文章编号:1004-0609(2015)-03-0641-11

钛合金表层机械处理的纳米化组织、力学性能与机理研究进展

李慧敏,李淼泉,刘印刚,刘洪杰

(西北工业大学 材料学院,西安 710072)

摘 要:

机械诱发局部剧烈塑性变形方法是钛合金表层纳米化的主要方法,主要包括表层机械研磨方法、超音速微粒轰击方法、高能喷丸方法和激光脉冲喷丸方法等。通过控制表层机械处理参数可在钛合金表层制备出一定厚度的纳米组织,并沿厚度方向由纳米晶逐渐过渡到基体的粗晶组织;表层纳米组织的形成明显提高了钛合金表层的强度、硬度和抗腐蚀性能等。钛合金的表层纳米化机理受α相和β相含量的影响较大,α相含量为主的钛合金中孪晶分割细化机制占主导地位;β相含量为主的钛合金中位错分割细化机制占主导地位。在总结钛合金表层纳米化近年来取得的进展基础上指出了该技术今后的研究发展方向。

关键词:

中图分类号:TG 146.2 文献标志码:A

Research progress in nanocrystalline microstructure, mechanical properties and nanocrystallization mechanism of titanium alloys via surface mechanical treatment

LI Hui-min, LI Miao-quan, LIU Yin-gang, LIU Hong-jie

(School of Materials Science and Engineering, Northwestern Polytechnical University, Xi’an 710072, China)

Abstract: Local severe plastic deformation via mechanical treatment is the main method for surface nanocrystallization of titanium alloys. The methods mainly include surface mechanical attrition, supersonic fine particles bombarding, high energy shot peening and laser shock peening. Nanostructured surface layer could be synthesized by controlling the processing parameters, and the microstructure gradually changes from nanocrystalline structure to the coarse grains in the base alloy along depth direction. The nonstructural surface layer increases the strength, hardness and corrosion resistance of titanium alloys evidently. The surface nanocrystallization mechanism of titanium alloys mainly depends on the content of α and β phases. The twin intersection mechanism dominate that the refinement in titanium alloys mainly consists of α phase, while the refinement in titanium alloys mainly consisting of β phase was induced by dislocation intersection instead. The investigation prospects of the surface nanocrystallization of titanium alloys via mechanical treatment were proposed on the basis of current status.

Key words: titanium alloy; surface nanocrystallization; microstructure; mechanical property; mechanism

纳米晶具有尺寸细小、界面密度高、晶界结构与普通大角度晶界相似等特点[1]。研究表明,相对于传统粗晶,纳米晶体金属的硬度、强度[2-4]、摩擦性能[5]及低温超塑性[6-7]等力学性能得到显著提高。因此,实现金属表层纳米化,获得纳米晶体结构的表层组织,有利于改善材料性能,扩大金属材料的应用领域。

钛合金作为轻金属合金,具有比强度高、抗腐蚀性能好和中温性能稳定等优良性能,广泛应用于航空航天及发动机结构中。为了满足苛刻服役环境对钛合金提出的更高要求,研究人员希望通过改善钛合金的表层组织来提高钛合金的使用性能。最初,采用机械合金化方法[8]和磁控溅射方法[9],制备出尺寸较小、形状简单的纳米晶样品,但在工程应用中受到限制。近年来,采用大塑性变形方法[10-12],如等通道转角挤压方法(ECAP)、高压扭转方法(HPT),制备出的纳米材料无孔隙,对提高其力学性能具有重要意义。但钛合金属难变形材料,采用上述大塑性变形方法只能获得尺寸为几百纳米的结构,难以进一步实现纳米化。LU等[13]率先提出通过表层机械处理实现金属材料表层自纳米化,所获得纳米晶体结构尺寸沿厚度方向逐渐增大,且与基体无明显界面,制备过程不改变材料尺寸。国内外学者已采用多种剧烈塑性变形方法实现合金表层自纳米化,并进行组织与性能研究。LIU等[14]采用超声喷丸方法在AISI 316L表层制备出厚度约30 μm的纳米晶层,最表层平均晶粒尺寸约10 nm。LU等[15]采用激光冲击方法在ANSI 304不锈钢表层制备出晶粒尺寸为50~200 nm的纳米晶层。TAO等[16]采用表层机械研磨方法在纯铁表层制备出厚度15 μm的纳米组织,位错墙、位错缠结,以及向亚晶界、晶界的转变过程是纳米组织形成的主要机制。LIN等[17]对表层纳米化后与未经处理的AISI 321分别进行低温渗氮处理后发现,表层纳米化后材料表层氮的扩散层厚度更大,耐磨性能及硬度均提高。MAO等[18]采用机械冲击技术使Cu-30Ni合金表面纳米化,从而提高其表面力学性能及耐腐蚀性能。MCFADDEN等[6]采用剧烈塑性变形方法使得Ni、1420-Al、Ni3Al的晶粒尺寸分别减小至20、100和50 nm,纳米化后Ni与Ni3Al的超塑性变形温度远低于常规Ni与Ni3Al的超塑性变形温度。鉴于已有的合金表层纳米化研究报道,本文作者认为将机械处理表层纳米化方法应用于钛合金,可显著提高其表层和整体性能,从而扩大钛合金的应用领域。

近年来国内外学者对钛合金机械处理表层纳米化技术的研究逐渐增多,已在多种钛合金材料表层制备出纳米晶体结构,并通过试验证明机械处理表层纳米化方法可显著改善材料表层和整体性能。在此,本文作者就钛合金表层纳米化在制备方法、组织与性能特点以及晶粒细化机理等方面取得的研究进展进行综述。

1 钛合金表层机械处理纳米化方法

机械诱发局部剧烈塑性变形方法是实现钛合金表层纳米化的主要方法。在外加载荷的重复作用下,材料表层的原始微观组织经过不同方向产生的剧烈塑性变形,逐渐细化至纳米结构[19]。钛合金表层机械处理纳米化方法主要包括表层机械研磨法(Surface mechanical attrition treatment,SMAT)[20-26]、超音速微粒轰击法(Supersonic fine particles bombardment,SFPB)[27]、高能喷丸法(High energy shot peening,HESP)[28-30]、激光脉冲喷丸法(Laser shock processing,LSP)[31-32]、深滚法(Deep rolling,DP)[33]、超声深滚法(Ultrasound-aided deep rolling,UDR)[34]等。在上述表层纳米化方法中,表层机械研磨法、超音速微粒轰击法和高能喷丸法应用最为广泛,激光脉冲喷丸法作为新的表层剧烈塑性变形方法正在受到关注,而采用深滚法和超声深滚法在材料表层获得的纳米晶层厚度较小[33, 35],在此,主要介绍前4种方法。

表层机械研磨法(SMAT)利用振动频率为50~20000 Hz的振动发生器,驱动容器内直径为1~10 mm的光滑球形弹丸产生共振,连续高速撞击材料层,产生高速率剧烈塑性变形,从而使表层晶粒细化至纳米量级[16, 36]。振动频率、振幅、弹丸材质与尺寸、容器形状与尺寸以及处理时间等工艺参数的选择均影响弹丸作用在材料表面的速率,SMAT方法中弹丸速率一般为1~20 m/s。国内外学者采用SMAT方法最先在纯铁、316L不锈钢等材料表层实现了纳米化,随后在多种钛合金材料上成功地制备出表层纳米组织,且改善了钛合金性能[21, 37]。但受振动容器限制,无法采用SMAT方法对尺寸或质量较大的零件进行表层纳米化处理。

通过弹丸撞击材料表面的方式引入高速率应变的方法还有超音速微粒轰击法(SFPB)和高能喷丸法(HESP)。SFPB方法是将小尺寸(直径为50 nm~200 μm)硬质微粒以大速率(300~1200 m/s)的超音速压缩气流轰击材料表面,使材料表层发生剧烈塑性变形,形成纳米晶[38]。SFPB方法主要通过控制空气压力、处理时间、硬质微粒尺寸与材质、喷嘴形状及距材料表层的距离控制表层纳米组织。其优点是可对形状复杂和大平面零件进行表层纳米化处理,克服了SMAT方法受零件尺寸及质量约束的缺点;且SFPB方法的表层纳米化效率较高,适合于工业化生产。其不足是SFPB方法引入材料表面的应变能量较小,导致获得较厚纳米层需要较长处理时间。国内学者已采用SFPB方法实现了纯钛[27]、TC4等[39]材料的表层纳米化,并对纳米化机制及纳米晶层的热稳定性、硬度等性能进行了研究。与SFPB相比,HESP方法可通过改造传统喷丸设备获得高空气压力,借助高压气流将较大尺寸弹丸(直径为0.5~2 mm,主要选用铸钢丸)高速喷射到材料表层,以较高弹丸能量在材料表层引入大应变能,获得较厚的纳米层,具有实际生产意义。HESP方法主要控制空气压力、弹丸类型、喷枪喷嘴与材料表层的距离及处理时间等工艺参数。HESP方法与传统的喷丸方法相似,但是工艺参数与工业应用的传统喷丸工艺参数不同,通常采用大空气压力及长处理时间。国内学者已采用该方法实现了纯钛[40]、TC4[29]、TA17[30]等材料表层纳米化,并对纳米化机制、纳米晶层的硬度及纳米化后材料的疲劳性能进行了研究。

对于变形方式为高速弹丸撞击的表层纳米化方法,采用较大弹丸速率、弹丸尺寸可获得高弹丸能量,有利于在较短处理时间内获得具有较大厚度的纳米晶层;另一方面却容易造成表面损伤[29, 40],增大表面粗糙度,引起应力集中等缺陷。因此,通过优选工艺参数,获得厚度适宜且不损伤表面质量的纳米层,是高速弹丸冲击类表层纳米化方法亟待解决的问题。

上述方法均以高速弹丸为介质在材料表层引入应变,而激光脉冲喷丸法(LSP)是则是典型的非弹丸撞击式表层纳米化方法。LSP方法利用激光能量激发的高压等离子体冲击波,使材料表面产生高应变塑性变形而形成纳米晶[41]。相对于前三种纳米化方法,LSP方法引入材料的应变速率高达1×107 s-1[31],且可在材料表层产生较大厚度的剧烈局部塑性变形,研究表明,LSP方法形成的残余压应力层厚度可达到2.0 mm[42]。高应变速率及大应变影响区为较短时间内形成大厚度细化层提供了有利条件。LSP方法可通过改变激光能量控制纳米化层的形成,主要控制参数有激光波长、脉冲宽度等。与其他表层机械处理方法相比,LSP方法具有以下优点:加工柔性大,零件外形和尺寸不受限制;不存在弹丸回收、筛选等问题,可避免弹丸对材料表面造成的损伤;工艺参数和路径可精确控制,重复性高。已有学者采用LSP方法实现了纯钛[31]和TC6[32]等材料的表层纳米化,并对其硬度和弹性模量等进行了研究。

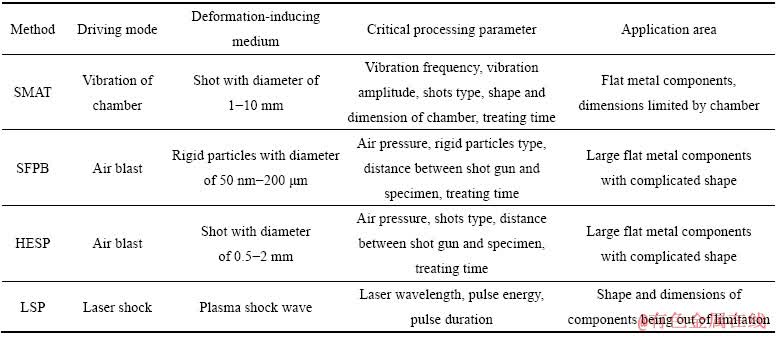

从上述分析可以看出,目前钛合金表层纳米化研究主要采用高速弹丸撞击方式,而对非弹丸撞击方式的研究也逐渐增多。表1所列为对上述钛合金表层纳米化方法的特点、关键工艺参数和应用范围进行了比较。

2 钛合金表层纳米组织与性能

2.1 组织特征

机械诱发局部剧烈塑性变形实现材料表层纳米化的过程中,由于外加载荷在材料表层产生的应力值、应变速率等随距表面深度的增加而逐渐减小,材料的变形程度和晶粒尺寸分布往往沿深度方向呈梯度变化,典型表层纳米化的组织特征和应变量及应变速率的分布如图1所示[36]。材料沿深度方向被划分为纳米晶层,晶粒细化层,形变粗晶层,无应变粗晶基体。各层组织形貌、厚度随各表层纳米化方法的工艺参数变化而变化。

表1 钛合金表层纳米化方法的比较

Table 1 Comparisons of different surface nanocrystallization methods for titanium alloys

图1 表层纳米化组织特征以及应变和应变速率分布示意图[36]

Fig. 1 Schematic illustration of microstructure characteristics and distributions of strain and strain rate along depth in surface layer subjected to SMAT[36]

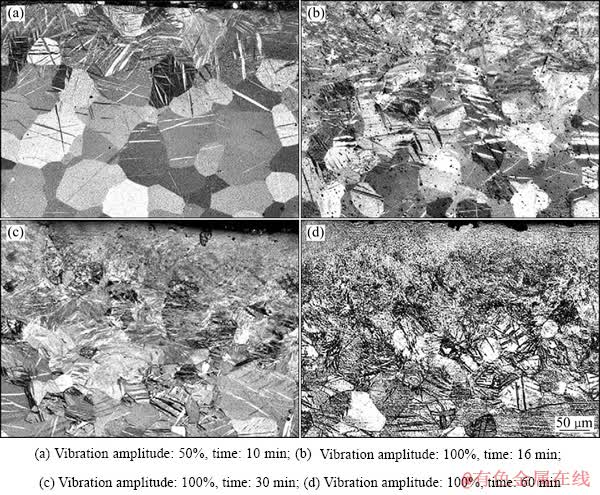

国内外学者[16, 20]采用OM、SEM、XRD、TEM等方法对金属纳米化后梯度组织进行表征。通过OM、SEM方法可对梯度纳米组织各分布层厚度、组织形貌进行观察。图2所示为采用SMAT方法对纯钛在不同振幅和处理时间条件下处理后横截面的组织形貌[20]。由图2可以看出,纯钛经过SMAT方法处理后变形层主要由纳米、亚微米尺寸、细小片层组织、机械孪晶组成,随着深度的增加,应变和应变速率逐渐减小,晶粒尺寸逐渐增大,直至过渡至基体组织。振幅较低、处理时间较短时,变形层主要由机械孪晶组成(见图2(a));振幅较高、处理时间较长时,变形层内逐渐出现细小片层组织(见图2(b)),光学显微镜难以识别的亚微米及纳米尺寸结构(见图2(c));当处理时间达到1 h时,由亚微米、纳米尺寸及细小片层组织组成的变形层厚度进一步增大(见图2 (d))。采用其他表面机械处理方法对进行材料纳米化的研究中,同样可观察到类似的梯度变化微观组织,以及工艺参数对变形层厚度及晶粒尺寸分布的影响规律[43, 29-30, 39]。已有研究结果表明,采用不同的表层纳米化方法,获得的钛合金纳米晶层厚度一般为10~20 μm[25, 44-47],最大变形层 厚度一般大于100 μm;在较优的处理工艺参数下,纳米晶层厚度可达到50 μm[20, 30, 39],最大变形层厚度可达到250~300 μm。

采用XRD方法可以表征材料纳米化后最表层的晶粒尺寸。XRD试验结果表明,钛合金表层纳米化后各衍射峰均发生明显宽化;不同工艺参数下各衍射峰的宽化程度不同,根据Scherrer-Wilson公式等可计算出表层平均晶粒尺寸。图3所示为采用SFPB方法对TC4合金经过不同时间处理后的XRD谱[45]。由图3可知,不同工艺参数下X射线衍射峰均明显宽化,宽化程度随处理时间的延长而增大。由衍射峰半高宽计算出表层的平均晶粒尺寸如表2所列。不同工艺参数下TC4合金表层平均晶粒尺寸均达到纳米级,且随着处理时间的延长不断减小。

图2 纯钛经过SMAT方法处理后横截面的组织形貌[20]

Fig. 2 Cross-sectional optical micrographs close to surfaces on SMATed CP-Ti[20]

图3 处理时间对TC4合金经过SFPB方法处理前后表层XRD谱的影响[45]

Fig. 3 Effect of treatment time on XRD patterns of TC4 alloy surface before and after SFPB treatment[45]

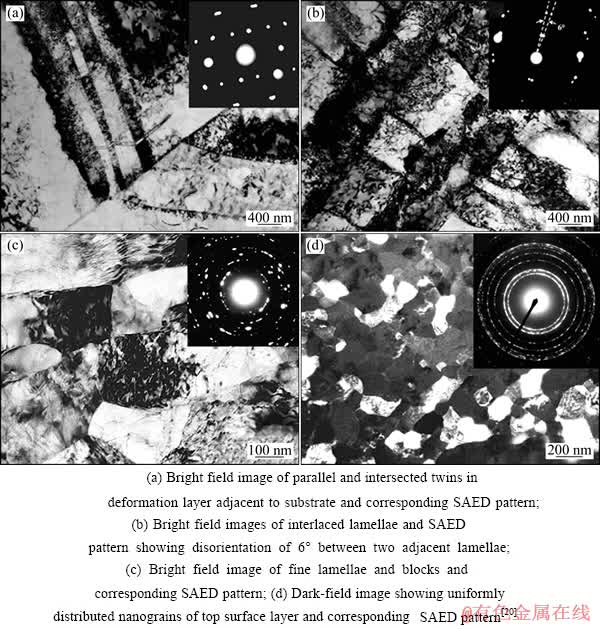

钛合金表层纳米化后的晶粒尺寸沿厚度方向呈梯度分布[16],当晶粒尺寸大于100 nm时,通过X射线衍射计算的平均晶粒尺寸与实际晶粒尺寸相差较大,因此,还需通过TEM观察表层纳米晶粒尺寸,同时观察晶粒形貌及微观组织特征,以进行纳米化机制分析。通过观察表层纳米化后材料的截面及距表层不同深度处TEM明、暗场像及选区电子衍射花样,可得到不同分布层的精细结构特征及晶粒尺寸分布:1) 粗晶变形层晶粒尺寸与无应变基体晶粒尺寸相近,可观察到大量塑性变形产生的孪晶、位错线、位错墙、位错胞、小角晶界等精细结构特征;2) 晶粒细化层可观察到由孪晶、位错分割产生的细小晶粒、亚晶界等,晶粒尺寸明显减小,为几百纳米至几微米;3) 纳米晶层可观察到晶粒内位错等缺陷明显减少晶粒通常呈等轴状且取向随机。

2.2 性能评价

表层纳米化改善了钛合金的表层组织和结构,有利于提高其表层及整体性能。目前,国内外学者对钛合金表层纳米化后的硬度、耐磨性、疲劳性能、扩散性能以及抗腐蚀性能等进行了较为广泛的研究。

表2 经过SFPB方法处理后TC4合金表层的平均晶粒尺寸

Table 2 Average grain size of surface layer on SFPBed TC4 alloy

钛合金表层纳米化后,由于晶粒细化和应变硬化,表层组织的硬度相对于基体组织显著提高,且随着深度增加逐渐减小,如图4所示[23]。与基体的硬度相比,钛合金纳米化后最表层硬度可提高0.35~3倍[23, 37, 39, 48]。表层变形组织的硬度还与采用的工艺参数有关,如采用SFPB方法对纯钛进行表层纳米化的处理时间越长,最表层硬度越高,且距表面同一深度处处理时间越长,硬度也越高[27]。表层硬度的提高有利于改善材料的摩擦磨损性能,KUMAR等[23]研究发现SMAT后,Ti-6Al-4V合金表层硬度提高、晶粒纳米化等可降低磨损量及磨损比,同时通过人工神经网络模型验证了试验结果[49]。但机械诱发局部剧烈塑性变形方法引起材料表面粗糙度的增加,可能对其耐磨性产生不利影响。在低载荷下材料的摩擦磨损性能与处理前相比变化不大,在高载荷下材料的摩擦磨损性能得到明显提高[50]。目前,应用表面纳米化技术提高耐磨性的研究主要集中在低碳钢[51]、纯铁[52]、纯铜[53]和镁合金[54]等材料上,而对钛合金表层纳米化后耐磨性的研究较少。

图4 深度对经过SMAT方法处理后Ti-6Al-4V合金硬度的影响[23]

Fig. 4 Effect of depth on hardness of SMATed Ti-6Al-4V alloy[23]

钛合金表层在纳米化后发生加工硬化,且表层残余压应力增大,这有利于提高其疲劳性能。研究表明,采用HESP方法经过2和8 h处理后TC4合金的疲劳强度分别提高了14.4%和20%[29]。对于LSP方法,材料表层残余应力的最大值和影响深度均随脉冲个数的增多而增大[55],经过单激光脉冲和连续双激光脉冲处理后,Ti-6Al-4V合金的疲劳强度分别提高了22.2%和41.7%。

表层纳米化在材料表层引入了大量具有高存储能的晶界、亚晶界、位错等非平衡相或高密度缺陷[20],高体积分数的晶界充当原子扩散通道,大大提高了材料的原子扩散系数[56-57],有利于提高扩散连接强度 等[58]。同时,晶界处各种非平衡缺陷以及大量的过剩能量为化学热处理提供了理想的界面条件,有助于大幅度提高材料表面化学元素的渗入浓度和深度,降低化学处理温度和减少保温时间[59-60]。

钛合金表层纳米化后晶粒尺寸的改变、残余应力的增加等均对其耐腐蚀性产生影响。晶界是腐蚀活性区,而钛合金表层纳米晶粒细小,晶界数目多,表层活性高,不利于提高其耐腐蚀性。但影响耐腐蚀性的因素还包括金属自身能否形成钝化膜、钝化膜与基体的结合力、形成钝化膜的钝化元素在材料表面的分布以及表面残余压应力等[61-62],研究表明[21, 63]钛合金耐腐性能的提高主要归因于纳米化表面能够快速形成致密且稳定的钝化膜。表层纳米化后材料的腐蚀特性由晶粒尺寸、变形程度、缺陷密度、微观应变等共同决定[21],且在不同的腐蚀环境和腐蚀介质中,表面纳米化处理对钛合金的影响也呈现不同趋势。何晓梅[46]发现在3.5% NaCl(质量分数)溶液中,纯钛经过SMAT方法处理后时间较短时耐腐蚀性能较处理前增强;随处理时间的增长表层出现损伤,耐腐蚀性能与处理前相比较差。而在还原性较强的0.5 mol/L H2SO4溶液中,虽然表层纳米化提高了纯钛钝化膜的生成能力,但晶界体积分数增加导致参与腐蚀反应的活性原子数增加,钝化膜溶解速度提高,耐腐蚀性能变差。而低温退火可消除残余应力分布不均匀、降低钝化膜溶解速度,从而提高耐腐蚀性能[64]。材料的腐蚀行为存在尺寸效应,腐蚀速度随晶粒尺度的增加而减小,但影响纳米材料腐蚀性能的因素还包括微观应力等,不同表层纳米化工艺往往对材料的微观结构、成分及微观应力状态等造成影响,都会导致材料腐蚀性能的改变,因此,需要进一步深入研究钛合金表层纳米化对其腐蚀性能的影响。

3 钛合金表层纳米化机理

金属材料剧烈塑性变形纳米化的过程,无论从宏观尺度还是从微观尺度讲,都是进行 “剪切错动”的塑性变形过程。因此其纳米化的本质可归纳为:大尺寸晶粒在剪切塑性变形的作用下不断地被分割而向多个细小晶粒,直至形成纳米晶的过程。这个过程需要一定的宏观塑性变形条件,并以位错、孪晶等作为基本变形方式,逐渐在大尺寸晶粒内引入小角度晶界,小角晶界逐渐演变为大角度晶界,细化为自由取向的小晶粒,如此反复直至细化为纳米晶粒。金属的塑性变形行为与位错运动方式在很大程度上取决于金属的晶体结构和层错能,而钛合金包括α型、α+β型、β型合金,各类钛合金中的α相和β相含量不同,其表层纳米化机理存在差异。

在对纯钛的研究中发现[20, 47],密排六方(HCP)晶体结构的纯钛虽然具有高层错能,但与较低层错能的面心立方结构多晶体(如铜、不锈钢)变形机理相似,通过滑移和孪生的共同作用进行塑性变形使晶粒细化。不同的是随应变程度增大,面心立方结构金属首先发生位错滑移,应变程度增大到一定程度时发生孪生,而纯钛恰与之相反。图5所示为SMAT后纯钛不同变形阶段的微观组织特征图,ZHU等[20]认为随应变及应变速率增大,纯钛的原始晶粒逐渐发生以下变化:1) 孪晶开动并发生孪晶系交割(见图5(a));2) 形成具有高密度位错的小取向差薄片组织(见图5(b));3) 薄片组织分割成具有小角取向差的块状组织,并逐渐演变为多边亚微米晶粒(见图5(c));4) 亚微米晶粒进一步分割成随机取向的纳米晶粒(见图5(d))。CHICHILI等[65]在高应变速率下纯钛的变形机制研究中发现了类似现象。在室温下,当应变低于15%时,纯钛首先通过孪生维持塑性变形,在室温下沿{1012}面形成孪晶;随着孪晶密度增加基体组织被分割为平行的薄片状结构;当应变增加到某一临界值时位错运动开始起主导作用,大量的位错在孪晶界处堆积形成位错墙,并进一步形成位错胞,随后转变成具有小取向差的亚微米多边形晶粒,这种分割会不断进行最终形成等轴的纳米晶。

近年来,关于α型钛合金和α+β型钛合金表层纳米化机理的研究逐渐增多[21, 28, 30, 39]。研究发现,由于α型钛合金主要由α相组成,其表层纳米化机理与纯钛类似[30],低应变速率下孪晶分割为主,随应变速率增大孪晶内产生位错滑移,位错塞积形成位错墙等对晶粒进一步分割形成亚晶,并促使亚晶界转动形成大角度晶界纳米晶。对于α相含量较多的近α型钛合金在表层纳米化过程中的细化机理主要为孪晶分割。JELLITI等[21]对Ti-6Al-4V合金的表层纳米化研究中发现,剧烈塑性变形过程中产生的大量畸变和高应变速率产生大量孪晶,分割原始晶粒成为亚晶,直至亚晶晶粒尺寸达到纳米量级。然而,近β型钛合金主要由体心立方结构的β相组成,其表层纳米化机理则与上述不同,与其他具有高层错能的金属如纯铁[52]、铝合金[66]等的表面纳米化机制类似,主要通过位错滑移和位错分割实现晶粒细化[67]。外界多方向载荷重复作用产生的大量位错通过滑移、堆积、交互作用产生位错墙和位错缠结,位错继续运动和分割产生亚晶界、亚晶;随着应变速率增大,更多位错在亚晶界处产生或湮灭,使亚晶界、亚晶转变为晶界、晶粒;位错产生和湮灭速率达到平衡时,形成纳米晶粒。目前,对钛合金表层纳米化机理的研究主要集中在α型和近α型钛合金,对于以β相含量为主的近β型和β型钛合金的表层纳米化机理研究较少,系统研究钛合金层错能、晶体结构及两相协调变形等对纳米化机理的影响是未来钛合金表层纳米化的主要研究方向。

图5 SMAT处理后纯钛不同变形阶段TEM像[20]

Fig. 5 TEM images of SMATed CP-Ti at different deformation stages[20]

4 结语

国内外学者采用SMAT方法、SFPB方法和HESP方法等在钛合金表层制备出具有一定厚度的纳米晶,实现了钛合金的表层纳米化,对其纳米化机理及表层纳米化后表层、整体性能等进行了初步研究。尽管如此,国内对钛合金表层纳米化的研究尚处于起步阶段。为了建立和完善钛合金表层纳米化理论与技术,应当系统、深入地研究钛合金表层纳米化方法、组织演变、纳米化机理以及钛合金表层纳米化后的性能表征与评估。主要包括以下几个方面工作。

1) 创新梯度纳米组织及精细结构特征的表征方法,准确描述晶粒形貌,精确测量晶粒尺寸及其分布,定量分析钛合金表层纳米化过程中的相组成变化、位错密度变化、孪晶分布、晶体取向分布等。

2) 研究钛合金表层纳米化过程中发生的微观组织及精细结构演变,系统分析局部剧烈塑性变形过程中的晶内、晶间变形方式,及各相在细化过程中的贡献,阐明剧烈塑性变形下的钛合金多相协调变形机制,揭示钛合金表层纳米化机理。

3) 优化工艺参数,制备大厚度表层纳米结构钛合金,并提高梯度组织均匀性,同时降低或消除机械纳米化处理导致的表层损伤等缺陷,有效提高钛合金表层纳米化后的表层和整体性能。

4) 创新钛合金表层纳米化性能表征方法,系统研究钛合金表层纳米化后的硬度、热稳定性、扩散性能、耐磨性、耐腐蚀性等表层性能,及疲劳性能、拉伸性能等整体性能,提高钛合金使用性能,从而扩大表层纳米化钛合金的应用范围。

5) 研究工艺参数和原始微观组织对钛合金表层纳米晶形成机理的影响,探索工艺参数、纳米组织与表层性能和整体性能的关系,完善钛合金表层纳米化过程的主动调控理论,创新符合工程应用需求的钛合金表层纳米晶制备新方法。

致谢:感谢中航工业北京航空材料研究院王俊丽老师提出的主要建议和细致修改。

REFERENCES

[1] 卢 柯, 周 飞. 纳米晶体材料的研究现状[J]. 金属学报, 1997, 33(1): 99-106.

LU Ke, ZHOU Fei. Recent research progress on nanocrystalline materials[J]. Acta Metallurgica Sinica, 1997, 33(1): 99-106.

[2] GLEITER H. Nanocrystalline materials[J]. Progress in Materials Science, 1989, 33: 223-315.

[3] SURYANARAYANA C. Nanocrystalline materials[J]. International Materials Reviews, 1995, 40(2): 41-64.

[4] LU Ke. Nanocrystalline metals crystallized from amorphous solids: nanocrystallization, structure, and properties[J]. Materials Science and Engineering R, 1996, 16(4): 161-221.

[5] MORRIS D G. Mechanical behavior of nanostructured materials[M]. Switzerland: Trans Tech Publication, 1998: 70.

[6] MCFADDEN S X, MISHRA R S, VALIEV R Z, ZHILYAEV A P, MUKHERJEE A K. Low-temperature superplasticity in nanostructured nickel and metal alloys[J]. Nature, 1999, 398(6729): 684-686.

[7] LU Lei, SUI Man-ling, LU Ke. Superplastic extensibility of nanocrystalline copper at room temperature[J]. Science, 2000, 287(5457): 1463-1466.

[8] SCHLUMP W, GREWE H. New materials by mechanical alloying[M]. Germany: Deutsche Gesellschaft für Materialkunde e.V., 1988: 307.

[9] AVERBACK R S, HAHN H, H FLER H J, LOGAS J C. Processing and properties of nanophase amorphous metallic alloys: Ni-Ti[J]. Applied Physics Letters, 1990, 57(17): 1745-1747.

FLER H J, LOGAS J C. Processing and properties of nanophase amorphous metallic alloys: Ni-Ti[J]. Applied Physics Letters, 1990, 57(17): 1745-1747.

[10] VALIEV R Z. Structure and mechanical properties of ultrafine-grained metals[J]. Materials Science and Engineering A, 1997, 234/236: 59-66.

[11] SERGUEEVA A V, STOLYAROV V V, VALIEV R Z, MUKHERJEE A K. Advanced mechanical properties of pure titanium with ultrafine grained structure[J]. Scripta Materialia, 2001, 45(7): 747-752.

[12] SHIN D H, KIM I, KIM J, KIM Y S, SEMIATIN S L. Microstructure development during equal-channel angular pressing of titanium[J]. Acta Materialia, 2003, 51(4): 983-996.

[13] LU Ke, LU Jian. Surface nanocrystallization (SNC) of metallic materials presentation of the concept behind a new approach[J]. Journal of Materials Science and Technology, 1999, 15(3): 193-197.

[14] LIU Gang, LU Jian, LU Ke. Surface nanocrystallization of 316L stainless steel induced by ultrasonic shot peening[J]. Materials Science and Engineering A, 2000, 286(1): 91-95.

[15] LU Jin-zhong, LUO Kai-yu, ZHANG Yong-kang, SUN Gui-fang, GU Yong-yu, ZHOU Jian-zhong, REN, Xu-dong, ZHANG Xian-cheng, ZHANG Liang, CHEN Kang-min, CUI Cheng-yun, JIANG Yin-fang, FENG Ai-xin, ZHANG Lei-hong. Grain refinement mechanism of multiple laser shock processing impacts on ANSI 304 stainless steel[J]. Acta Materialia, 2010, 58: 5354-5362.

[16] TAO Nai-rong, WANG Zhen-bo, TONG Wei-ping, SUI Man-ling, LU Jian, LU Ke. An investigation of surface nanocrystallization mechanism in Fe induced by surface mechanical attrition treatment[J]. Acta Materialia, 2002, 50(18): 4603-4616.

[17] LIN Yi-min, LU Jian, WANG Li-ping, XU Tao, XUE Qun-ji. Surface nanocrystallization by surface mechanical attrition treatment and its effect on structure and properties of plasma nitrided AISI 321 stainless steel[J]. Acta Materialia, 2006, 54(20): 5599-5605.

[18] MAO Xiang-yang, LI Dong-yang, WANG Zhang-zhong, ZHAO Xiu-ming, CAI Lu. Surface nanocrystallization by mechanical punching process for improving microstructure and properties of Cu-30Ni alloy[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(6): 1694-1700.

[19] 徐滨士, 刘世参. 中国材料工程大典(第17卷)[M]. 北京: 化学工业出版社, 2006: 409.

XU Bin-shi, LIU Shi-can. China materials engineering canon (Volume 17)[M]. Beijing: Chemical Industry Press, 2006: 409.

[20] ZHU Kang-ying, VASSEL A, BRISSET F, LU Ke, LU Jian. Nanostructure formation mechanism of α-titanium using SMAT[J]. Acta Materialia, 2004, 52(14): 4101-4110.

[21] JELLITI S, RICHARD C, RETRAINT D, ROLAND T, CHEMKHI M, DEMANGEL C. Effect of surface nanocrystallization on the corrosion behavior of Ti-6Al-4V titanium alloy[J]. Surface and Coatings Technology, 2013, 224: 82-87.

[22] WEN Ming, LIU Gang, GU Jian-feng, GUAN Wei-ming, LU Jian. The tensile properties of titanium processed by surface mechanical attrition treatment[J]. Surface and Coatings Technology, 2008, 202(19): 4728-4733.

[23] KUMAR S A, RAMAN S G S, NARAYANAN T S N S, GNANAMOORTHY R. Influence of counterbody material on fretting wear behaviour of surface mechanical attrition treated Ti-6Al-4V[J]. Tribology International, 2013, 57: 107-114.

[24] HUANG Run, HAN Yong. Structure evolution and thermal stability of SMAT-derived nanograined layer on Ti-25Nb-3Mo- 3Zr-2Sn alloy at elevated temperature[J]. Journal of Alloys and Compounds, 2013, 554: 1-11.

[25] 张聪惠, 何晓梅. 表面机械研磨工业纯钛表面纳米化研究[J]. 稀有金属, 2009, 33(6): 769-772.

ZHANG Cong-hui, HE Xiao-mei. Mechanism of surface nanocrystallization of titanium during surface mechanical attrition[J]. Chinese Journal of Rare Metals, 2009, 33(6): 769-772.

[26] 张淑兰, 陈怀宁, 林泉洪, 刘 刚. 工业纯钛的表面纳米化及其机制[J]. 有色金属, 2003, 55(4): 5-8.

ZHANG Shu-lan, CHEN Huai-ning, LIN Hong-quan, LIU Gang. Surface nanocrystallization of industrial pure titanium and its mechanism[J]. Nonferrous Metals, 2003, 55(4): 5-8.

[27] 葛利玲, 袁战伟, 井晓天, 卢正欣. 纯钛(TA2)表面纳米化及其热稳定性研究[J]. 稀有金属材料与工程, 2011, 40(7): 1239-1242.

GE Li-ling, YUAN Zhan-wei, JING Xiao-tian, LU Zheng-xin. Study of pure titanium (TA2) surface nanocrystallization and its thermal stability[J]. Rare Metal Materials and Engineering, 2011, 40(7): 1239-1242.

[28] HAN Jing, SHENG Guang-min, ZHOU Xiao-ling. Diffusion bonding of surface self-nanocrystallized Ti-4AI-2V and OCr18Ni9Ti by means of high energy shot peening[J]. ISIJ International, 2008, 48(9): 1238-1245.

[29] 温爱玲, 闫秀侠, 任瑞铭, 王生武. 高能喷丸时间对TC4疲劳性能的影响[J]. 材料热处理技术, 2009, 38(14): 127-129.

WEN Ai-ling, YAN Xiu-xia, REN Rui-ming, WANG Sheng-wu. Effect of High-energy shot peening time on fatigue performance of TC4 alloy[J]. Material and Heat Treatment, 2009, 38(14): 127-129.

[30] 韩 靖, 盛光敏, 胡国雄. 高能喷丸TA17近α钛合金晶粒细化机制[J]. 中国有色金属学报,2008, 18(5): 799-804.

HAN Jing, SHENG Guang-min, HU Guo-xiong. Mechanism of grain refinement for TA17 near α Ti alloy by high energy shot peening[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(5): 799-804.

[31] LUI Hui-xia, HU Yang, WANG Xiao, SHEN Zong-bao, LI Pin, GU Chun-xing, LIU, Hui-xia, DU Dao-zhong, GUO Chao. Grain refinement progress of pure titanium during laser shock forming (LSF) and mechanical property characterizations with nanoindentation[J]. Materials Science and Engineering A, 2013, 564: 13-21.

[32] ZHOU Liu-cheng, LI Ying-hong, HE Wei-feng, HE Guang-yu, NIE Xiang-fan, CHEN Dong-lin, LAI Zhi-lin, An Zhi-bin. Deforming TC6 titanium alloys at ultrahigh strain rates during multiple laser shock peening[J]. Materials Science and Engineering A, 2013, 578: 181-186.

[33] ALTENBERGER I, NALLA R K, SANO Y, WAGNER L, RITCHIE R O. On the effect of deep-rolling and laser-peening on the stress-controlled low-and high-cycle fatigue behavior of Ti-6Al-4V at elevated temperatures up to 550℃[J]. International Journal of Fatigue, 2012, 44: 292-302.

[34] 李 礼, 朱有利. Ti6Al4V合金超声深滚层的组织结构特征[J]. 稀有金属材料与工程, 2010, 39(10): 1754-1758.

LI Li, ZHU You-li. Microstructure characteristics of ultrasound-aided deep rolling treated Ti6Al4V alloy[J]. Rare Metal Materials and Engineering, 2010, 39(10): 1754-1758.

[35] ALTENBERGER I, STACH E A, LIU Gang, NALLA R K, RITCHIE R O. An in situ transmission electron microscope study of the thermal stability of near-surface microstructures induced by deep rolling and laser-shock peening[J]. Scripta Materialia, 2003, 48(12): 1593-1598.

[36] LU Ke, LU Jian. Nanostructured surface layer on metallic materials induced by surface mechanical attrition treatment[J]. Materials Science and Engineering A, 2004, 375(377): 38-45.

[37] HUANG Li-ye, LU Jian, TROYON M. Nanomechanical properties of nanostructured titanium prepared by SMAT[J]. Surface and Coatings Technology, 2006, 201(1): 208-213.

[38] 熊天英, 刘志文, 李智超, 吴 杰, 金花子, 李铁藩. 超音速微粒轰击金属表面纳米化新技术[J]. 材料导报, 2003, 17(3): 69-71.

XIONG Tian-ying, LIU Zhi-wen, LI Zhi-chao, WU Jie, JIN Hua-zi, LI Tie-fan,. Supersonic fine particles bombarding: a novel surface nanocrystallization technology[J]. Materials Review, 2003, 17(3): 69-71.

[39] 王 敏, 蔺成效, 马彩霞. Ti-6Al-4V钛合金表面纳米化机制研究[J]. 稀有金属, 2011, 35(5): 633-638.

WANG Min, LIN Cheng-xiao, MA Cai-xia. Mechanism of surface nanocrystallization of Ti-6AI-4V alloy[J]. Chinese Journal of Rare Metals, 2011, 35(5): 633-638.

[40] 杨 磊, 赵秀娟, 陈春焕, 陈婷婷, 徐祥来, 任瑞铭. 纯钛高能喷丸表面纳米化后粗糙度的分析[J]. 中国表面工程, 2006, 19(4): 43-46.

YANG Lei, ZHAO Xiu-juan, CHEN Chun-huan, CHEN Ting-ting, XU Xiang-lai, REN Rui-ming. Analysis of surface roughness of pure titannium after surface nanocrystallization by high-energy shot peening[J]. China Surface Engineering, 2006, 19(4): 43-46.

[41] MORDYUK B N, MILMAN Y V, IEFIMOV M O, PROKOPENKO G I, SILBERSCHIMIDT V V, DANYLENKO M I, KOTKO A V. Characterization of ultrasonically peened and laser-shock peened surface layers of AISI 321 stainless steel[J]. Surface and Coatings Technology, 2008, 202(19): 4875-4883.

[42] KING A, EVANS A D, WITHERS P J, WOODWARD C. The effect of fatigue on residual peening stresses in aerospace components[J]. Mater Science Forum, 2005, 490/491: 340-345.

[43] ZHAO Jing, XIA Wei, LI Ning, LI Feng-lei. A gradient nano/micro-structured surface layer on copper induced by severe plasticity roller burnishing[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(2): 441-448.

[44] 张聪慧, 刘研蕊, 兰新哲. 钛合金表面高能喷丸纳米化后的组织与性能[J]. 热加工工艺, 2006, 35(2): 5-7.

ZHANG Cong-hui, LIU Yan-rui, LAN Xin-zhe. Microstructure and properties of surface high-energy shot peening nanocrystallization on TC4 titanium alloy[J]. Hot Working Technology, 2006, 35(2): 5-7.

[45] 郭周强, 葛利玲, 袁 航, 秦 超. 钛合金 TC4 表面纳米化及其热稳定性[J]. 材料热处理学报, 2012, 33(3): 114-118.

GUO Zhou-qiang, GE Li-ling, YUAN Hang, QIN Chao. Surface nano-crystallization of TC4 titanium alloy and its thermal stability[J]. Transactions of Materials and Heat Treatment, 2012, 33(3): 114-118.

[46] 何晓梅. 机械研磨工业纯钛表面纳米化与组织性能研究[D]. 西安: 西安建筑科技大学, 2008: 36.

HE Xiao-mei. Microstructure and properties of surface nanocrystallized CP-Ti processed by SMAT[D]. Xi’an: Xi’an University of Architecture and Technology, 2008: 36.

[47] WEN Ming, LIU Gang, GU Jian-feng, GUAN Wei-ming, LU Jian. Dislocation evolution in titanium during surface severe plastic deformation[J]. Applied Surface Science, 2009, 255(12): 6097-6102.

[48] XIE Le-chun, WANG Li-qiang, JIANG Chuan-hai, LU Wei-jie. The variations of microstructures and hardness of titanium matrix composite (TiB+TiC)/Ti-6Al-4V after shot peening[J]. Surface and Coatings Technology, 2014, 244: 69-77.

[49] KUMAR S A, RAMAN S G S, NARAYANAN TSN S, GNANAMOORTHY R. Prediction of fretting wear behavior of surface mechanical attrition treated Ti-6Al-4V using artificial neural network[J]. Materials and Design, 2013, 49: 992-999.

[50] 刘 刚, 雍兴平, 卢 柯. 金属材料表面纳米化的研究现状[J]. 中国表面工程, 2001, 3: 1-5.

LIU Gang, YONG Xing-ping, LU Ke. The current situation of researches of surface-nanocrystallization on metallic materials[J]. China Surface Engineering, 2001, 3: 1-5.

[51] WANG Zhen-bo, TAO Nai-rong, LI Shi-sheng, WANG Wei, LIU Gang, LU Jian, LU Ke. Effect of surface nanocrystallization on friction and wear properties in low carbon steel[J]. Materials Science Engineering A, 2003, 352(1/2): 144-149.

[52] TAO Nai-rong, TONG Wei-ping, WANG Zhen-bo, WANG Wei, SUI Man-ling, LU Jian, LU Ke. Mechanical and wear properties of nanostructured surface layer in iron induced by surface mechanical attrition treatment[J]. Journal of Mater Science and Technology, 2003, 19(6): 563-566.

[53] ZHANG Yu-sheng, HAN Zhong, WANG Ke, LU Ke. Friction and wear behaviors of nanocrystalline surface layer of pure copper[J]. Wear, 2006, 260: 942-948.

[54] SUN Hai-qing, SHI Yi-nong, ZHANG Ming-xing. Wear behavior of AZ91D magnesium alloy with a nanocrystalline surface layer[J]. Surface Coating Technology, 2008, 202: 2859-2864.

[55] ZHANG Xian-cheng, ZHANG Yong-kang, LU Jin-zhong, XUAN Fu-zhen, WANG Zheng-dong, TU Shan-tang. Improvement of fatigue life of Ti-6Al-4V alloy by laser shock peening[J]. Materials Science and Engineering A, 2010, 527(15): 3411-3415.

[56] 黄 利, 盛光敏, 罗 军, 薛昊飞. 表面纳米化0Cr18Ni9Ti/TA17加镍中间层扩散连接[J]. 中南大学学报: 自然科学版, 2012, 43(3): 864-869.

HUANG Li, SHENG Guang-min, LUO Jun, XUE Hao-fei. Diffusion bonding of surface nanocrystallized 0Cr18Ni9Ti/TA17 using a nickel interlayer[J]. Journal of Central South University: Science and Technology, 2012, 43(3): 864-869.

[57] LU Ke. Nanocrystalline metals crystallized from amorphous solids: nanocrystallization, structure, and properties[J]. Materials Science and Engineering R, 1996, 16(4): 161-221.

[58] 韩 靖, 盛光敏, 周小玲, 孙建春. 表面纳米化钛合金与不锈钢扩散连接[J]. 稀有金属材料与工程, 2010, 39(1): 42-45.

HAN Jing, SHENG Guang-min, ZHOU Xiao-ling, SUN Jian-chun. Diffusion bonding of titanium alloy and stainless steel with surface nanocrystallization[J]. Rare Metal Materials and Engineering, 2010, 39(1): 42-45.

[59] VASYLYEV M A, CHENAKIN S P, YATSENKO L F. Nitridation of Ti-6Al-4V alloy under ultrasonic impact treatment in liquid nitrogen[J]. Acta Materialia, 2012, 60: 6223-6233.

[60] TONG Wei-ping, TAO Nai-rong, WANG Zhen-bo, LU Jian, LU Ke. Nitriding iron at lower temperature[J]. Science, 2003, 299: 686-688.

[61] 欧信兵, 张 津. 强烈塑性变形表面纳米化的研究现状[J]. 表面技术, 2008, 37(3): 60-64.

OU Xin-bing, ZHANG Jin. Research progress in surface nanocrystallization induced by severe plastic deformation[J]. Sureface Technology, 2008, 37(3): 60-64.

[62] 李 瑛, 王福会. 表面纳米化对金属材料电化学腐蚀行为的影响[J]. 腐蚀与防护, 2003, 24(1): 6-12.

LI Ying, WANG Fu-hui. Effects of surface nanocrystallization on the electrochemical corrosion behavior of metals[J]. Corrosion and Protection, 2003, 24(1): 6-12.

[63] JIN Lei, CUI Wen-fang, SONG Xiu, LIU Gang, ZHOU Lian. Effects of surface nanocrystallization on corrosion resistance of β-type titanium alloy[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(10): 2529-2535.

[64] 何晓梅, 张聪惠, 杨占林, 刘晓燕, 赵西成, 于 飞. 退火对表面机械研磨处理纳米化工业纯钛性能的影响[J]. 金属热处理, 2013, 38(4): 69-73.

HE Xiao-mei,ZHANG Cong-hui,YANG Zhan-lin,LIU Xiao-yan,ZHAO Xi-cheng,YU Fei. Effect of annealing on property of CP-Ti nanocrystallized by surface mechanical attrition treatment[J]. Heat Treatment of Metals, 2013, 38(4): 69-73.

[65] CHICHILI D R, RAMESH K T, HEMKER K J. The high strain rate response of alpha titanium: experiments, deformation mechanisms and modeling[J]. Acta Materialia, 1998, 46(3): 1025-1043.

[66] 胡兰青, 李茂林, 王 科, 刘 刚, 卫英慧, 许并社. 铝合金表面纳米化处理及显微结构特征[J]. 中国有色金属学报, 2004, 14(12): 2016-2020.

HU Lan-qing, LI Mao-lin, WANG Ke, LIU Gang, WEI Ying-hui, XU Bin-she. Microstructure and characterization of surface nanocrystallization of aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(12): 2016-2020.

[67] 赵 坤, 王 敏, 蔺成效, 拓 川. TC17 钛合金自表面纳米化机制及组织演化[J]. 稀有金属材料与工程, 2013, 42(10): 2048-2052.

ZHAO Kun, WANG Min, LIN Cheng-xiao, TUO Chuan. Mechanism and Nanostructure Evolution of Surface Self-Nanocrystallization of TC17[J]. Rare Metal Materials and Engineering, 2013, 42(10): 2048-2052.

(编辑 龙怀中)

基金项目:凝固技术国家重点实验室(西北工业大学)自主研究课题资助项目(KP201305);西北工业大学科技创新基金资助项目(2012KJ02002);国家自然科学基金资助项目(51275416)

收稿日期:2014-07-13;修订日期:2014-11-14

通信作者:李淼泉,教授,博士;电话:029-88460328;E-mail:honeymli@nwpu.edu.cn

摘 要:机械诱发局部剧烈塑性变形方法是钛合金表层纳米化的主要方法,主要包括表层机械研磨方法、超音速微粒轰击方法、高能喷丸方法和激光脉冲喷丸方法等。通过控制表层机械处理参数可在钛合金表层制备出一定厚度的纳米组织,并沿厚度方向由纳米晶逐渐过渡到基体的粗晶组织;表层纳米组织的形成明显提高了钛合金表层的强度、硬度和抗腐蚀性能等。钛合金的表层纳米化机理受α相和β相含量的影响较大,α相含量为主的钛合金中孪晶分割细化机制占主导地位;β相含量为主的钛合金中位错分割细化机制占主导地位。在总结钛合金表层纳米化近年来取得的进展基础上指出了该技术今后的研究发展方向。

[1] 卢 柯, 周 飞. 纳米晶体材料的研究现状[J]. 金属学报, 1997, 33(1): 99-106.

[2] GLEITER H. Nanocrystalline materials[J]. Progress in Materials Science, 1989, 33: 223-315.

[19] 徐滨士, 刘世参. 中国材料工程大典(第17卷)[M]. 北京: 化学工业出版社, 2006: 409.

[25] 张聪惠, 何晓梅. 表面机械研磨工业纯钛表面纳米化研究[J]. 稀有金属, 2009, 33(6): 769-772.

[26] 张淑兰, 陈怀宁, 林泉洪, 刘 刚. 工业纯钛的表面纳米化及其机制[J]. 有色金属, 2003, 55(4): 5-8.

[27] 葛利玲, 袁战伟, 井晓天, 卢正欣. 纯钛(TA2)表面纳米化及其热稳定性研究[J]. 稀有金属材料与工程, 2011, 40(7): 1239-1242.

[29] 温爱玲, 闫秀侠, 任瑞铭, 王生武. 高能喷丸时间对TC4疲劳性能的影响[J]. 材料热处理技术, 2009, 38(14): 127-129.

[30] 韩 靖, 盛光敏, 胡国雄. 高能喷丸TA17近α钛合金晶粒细化机制[J]. 中国有色金属学报,2008, 18(5): 799-804.

[34] 李 礼, 朱有利. Ti6Al4V合金超声深滚层的组织结构特征[J]. 稀有金属材料与工程, 2010, 39(10): 1754-1758.

[38] 熊天英, 刘志文, 李智超, 吴 杰, 金花子, 李铁藩. 超音速微粒轰击金属表面纳米化新技术[J]. 材料导报, 2003, 17(3): 69-71.

[39] 王 敏, 蔺成效, 马彩霞. Ti-6Al-4V钛合金表面纳米化机制研究[J]. 稀有金属, 2011, 35(5): 633-638.

[40] 杨 磊, 赵秀娟, 陈春焕, 陈婷婷, 徐祥来, 任瑞铭. 纯钛高能喷丸表面纳米化后粗糙度的分析[J]. 中国表面工程, 2006, 19(4): 43-46.

[44] 张聪慧, 刘研蕊, 兰新哲. 钛合金表面高能喷丸纳米化后的组织与性能[J]. 热加工工艺, 2006, 35(2): 5-7.

[45] 郭周强, 葛利玲, 袁 航, 秦 超. 钛合金 TC4 表面纳米化及其热稳定性[J]. 材料热处理学报, 2012, 33(3): 114-118.

[46] 何晓梅. 机械研磨工业纯钛表面纳米化与组织性能研究[D]. 西安: 西安建筑科技大学, 2008: 36.

[50] 刘 刚, 雍兴平, 卢 柯. 金属材料表面纳米化的研究现状[J]. 中国表面工程, 2001, 3: 1-5.

[56] 黄 利, 盛光敏, 罗 军, 薛昊飞. 表面纳米化0Cr18Ni9Ti/TA17加镍中间层扩散连接[J]. 中南大学学报: 自然科学版, 2012, 43(3): 864-869.

[58] 韩 靖, 盛光敏, 周小玲, 孙建春. 表面纳米化钛合金与不锈钢扩散连接[J]. 稀有金属材料与工程, 2010, 39(1): 42-45.

[61] 欧信兵, 张 津. 强烈塑性变形表面纳米化的研究现状[J]. 表面技术, 2008, 37(3): 60-64.

[62] 李 瑛, 王福会. 表面纳米化对金属材料电化学腐蚀行为的影响[J]. 腐蚀与防护, 2003, 24(1): 6-12.

[64] 何晓梅, 张聪惠, 杨占林, 刘晓燕, 赵西成, 于 飞. 退火对表面机械研磨处理纳米化工业纯钛性能的影响[J]. 金属热处理, 2013, 38(4): 69-73.

[66] 胡兰青, 李茂林, 王 科, 刘 刚, 卫英慧, 许并社. 铝合金表面纳米化处理及显微结构特征[J]. 中国有色金属学报, 2004, 14(12): 2016-2020.

[67] 赵 坤, 王 敏, 蔺成效, 拓 川. TC17 钛合金自表面纳米化机制及组织演化[J]. 稀有金属材料与工程, 2013, 42(10): 2048-2052.