Creep behavior of ageing hardened Mg-10Gd-3Y alloy

LIU Xi-bo(刘喜波)1, 2, GUAN Xun(关 逊)3, CHEN Rong-shi(陈荣石)1, HAN En-hou(韩恩厚)1

1. State Key Laboratory for Corrosion and Protection, Institute of Metal Research,Chinese Academy of Sciences, Shenyang 110016, China;

2. Luoyang Ship Material Research Institute, Luoyang 471039, China;

3. High Temperature Creep Laboratory, Institute of Metal Research, Chinese Academy of Sciences,Shenyang 110016, China

Received 23 September 2009; accepted 30 January 2010

Abstract:

Tensile creep behaviors of the ageing hardened Mg-10Gd-3Y alloy (referred to GW103) were investigated at temperatures up to 300 ℃. The extruded-T5 specimen exhibited high creep resistance, i.e. the low steady-state creep rate and long creep rupture time, while the better creep properties were observed in the cast-T6 one. The low steady-state creep rate of 1.71×10-9 s-1 is obtained at 200 ℃ and 80 MPa for the extruded-T5 GW103 alloy. In addition, the microstructure development of GW103-T5 alloy was also examined after creep exposure at different temperatures. On the other hand, the stress exponent and activation energy were studied in the temperature range of 200-300 ℃ for the extruded-T5 specimens, and the creep mechanism was also discussed.

Key words:

creep; Mg-10Gd-3Y alloy; microstructure; crack;

1 Introduction

As the lightest structural materials, magnesium alloys are attracting more and more attention. However, the applications of conventional Mg-Al-based alloys are limited to temperatures below 120 ℃ due to the rapid degradation of mechanical properties, especially creep resistance[1-2]. The poor creep resistance is ascribed to the coarsening and inhomogeneous distribution of β-Mg17Al12 precipitates in Mg-Al-based alloys[3-4], and their creep mechanisms have been widely investigated. Mg alloys containing yttrium and/or rare earth metals (RE) have the good combination of room and high temperature mechanical properties[5-6]. Adding RE is an important approach for attaining high temperature creep resistance Mg alloys above 120 ℃. The effects of RE are solution-hardening and precipitation-hardening, especially the latter, resulting in excellent mechanical properties even at high temperatures[7]. These RE elements improve the creep resistance by the formation of RE precipitates[8-9].

The Mg-Gd system alloys were found to exhibit higher strength and better high temperature properties than the commercial Mg-Y-RE (WE) ones[10-11]. However, their creep properties have few been investigated. The present work aims to investigate and compare the creep behavior, microstructural evolution and deformation mechanism of Mg-10Gd-3Y (mass fraction, %, referred to GW103) alloys at elevated temperatures.

2 Experimental

The GW103 alloy with an actual chemical composition of Mg-10.4%Y-3.3%Gd-0.46%Zr (mass fraction) was extruded at 420 ℃ and then, the peak ageing was carried out at 200 ℃ for 72 h (T5 treatment). In addition, the solid solution and peak ageing treatment (200 ℃, 80 h) were also conducted for the cast-GW103 alloy (T6 treatment). Tensile creep tests were carried out at temperatures ranging from 200 to 300 ℃ and stresses ranging from 40 to 120 MPa. Specimens were tested in air in a three-zone-split electric resistance furnace. The temperature accuracy was controlled within ±2 ℃. The gauge section of creep specimen is d10 mm×50 mm according to GB/T2039—1997. The samples were held for about 30 min prior to the creep test to reach a thermal equilibrium. The microstructures were examined with optical microscope and scanning electron microscope (SEM, Philips XL30 ESEM-FEG/EDAX). The specimen was etched using a solution of 5% HNO3 in ethanol, and the grain size (L) was determined by a mean linear intercept method.

3 Results and discussion

3.1 Creep behaviors of GW103 alloy

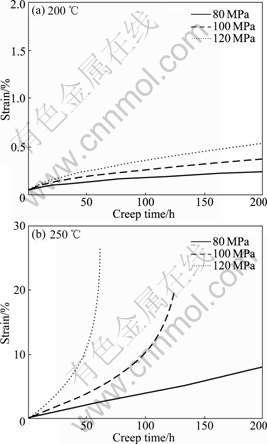

Fig.1 compares tensile creep curves of GW103-T5 alloys at 200 ℃ and 250 ℃ in the stress range of 80-120 MPa. Usually, the creep curve contains three stages: primary creep, steady-steady creep and tertiary creep. Crept at 200 ℃, as shown in Fig.1(a), the creep curve only includes primary creep and steady-steady creep up to 200 h. The primary creep is very short, followed by a prolonged steady-state creep. The specimens exhibit excellent creep resistance at 200 ℃, and the total creep strains are below 0.6% even crept for 200 h at a stress of 120 MPa. With increasing temperature to 250 ℃, as exhibited in Fig.1(b), the creep strains evidently increase. At relatively low stress of 80 MPa, the specimen shows a good creep resistance and the total strain is about 8% after tensile test for 200 h, which still locates in the

Fig.1 Creep curves of GW103-T5 alloys at 200 ℃ (a) and 250 ℃ (b) in stress range of 80-120 MPa

steady-state creep stage; furthermore, the creep resistance significantly decreases and ends with a short tertiary creep with increasing stress. The tertiary creeps are observed after 100 h and 50 h for the specimens crept at 100 MPa and 120 MPa, respectively, subsequently, the creep rupture occurs. Rupture strain is about 26% in Fig.1(b) when the creep stress is 120 MPa.

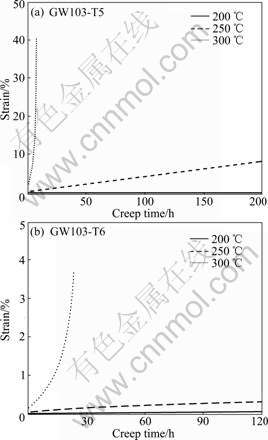

Fig.2 reveals the creep behaviors of GW103-T5 and T6 alloys at different temperatures under the same stress of 80 MPa. As shown in Figs.2(a) and (b), similarly, the creep rates of different stages and creep strains obviously increase for the T5 and T6 specimens with increasing temperature. Especially, at the highest test temperature of 300 ℃, the rupture strains are quickly reached, and the total strain times are about 7 h and 23 h for the T5 and T6 specimens, respectively (Figs.2(a) and (b)). In comparison, under the same creep condition, the T6 specimens exhibit better creep resistance than the T5 ones, which can be ascribed to the larger grain size of T6 ones. For example, for the GW103-T6 alloy, after creep test at 200 ℃ and 80 MPa, the creep strain of 100 h and steady-state creep rate are about 0.06% and 7.04×10-10 s-1, respectively, which is significantly better than the T5 specimen.

Table 1 lists the creep strains (ε) of 100 h or rupture

Fig.2 Creep curves of GW103-T5 (a) and T6 alloys at different temperatures under the same stress of 80 MPa

Table 1 Creep properties of GW103-T5 alloys

strains and steady-state creep rates ![]() of GW103-T5 alloys at 200, 250 and 300 ℃ with different stresses. For the specimens tested at high stress or high temperature, the steady-state creep stage is short or unconspicuous, thus, these steady-state creep rates are approximate in the present investigation. For the specimens crept at 200 ℃, the creep strain of 100 h and steady-state creep rate are very low, which gradually increase with increasing stresses. After crept at 200 ℃ and 80 MPa, the creep strain of 100 h and steady-state creep rate are about 0.18% and 1.71×10-9 s-1, respectively. At 250 ℃, the creep resistance obviously deceases, whose steady-state creep rate increases to the magnitude of 10-7 s-1; furthermore, the steady-state creep rate, obtained at the highest test temperature of 300 ℃ and 80 MPa, is approximately 5.89×10-6 s-1, which is three orders of magnitude higher than that at 200 ℃. This may be

of GW103-T5 alloys at 200, 250 and 300 ℃ with different stresses. For the specimens tested at high stress or high temperature, the steady-state creep stage is short or unconspicuous, thus, these steady-state creep rates are approximate in the present investigation. For the specimens crept at 200 ℃, the creep strain of 100 h and steady-state creep rate are very low, which gradually increase with increasing stresses. After crept at 200 ℃ and 80 MPa, the creep strain of 100 h and steady-state creep rate are about 0.18% and 1.71×10-9 s-1, respectively. At 250 ℃, the creep resistance obviously deceases, whose steady-state creep rate increases to the magnitude of 10-7 s-1; furthermore, the steady-state creep rate, obtained at the highest test temperature of 300 ℃ and 80 MPa, is approximately 5.89×10-6 s-1, which is three orders of magnitude higher than that at 200 ℃. This may be

associated with the accelerated precipitate coarsening at high temperatures[12-13]. It is noted that the creep resistance of GW103-T5 alloy evidently decreases at or above 250 ℃. In comparison, the steady-state creep rates of WE43-T6 alloys at 200 ℃, 120 MPa and 250 ℃, 80 MPa were reported to be 1.05×10-9 s-1 and 2.17×10-7 s-1, respectively[13], and the creep properties of present GW103-T5 alloy can rival the WE43-T6 one.

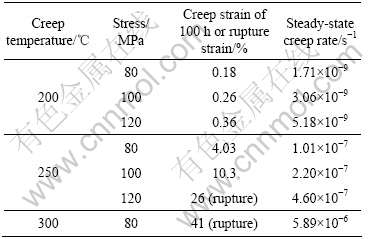

3.2 Microstructures of GW103 alloys before and after creep

Microstructures of the GW103-T5 alloy both before and after creep are shown in Fig.3, under the same tensile creep stress of 80 MPa. As shown in Fig.3(a), the microstructure of GW103-T5 alloy consists of equiaxed α-Mg matrix with a mean grain size of about 12 μm and many large secondary phase particles distribute along the extrusion direction. After being crept at 200 ℃ (Fig.3(b)), the microstructure of the GW103 occurs growing, whose grain size is about 17 μm, and no crack or cavity is found. Creeping at 250 ℃ (Fig.3(c)) leads to coarser grain sizes and some twin grains, suggesting that twining deformation assists the creep strain; in addition, there are some intergranular cavities and cracks perpendicular to the stress direction, where the cavities develop into cracks due to creep stress. With further increasing test temperature to 300 ℃ (Fig.3(d)), the cavities occur coarsening, interlinking and coalescence, correspondingly, the creep rupture time is about 7 h; in addition, the evidently extending grains appear along the tensile direction, which may be related to plastic deform and

Fig.3 Microstructures of GW103-T5 alloys before and after creep tests (creep stress of 80 MPa along horizontal creep direction): (a) T5; (b) 200 ℃; (c) 250 ℃; (d) 300 ℃

dislocation slip at high temperature. It is pointed out that the precipitate particles appeared coarsening at elevated temperature for Mg-RE alloys, especially under stress conditions, which softened an alloy and accelerated the creep rate[12-13]. WANG et al[13] observed the precipitate coarsening in WE43 alloy above 200 ℃, which caused evidently softening effect. Therefore, the creep resistance of GW103-T5 alloy is easy to decrease at or above 250 ℃.

3.3 Creep behavior analysis and discussion

The steady-stage strain rate ![]() was expressed by the conventional power-law equation[14-15]:

was expressed by the conventional power-law equation[14-15]:

![]() (1)

(1)

where A is the dimensionless constant; σ is the applied stress; R is the molar gas constant; T is the absolute temperature; n is the stress exponent and Q is the activation energy.

In Eq.(1), parameters n and Q are usually used to elucidate the probable dominant deformation mechanism in the alloy. From Eq.(1), one readily obtains

![]() (2)

(2)

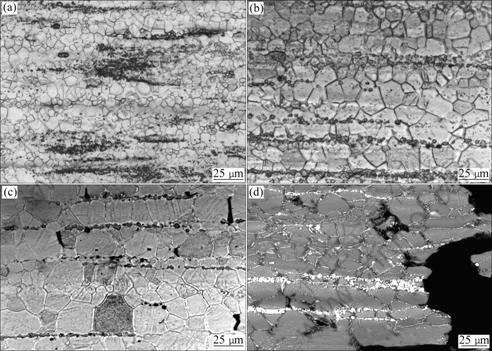

Thus, the n and Q can be obtained from the temperature dependence of the steady-state creep rate. To characterize the creep flow behavior, the relationships between the steady-state creep rate and applied stress (σ) are plotted at different temperatures, as shown in Fig.4. As expected, the creep rate and applied stress or temperature data fit well together. The stress exponent (n) values gradually increase from 2.7 to 3.8 with increasing temperature from 200 ℃ to 300 ℃ (Fig.4(a)). The activation energy for GW103-T5 alloy is calculated to be about 183 kJ/mol between 200 ℃ and 300 ℃ (Fig.4(b)), which is higher than that of the lattice self-diffusion of pure magnesium (135 kJ/mol). This suggests that the dislocation climb may play a dominant role in creep in the GW103-T5 alloy.

After summarizing the creep behaviors of Mg alloys, LUO[14] indicated that the creep was mainly controlled by the grain boundary slip when n<4, while the creep was mainly controlled by the dislocation climb mechanism when n>4. As for the present GW103-T5 alloy, the grain boundary slip operates during the creep strain due to low stress exponent (n<4). On the other hand, MORDIKE and STULIKOVA[16] found that the creep activation energies of Mg-Y-Nd alloys were in the range of 100-226 kJ/mol, and their creep mechanisms were ascribed to the dislocation climb. The activation energy usually shows an increasing trend with temperature. It is known that both stress exponent and

Fig.4 Relationships between steady-state creep rate and applied stress and temperatures for GW103-T5 alloys at various temperatures

creep activation energy change with variation of temperature and stress level for many Mg-RE alloys[13].

In the present investigation, according to the activation energy (183 kJ/mol) of GW103-T5 alloy, which is above the lattice diffusion activation energy of pure Mg (135 kJ/mol), the creep mechanism can also be attributed to dislocation climb controlling. As a result, the creep mechanism of GW103-T5 alloy can be ascribed to the combined effects of dislocation climb controlled by diffusion and grain boundary slip.

4 Conclusions

1) After being crept at 200 ℃ and 80 MPa, the creep strain of 100 h and steady-state creep rate are about 0.18% and 1.71×10-9 s-1 for GW103-T5 alloy.

2) The creep resistance of GW103-T5 alloy evidently decreases at or above 250 ℃. The stress exponent and activation energy are respectively 2.7-3.8 and 183 kJ/mol in the high-temperature regime (200-300 ℃). The creep mechanism of GW103-T5 alloy can be ascribed to the combined effects of dislocation climb controlled by diffusion and grain boundary slip.

3) The creep resistance of GW103-T6 alloy is superior to the T5 one. After creep test at 200 ℃ and 80 MPa for T6 specimen, the creep strain of 100 h and steady-state creep rate are 0.06% and 7.04×10-10 s-1, respectively.

References

[1] MORDIKE B L, EBERT T. Magnesium: Properties-applications- potential [J]. Materials Science and Engineering A, 2001, 302(1): 37-45.

[2] BLUM W, ZHANG P, WATZINGER B, GROSSMANN B V, HALDENWANGER H G. Comparative study of creep of the die-cast Mg-alloys AZ91, AS21, AS41, AM60 and AE42 [J]. Materials Science and Engineering A, 2001, 319/321: 735-740.

[3] SRINIVASAN A, SWAMINATHAN J, PILLAI U T S, GUGULOTH K, PAI B C. Effect of combined addition of Si and Sb on the microstructure and creep properties of AZ91 magnesium alloy [J]. Materials Science and Engineering A, 2008, 485(1/2): 86-91.

[4] EVANGELISTA E, SPIGARELLI S, CABIBBO M, SCALABRONI C, LOHNE O, ULSETH P. Analysis of the effect of Si content on the creep response of an Mg-5Al-Mn alloy [J]. Materials Science and Engineering A, 2005, 410/411: 62-66.

[5] MORDIKE B L,

[6] HENNING W, MORDIKE B L. Magnesium and applications [C]// Strength of Metals and Alloys. Oxford, UK: Pergamon, 1985: 803-808.

[7] SUZUKI M, SATO H, MARUYAMA K, OIKAWA H. Creep behavior and deformation microstructures of Mg-Y alloys at 550 K [J]. Materials Science and Engineering A, 1998, 252(2): 248-255.

[8] HUANG Y, HORT N, DIERINGA H, KAINER K U. Micro-strain induced by thermal cycling in short fiber reinforced AlSi12CuMgNi piston alloy and AE42 magnesium alloy [J]. Advanced Engineering Materials, 2004, 6(11): 883-888.

[9] PEKGUELERYUEZ M O, AVEDESIAN M M. Magnesium alloys and their applications [M]. Oberursel: DGM-Informationsges, 1992: 213-220.

[10] HONMA T, OHKUBO T, HONO H, KAMADO S. Chemistry of nanoscale precipitates in Mg-2.1Gd-0.6Y-0.2Zr (at.%) alloy investigated by the atom probe technique [J]. Materials Science and Engineering A, 2005, 395(1/2): 301-306.

[11] NIE J F, GAO X, ZHU S M. Enhanced age hardening response and creep resistance of Mg-Gd alloys containing Zn [J]. Scripta Materialia, 2005, 53(9): 1049-1053.

[12] MOHRI T, MABUCHI M, SAITO N, NAKAMURA M. Microstructure and mechanical properties of a Mg-4Y-3RE alloy processed by thermo-mechanical treatment [J]. Materials Science and Engineering A, 1998, 257(2): 287-294.

[13] WANG J G, HSIUNG L M, NIEH T G, MABUCHI M. Creep of a heat treated Mg-4Y-3RE alloy [J]. Materials Science and Engineering A, 2001, 315(1/2): 81-88.

[14] LUO A A. Recent magnesium alloy development for elevated temperature applications [J]. International Materials Reviews, 2004, 49(1): 13-30.

[15] VAGARALI S S, LANGDON T G. Deformation mechanisms in h.c.p. metals at elevated temperatures (I): Creep behavior of magnesium [J]. Acta Metallurgica, 1981, 29(12): 1969-1982.

[16] MORDIKE B L, STULIKOVA I. Magnesium properties application potential [C]// Proceedings of the International Conference on Metallic Light Alloys. London: Institution of Metallurgists, 1983: 146-153.

Foundation item: Project(2007CB613704) supported by the National Basic Research Program of China; Project(50874100) supported by the National Natural Science Foundation of China

Corresponding author: HAN En-hou; Tel: +86-24-23926646; Fax: +86-24-23894149; E-mail: ehhan@imr.ac.cn