Superplasticity-like creep behavior of coarse grained ternary Al alloys

QIAO Jun(乔 军)1, E. M. TALEFF 2

1. College of Materials Science and Engineering, University of Science and Technology Liaoning,

Anshan 114051, China;

2. Department of Mechanical Engineering, University of Texas at Austin, Austin 78705, USA

Received 25 March 2009; accepted 26 June 2009

Abstract:

Enhanced tensile ductilities in coarse grained Al-Mg-Zn and Al-Mg-Fe materials were studied. The materials were Al-2Mg-5Zn, Al-3Mg-5Zn, Al-4Mg-5Zn, Al-3Mg-0.11Fe, Al-3Mg-0.27Fe, and Al-3Mg-0.40Fe. Tensile elongation-to-failure tests were conducted at constant cross-head speed and constant temperatures from 300 to 450 ℃. Strain rate change tests were conducted at a constant temperature from 300 to 450 ℃ and in strain-rate range from 4.31×10-5 to 1.97×10-2 s-1. Experimental results show that over 100% ductilities are consistently achieved in these materials. This superplasticity-like behavior is rate-controlled by solute-drag creep. Although ternary Zn and Fe additions do not have an adverse effect on solute-drag creep and ductility, they increase stress exponent and its sensitivity to Mg content during solute-drag creep.

Key words:

Al-Mg alloys; superplasticity; solute-drag creep; tensile ductility; strain-rate sensitivity;

1 Introduction

High temperature deformation in polycrystalline solids is generally viewed as a power-law relationship between the creep rate ![]() and flow stress σ, as given in the phenomenological equation for creep.

and flow stress σ, as given in the phenomenological equation for creep.

![]()

where A is material constant related to stacking fault energy; n is the stress exponent, commonly taking values from 2 to 8; E is the dynamic elastic modulus; Q is the creep activation energy; R is the gas constant; and T is the absolute temperature.

For 5000-series Al-Mg alloys, enhanced ductilities during high-temperature creep deformation can be achieved from either fine grained superplasticity or solute-drag creep. Fine grained superplasticity typically provides a low stress exponent of n=2 and some Al-Mg alloys present very high ductility (~500%), where the deformation is dominated by a grain-boundary-sliding (GBS) creep mechanism. GBS in polycrystalline solids is rate-controlled by the accommodation process of dislocation migration, which is controlled by either lattice diffusion or grain boundary diffusion. GBS typically requires a fine-grained, equiaxed microstructure which is resistant to grain growth[1-3].

It is of great interest now to develop solute-drag creep in Al-Mg materials. Solute-drag creep is rate dominated by viscous glide of dislocation interacting elastically with stress field of a solute atmosphere, which exerts a drag force to slow dislocation motion[4]. Compared to superplasticity, solute-drag creep is insensitive to grain size, which precludes the necessity of the special alloying or processing steps typically used to refine grain size and achieve superplasticity.

Requirements for a solid solution to exhibit solute-drag-creep behavior include large atom-misfit parameter, relatively high solute concentration, high stacking fault energy and uniform distribution of dislocations. Al-3Mg alloys may fulfill all these requirements. The linear misfit factor of Mg in Al is +0.12. According to the binary Al-Mg phase diagram, 3% (mass fraction) Mg could be completely dissolved in Al matrix at temperatures over 190 ℃, which contributes to the solute-drag effect. High stacking-fault energy of Al-3Mg makes cross-slip and climb easier and helps provide a uniform dislocation distribution, which is important to inhibit discontinuous dynamic recrystalliza- tion because of the high mobility of dislocations, although continuous dynamic recrystallization and geometric dynamic recrystallization may occur during high temperature deformation[5-9].

TALEFF et al[10-11] studied the ductility and creep mechanisms of coarse grained binary Al-Mg alloys and 5000-series commercial alloys. It is shown that when Mg content is higher than 2% (mass fraction), solute-drag creep dominates deformation and stress exponent does not greatly change with the increase of Mg content. Ductilities over 100% are consistently achieved when deformation takes place in the solute-drag creep region.

Although 5000-series Al-Mg alloys offer enhanced high temperature ductility, their application is inhibited by low strength at room temperature. In contrast, 7000-series Al-Mg-Zn alloys offer a much higher room temperature strength because of their potentially improved age hardenability and strength from Zn addition.

In present work, two groups of alloys are studied: three Al-xMg-5Zn alloys with approximately 5.25% Zn (mass fraction) and 2%-4% (mass fraction) Mg, three Al-3Mg-xFe alloys with approximately 3%Mg (mass fraction) and 0.11%-0.40%Fe (mass fraction). Compared to 7000-series alloys, the Al-xMg-5Zn materials have similar Zn content and higher Mg content, which is designed to investigate the effects of Zn on warm deformation mechanisms under different Mg content. The Al-3Mg-xFe materials with dilute Fe contents are designed to study the effect of Fe on creep mechanisms because Fe often exists as impurity in processing. For these materials, the relationships between strain-rate sensitivity and solute concentration are analyzed in detail, and the creep mechanisms operating under hot deformation are discussed.

2 Experimental

2.1 Materials

The compositions of the investigated Al-Mg-X alloys are shown in Table 1. These materials were prepared as book mold castings, and each casting was scalped and homogenized at 550 ℃ for 8 h. Then, the castings were hot rolled at temperatures from 450 to 350 ℃ and cold rolled to a thickness of 4 mm. The grain sizes after recrystallization were measured to be in the range of 30 to 45 μm. Because of limited cold deformation and lack of grain-refining alloy additions, the microstructures were significantly less refined than that of typical commercial sheet Al materials.

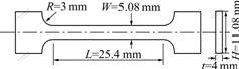

The tensile test specimens were machined from the cold rolled plate along the rolling direction, as shown in Fig.1.

Fig.1 Dimensions of specimen for high-temperature mechanical test

2.2 Elongation-to-failure (EF) tests

In high temperature mechanical tests, samples were heated in the middle zone of a three-zone split-tube furnace. Two thermocouples were placed in contact with the two ends of the specimen. Temperature was controlled to be within ±2 ℃.

The tensile elongation-to-failure tests were conducted on a testing machine for the Al-Mg-Zn and Al-Mg-Fe specimens at constant cross-head speed for strain rates from 10-3 s-1 to 10-2 s-1, at constant temperatures from 300 ℃ to 450 ℃. Ductilities for each failed sample were calculated based on uniform deformation in the gage section.

2.3 Strain-rate-change (SRC) tests

Strain-rate-change tests were conducted on the Al-Mg-Zn and Al-Mg-Fe specimens under strain rates from 4.31×10-5 to 1.97×10-2 s-1 and at constant temperature ranging from 300 ℃ to 450 ℃. In each SRC test, strain rate was varied from slow to fast in ten steps of constant cross-head speeds, with a 15%-20% prestrain in first step and 2%-5% strain in each subsequent step. The initial prestrain was imposed at a low rate in order to stabilize the microstructure before strain-rate jumps.

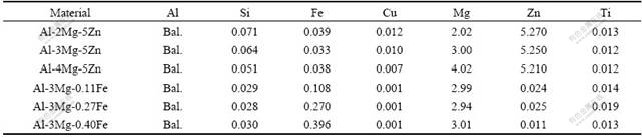

Table 1 Compositions of ternary alloys in present investigation (mass fraction, %)

2.4 Polarized light microscopy

The microstructures of each Al-xMg-5Zn and Al-3Mg-xFe material after EF test were examined using polarized light microscopy. Metallographic samples were taken from the undeformed grip regions, which assured sufficient time to completely recrystallize, to observe surfaces in longitudinal, short-transverse and long- transverse orientations. Samples were also taken from the deformed gage regions along tensile direction to observe failure features. Each polished specimen was electrolytically etched in Barker’s reagent, 5 mL fluoboric acid (HBF4, 48%) and 200 mL deionized water, under an electric potential of 20 V for 35 s. Micrographs were taken to observe cavitation and measure grain size using linear intercept method.

3 Results

3.1 Elongation-to-failure tests

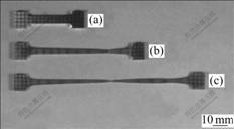

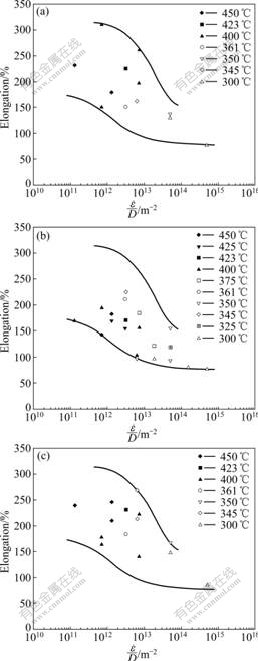

For Al-2Mg-5Zn material, the photo of one untested specimen and two specimens after EF tests with different elongations is shown in Fig.2. Complete elongation-to- failure data are given in Fig.3 for the Al-xMg-5Zn materials and in Fig.4 for the Al-3Mg-xFe materials, as EF versus logarithm of strain rate compensated by the diffusivity of Mg in Al, for which D0=5×10-5 m-2/s[12], and Q=136 kJ/mol[13]. The compensation of strain rate, ![]() is similar to the Zener-Hollomon parameter,

is similar to the Zener-Hollomon parameter, ![]() , which accounts for the temperature dependence of diffusivity.

, which accounts for the temperature dependence of diffusivity.

![]()

where ![]() is the strain rate, D is the diffusivity of Mg atoms in Al; D0 is the frequency factor; z is the Zener-Hollomon parameter; R is the gas constant and T is absolute temperature.

is the strain rate, D is the diffusivity of Mg atoms in Al; D0 is the frequency factor; z is the Zener-Hollomon parameter; R is the gas constant and T is absolute temperature.

Fig.2 Photo of samples before and after EF tests (Al-2Mg-5Zn, 400 ℃, ![]() =10-3 s-1): (a) Untested sample; (b) EF=153%; (c) EF=312%

=10-3 s-1): (a) Untested sample; (b) EF=153%; (c) EF=312%

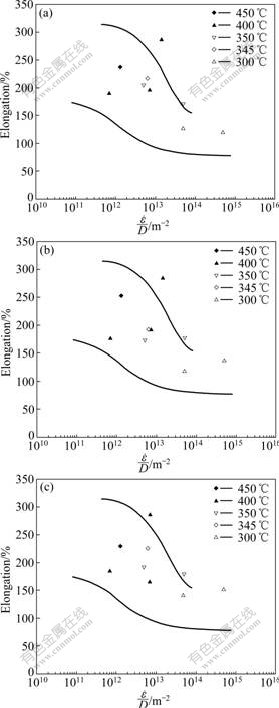

Fig.3 shows that the ductilities over 100% are consistently achieved at high temperatures and low strain rates, i.e. ![]() <1013 m-2, where solute drag creep dominates the deformation. In the region of

<1013 m-2, where solute drag creep dominates the deformation. In the region of ![]() >1013 m-2. The ductilities are reduced to below 100% with the limits of data provided. It is noted that the tensile ductilities of these Zn-containing alloys are similar to those of the binary Al-Mg alloys[14], indicating that the Zn addition of approximately 5% (mass fraction) does not strongly affect the tensile ductility of Al-Mg materials. Fig.4 shows that the tensile ductilities over 100% are also consistently achieved and the ductilities do not differ significantly from each other for the three Al-3Mg-xFe alloys, indicating that the ductilities are not strongly affected by the dilute concentration of Fe in the range of 0.11%-0.40% (mass fraction). To give a convenient comparison of the Al-xMg-5Zn and Al-3Mg-xFe materials, two hand-fit curves representing the limits of all the EF data from the three Al-xMg-5Zn materials are given in each plot of Fig.3 and Fig.4. The ductilities of the Al-3Mg-xFe materials are slightly higher, in general, than those of Al-xMg-5Zn materials.

>1013 m-2. The ductilities are reduced to below 100% with the limits of data provided. It is noted that the tensile ductilities of these Zn-containing alloys are similar to those of the binary Al-Mg alloys[14], indicating that the Zn addition of approximately 5% (mass fraction) does not strongly affect the tensile ductility of Al-Mg materials. Fig.4 shows that the tensile ductilities over 100% are also consistently achieved and the ductilities do not differ significantly from each other for the three Al-3Mg-xFe alloys, indicating that the ductilities are not strongly affected by the dilute concentration of Fe in the range of 0.11%-0.40% (mass fraction). To give a convenient comparison of the Al-xMg-5Zn and Al-3Mg-xFe materials, two hand-fit curves representing the limits of all the EF data from the three Al-xMg-5Zn materials are given in each plot of Fig.3 and Fig.4. The ductilities of the Al-3Mg-xFe materials are slightly higher, in general, than those of Al-xMg-5Zn materials.

Fig.3 Elongations at different temperatures and strain rates: (a) Al-2Mg-5Zn; (b) Al-3Mg-5Zn; (c) Al-4Mg-5Zn

Fig.4 Elongations at different temperatures and strain rates: (a) Al-3Mg-0.11Fe; (b) Al-3Mg-0.27Fe; (c) Al-3Mg-0.40Fe

3.2 Strain-rate change tests

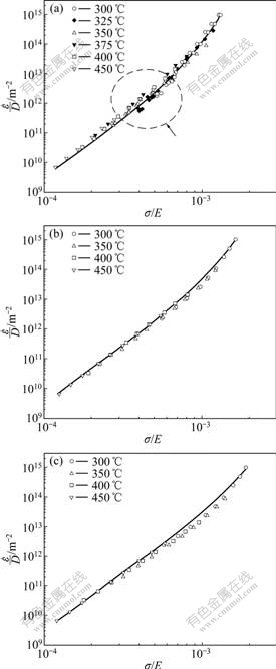

Fig.5 presents the SRC results from the Al-xMg-5Zn materials as the logarithm of diffusion-compensated strain rate, ![]() against the logarithm of modulus-compensated flow stress, σ/E. The strain rate is compensated by the diffusivity of Mg in Al.

against the logarithm of modulus-compensated flow stress, σ/E. The strain rate is compensated by the diffusivity of Mg in Al.

Fig.5 SRC test data of Al-xMg-5Zn samples: (a) Al-2Mg-5Zn; (b) Al-3Mg-5Zn; (c) Al-4Mg-5Zn

In these plots, the transitions to power-law breakdown (PLB) are evident at low temperatures and high strain rates, i.e. ![]() >1013 m-2. As marked in Fig.5(a), the Al-2Mg-5Zn material at 300 ℃ and 325 ℃ is found to exhibit a strong offset from the master curve, and persist in repeated tests, which is not observed for the Al-3Mg-5Zn and Al-4Mg-5Zn materials. The evidence indicates that the test temperatures below 325 ℃ may not be high enough to dissolve all precipitates in the as-received materials.

>1013 m-2. As marked in Fig.5(a), the Al-2Mg-5Zn material at 300 ℃ and 325 ℃ is found to exhibit a strong offset from the master curve, and persist in repeated tests, which is not observed for the Al-3Mg-5Zn and Al-4Mg-5Zn materials. The evidence indicates that the test temperatures below 325 ℃ may not be high enough to dissolve all precipitates in the as-received materials.

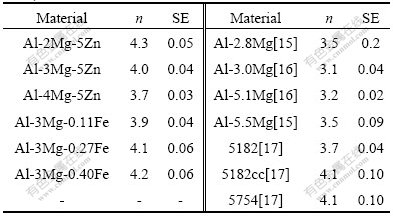

Linear regression method was applied to calculate the stress exponents in the data range of ![]() <1013 m-2. The values of n and its standard errors are listed in Table 2, where data for four Al-Mg materials[15-16] and three commercial Al-Mg alloys[17] from literature are included. For the Al-xMg-5Zn materials, the stress exponent decreases from 4.3 to 3.7 with the increase of Mg concentration, while the stress exponent for dilute, binary Al-xMg materials does not change greatly with the Mg concentration. It is indicated that ternary Zn additions increase the sensitivity of stress exponent to Mg content.

<1013 m-2. The values of n and its standard errors are listed in Table 2, where data for four Al-Mg materials[15-16] and three commercial Al-Mg alloys[17] from literature are included. For the Al-xMg-5Zn materials, the stress exponent decreases from 4.3 to 3.7 with the increase of Mg concentration, while the stress exponent for dilute, binary Al-xMg materials does not change greatly with the Mg concentration. It is indicated that ternary Zn additions increase the sensitivity of stress exponent to Mg content.

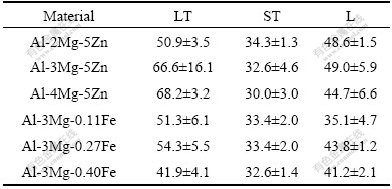

Table 2 Stress exponent n, of different alloys (SE: standard error)

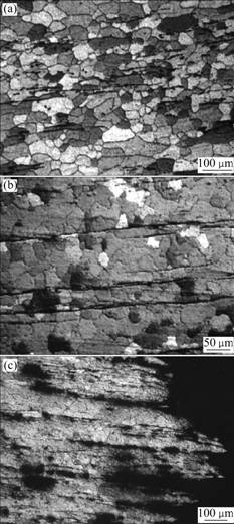

3.3 Polarized light microscopy

Horizontally oriented in the longitudinal direction, optical micrographs of a failed Al-3Mg-5Zn sample after EF test are shown in Fig.6. The grains in the grip region were somewhat elongated along the rolling direction, as shown in Fig.6(a). Table 3 gives the grain sizes in the grip region measured by linear-intercept method. It is evident that the grains are much larger than the size typically required for fine grained superplasticity, d≤10 μm.

Fig.6 Optical micrographs of failed Al-3Mg-5Zn sample after EF test at 400 ℃ and 2×10-4 s-1: (a) Grip region; (b) Gage point far from failure end; (c) Failure end

Table 3 Grain sizes in grip regions for long-transverse (LT), short-transverse (ST) and longitudinal (L) orientations (μm)

Observations of the failed EF specimens indicate that most specimens failed by necking to a point, which is similar to the necking behavior of superplastic binary Al-Mg alloys[15, 18-19]. Some specimens show moderate necking with cavities at the failure end. Fig.6(b) shows a gage point far from the failure end, and Fig.6(c) shows the failure end of the same sample at a larger magnification. The dark lines in both pictures are believed to be cavity bands. Some cavities with sizes of approximately 100 μm are apparent in Fig.6(c). The shape of the failure end in the picture is consistent with the jagged failure surface, which indicates that cavity growth and interlinkage cause the failure of the sample.

4 Discussion

To make a better comparison of the data from the Al-xMg-5Zn and Al-3Mg-xFe alloys, hyperbolic-sine curves were fitted to the SRC test data, as shown in Fig.7.

Fig.7 Fitted curves of SRC test data: (a) Al-xMg-5Zn; (b) Al- 3Mg-xFe

In Fig.7(a), the three Al-xMg-5Zn materials exhibit similar creep behaviors at low strain rates and high temperatures, i.e. ![]() <1013 m-2, 350 ℃<T<450 ℃. In this region, Mg concentration does not affect the creep behavior strongly, which indicates that 2%-4% (mass fraction) Mg is enough to ensure solute-drag creep. This conclusion is supported by the theory of Mg atoms saturation around an edge dislocation. There exists a temperature- dependent critical Mg concentration around an edge dislocation, over which the stress exponent is not sensitive to the concentration of Mg[13]. At low temperatures and high strain rates, i.e.

<1013 m-2, 350 ℃<T<450 ℃. In this region, Mg concentration does not affect the creep behavior strongly, which indicates that 2%-4% (mass fraction) Mg is enough to ensure solute-drag creep. This conclusion is supported by the theory of Mg atoms saturation around an edge dislocation. There exists a temperature- dependent critical Mg concentration around an edge dislocation, over which the stress exponent is not sensitive to the concentration of Mg[13]. At low temperatures and high strain rates, i.e. ![]() >1013 m-2, 350 ℃<T<350 ℃, Fig.7(a) shows a significant difference in creep behaviors for the three Al-xMg-5Zn materials. Al-4Mg-5Zn has the highest strength and Al-2Mg-5Zn is the weakest. For materials with high Mg content, more Mg atoms are available to retain solute-drag creep and slow the transition to power law breakdown (PLB), which requires that the material be of equal or higher strength during the transition. Therefore, the decrease of stress exponent in the three Al-xMg-5Zn materials with increasing Mg content is related to the suppression of the transition to PLB.

>1013 m-2, 350 ℃<T<350 ℃, Fig.7(a) shows a significant difference in creep behaviors for the three Al-xMg-5Zn materials. Al-4Mg-5Zn has the highest strength and Al-2Mg-5Zn is the weakest. For materials with high Mg content, more Mg atoms are available to retain solute-drag creep and slow the transition to power law breakdown (PLB), which requires that the material be of equal or higher strength during the transition. Therefore, the decrease of stress exponent in the three Al-xMg-5Zn materials with increasing Mg content is related to the suppression of the transition to PLB.

SRC data from the Al-3Mg-xFe materials were fitted using Garofalo’s hyperbolic-sine relation, as shown in Fig.7(b). The three materials exhibit similar creep behavior in both the solute-drag creep and PLB regions. Al-3Mg-0.27Fe and Al-3Mg-0.40Fe are slightly stronger than Al-3Mg-0.11Fe at high temperatures and low strain rates, which may be related to an increase in the volume fraction of iron-aluminide particulates with increasing Fe content.

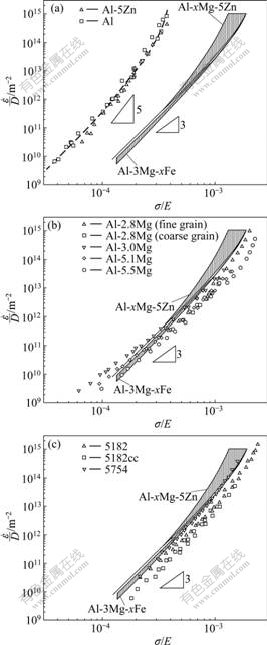

SRC test data from pure Al, Al-xMg, Al-xZn, Al-3Mg-xMn and commercial 5000-series materials are available in the literature. Many of these materials were tested in a similar regime of ![]() to the present study. Fig.8(a) shows the SRC test data from pure Al[20] and Al-5Zn alloys[10]. The areas covered by data from the Al-xMg-5Zn and Al-3Mg-xFe materials are hatched with vertical lines, which provide a clear way to compare data from different materials. The strain rates of Al and Al-5Zn are compensated by the diffusivity of Mg in Al, Q=136 kJ/mol and D0=5.0×10-5 m2/s. As expected, pure Al exhibits dislocation climb-controlled creep with a typical stress exponent of n≈5. The similarity between the stress exponents of Al and Al-5Zn indicates that the Zn addition of 5% (mass fraction) in Al does not produce a significant solute-drag effect. Therefore, both the Al and Al-5Zn materials exhibit dislocation-climb- controlled creep and the creep activation energy is equal to the activation energy of lattice self-diffusion in Al[21]. The compensation of strain rates in Fig.8(a) is valid for the Al-xMg-5Zn and Al-3Mg-xFe materials because the solute-drag behavior is induced by Mg, and it is also approximately valid for the Al and Al-5Zn data because the activation energy for lattice self-diffusion in Al is similar, which is 142 kJ/mol.

to the present study. Fig.8(a) shows the SRC test data from pure Al[20] and Al-5Zn alloys[10]. The areas covered by data from the Al-xMg-5Zn and Al-3Mg-xFe materials are hatched with vertical lines, which provide a clear way to compare data from different materials. The strain rates of Al and Al-5Zn are compensated by the diffusivity of Mg in Al, Q=136 kJ/mol and D0=5.0×10-5 m2/s. As expected, pure Al exhibits dislocation climb-controlled creep with a typical stress exponent of n≈5. The similarity between the stress exponents of Al and Al-5Zn indicates that the Zn addition of 5% (mass fraction) in Al does not produce a significant solute-drag effect. Therefore, both the Al and Al-5Zn materials exhibit dislocation-climb- controlled creep and the creep activation energy is equal to the activation energy of lattice self-diffusion in Al[21]. The compensation of strain rates in Fig.8(a) is valid for the Al-xMg-5Zn and Al-3Mg-xFe materials because the solute-drag behavior is induced by Mg, and it is also approximately valid for the Al and Al-5Zn data because the activation energy for lattice self-diffusion in Al is similar, which is 142 kJ/mol.

Fig.8 Comparison of SRC test data: (a) Al[20], Al-5Zn[10]; (b) Al-xMg[15-16]; (c) 5182, 5182cc, and 5754[17]

It is noted in Fig.8(a) that the Zn addition does not strongly affect the strength of Al over the given range of temperatures and strain rates. In contrast, the Al-xMg-5Zn and Al-3Mg-xFe materials have higher strengths and exhibit solute-drag behavior with lower stress exponents, n≈4. The Al-3Mg-xFe materials are slightly stronger than the Al-xMg-5Zn materials when ![]() ≤1013 m-2. In the transition region from solute-drag creep to PLB,

≤1013 m-2. In the transition region from solute-drag creep to PLB, ![]() ≥1013 m-2, the three Al-3Mg-xFe materials show a similar behavior to the Al-4Mg-5Zn material, being stronger than the Al-3Mg-5Zn and Al-2Mg-5Zn materials. This stronger behavior of the Fe-containing ternary materials is attributed to both of the strengthening effect of iron-aluminide particulates, which exist even at high temperatures, and the slower transition to PLB for the Al-4Mg-5Zn material.

≥1013 m-2, the three Al-3Mg-xFe materials show a similar behavior to the Al-4Mg-5Zn material, being stronger than the Al-3Mg-5Zn and Al-2Mg-5Zn materials. This stronger behavior of the Fe-containing ternary materials is attributed to both of the strengthening effect of iron-aluminide particulates, which exist even at high temperatures, and the slower transition to PLB for the Al-4Mg-5Zn material.

The effectiveness of Mg at producing solute-drag creep is illustrated in Fig.8(b)[15-16]. The binary Al-Mg alloys all exhibit a stress exponent characteristic of solute-drag creep, n≈3.3. For values of ![]() ≤1013 m-2, the Al-xMg-5Zn and Al-3Mg-xFe materials exhibit approximately similar strengths but higher stress exponents than Al-Mg alloys as shown in Table 2. When

≤1013 m-2, the Al-xMg-5Zn and Al-3Mg-xFe materials exhibit approximately similar strengths but higher stress exponents than Al-Mg alloys as shown in Table 2. When ![]() ≥1013 m-2, the Al-2Mg-5Zn material is the weakest and exhibits the earliest transition to PLB, which is generally associated with an increase in excess vacancy concentration caused by dislocation interactions at high strain rates and low temperatures[22]. Deformation- induced increases of excess vacancy concentration in Al have been confirmed by MURTY et al using nuclear magnetic resonance methods[23]. If Al-2Mg-5Zn cannot retain the solute-drag effect at low temperatures and high strain rates because of the low mobility of Mg atoms, dislocation glide becomes easier, allowing dislocation climb to control the rate of deformation. At high stresses, however, excess vacancies generated by dislocation intersections produce a high effective diffusivity, which enhances dislocation climb and accelerates the creep rate into PLB. The Al-4Mg-5Zn material, with the highest Mg content, is able to retain the solute-drag effect at low temperatures and high strain rates, exhibiting a low stress exponent and a slow transition to PLB.

≥1013 m-2, the Al-2Mg-5Zn material is the weakest and exhibits the earliest transition to PLB, which is generally associated with an increase in excess vacancy concentration caused by dislocation interactions at high strain rates and low temperatures[22]. Deformation- induced increases of excess vacancy concentration in Al have been confirmed by MURTY et al using nuclear magnetic resonance methods[23]. If Al-2Mg-5Zn cannot retain the solute-drag effect at low temperatures and high strain rates because of the low mobility of Mg atoms, dislocation glide becomes easier, allowing dislocation climb to control the rate of deformation. At high stresses, however, excess vacancies generated by dislocation intersections produce a high effective diffusivity, which enhances dislocation climb and accelerates the creep rate into PLB. The Al-4Mg-5Zn material, with the highest Mg content, is able to retain the solute-drag effect at low temperatures and high strain rates, exhibiting a low stress exponent and a slow transition to PLB.

SRC test data from fine and coarse grained Al-2.8Mg material are included in Fig.8(b). It is noted that despite a large difference in grain size, 450 μm versus 30 μm, they exhibit a similar steady-state stress exponent, n≈3.5. Neither strength nor strain-rate sensitivity in the solute-drag-creep regime is significantly affected by grain size within the range examined.

Commercial alloys, 5182, 5182cc, and 5754[17] show higher strength than the Al-xMg-5Zn and Al-3Mg-xFe materials, as shown in Fig.8(c). This can be attributed to the Cu, Mn additions in the commercial alloys. It is important to note that the Al-xMg-5Zn, Al-3Mg-xFe and commercial materials in Fig.8(c) exhibit consistent solute drag creep behaviors, from which enhanced tensile ductilities of over 100% have been repeatedly achieved.

5 Conclusions

1) In the regime of ![]() <1013 m-2, solute-drag creep dominates the deformation of these ternary materials, and the Al-xMg-5Zn and Al-3Mg-xFe materials have similar strengths.

<1013 m-2, solute-drag creep dominates the deformation of these ternary materials, and the Al-xMg-5Zn and Al-3Mg-xFe materials have similar strengths.

2) Ternary additions of Zn and Fe do not strongly affect tensile ductilities. Enhanced tensile ductilities of over 100% are repeatedly achieved from the Al-xMg-5Zn and Al-3Mg-xFe materials when deformed in the solute-drag-creep regime.

3) The dominated failure mechanism in these materials during elongation-to-failure tests is necking to a point. Cavity growth and interlinkage can also cause failures.

4) Ternary Zn additions increase the sensitivity of stress exponent to Mg content, and n decreases with the increase of Mg content. This decrease of n value is related to the suppression of the transition to dislocation-climb creep and PLB with increasing Mg content.

References

[1] PARK K T, HWANG D Y, CHANG S Y, SHIN D H. Low-temperature superplastic behavior of a submicrometer-grained 5083 Al alloy fabricated by severe plastic deformation [J]. Metallurgical and Materials Transactions A, 2002, 33(9): 2859-2867.

[2] GREEN W P, KULAS M A, NIAZI A, OH-ISHI K, TALEFF E M, KRAJEWSKI P E, MCNELLEY T R. Deformation and failure of a superplastic AA5083 aluminum alloy with Cu additions [J]. Metallurgical and Materials Transactions A, 2006, 37: 2727-2738.

[3] FRIEDMAN P A, COPPLE W B. Superplastic response in Al-Mg sheet alloys [J]. Journal of Materials Engineering and Performance, 2004, 13(3): 335-347.

[4] GARC?A-BERNAL M A, HERNANDEZ-SILVA D, SAUCE- RANGEL V. Superplastic behavior of coarse-grained Al-Mg-Zn alloys [J]. Journal of Materials Science, 2007, 42: 3958-3963.

[5] SOER W A, CHEZAN A R, HOSSON J T M D. Deformation and reconstruction mechanisms in coarse-grained superplastic Al-Mg alloys [J]. Acta Materialia, 2006, 54(14): 3827-3833.

[6] MCQUEEN H J. Development of dynamic recrystallization theory [J]. Materials Science and Engineering A, 2004, 387/389(15): 203-208.

[7] JAZAERI H, HUMPHREYS F J. The transition from discontinuous to continuous recrystallization in some aluminium alloys (I): The deformed state [J]. Acta Materialia, 2004, 52(11): 3239-3250.

[8] CRUZ-PALACIOS M I, HERN?NDEZ-SILVAA D, BARRALES-MORA L A, GARC?A-BERNAL M A. Grain refinement during superplastic deformation of coarse-grained Al-Mg-Cu alloys [J]. Materials Science Forum, 2006, 509: 75-80.

[9] AGARWAL S, KRAJEWSKI P E, BRIANT1 C L. Dynamic recrystallization of AA5083 at 450 ℃: The effects of strain rate and particle size [J]. Metallurgical and Materials Transactions A, 2008, 39(6): 1277-1289.

[10] TALEFF E M, NEVLAND P J, KRAJEWSKI P E. Solute-drag creep and tensile ductility in aluminum alloys [C]// MISHRA R S, MUKHERJEE A K, MURTY K L. Creep Behavior of Advanced Materials of the 21st Century. San Diego, CA: TMS. Warrendale, PA, 1999: 349-358.

[11] KULAS M A, GREEN W P, TALEFF E M, KRAJEWSKI P E, MCNELLEY T R. Deformation mechanisms in superplastic AA5083 materials [J]. Metallurgical and Materials Transactions A, 2005, 36(5): 1249-1261.

[12] FUNAMIZU Y, WATANABE K. Interdiffusion in the Al-Mg system [J]. Trans JIM, 1972, 13: 278-283.

[13] MCNELLEY T R, MICHEL D J, SALAMA A. The Mg-concentration dependence of the strength of Al-Mg alloys during glide-controlled deformation [J]. Scripta Metall, 1989, 23: 1657-1662.

[14] TALEFF E M, NEVLAND P J. The high-temperature deformation and tensile ductility of Al alloys [J]. JOM, 1999, 51: 34-36.

[15] TALEFF E M, HENSHALL G A, NIEH T G, LESUER D R, WADSWORTH J. Warm-temperature tensile ductility in Al-Mg alloys [J]. Metall Mater Trans A, 1998, 29: 1081-1091.

[16] YAVARI P, MOHAMED F A, LANGDON T G. Creep and substructure formation in an Al-5% Mg solid solution alloy [J]. Acta Metall, 1981, 29: 1495-1507.

[17] TALEFF E M, NEVLAND P J, KRAJEWSKI P E. Tensile ductility of several commercial aluminum alloys at elevated temperatures [J]. Metall Mater Trans A, 2001, 32: 1119-1130.

[18] BAE D H, GHOSH A K. Cavity formation and early growth in a superplastic Al-Mg alloy [J]. Acta Materialia, 2002, 50(3): 511-523.

[19] KULAS M-A, GREEN W P, TALEFF E M, KRAJEWSKI P E, MCNELLEY T R. Failure mechanisms in superplastic AA5083 materials [J]. Metallurgical and Materials Transactions A, 2006, 37(3): 645-655.

[20] SERVI I S, GRANT N J. Creep and stress rupture behavior of aluminum as a function of purity [J]. Trans AIME, 1951, 191: 909-916.

[21] FROST H J, ASHBY M F. Deformation-mechanism maps. The plasticity and creep of metals and ceramics [M]. Chapter 1. New York: Pergamon Press Inc, 1982: 1-19.

[22] SHERBY O D, BURKE P M. Mechanical behavior of crystalline solids at elevated temperature [J]. Prog Mater Sci, 1968, 13: 325-390.

[23] MURTY K L, DETEMPLE K, KANERT O, DEHOSSON J T M. In-situ nuclear magnetic resonance investigation of strain, temperature, and strain-rate variations of deformation-induced vacancy concentration in aluminum [J]. Metallurgical and Materials Transactions A, 1998, 29: 153-159.

Foundation item: Project(DMR-9702156) supported by the National Science Foundation of USA; Project(50801034) supported by the National Natural Science Foundation of China; Project(20060425) supported by the Scientific and Technological Research Key Lab Foundation of Liaoning Education Department

Corresponding author: QIAO Jun; Tel: +86-412-5929532; E-mail: qiaoj@ustl.edu.cn

DOI: 10.1016/S1003-6326(09)60179-5

Abstract: Enhanced tensile ductilities in coarse grained Al-Mg-Zn and Al-Mg-Fe materials were studied. The materials were Al-2Mg-5Zn, Al-3Mg-5Zn, Al-4Mg-5Zn, Al-3Mg-0.11Fe, Al-3Mg-0.27Fe, and Al-3Mg-0.40Fe. Tensile elongation-to-failure tests were conducted at constant cross-head speed and constant temperatures from 300 to 450 ℃. Strain rate change tests were conducted at a constant temperature from 300 to 450 ℃ and in strain-rate range from 4.31×10-5 to 1.97×10-2 s-1. Experimental results show that over 100% ductilities are consistently achieved in these materials. This superplasticity-like behavior is rate-controlled by solute-drag creep. Although ternary Zn and Fe additions do not have an adverse effect on solute-drag creep and ductility, they increase stress exponent and its sensitivity to Mg content during solute-drag creep.