing the ratio, the elastic modulus and compressive strength of plastic concrete specimens increase. Furthermore, shear strength parameters are affected by the coarse to fine aggregates ratio insomuch as the cohesion parameter and the internal friction angle increase (Fig. 11). The physical interpretation of the observed trend is that as the aggregates gradation of the plastic concrete specimen becomes coarser, the specific surfaces of particles are reduced; thus, the cement paste bonding around particles is reinforced and the cohesion parameter increases. In addition, the increase in the coarseness of the aggregates to some extent reinforces the interlocking of grains, hence increasing the internal friction angle slightly.

Fig. 10 Effect of coarse to fine aggregates ratio on compressive strength of plastic concrete specimens

Fig. 11 Effect of coarse to fine aggregates ratio on shear strength parameters

4.4 Bentonite content

The effect of bentonite content on the mechanical properties of plastic concrete is shown in Figs. 7 and 12. Figure 7 states that the elastic modulus of plastic concrete decreases as the bentonite content increases. Therefore, it can be observed that with increasing the bentonite content in plastic concrete specimens, the rigidity of the materials involved will decrease. As can be seen, in the higher magnitude of bentonite content, the trend of reduction of elastic modulus is more obvious so that the specimens with the mix design S2 may experience a 15%-26% decrease in elastic modulus rather than mix S1 as a result of increasing bentonite content. Figure 12 demonstrates that by increasing the bentonite content, the compressive strength of the plastic concrete specimens decreases. This outcome may be attributed to the weakening of bonds between cement and aggregates.

Fig. 12 Effect of bentonite content on compressive strength of specimens

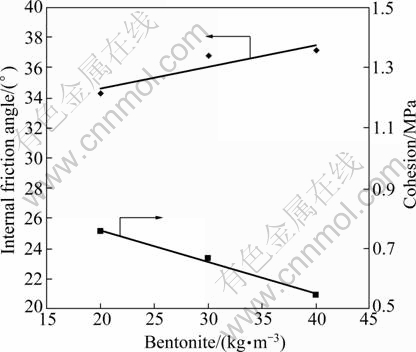

As seen in Fig. 13, by increasing the bentonite content, the cohesion parameter of plastic concrete material decreases although the internal friction angle experiences a small growth.

Fig. 13 Influence of bentonite content on shear strength parameters of plastic concrete specimens

4.5 Cement factor

Akin to normal concrete, the compressive strength and elasticity of plastic concrete are dependent on the cement factor. Figures 7 and 14 show the effect of cement factor on the elastic modulus and compressive strength, respectively. Accordingly, a 30 kg/m3 increase in the cement factor can result in 11%-15% and 32%-37% increase in compressive strength and elastic modulus, respectively, depending on the confining pressure.

Figure 15 illustrates the effects of cement factor on the shear strength parameters of plastic concrete. Increasing the cement factor leads to increase in the cohesion parameter; however, the internal friction angle slightly declines. This effect is different for plastic concrete specimens with dissimilar mixtures.

Fig. 14 Effect of cement factor on compressive strength variations of plastic concrete specimens

Fig. 15 Effects of cement factor on shear strength parameters of specimens

5 Conclusions

1) The mechanical behavior and shear strength parameters of plastic concrete materials under different triaxial stress states are investigated and the effects of confining pressure, specimen age, ratio of coarse to fine aggregates, bentonite content and cement factor are parametrically studied.

2) Based on the research findings, the compressive strength of the plastic concrete materials increases with the increase in the age of the specimens. Moreover, the shear strength parameters including the cohesion and the internal friction angle will change as being affected by the age of the specimens such that with the increase of the age of the specimens, the cohesion parameter increases and the internal friction angle decreases slightly. The elastic modulus of the material increases with the age of the specimens as well.

3) Having increased the confining pressures applied to the plastic concrete specimens, both the compressive strength and the elastic modulus increase. Furthermore, increasing the confining pressure, the axial strain corresponding to the failure tends to higher magnitude and the material behavior becomes more ductile.

4) By increasing the coarse to fine aggregates ratio, the cement bonding around aggregate particles is reinforced. As a result, the cohesion parameter obviously increases. In addition, an increase in the bentonite content results in a decrease of the compressive strength and elastic modulus of the material.

5) The increase of the cement factor in the plastic concrete mixtures increases the compressive strength as well as the elastic modulus of such materials. Furthermore, the shear strength parameters of such materials are affected by characteristic features of the cement used such that the increase in the cement factor increases the cohesion parameter of the material but it decreases the internal friction angle slightly.

References

[1] HAJI GHASEMI A A. Investigation of allowable hydraulic gradient in the plastic concrete [D]. Tehran: University of Tehran, 1998.

[2] SHAHBAZIAN AHARI R. Interaction of plastic concrete cut-off walls with non-homogeneous layered foundations of dams [D]. Tehran: University of Tehran, 2000.

[3] XANTHAKOS P P, ABRAMSON L W, BRUCE L W. Ground control and improvement [M]. New York: Wiley inter-Science, 1994: 87-92.

[4] FADAEI M. Evaluation of dynamic properties of plastic concrete materials using bender elements in the small strain domain [D]. Tehran: Sharif University of Technology, 2010.

[5] RAFT POUR A. The comparison of plastic concrete behavior during uniaxial and triaxial compression tests for two constant slumps: 15 and 17.5 cm [D]. Isfahan: Isfahan University of Technology, 2004.

[6] RAHIMI S. Stress-strain analysis of plastic concrete cutoff walls connection to earth dam cores in the static and dynamic loadings [D]. Tehran: Sharif University of Technology, 2009.

[7] ZOORASNA Z, HAMIDI A, GHANBARI A. Mechanical and hydraulic behavior of cutoff-core connecting systems in earth dams [J]. Electronic Journal of Geotechnical Engineering, 2008, 13(K): 1-12.

[8] ZOORASNA Z, HAMIDI A, GHANBARI A. Stress-strain analysis of different concrete cutoff wall connection systems, case study: Karkheh storage dam [C]// Proceeding of the Sixth International Conference on Case Histories in Geotechnical Engineering. Arlington, USA, 2008: 407-413.

[9] YU Y, PU J, UGAI K. Study of mechanical properties of soil-cement mixture for a cut-off wall [J]. Soils Found, 1997, 37(4): 93-103.

[10] ICOLD. Filling materials for watertight cut off walls [R]. International Committee of Large Dams. Paris: Bulletin No. 51, 1985.

[11] REMR. Design procedure for plastic concrete cut-off walls [R]. Technical note GT-SR-1.3. 1992.

[12] ASTM. Test method for unconfined compressive strength of cohesive soils [M]. Annual book of ASTM standards. American Society of Testing and Materials. ASTM D2166, Philadelphia, 1989.

[13] ASTM. Test method for unconsolidated undrained compressive strength of cohesive soils in triaxial compression [M]. Annual book of ASTM standards. American Society of Testing and Materials. ASTM D2850, Philadelphia, 1989.

[14] HAMIDI A, HAERI S M. Stiffness and deformation characteristics of cemented gravely sands [J]. International Journal of Civil Engineering, 2008, 6(3): 159-173.

[15] MAHBOUBI A, AJORLOO A. Experimental study of the mechanical behavior of plastic concrete in triaxial compression [J]. Cement and Concrete Research, 2005, 35: 412-419.

[16] SFER D, CAROL I, GETTU R, ETSE G. Study of the behavior of concrete under triaxial compression [J]. Journal of Engineering Mechanics, 2002, 128(2): 156-163.

[17] COOP M R, ATKINSON J H. The mechanics of cemented carbonate sands [J]. Geotechnique, 1993, 43(1): 53-67.

[18] LAGIOIA R, NOVA R. An experimental and theoretical study of the behavior of a calcarenite in triaxial compression [J]. Geotechnique, 1995, 45(4): 633-648.

[19] CHAZALLON C, HICHER P Y. A constitutive model coupling elastoplasticity and damage for cohesive frictional materials [J]. Mechanics of Cohesive-frictional Materials, 1998, 3(1): 41-63.

[20] AIREY D W. Triaxial testing of naturally cemented carbonate soil [J]. Journal of Geotechnical Engineering, ASCE, 1993, 119(9): 1379-1397.

[21] NOVELLO E A, JOHNSTON I W. Geotechnical materials and the critical state [J]. Geotechnique, 1995, 45(2): 223-235.

(Edited by HE Yun-bin)

Received date: 2011-04-15; Accepted date: 2011-08-25

Corresponding author: S. M. Mir Mohammad Hosseini, Professor; Tel: +98-21-22250151; E-mail: mirh53@yahoo.com

Abstract: The mechanical behavior of plastic concrete used in the cut-off walls of earth dams has been studied. Triaxial compression tests on the specimens in various ages and mix designs under different confining pressures have been done and the stress-strain behavior of such materials and their strength parameter changes have been experimentally investigated. It has been observed that increasing the confining pressures applied on the specimens causes the material behavior to be alike the more ductile materials and the compressive strength increases considerably as well. Moreover, a parametric study has been carried out to investigate the influence of essential parameters on the shear strength parameters of these materials. According to the research, increasing the coarse to fine aggregates ratio leads to the increase of compressive strength of the specimens as well as the increase of the cohesion and internal friction angle of the materials. Furthermore, the bentonite content decrease and the cement factor increase result in an increase of the cohesion parameter of plastic concretes and decrease of the internal friction angle of such materials.