Trans. Nonferrous Met. Soc. China 22(2012) s175-s180

In vitro corrosion resistance and cytotoxicity of novel TiNbTaZr alloy

GUO Yong-yuan1, CHENG Meng-qi1, CHEN De-sheng1, XUE Xiao-bing2, ZHANG Xian-long1

1. Orthopaedic Department, The Sixth Affiliated People’s Hospital, Medical School of Shanghai Jiao Tong University, Shanghai 200233, China;

2. State Key Laboratory of Metal Matrix Composites, Shanghai Jiao Tong University, Shanghai 200240, China

Received 9 July 2012; accepted 16 August 2012

Abstract:

A novel β type Ti35Nb2Ta3Zr alloy with low modulus (48 GPa) was fabricated using vacuum consumable arc melting. The corrosion resistance and cytotoxicity of Ti35Nb2Ta3Zr were evaluated. The open circuit potential, electrochemical impedance spectroscopy (EIS) and potentiodynamic polarization methods were used to determine the corrosion resistance. In Ringer’s solution, Ti35Nb2Ta3Zr alloy exhibits better corrosion resistance, as compared to that of Ti6Al4V and Ti. The cytotoxicity tests indicate that the biocompatibility of Ti35Nb2Ta3Zr is as good as Ti and Ti6Al4V which are widely used in biomedical fields. Based on corrosion resistance and cytotoxicity, the novel β type Ti35Nb2Ta3Zr alloy can be considered as a potential biomaterial.

Key words:

β-type titanium alloy; corrosion behavior; electrochemical techniques; cytotoxicity;

1 Introduction

The pure titanium and Ti6Al4V (α+β type) are presently the most widely used materials for orthopedic implants due to their high corrosion resistance and good biocompatibility. However, the elastic modulus of Ti6Al4V (110 GPa) is much higher than that of human cortical bone (30 GPa). The mismatch of elastic modulus between the implant and bone leads to stress shielding, which results in bone resorption and eventually leads to the loosening and premature failure of the implant [1]. On the other hand, the release of potentially harmful metal elements, such as Al and V from Ti6Al4V and their accumulation in the body have been proved to be toxic to human body [2]. So, there is a thrust towards the development of novel titanium alloys with lower modulus and nontoxic elements.

Under these conditions, β type titanium alloys satisfy most of the requirements for an orthopedic implant, which consist of β stable elements, such as molybdenum, silicon, niobium, zirconium and tantalum. Researchers reported that the moduli of Ti29Nb13Ta4.6Zr [3], Ti25Ta25Nb [4] and Ti35Nb4Sn [5] are 65 GPa, 55 GPa, and 40 GPa, respectively, which are much closer to the modulus of nature bone. The biocompatibility of β type titanium alloys is increased significantly compared to that of Ti6Al4V. PARK et al [6] reported that the Ti13Nb13Zr alloy showed significantly increased cellular attachment compared with Ti6Al4V.

As an implant in the human body, corrosion resistance and biocompatibility are the most important characteristics expanding the use of alloys as biomaterials [7]. The addition of niobium (Nb) could increase the corrosion resistance of materials [8]. Zirconium (Zr) shows acceptable mechanical strength [9] and in vivo evidences have demonstrated that zirconium implants exhibit good osteointegration [10,11]. Tantalum (Ta) is more corrosion resistant than niobium because of the higher stability of its oxide [12,13] and its superior corrosion resistance and the biocompatibility of tantalum have been extensively evaluated [14]. Therefore, considering the individual characteristics of Nb, Ta and Zr, TiNbTaZr alloys are expected to present a good combination of low elastic modulus, high corrosion resistance and good biocompatibility.

In our previous study, a novel β type Ti35Nb2Ta3Zr alloy was fabricated using vacuum consumable arc melting, which has an elastic modulus of about 48 GPa and an ultimate tensile strength of around 880 MPa [15]. There is no knowledge of the corrosion resistance and in vitro cytotoxicity of this new material. Therefore, the current study focuses on these aspects of the Ti35Nb2Ta3Zr alloy.

2 Experimental

2.1 Alloy fabrication

Ti35Nb2Ta3Zr alloy (mass fraction, %) was fabricated by vacuum consumable arc melting using the mixture of high purity sponge titanium, Ti-Nb interalloy and high purity Ta and Zr. The ingot was re-melted three times to homogenize the alloy chemical composition. To homogenize the microstructure, the ingot was heat-treated at 1223 K for 1 h in vacuum. The ingot was then forged into a quadrate casting of 70 mm×30 mm× 100 mm followed by a solution treatment at 1053 K for 0.5 h in vacuum. The ingot was deformed by cross- rolling at the reduction ratios of 99%. The chemical composition (mass fraction, %) of Ti35Nb2Ta3Zr is determined by EDX (X-MAX80, Oxford) as w(Ti): w(Nb):w(Ta):w(Zr)=59.55:35.44:2.14:2.86 .

Disk samples of 12 mm in diameter and 4 mm in thickness were prepared from the Ti35Nb2Ta3Zr alloy. Ti6Al4V and pure Ti were used as control. All the samples were polished to a surface finish of 0.1 μm and then were ultrasonically washed in ethanol and then deionized water. All samples were sterilized in an autoclave prior to cell culture.

2.2 Corrosion test

The corrosion tests of the three Ti alloys were performed in Ringer’s solution (NaCl 9 g/L, KCl 0.43 g/L, CaCl2 0.24 g/L and NaHCO3 0.2 g/L) at 37 °C [16], which was known as a simulated body solution [17,18]. A PARSTAT 2273 electrochemical station and a standard three-electrode cell were used with a saturated calomel electrode (SCE) as a reference electrode and a platinum plate as a counter electrode. The open-circuit potential and electrochemical impedance were measured before the potentiodynamic polarization test. The values of open circle potential (OCP) were recorded for 1 h after the samples were immersed in Ringer’s solution. Eoc was defined as the value of OCP for 1 h. The electrochemical impedance spectrum (EIS) measurements were performed at the Eoc at the frequency range of 100 kHz to 100 mHz with a signal amplitude of 10 mV. An equivalent circuit was assigned for the EIS data and the data were curve fitted by ZSimpWin 3.21 software. The potentiodynamic polarization tests of samples were carried out over the potential range from -500 to +500 mV (vs Eoc) at a scanning rate of 0.5 mV/s. Each test was carried out in triplicate to evaluate the reproducibility of the results.

2.3 Cytotoxicity

2.3.1 Cell culture

L929, a murine fibroblast cell line (Cellbank of Chinese Science Academy, China) was cultured in DMEM (Biowest, France) containing 10% FBS (Biowest, France) and 1% penicillin/streptomycin at 37 °C in an atmosphere of 5% CO2 and 95% humidity. The medium was refreshed every 2 d, and confluent flasks were subcultured using trypsin/EDTA. Ti and Ti6Al4V were used as control, which have already been used for orthopedic fields in humans. Each experiment was performed 4 times (n=4). The data obtained were expressed as mean±s.d. ANOVA analyses were performed with the SPSS 16.0 software, and P less than 0.05 was considered statistically significant.

2.3.2 Cell adhesion

1 mL cell suspension with a density of 5000 cells/mL was seeded on the surfaces of Ti, Ti6Al4V and Ti35Nb2Ta3Zr for 24 h. At the prescribed time point, the samples were rinsed with PBS, and the cells were fixed and stained with 4’, 6’-diamidino-2-phenylindole (DAPI). The cell numbers in five random fields were counted under a fluorescence microscope (Leica DM400).

2.3.3 Cell viability

The cell viability was evaluated by the Cell Counting Kit-8 (CCK-8, Dojindo, Japan). 1 mL cell suspension with a density of 5000 cells/mL was seeded on the substrates. After culturing for 24 h, samples were rinsed with PBS and 10 μL of pre-warmed CCK-8 solution with 90 μL culture medium was added. After 1 h of further incubation, the 100 μL working solution was transferred to a new 96-well culture plate for measuring the absorbance using an ELISA reader at 450 nm.

3 Results and discussion

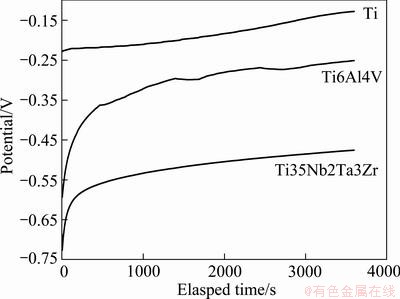

The open circuit potentials became less negative with exposure time of Ti, Ti6Al4V and Ti35Nb2Ta3Zr alloys in Ringer’s solution at 37 °C. The representative images are shown in Fig. 1. Almost immediately after exposure, the potential of the Ti35Nb2Ta3Zr was approximately -725 mV, and it increased to more noble potentials and stabilized at -476 mV after exposing for 1 h. For Ti and Ti6Al4V alloy, the initial open circuit potentials were around -593 mV and -227 mV, and then increased to -253 mV and -128 mV after exposure for 1 h, respectively. For all the three alloys, the change towards less negative potentials demonstrates that the metal surfaces are spontaneously passivated in Ringer’s solution due to the formation of an oxide film. From Fig. 1, it is shown that Ti6Al4V has the least negative Eoc values compared to Ti and Ti35Nb2Ta3Zr, while Ti35Nb2Ta3Zr presents the most negative Eoc values. These data suggest that the tendency for the formation of a spontaneous oxide on Ti35Nb2Ta3Zr is less than the ones formed on Ti and Ti6Al4V in Ringer’s solution.

Fig. 1 Potential versus time profile for Ti, Ti6Al4V and Ti35Nb2Ta3Zr alloys after exposing for 1 h in Ringer’s physiological solution

Electrochemical impedance spectra of Ti, Ti6Al4V and Ti35Nb2Ta3Zr alloys exhibit as Bode plot in Fig. 2 after exposing for 1 h in Ringer’s solution. High impedance values (in the order of 104-105 Ω/cm2) were obtained for medium to low frequencies in the three samples, implying high corrosion resistance in the simulated body solution, and were indicative of a single passive oxide film formed at the surface of the samples [19,20]. The phase angle θ, a sensitive parameter, was used to indicate the presence of additional time constants in EIS. From Bode plots in Fig. 2, only one time constant was involved and the phase angle θ was close to 90°.

Fig. 2 Bode plots for Ti, Ti6Al4V and Ti35Nb2Ta3Zr alloys after exposing for 1 h in Ringer’s solution

A simple equivalent circuit (EC) Rs(QRp) (Fig. 3) was used to model the EIS data, which has been used to fit oxides grown on Ti alloys under different situations by other researchers [21-24]. Rs and Rp represent the solution and the parallel (film) resistances, respectively. Q is a constant phase element (CPE) for the capacitance of the passive oxide film. The impedance of the CPE is given by Z(CPE)= [Q(jω)n]-1, where ω is the angular frequency in rad/s and n is the exponential term. While Q is defined as pure capacitance for n=1, resistance for n=0, and inductance for n=-1. The fitting results of the EIS data are shown in Table 1. The chi-square value of less than 0.01 for the model showed good agreement between the experimental data and the fitted data. n was near 1, indicating that Q presented an almost pure capacity. The film resistance Rp of Ti6Al4V and Ti35Nb2Ta3Zr had the same order of 105 Ω/cm-2. The Rp of Ti35Nb2Ta3Zr was higher than that of Ti6Al4V and Ti, demonstrating that the spontaneously formed oxide film on Ti35Nb2Ta3Zr was more resistive than that on Ti6Al4V and Ti. Namely, The Ti35Nb2Ta3Zr had the best corrosion resistance among the three materials.

Fig. 3 Equivalent circuit, Rs(QRp), used to fit the experimental impedance data from Fig. 2

Table 1 Electrical parameters obtained by fitting the experimental results of EIS tests for Ti, Ti6Al4V and Ti35Nb2Ta3Zr

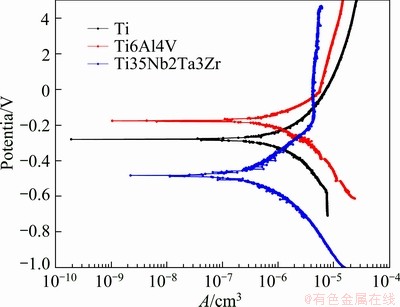

Figure 4 presents the typical potentiodynamic polarization plots obtained from Ti, Ti6Al4V and Ti35Nb2Ta3Zr in Ringer’s solution. When the applied potential voltage increased to 500 mV, very low current densities were obtained for all the tested samples, which suggested that no pitting corrosion occurred. In the case of Ti35Nb2Ta3Zr alloy, the current density increased with potential from the corrosion potential until approximately -150 mV, and then the current density remained unchanged as the potential increased until the end of the test at 500 mV, indicating typical passive behavior. The current density of the titanium alloy in this passive region was approximately 2.16 μA/cm2. The corresponding corrosion parameter icorr means the corrosion rate and Eo means the potential where the current density noticeably increases with increasing potential. The trend for Eo is Ti35Nb2Ta3Zr<Ti< Ti6Al4V, which agrees with Eoc. icorr increased in the order of Ti35Nb2Ta3Zr<Ti6Al4V<Ti. The Ti35Nb2- Ta3Zr alloy exhibited significantly the lowest corrosion current density values among the three materials, suggesting a better corrosion resistance property compared to Ti and Ti6Al4V. The results matched with the results of EIS.

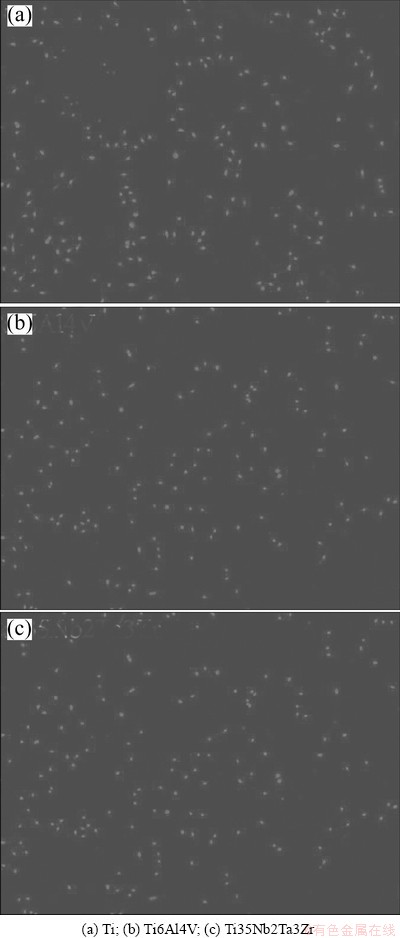

The cell adhesion and viability of L929 on Ti, Ti6Al4V and Ti35Nb2Ta3Zr are shown in Figs. 5-7.

Fig. 4 Representative image of potentiodynamic polarization for Ti, Ti6Al4V and Ti35Nb2Ta3Zr alloys in Ringer’s solution

Fig. 5 Fluorescence images of L929 fibroblasts (nuclei in blue) incubated on surface of Ti, Ti6Al4V and Ti35Nb2Ta3Zr after culturing for 24 h

Fig. 6 Values of fibroblasts adhesion measured by cell counting for 24 h

Fig. 7 Cell viability after culturing for 24 h on surface of Ti, Ti6Al4V and Ti35Nb2Ta3Zr

The L929 fibroblasts proliferated well on all the three samples. There were no significant differences in cell adhesion and proliferation between Ti35Nb2Ta3Zr and Ti or Ti6Al4V. Therefore, it can be concluded that the cytotoxicity of the Ti35Nb2Ta3Zr alloy is almost equal to that of the Ti6Al4V alloy and Ti, which are already in use in biomedical implantation in humans. In accord with our results, other studies of the cytotoxicity of new titanium alloys containing Nb, Ta or Zr demonstrated that cells proliferated well on TiNbTaZr, TiNbSn and TiTaSn alloy disks [3,25-28].

4 Conclusions

The in vitro corrosion resistance and cytotoxicity of a novel Ti35Nb2Ta3Zr alloy have been assessed and compared with those of Ti and Ti6Al4V.

1) Ti35Nb2Ta3Zr presents the most negative OCP values after exposing for 1 h in Ringer’s solution.

2) The EIS data shows that the Rp of Ti35Nb2Ta3Zr is higher than that of Ti6Al4V and Ti, and the potentiodynamic polarization results suggest the corrosion current density of Ti35Nb2Ta3Zr is lower compared to Ti6Al4V and Ti. Both of them demonstrate that Ti35Nb2Ta3Zr has the best corrosion resistance among the three materials.

3) There are no significant differences in the cell adhesion and proliferation between cells grown on the Ti35Nb2Ta3Zr, Ti and Ti6Al4V in direct contact cell culture tests.

These results imply that Ti35Nb2Ta3Zr alloys are potentially promising candidates for orthopedic fields.

References

[1] HUISKES R, WEINANS H, RIETBERGEN B. The relationship between stress shielding and bone resorption around total hip stems and the effects of flexible materials [J]. Clinical Orthopaedics and Related Research, 1992, 274: 124-134.

[2] HALLAB N J, VERMES C, MESSINA C, ROEBUCK K A, GLANT T T, JACOBS J J. Concentration- and composition- dependent effects of metal ions on human MG-63 osteoblasts [J]. Journal of Biomedical Materials Research, 2002, 60(3): 420-433.

[3] NIINOMI M. Fatigue performance and cyto-toxicity of low rigidity titanium alloy, Ti-29Nb-13Ta-4.6Zr [J]. Biomaterials, 2003, 24(16): 2673-2683.

[4] BERTRAND E, GLORIANT T, GORDIN D M, VASILESCU E, DROB P, VASILESCU C, DROB S I. Synthesis and characterisation of a new superelastic Ti-25Ta-25Nb biomedical alloy [J]. Journal of the Mechanical Behavior of Biomedical Materials, 2010, 3(8): 559-564.

[5] JUNG T K M H, ABUMIYA T, MASAHASHI N, KIM M S, HANADA S. Mechanical properties-graded Ti alloy implants for orthopedic applications. [J]. Materials Science Forum, 2010, 631-632: 205-210.

[6] PARK C H, LEE C S, KIM Y J, JANG J H, SUH J Y, PARK J W. Improved pre-osteoblast response and mechanical compatibility of ultrafine-grained Ti-13Nb-13Zr alloy [J]. Clinical Oral Implants Research, 2011, 22(7): 735-742.

[7] RUAN J, GRANT M. Biocompatibility evaluation in vitro. Part III: Cytotoxicity expression of human and animal osteoblasts on the biomaterials [J]. Journal of Central South University of Technology, 2001, 8(3): 147-155.

[8] HAMDY A S, EL-SHENAWY E, EL-BITAR T. Electrochemical impedance spectroscopy study of the corrosion behavior of some niobium bearing stainless steels in 3.5% NaCl [J]. International Journal of Electrochemical Science, 2006, 1: 171-180.

[9] SHEREPO K M, RED'KO I A. The use of zirconium for implants in traumatology and orthopedics [J]. Med Tekh, 2004, 2: 22-24.

[10] CABRINI R L, GUGLIELMOTTI M B, ALMAGRO J C. Histomorphometry of initial bone healing around zirconium implants in rats [J]. Implant Dentistry, 1993, 2(4): 264-267.

[11] KULAKOV O B, DOKTOROV A A, D'IAKOVA S V, DENISOV-NIKOL'SKII IU I, GROTZ K A. Experimental study of osseointegration of zirconium and titanium dental implants [J]. Morfologiia, 2005, 127(1): 52-55.

[12] ROBIN A, ROSA J L. Corrosion behavior of niobium, tantalum and their alloys in hot hydrochloric and phosphoric acid solutions [J]. International Journal of Refractory Metals and Hard Materials, 2000, 18(1): 13-21.

[13] YANG H P, YANG S H, CAI Y N, HOU G F, XIA J Y, TANG M T. Electrochemical behaviors of tantalum in anhydrous ethanol containing hydrogen sulfate ions [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(1): 179-184.

[14] MATSUNO H, YOKOYAMA A, WATARI F, UO M, KAWASAKI T. Biocompatibility and osteogenesis of refractory metal implants, titanium, hafnium, niobium, tantalum and rhenium [J]. Biomaterials, 2001, 22(11): 1253-1262.

[15] WANG L Q, LU W J, QIN J N, ZHANG F, ZHANG D. Microstructure and mechanical properties of cold-rolled TiNbTaZr biomedical beta titanium alloy [J]. Materials Science and Engineering A-Structural Materials Properties Microstructure and Processing, 2008, 490(1-2): 421-426.

[16] SAMUEL S, NAG S, NASRAZADANI S, UKIRDE V, BOUANANI M E, MOHANDAS A, NGUYEN K, BANERJEE R. Corrosion resistance and in vitro response of laser-deposited Ti-Nb-Zr-Ta alloys for orthopedic implant applications [J]. Journal of Biomedical Materials Research Part A, 2010, 94(4): 1251-1256.

[17] GUO L, LIANG C H, SUI H Y. Corrosion behavior of commercially pure Ti and Ti6Al4V alloy in artificial body fluid [J]. The Chinese Journal of Nonferrous Metals, 2001, 11(1): 4. (in Chinese)

[18] LUO L J, YU Z T, ZHOU L. Mechanical and corrosion properties of near β biomedical titanium alloy [J]. Chinese Journal of Rare Metals, 2005, 29(2): 3. (in Chinese)

[19] ROSALBINO F, MACCIO D, GIANNONI P, QUARTO R, SACCONE A. Study of the in vitro corrosion behavior and biocompatibility of Zr-2.5Nb and Zr-1.5Nb-1Ta (at%) crystalline alloys [J]. Journal of Materials Science-Materials in Medicine, 2011, 22(5): 1293-1302.

[20] MARECI D, CHELARIU R, GORDIN D M, UNGUREANU G, GLORIANT T. Comparative corrosion study of Ti-Ta alloys for dental applications [J]. Acta Biomaterialia, 2009, 5(9): 3625-3639.

[21] GODLEY R, STAROSVETSKY D, GOTMAN I. Corrosion behavior of a low modulus beta-Ti-45%Nb alloy for use in medical implants [J]. Journal of Materials Science-Materials in Medicine, 2006, 17(1): 63-67.

[22] YU W Q, QIU J, XU L, ZHANG F Q. Corrosion behaviors of TiO2 nanotube layers on titanium in Hank's solution [J]. Biomedical Materials, 2009, 4(6): 065012.

[23] OLIVEIRA N, BIAGGIO S, PIAZZA S, SUNSERI C, DI QUARTO F. Photo-electrochemical and impedance investigation of passive layers grown anodically on titanium alloys [J]. Electrochimica Acta, 2004, 49(26): 4563-4576.

[24] OLIVEIRA N, BIAGGIO S, NASCENTE P, PIAZZA S, SUNSERI C, DI QUARTO F. The effect of thickness on the composition of passive films on a Ti-50Zr at% alloy [J]. Electrochimica Acta, 2006, 51(17): 3506-3515.

[25] MIURA K, YAMADA N, HANADA S, JUNG T K, ITOI E. The bone tissue compatibility of a new Ti-Nb-Sn alloy with a low Young's modulus [J]. Acta Biomaterialia, 2011, 7(5): 2320-2326.

[26] WANG X, LI Y, HODGSON P D, WEN C. Biomimetic modification of porous TiNbZr alloy scaffold for bone tissue engineering [J]. Tissue Engineering Part A, 2010, 16(1): 309-316.

[27] LI Y, XIONG J, WONG C S, HODGSON P D, WEN C. Ti6Ta4Sn alloy and subsequent scaffolding for bone tissue engineering [J]. Tissue Engineering Part A, 2009, 15(10): 3151-3159.

[28] WANG R, GAO B, GAO Y, HAO Y L, LI S J. The biological safety evaluation of new Ti-24Nb-4Zr-7.9Sn alloy [J]. Journal of Clinical Stomatology, 2007, 23(6): 4. (in Chinese).

新型TiNbTaZr合金的生物腐蚀性和细胞毒性

郭永园1,程萌旗1,陈德胜1,薛晓冰2,张先龙1

1. 上海交通大学 附属第六人民医院,上海 200233;

2. 上海交通大学 金属基复合材料国家重点实验室,上海 200240

摘 要:通过真空自耗电弧炉开发一种新型β钛合金Ti35Nb2Ta3Zr,其弹性模量仅为48 GPa,探讨该合金的耐腐蚀性能和细胞毒性。在Ringer 模拟体液中,通过测量开路电位、极化阻抗谱和极化曲线发现Ti35Nb2Ta3Zr的腐蚀性优于Ti6Al4V 和 Ti。细胞毒性试验证明Ti35Nb2Ta3Zr的生物相容性与目前临床常用的Ti6Al4V 和Ti相当。因此,该新型β钛合金Ti35Nb2Ta3Zr具有良好的耐腐蚀性和生物相容性,未来作为生物材料具有广阔前景。

关键词:β型钛合金;腐蚀行为;电化学技术;细胞毒性

(Edited by CHEN Ai-hua)

Foundation item: Project (81171688) supported by the National Natural Science Foundation of China; Project (YG2011MS30) supported by the Interdisciplinary (Engineering–Medical) Research Fund of Shanghai Jiao Tong University, China; Project (2010QJ036A) supported by the Shanghai Municipal Health Bureau Science Fund for Young Scholars, China

Corresponding authors: ZHANG Xian-long; Tel: +86-134-82699313; Fax: +86-21-64701361; E-mail: orthopedics2012@163.com; XUE Xiao-bing; Tel: +86-150-21530723; Fax: +86-21- 64701361; E-mail: titanium12@163.com

Abstract: A novel β type Ti35Nb2Ta3Zr alloy with low modulus (48 GPa) was fabricated using vacuum consumable arc melting. The corrosion resistance and cytotoxicity of Ti35Nb2Ta3Zr were evaluated. The open circuit potential, electrochemical impedance spectroscopy (EIS) and potentiodynamic polarization methods were used to determine the corrosion resistance. In Ringer’s solution, Ti35Nb2Ta3Zr alloy exhibits better corrosion resistance, as compared to that of Ti6Al4V and Ti. The cytotoxicity tests indicate that the biocompatibility of Ti35Nb2Ta3Zr is as good as Ti and Ti6Al4V which are widely used in biomedical fields. Based on corrosion resistance and cytotoxicity, the novel β type Ti35Nb2Ta3Zr alloy can be considered as a potential biomaterial.