文章编号:1004-0609(2016)-01-0031-06

超轻Mg-Li-Al系变形镁合金挤压板材的组织及性能

李瑞红1,蒋 斌2,陈志军3,潘复生4

(1. 内蒙古科技大学 材料与冶金学院,包头 014010;

2. 重庆大学 材料科学与工程学院,重庆 400044;

3. 内蒙古第一机械集团有限公司 第十分公司,包头 014030;

4. 重庆大学 国家镁合金工程技术研究中心,重庆 400044)

摘 要:

通过OM、SEM、XRD和拉伸实验研究3种典型的Mg-Li-Al合金的铸态和挤压态组织及力学性能。结果表明:随着Li含量的增加,合金的结构从密排六方向体心立方转变,合金的铸态组织随之发生改变。经过250 ℃挤压处理后,Mg-5Li-1Al和Mg-9Li-1Al合金的晶粒沿挤压方向呈方向性排列,Mg-14Li-1Al合金由均匀的等轴晶(再结晶晶粒)组成。随着Li含量的增加,挤压态合金板材的屈服强度逐渐增大,其中挤压态Mg-9Li-1Al合金板材的综合力学性能最佳(屈服强度达到149 MPa,伸长率达到25%)。

关键词: 镁锂合金;挤压;显微组织;力学性能

中图分类号:TG113.25 TG146.22 文献标志码:A

作为最轻的金属结构材料,镁锂合金具有比强度和比刚度高、阻尼减震性能优良、抗高能粒子穿透能力强,尤其是其变形性能的优势,使得它在宇航、兵器、汽车、电子等领域有广阔的应用前景[1-4]。根据Mg-Li合金相图[5-7],随着Li含量的增加,Mg-Li合金可分为α相合金(w(Li)<5.5%)、α+β两相合金(5.5%<w(Li)<11%)和β相合金(w(Li)>11%)。其中α相为锂固溶于镁中的固溶体,具有密排六方晶体(HCP)结构;β相为镁固溶于锂中的固溶体,具有体心立方(BCC)结构。由于体心立方结构的出现,使Mg-Li合金的塑性得到极大改善,并改变了镁合金因滑移系少、加工成型困难的缺点,从而引起各国研究者的极大兴趣[8-11]。

同时,随着Li含量的增加,镁锂合金的强度、耐蚀性及抗蠕变性能下降比较多。为得到性能优良、稳定性好的镁锂系合金,合金化作为一种强化手段,被广泛应用。铝在固态镁中有较大的固溶度,它是Mg-Li合金的主要强化元素之一[12-14]。近年来,已经广泛应用的Mg-Li-Al合金主要有Mg-14Li-1Al(LA141)、Mg-9Li-1Al(LA91)等。

由于Li元素的出现,使得镁锂合金的结构发生了变化。因此,近年来对于镁锂合金的研究在逐年增加,研究人员的主要精力集中于镁锂合金中的结构转变,对于单相合金而言,随着Li含量的增加,其性能的变化以及其中的机理研究[15-18]。WANG等[19]研究了随着Li含量的增加,铸态镁锂合金的阻尼性能,但是并没有研究其力学性能的变化。XU等[1]研究Mg-8Li-3Al- 0.5Mn-Sr合金的铸态及挤压态显微组织,同时也研究了挤压棒材的力学性能。结果表明:LAM830-0.75Sr合金的抗拉强度可以达到265.46 MPa,但其伸长率只有17.1%。随着镁合金产品的逐步推广,作为高技术含量、高附加值的产品,镁合金板材是支撑镁合金广泛应用的主要基础结构材料。因此,如何在密度、塑性和强度三者之间取得较好的结果是Mg-Li系合金板材发展和应用中的关键问题。本文作者对3种不同锂含量、较为典型的Mg-Li-Al合金的组织与力学性能进行了研究,以期为镁锂合金板材的广泛应用提供理论依据。

1 实验

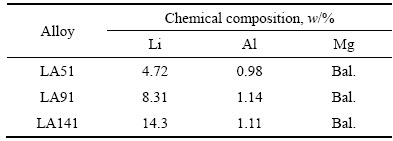

本实验中所用原料为99.90%Mg、99.90%Li、99.90%Al(质量分数)。实验所使用的合金是在真空感应熔炼炉中,采用氩气气氛保护熔炼而成。按照纯锂锭的质量计算设计合金的质量。首先,将纯镁锭和纯铝锭按照设定成分进行切割、称量、打磨、清洗,使其表面光滑无氧化层。其次,将熔炼炉加热至 150 ℃烘干,把所有原料快速加入到熔炼炉中的坩埚,并将炉密封;对感应熔炼炉抽真空至气压≤1×10-2 Pa,然后充入纯氩气至 30 kPa;之后将感应炉加热进行熔炼,待原料充分熔化后,在 720 ℃保温静置 20 min,然后加大氩气的通入量增加炉膛内压力,将熔体压入预热的金属模具(模具尺寸为d168 mm×510 mm)中;待铸锭在空气中冷却后,从模具中取出。为防止金属锂被氧化,实验全程在氩气保护下进行。合金的实测化学成分如表1所列。

表1 试验合金的化学成分

Table 1 Chemical compositions of alloys

合金铸锭经250 ℃保温10 h均匀化处理后,在1250T型挤压机上挤压成宽120 mm、厚2 mm的板材。挤压方式为正向热挤压,挤压比为83.7。由于锂含量不同,3种合金的变形温度也不同,LA51的挤压温度为350 ℃,而LA91与LA141合金的挤压温度设定为280 ℃。从铸态及挤压态合金上分别截取试样,在Newphot-30型金相显微镜观察组织形貌,采用Rigaku D/max 2500PC X型射线衍射仪进行合金相成分分析。采用CMT5000系列微机控制电子万能试验机对挤压态合金进行力学性能测试,按照与挤压方向呈0°、45°、90° 3个方向取样,力学性能数据取至3个试样的平均值。

2 结果与分析

2.1 合金的显微组织

图1所示为3种铸态合金的XRD谱。从图1中可以看出,3种合金的相组成完全不同:LA51合金主要由α-Mg单相组成(见图1(a)),LA91合金主要由α-Mg和β-Li相组成(见图1(b)),而LA141合金则主要由β-Li组成(见图1(c))。另外,在LA91和LA141合金中还有少量的LiMgAl2相存在,这种相组成也与后面的显微组织相对应。

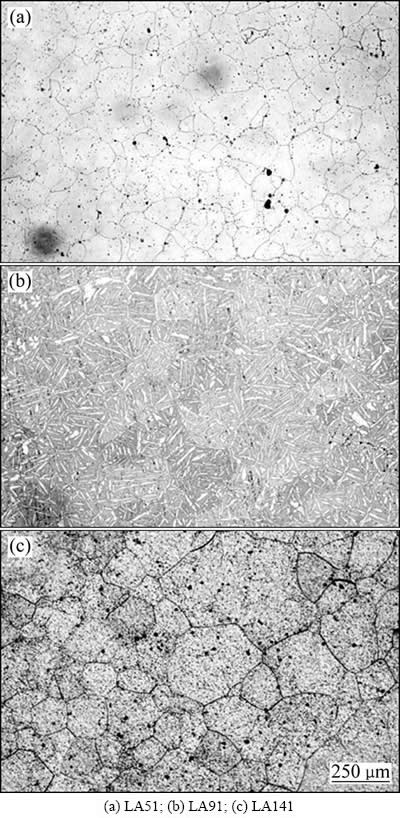

图2所示为3种合金的铸态显微组织。如图2(a)所示,LA51合金由均匀的等轴状晶粒组成,晶粒内几乎没有其他相的存在。LA91合金由细小白色针状的α-Mg(HCP)相和灰色β-Li(BCC)相组成(见图2(b))。LA141铸态合金的晶粒比较粗大(见图2(c))。

图1 试验合金的XRD谱

Fig. 1 XRD patterns of studied alloys

图2 试验合金的铸态金相组织

Fig. 2 As-cast optical microstructures of studied alloys

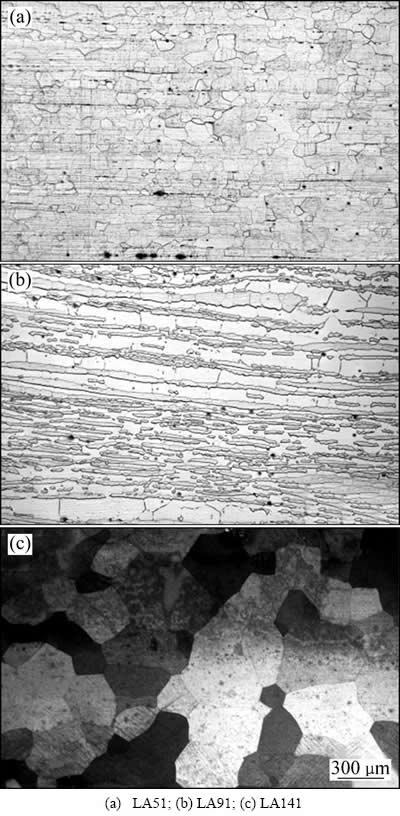

图3所示为不同Li含量的3种镁锂合金的挤压态组织。由图3可以看出,3种合金的组织较铸态时细小许多。其中LA51合金由均匀细小的再结晶晶粒组成,大部分晶粒沿着挤压方向(ED)排列。LA91合金仍然由两相组成,只是α相与β相沿挤压方向呈现出明显的方向性。LA141合金虽然与LA91的挤压温度相同,但表现出截然不同的组织形貌,由均匀的再结晶晶粒组成。

图3 试验合金的挤压态组织

Fig. 3 As-extruded microstructures of studied alloys

2.2 挤压态合金的力学性能

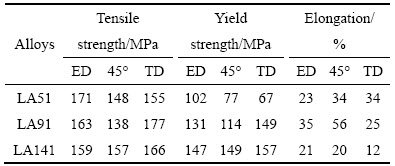

对挤压态的试验合金进行了拉伸实验,其实验结果如表2所列。由于基体相的不同,3种合金表现出不同的力学性能。在本试验范围内,屈服强度(YS)随着Li含量的增加而增大(沿各个方向的数据变化一致),这与许天才等[20]的研究结果不符,而伸长率在Li含量为9%时达到最大值。LA141合金的屈服强度比较大,LA51合金在各个方向上的塑性各向异性最小。

表2 挤压态合金沿着不同方向的力学性能

Table 2 Mechanical properties of extruded alloys along different tensile directions

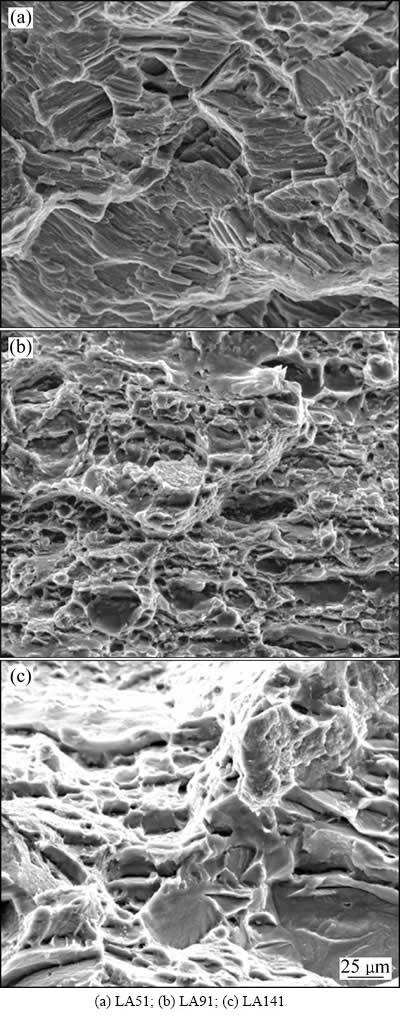

2.3 合金的断口形貌

3种挤压态合金板材拉伸后的断口形貌如图4所示。由图4可见,3种合金的拉伸断口完全不同。LA51合金的断口以解理面和解理台阶为主,呈现脆性断裂机制(见图4(a));LA91合金断口为大量密集且较深的韧窝,表明该合金主要以韧性断裂为主(见图4(b));LA141合金的断口上既有解理面,又有小而深的韧窝,呈现脆性和韧性混合的断裂机制(见图4(c))。3种合金断裂方式的不同主要与合金的晶体结构有关。虽然LA51合金的塑性较好(伸长率达到23%,较LA141的伸长率高),但其晶体结构仍为密排六方,在室温下的变形没有体心立方结构合金的容易。LA141合金由于体心立方结构的出现,断口形貌呈现脆性和韧性混合断裂特征。LA91合金由于α相和β相的相互协调作用,使其具有较好的塑性,因而断口形貌呈现韧性断裂特征。

图4 实验合金沿挤压方向拉伸后的断口形貌

Fig. 4 Fracture surface morphologies of extruded alloys tested along ED

2.4 合金的力学性能变化

挤压变形是提高合金力学性能的有效手段之一。在一定的温度条件下施加应力,使原有的组织形貌完全破碎,同时获得较为细小的部分再结晶或完全再结晶晶粒组织。挤压变形还能使铸态合金中存在的一些气孔和显微裂纹消失。在挤压变形过程中还有可能伴随着固态相变的发生,由于组织细化及一定数量的弥散相的出现,使得挤压变形后合金的力学性能往往会显著提升[21-23]。

通常情况下,随着Li含量的增加,由于具有体心立方结构的β-Li相的出现,合金的塑性随之增加,合金的强度则随之下降。而本试验中的结果则与之不同。挤压态LA141合金板材的屈服强度最大,伸长率最小;但LA91的伸长率最佳。

对于α-Mg基合金而言,较“软”的相为α-Mg相,即位错更容易在大晶粒尺寸的α-Mg相中开动。LA51由于是以密排六方α相为基体,故其拉伸强度较其他高锂含量合金的高。文献[2,24]中报道,在镁中添加Li元素,会使镁的轴比c/a降低,原子间距的减小降低了六方晶格沿{1010}<1210>棱面滑移的启动能,从而使得非基面滑移在室温下与基面滑移同时发生。因此,对于α单相的Mg-Li合金,虽仍为HCP结构,也具有良好的变形能力,且各向异性行为减弱。但从另一方面来讲,由于非基面滑移的启动,使得位错的移动较为容易,所以合金的强度会比常规镁合金的强度低,如AZ31(Mg-3Al-1Zn)合金[25-26]。这与本实验中LA51合金的研究较为符合。

当继续增加Li含量,合金的组织由α(HCP)→α+β→β(BCC)转变,合金的塑性变形能力进一步得到改善,使其在室温下的伸长率得到提高。在LA91合金中,由于BCC结构的β相和HCP结构的α相的相互协调作用,从图3(b)中可以看出,在挤压变形过程中,α-Mg相及β-Li相均沿挤压方向呈现带状分布。这也说明在β-Li相存在的情况下,α-Mg相的变形更加顺利,使得合金的强度和塑性大为改善。当Li含量增加到14%时,合金完全由β-Li相组成,在挤压变形的作用下,LA141合金的晶粒尺寸较铸态时细化更多,同时,本实验采用的挤压温度较低,所以,LA141合金的屈服强度较高。这也说明了本实验工艺制备的LA141合金的力学性能较好。在本实验中,LA91合金的屈服强度较LA141合金的略低,但其屈强比也较LA141的低,故可通过冷变形进一步强化。

3 结论

1) 随着Li含量的增加,合金的结构由α-Mg(HCP)向β-Li(BCC)转变,且合金的组织随之发生改变。

2) 挤压后LA51和LA91合金的晶粒沿挤压方向呈现方向性排列,LA141合金的晶粒由均匀的再结晶晶粒构成。

3) 随着Li含量的增加,挤压态合金板材的屈服强度随之增加,这与合金的结构和织构有关。LA91的综合力学性能最佳。

REFERENCES

[1] XU Tian-cai, PENG Xiao-dong, JIANG Jun-wei, XIE Wei-dong, CHEN Yuan-fang, WEI Guo-bing. Effect of Sr content on microstructure and mechanical properties of Mg-Li-Al-Mn alloy[J]. Transactions of Nonferrous Metals Society of China, 2014, 24 (9): 2752-2760.

[2] 吴章斌, 桂良进, 范子杰. AZ31B镁合金挤压材料的力学性能与本构分析[J]. 中国有色金属学报, 2015, 25(2): 293-300.

WU Zhang-bin, GUI Liang-jin, FAN Zi-Jie. Mechanical properties and constitutive analysis of extruded AZ31B magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(2): 293-300.

[3] DONG Han-Wu, PAN Fu-Sheng, JIANG Bin, LI Rui-Hong, HUANG Xiao-Yong. Mechanical properties and deformation behaviors of hexagonal Mg-Li alloys[J]. Materials & Design, 2015, 65: 42-49.

[4] SUH B, SHIM M, SHIN K S, KIM N J. Current issues in magnesium sheet alloys: Where do we go from here? [J] Scripta Materialia, 2014, 84/85: 1-6.

[5] 王军武, 刘旭贺, 王飞超, 肖 阳. 航空航天用高性能超轻镁锂合金[J]. 军民两用技术与产品, 2013(6): 21-24.

WANG Jun-wu, LIU Xu-he, WANG Fei-chao, XIAO Yang. High performance super light magnesium lithium alloy used in aerospace[J]. Dual Use Technologies & Products, 2013(6): 21-24.

[6] 宋 波, 辛仁龙, 郭 宁, 刘婷婷, 杨青山. 变形镁合金室温应变硬化行为的研究进展[J]. 中国有色金属学报, 2014, 24(11): 2699-2710.

SONG Bo, XIN Ren-long, GUO Ning, LIU Ting-Ting, YANG Qing-shan. Research progress of strain hardening behavior at room temperature in wrought magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(11): 2699-2710.

[7] YIN Heng-mei, JIANG Bin, HUANG Xiao-yong, ZENG Ying, YANG Qing-shan, ZHANG Ming-xing. Effect of Ce addition on microstructure of Mg-9Li alloy[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(7): 1936-1941.

[8] 崔崇亮, 朱天龙, 冷 哲, 巫瑞智, 张景怀, 张密林. 复合添加Y和Nd对Mg-Li合金显微组织及室温压缩织构的影响[J]. 金属学报, 2012, 48(6): 725-732.

CUI Chong-liang, ZHU Tian-long, LENG Ze, WU Rui-zhi, ZHANG Jing-huai, ZHANG Ming-lin. Effects of combined addition of Y and Nd on microstructure and texture after compression of Mg-Li alloy at room temperature[J]. Acta Metallurgica Sinica, 2012, 48(6): 725-732.

[9] LI Rui-hong, PAN Fu-sheng, JIANG Bin, YANG Qing-shan, TANG Ai-tao. Effects of combined additions of Li and Al–5Ti–1B on the mechanical anisotropy of AZ31 magnesium alloy[J]. Materials & Design, 2013, 46: 922-927.

[10] DING Han-lin, ZHANG Peng, CHENG Guang-ping, KAMADO S. Effect of calcium addition on microstructure and texture modification of Mg rolled sheets[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(9): 2875-2883.

[11] LI Rui-hong, PAN Fu-sheng, JIANG Bin, DONG Han-wu, YANG Qing-shan. Effect of Li addition on the mechanical behavior and texture of the as-extruded AZ31 magnesium alloy[J]. Materials Science and Engineering A, 2013, 562: 33-38.

[12] 余远清. 新型超轻Mg-Li-Al-Gd合金制备及组织性能研究[D]. 重庆: 重庆大学, 2014.

YU Yuan-qing. Preparation and research on microstructure and properties of new ultralight Mg-Li-Al-Gd alloys[D]. Chongqing: Chongqing University, 2014.

[13] 李 明, 郝 海, 张爱民, 宋迎德, 张兴国. Al-Ti-C中间合金对Mg-8Li-3Al合金组织和性能的影响[J]. 特种铸造及有色合金, 2013, 33(1): 81-84.

LI Ming, HAO Hai, ZHANG Ai-ming, SONG Ying-de, ZHANG Xing-guo. Effects of Al-Ti-C master alloy on microstructure and mechanical properties of Mg-8Li-3Al alloy[J]. Special Casting & Nonferrous Alloys, 2013, 33(1): 81-84.

[14] YANG Yan, PENG Xiao-dong, WEN Hai-ming, ZHENG Bao-long, ZHOU Yi-zhang, XIE Wei-dong, LAVERNIA E J. Influence of extrusion on the microstructure and mechanical behavior of Mg-9Li-3Al-xSr alloys[J]. Metallurgical and Materials Transactions A, 2013, 44(2): 1101-1113.

[15] ZHU Tian-long, SUN Jian-feng, CUI Chong-liang, WU Rui-zhi, BETSOFEN S, LENG Zhe, ZHANG Jing-huai, ZHANG Mi-lin. Influence of Y and Nd on microstructure, texture and anisotropy of Mg-5Li-1Al alloy[J]. Materials Science and Engineering A, 2014, 600: 1-7.

[16] ZHOU Li-juan, SU Ke-he, WANG Yan-li, ZENG Qing-feng, LI Yu-long. First-principles study of the properties of Li, Al and Cd doped Mg alloys[J]. Journal of Alloys and Compounds, 2014, 596: 63-68.

[17] SHIN I, CARTER E A. First-principles simulations of plasticity in body-centered-cubic magnesium–lithium alloys[J]. Acta Materialia, 2014, 64: 198-207.

[18] KIM Y, KIM J, YU H, CHOI J, SON H. Microstructure and mechanical properties of Mg-xLi-3Al-Sn-0.4Mn alloys (x=5, 8 and 11wt%)[J]. Journal of Alloys and Compounds, 2014, 583: 15-20.

[19] WANG Jing-feng, XU Dan-dan, LU Ruo-peng, PAN Fu-sheng Damping properties of as-cast Mg-xLi-1Al alloys with different phase composition[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(2): 334-348.

[20] 许天才, 彭晓东, 张 玺, 陈元芳, 姜军伟, 陈 洁. Mg-xLi-Al变形镁合金微观组织与拉伸性能[J]. 功能材料, 2014, 45(7): 7066-7069.

XU Tian-cai, PENG Xiao-dong, ZHANG Xi, CHEN Yuan-fang, JIANG Jun-wei, CHEN Jie. Microstructure and tensile properties of Mg-xLi-Al wrought alloy[J]. Journal of Functional Materials, 2014, 45(7): 7066-7069.

[21] 许天才, 彭晓东, 张 宝, 魏国兵, 陈元芳, 姜军伟. 微量Sr和Mn对Mg-8Li-3Al变形合金力学性能的影响[J]. 材料研究学报, 2014, 28(9): 649-565.

XU Tian-cai, PENG Xiao-dong, ZHANG Bao, WEI Guo-bing, CHEN Yuan-fang, JIANG Jun-wei. Effects of minor addition of Sr and Mn on mechanical properties of micro-alloying Mg-8Li-3Al wrought alloy[J]. Chinese Journal of Materials Research, 2014, 28(9): 649-565.

[22] 程丽任. 铸造态、挤压态、半固态Mg-Li-Al系合金组织和力学性能研究[D]. 吉林: 吉林大学, 2011.

CHENG Li-ren. Investigation on microstructure and mechanical properties of as-east, extruded and semisolid Mg-Li-Al magnesium alloys[D]. Jilin: Jilin University, 2011.

[23] GUO Fei, ZHANG Ding-fei, YANG Xu-sheng, JIANG Lu-yao, PAN Fu-sheng. Microstructure and texture evolution of AZ31 magnesium alloy during large strain hot rolling[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(1): 14-21.

[24] LENTZ M, COELHO R S, CAMIN B. In-situ, ex-situ EBSD and (HR-) TEM analyses of primary, secondary and tertiary twin development in an Mg-4wt%Li alloy[J]. Materials Science and Engineering A, 2014, 610: 54-64.

[25] YIN De-liang, LIU Jin-qiang, WU Bing. Deformation mechanisms of Mg-3Al-1Zn alloy by polycrystal plasticity modeling[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(7): 2188-2194.

[26] LU Li-wei, LIU Tian-mo, CHEN Yong, WANG Li-guang, WANG Zhong-chang. Double change channel angular pressing of magnesium alloys AZ31[J]. Materials & Design, 2012, 35: 138-143.

Microstructure and mechanical properties of as-extruded ultra-light Mg-Li-Al sheet

LI Rui-hong1, JIANG Bin2, CHEN Zhi-jun3, PAN Fu-sheng4

(1. School of Materials and Metallurgy, Inner Mongolia University of Science and Technology, Baotou 014010, China;

2. College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China;

3. The Tenth Sub-company, Inner Mongolia First Machinery Group Corporation, Baotou 014030, China;

4 National Engineering Research Center for Magnesium Alloys, Chongqing University, Chongqing 400044, China)

Abstract: The as-cast and extruded microstructures and mechanical properties of three kinds of Mg-Li-Al alloys were studied by optical microscopy, SEM, XRD and tensile test. The results show that, with the increase of lithium additions, the crystal structure transforms from close-packed hexagonal (HCP) structure to body centered cubic (BCC) structure, and the as-cast microstructures of the Mg-Li-Al alloys change correspondingly. After extrusion at 250℃, the grain of Mg-5Li-1Al and Mg-9Li-1Al alloys are arranged along the extruded direction, but the microstructures of Mg-14Li-1Al alloy sheet consist of equiaxed crystals. The yield stress of the extruded alloys is improved gradually with the increase of lithium content. The extruded Mg-9Li-1Al alloy obtains the optimal mechanical properties (the yield stress and elongation are 149 MPa and 25%, respectively), along the transverse direction.

Key words: Mg-Li alloy; extrusion; microstructure; mechanical property

Foundation item: Project (2015BS0512) supported by the Natural Science Foundation of the Inner Mongolia Autonomous Region, China; Project (2014QDL016) supported by Inner Mongolia University of Science and Technology Innovation Fund, China; Project (51171212) supported by the National Natural Science Foundation of China

Received date: 2015-05-08; Accepted data: 2015-10-18

Corresponding author: LI Rui-hong; Tel: +86 472 6896872; E mail: liruihong1019@163.com

(编辑 李艳红)

基金项目:内蒙古自治区自然科学基金资助项目(2015BS0512);内蒙古科技大学创新基金资助项目(2014QDL016);国家自然科学基金资助项目(51171212)

收稿日期:2015-05-08;修订日期:2015-10-18

通信作者:李瑞红,讲师,博士;电话:0472-6896872;E-mail:liruihong1019@163.com

摘 要:通过OM、SEM、XRD和拉伸实验研究3种典型的Mg-Li-Al合金的铸态和挤压态组织及力学性能。结果表明:随着Li含量的增加,合金的结构从密排六方向体心立方转变,合金的铸态组织随之发生改变。经过250 ℃挤压处理后,Mg-5Li-1Al和Mg-9Li-1Al合金的晶粒沿挤压方向呈方向性排列,Mg-14Li-1Al合金由均匀的等轴晶(再结晶晶粒)组成。随着Li含量的增加,挤压态合金板材的屈服强度逐渐增大,其中挤压态Mg-9Li-1Al合金板材的综合力学性能最佳(屈服强度达到149 MPa,伸长率达到25%)。

[2] 吴章斌, 桂良进, 范子杰. AZ31B镁合金挤压材料的力学性能与本构分析[J]. 中国有色金属学报, 2015, 25(2): 293-300.

[5] 王军武, 刘旭贺, 王飞超, 肖 阳. 航空航天用高性能超轻镁锂合金[J]. 军民两用技术与产品, 2013(6): 21-24.

[6] 宋 波, 辛仁龙, 郭 宁, 刘婷婷, 杨青山. 变形镁合金室温应变硬化行为的研究进展[J]. 中国有色金属学报, 2014, 24(11): 2699-2710.

[8] 崔崇亮, 朱天龙, 冷 哲, 巫瑞智, 张景怀, 张密林. 复合添加Y和Nd对Mg-Li合金显微组织及室温压缩织构的影响[J]. 金属学报, 2012, 48(6): 725-732.

[12] 余远清. 新型超轻Mg-Li-Al-Gd合金制备及组织性能研究[D]. 重庆: 重庆大学, 2014.

[13] 李 明, 郝 海, 张爱民, 宋迎德, 张兴国. Al-Ti-C中间合金对Mg-8Li-3Al合金组织和性能的影响[J]. 特种铸造及有色合金, 2013, 33(1): 81-84.

[20] 许天才, 彭晓东, 张 玺, 陈元芳, 姜军伟, 陈 洁. Mg-xLi-Al变形镁合金微观组织与拉伸性能[J]. 功能材料, 2014, 45(7): 7066-7069.

[21] 许天才, 彭晓东, 张 宝, 魏国兵, 陈元芳, 姜军伟. 微量Sr和Mn对Mg-8Li-3Al变形合金力学性能的影响[J]. 材料研究学报, 2014, 28(9): 649-565.

[22] 程丽任. 铸造态、挤压态、半固态Mg-Li-Al系合金组织和力学性能研究[D]. 吉林: 吉林大学, 2011.