文章编号:1004-0609(2013)S1-s0467-05

热处理对医用Ti-15Nb-5Zr-6Mo合金组织与力学性能的影响

田宇兴,于振涛,李 程,车永平,唐 蛟,刘少辉

(西北有色金属研究院,西安 710016)

摘 要:

研究固溶和时效热处理对近β型医用Ti-15Nb-5Zr-6Mo合金的组织与力学性能的影响。结果表明:固溶温度的升高使得β晶粒尺寸增大,但是对性能的影响不大,合金表现出较高的强度及良好的塑性。然而较高的屈强比以及塑性硬化阶段的缺失,使其应用受到局限。时效处理引入的α相强化使得合金强度提高到1 000 MPa以上,塑性提高到15%~20%;同时,塑性阶段出现应力平台,表现为稳态塑性变形。因此,通过合理的热处理工艺可以在保证合金高强度的同时提高塑性。

关键词:

Ti-15Nb-5Zr-6Mo合金;固溶处理;时效处理;相转变;力学性能;

中图分类号:TG146.2 文献标志码:A

Effect of heat treatment on microstructure and mechanical properties of Ti-15Nb-5Zr-6Mo alloy for biomedical application

TIAN Yu-xing, YU Zhen-tao, LI Cheng, CHE Yong-ping, TANG Jiao, LIU Shao-hui

(Northwest Institute for Nonferrous Metal Research, Xi’ an 710016, China)

Abstract: The effects of solution treatment and aging on microstructure and mechanical properties of near β Ti-15Nb-5Zr-6Mo alloy developed for biomedical application were investigated. The results show that the increase in solution temperature results in an increased β grain size, while shows no obvious influence on the mechanical properties. The solution-treated alloy exhibits high strength and good ductility. However, the properties matching is limited in actual application due to its high ratio of yield to ultimate strength and the lack of hardening stage during plastic deformation. The precipitation of α phase during aging treatment leads to a great strength of above 1 000 MPa and good ductility with elongation of 15%-20%. Additionally, a stress flat is observed, exhibiting stable plastic deformation. Therefore, the strength and ductility of Ti-15Nb-5Zr-6Mo alloy can be improved simultaneously by a reasonable heat treatment.

Key words: Ti-15Nb-5Zr-6Mo alloy; solution treatment; aging treatment; phase transformation; mechanical properties

钛合金具有良好的生物相容性、抗腐蚀能力和高强度,已经用于人体硬骨组织修复治疗。然而常规医用Ti-6Al-4V合金相对于人体皮质骨较高的弹性模量(110~114 GPa[1])导致的“应力屏蔽”效应和植入体端部的应力集中,使得愈合过程中产生骨萎缩或骨吸收。为了实现骨组织与植入体之间更优的弹性匹配,兼具高强度和低弹性模量的新型β钛合金成为材料学的重要研究方向。尽管基于价电子浓度、d电子参数、第一原理计算等多种设计方法开发出了多种低模量β钛合金,并且已将弹性模量降低至接近人体皮质骨[2-6],但是此类合金在使用时均需要通过时效处理以达到强度要求,与此同时,弹性模量也增大至相对较高范围60~80 GPa[7];更加值得关注的是这种时效强化导致了合金塑性的大幅下降,这影响着材料在人体重复加载中的疲劳寿命、冲击载荷下材料的断裂韧性以及材料的可加工性能。因此,在保证低模量高强度的条件下,提高此类合金的塑性是性能优化的一种新思路。

Ti-15Nb-5Zr-6Mo合金是基于Mo当量及d电子参数设计的一种新型医用近β型钛合金,由于其良好的生物相容性、高强度、优异的塑性及较低的弹性模量而有望应用于硬骨组织替代及介入微创治疗。本文作者通过对Ti-15Nb-5Zr-6Mo合金进行固溶及时效处理,在保证合金高强度的条件下提高塑性,研究相转变对合金的强韧化机理。

1 实验

利用海绵钛、Ti-Nb中间合金、纯Zr、纯Sn和纯Mo,通过真空电弧炉熔炼获得直径为100 mm的Ti-15Nb-5Zr-6Mo(质量分数,%)合金铸锭,其化学成分为:15.2%Nb,5.0%Zr,3.1%Mo,0.10%O,余量为Ti。通过金相法测得合金的β相转变温度为670~ 680 ℃。合金铸锭经过850 ℃锻造、热轧,最终获得直径为12 mm的棒材。从热轧棒材上切取试样进行热处理,固溶处理为在680、750、820 ℃保温1 h,空冷;时效处理为在510 ℃保温6 h,空冷。将热处理后的短棒加工成标距尺寸为d5 mm×25 mm的拉伸试样,在INSTRON5985试验机上进行室温拉伸,应变速率为6.5×10-4 s-1;合金弹性模量由应变仪记录的应力—应变曲线获得。采用8%的氢氟酸溶液蚀刻试样,在MeF2型光学显微镜下观察其显微组织。利用JSM6460型扫描电镜观察其拉伸断口。

2 结果与讨论

2.1 合金的组织转变

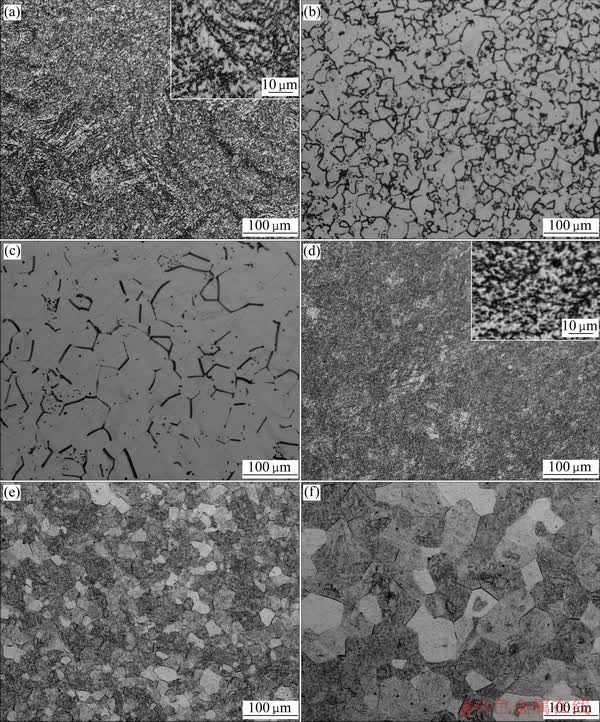

经固溶和时效处理后Ti-15Nb-5Zr-6Mo合金的显微组织如图1所示。尽管在局部区域存在尚未等轴化的不规则变形晶粒,较低温度(680 ℃)的固溶组织表现为非常细小的β晶粒,晶粒尺寸约为10 μm,如图1(a)所示。所有固溶处理后的合金组织中未能观察到α″等亚稳相,由于从β转变点以上空冷,β稳定元素Nb和Mo已经将高温BCC结构稳定至室温(见图1(a)~(c))。前期研究表明[8],透射电镜观察发现极少量的α″相存在于β相稳定性更高的Ti-25Nb-3Mo-3Zr-2Sn合金的水冷试样中,而在空冷试样中则没有观察到亚稳相。因此,在Ti-15Nb-5Zr-6Mo合金的空冷试样中可能也存在亚稳相。随着固溶温度的升高,等轴β相晶粒尺寸明显增加(图1(b)和(c)),这与高层错能β钛合金组织的静态回复有关[9]。

对固溶态组织进行时效处理后,等轴β晶粒内析出α相(图1(d)~(f))。细小的β相组织和更多的晶界数量为α相析出提供更多的形核点,高倍组织中可见更加弥散的α相形成(图1(d))。在晶粒尺寸较大的β组织中,可以清晰地观察到以取向选择生长的针状α相[10](图1(f))。这些多样的组织状态将影响合金强度、模量及塑性的不同匹配。

图1 经固溶和时效处理后Ti-15Nb-5Zr-6Mo合金的显微组织

Fig. 1 Optical microstructures of Ti-15Nb-5Zr-6Mo alloy subjected to solution treatment at 680 ℃ (a), 750 ℃ (b), 820 ℃ (c), and subsequent aging at 510 ℃ (d)~(f)

2.3 合金的拉伸性能及弹性模量

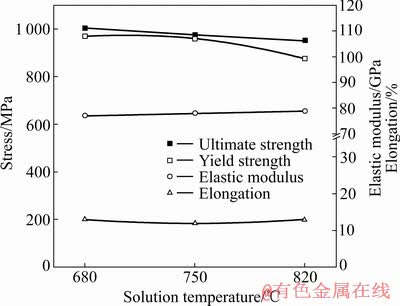

Ti-15Mb-5Zr-6Mo合金的固溶温度和力学性能的关系如图2所示。合金强度随着固溶温度的降低而增大;合金在680 ℃固溶后强度达到1 000 MPa。另外,固溶态合金的屈服强度接近抗拉强度,这种高屈强比有望通过后续时效处理得到改善。由于弹性模量对晶粒尺寸不敏感[11-12],尽管固溶温度的升高导致β晶粒尺寸增大,但合金弹性模量保持在78~80 GPa。固溶处理后,合金在高强度条件下仍然具有较好的塑性,伸长率达到12%~15%。

图2 固溶温度与强度、伸长率及弹性模量的关系

Fig. 2 Relationships of strength, elongation and elastic modulus related to solution temperature

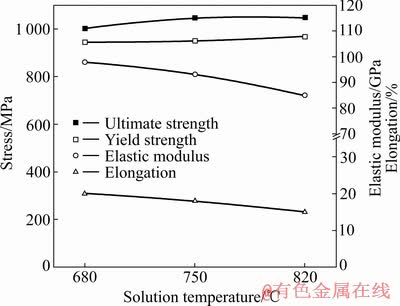

固态合金经过510 ℃时效处理后,合金的抗拉强度均得到提高,屈服强度基本保持不变,合金屈强比减小。值得注意的是图3中强度随固溶温度的提高而提高,与图2中的强度趋势相反,这很可能是由于α相形貌、含量及取向对合金性能造成的综合影响。经过时效处理后,合金的弹性模量明显升高,于较低温度固溶处理后的细晶组织在时效后模量达到97 GPa,较高温度固溶处理后得到的粗晶组织在时效后模量升高至85 GPa;弹性模量联系着析出α相的含量及晶体学特征[10]。时效处理使得合金塑性提高至15%~ 20%,尤其是在680 ℃固溶处理后的细晶组织,在强度提高的同时,伸长率由12%提高到20%。这是由固溶处理获得的细晶β组织以及时效析出的细小α相的共同作用。

图3 时效处理与强度、伸长率及弹性模量的关系

Fig. 3 Relationships of strength, elongation and elastic modulus related to aging treatment

2.3 合金的拉伸变形行为及断口特征

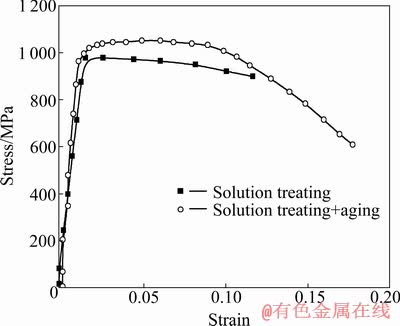

图4所示为Ti-15Nb-5Zr-6Mo合金在750 ℃固溶处理及随后在510 ℃时效后的合金拉伸曲线。可以看出,固溶态合金在弹性变形阶段之后很快达到最大强度,这对应着合金高屈强比特征;尽管固溶态合金的伸长率可达到12%~15%,但是合金在塑性变形中没有塑性硬化阶段,应力随着位移的增大而快速降低,这种变形行为很可能与强化机制缺失导致的合金快速失稳有关[13]。

时效处理后,尽管没有出现塑性强化阶段,合金在屈服后达到应力平台,这是由于时效析出的α相与位错滑移的相互作用[14-15],同时,伸长率提高至15%~ 20%。因此,通过时效处理,可以在保证高强度的同时提高合金塑性,并获得良好的力学性能匹配。

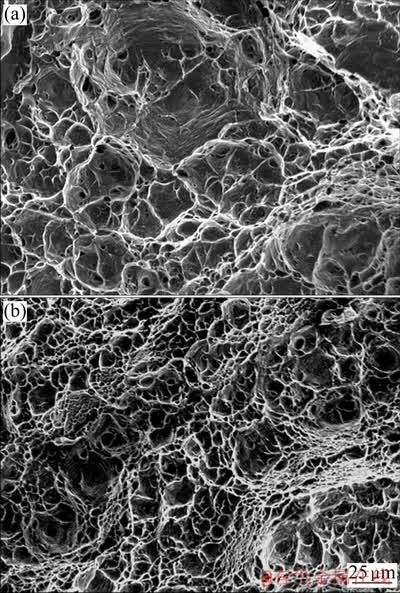

固溶态和时效态合金的拉伸断口形貌均表现为韧性断口特征(图5)。然而,时效态合金表现出比固溶态更加均匀的小尺寸韧窝。尽管仅通过断口分析很难判断合金塑性性能,但是这种宏观观察可以为合金的断裂模式提供证据。

图4 750 ℃固溶处理及随后510 ℃时效后的Ti-15Nb-5Zr- 6Mo合金拉伸曲线

Fig. 4 Tensile curves of Ti-15Nb-5Zr-6Mo alloy subjected to solution treatment at 750 ℃ and subsequent aging at 510 ℃

图5 Ti-15Nb-5Zr-6Mo合金在750 ℃固溶(a)及510 ℃时效后(b)的拉伸断口形貌

Fig. 5 Fracture morphology of Ti-15Nb-5Zr-6Mo alloy subjected to solution treatment at 750 ℃ (a) and subsequent aging at 510 ℃ (b)

3 结论

1) 通过固溶和时效热处理对近β型Ti-15Nb-5Zr- 6Mo合金的强度及塑性进行调整,在保证高强度的条件下以相转变提高合金塑性,获得力学性能的良好匹配。

2) 固溶温度的升高使得β晶粒尺寸增大,但是对性能的影响不大,合金表现出较高的强度及良好的塑性;具有较高的屈强比且在塑性变形中缺失硬化阶段。

3) 时效处理引入的α相强化使得合金强度增加至1 000 MPa以上,同时塑性提高至15%~20%;同时,塑性阶段出现应力平台,表现为稳态塑性变形。

4) 合理的热处理使得合金在保证高强度的同时提高了塑性,获得良好的力学性能匹配。

REFERENCES

[1] NIIOMI M. Mechanical properties of biomedical titanium alloys [J]. Materials Science and Engineering A, 1998, 243: 231-236.

[2] SAITO T, FURUTA T, HWANG J H, KURAMOTO S, NISHINO K, SUZUKI N, CHEN R, YAMADA A, ITO K, SENO Y, NONAKA T, IKEHATA H, NAGASAKO N, IWAMOTO C, IKUHARA Y, SAKUMA T. Multifunctional alloys obtained via a dislocation-free plastic deformation mechanism [J]. Science, 2003, 300(5618): 464-467.

[3] KURODA D, NIINOMI M, MORINAGA M, KATO Y, YASHIRO T. Design and mechanical properties of new β type titanium alloys for implant materials [J]. Materials Science and Engineering A, 1998; 243: 244-249.

[4] HAO Y L, NIIOMI M, KURODA D, FUKUNAGA K, ZHOU Y L, YANG R, SUZUKI A. Aging response of the young’s modulus and mechanical properties of Ti-29Nb-13Ta-4.6Zr for biomedical applications [J]. Metallurgical and Materials Transaction A, 2003, 34: 1007-1012.

[5] BANERJEE R, NAG S, FRASER H L. A novel combinatorial approach to the development of beta titanium alloys for orthopedic implants [J]. Materials Science and Engineering C, 2005, 25(3): 282-289.

[6] HAO Y L, LI S J, SUN C Y, ZHENG C Y, YANG R. Elastic deformation behaviour of Ti-24Nb-4Zr-7.9Sn for biomedical applications [J]. Acta Biomaterialia, 2007, 3: 277-286.

[7] NIINOMI M, NAKAI M, HIEDA J. Development of new metallic alloys for biomedical applications [J]. Acta Biomaterialia, 2012, 8: 3888-3903.

[8] 麻西群, 憨 勇, 于振涛, 孙巧艳, 牛金龙, 袁思波. 骨科植入用TLM 钛合金的相转变与力学性能[J]. 稀有金属材料与工程, 2012, 41(9): 1535-1538.

MA Xi-qun, HAN Yong, YU Zhen-tao, SUN Qiao-yan, NIU Jin-long, YUAN Si-bo. Phase transformation and mechanical properties of TLM titanium alloy for orthopaedic implant application [J]. Rare Meta Materials and Engineering, 2012, 41(9): 1535-1538.

[9] 田宇兴, 李述军, 郝玉琳, 杨 锐. Ti2448合金高温变形行为及组织演变机制的转变[J]. 金属学报, 2012, 48(7): 837-844.

TIAN Yu-xing, LI Shu-jun, HAO Yu-lin, YANG Rui. High temperature deformation behavior and microstructure evolution mechanism transformation in Ti2448 alloy [J]. Acta Metallurgical Scinica, 2012, 48(7): 837-844.

[10] BOHEMEN S M C V, KAMP A, PETROV R H, KESTENS L A I, SIETSMA J. Nucleation and variation selection of secondary α plates in a β Ti alloy [J]. Acta Materialia, 2008, 56: 5907-5917.

[11] HAO Y L, NIINOMI M, KURODA D, FUKUNACA K, ZHOU Y L, YANG R, SUZUKI A. Young’s modulus and mechanical properties of Ti-29Nb-13Ta-4.6Zr in relation to α″ martensite [J]. Metallurgical and Materials Transaction A, 2002, 33: 3137-3144.

[12] KIM H S, RA T Y, YEO I D, BANG H J, YOO Y G, KIM W Y. Microstructure, elastic modulus and tensile properties of Ti-Nb-O alloy system [J]. Journal of Materials Science and Technology, 2008, 24(1): 33-36.

[13] HAO Y L, LI S J, SUN S Y, ZHENG C Y, HU Q M, YANG R. Super-elastic titanium alloy with unstable plastic deformation [J]. Applied Physics Letter, 2005, 87: 091906.

[14] MINA X H, EMURA S, NISHIMURA T, ZHANG L, TAMILSELVI S, TSUCHIYA K. TSUZAKI K. Effects of α phase precipitation on crevice corrosion and tensile strength in Ti-15Mo alloy [J]. Materials Science and Engineering A, 2010, 527: 1480-1488.

[15] LI P, HAO J Y, ZHAO J, DUAN H T. The influence of ageing treatment on the microstructure and the elastic modulus of Ti27Nb8Zr alloy [J]. Materials Science and Engineering A, 2010, 527: 7469-7474.

(编辑 方京华)

基金项目:国家“十二五”科技支撑计划资助项目(2012BAI18B02);国家自然科学基金资助项目(31100693/C100302);国家重点基础研究发展计划(2012CB619102);国家高技术研究发展计划资助项目(2011AA0301- 01);陕西省工业攻关资助项目(2012K07-03)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:田宇兴,助理研究员;电话:029-86222297; E-mail: yxtiannin@163.com

摘 要:研究固溶和时效热处理对近β型医用Ti-15Nb-5Zr-6Mo合金的组织与力学性能的影响。结果表明:固溶温度的升高使得β晶粒尺寸增大,但是对性能的影响不大,合金表现出较高的强度及良好的塑性。然而较高的屈强比以及塑性硬化阶段的缺失,使其应用受到局限。时效处理引入的α相强化使得合金强度提高到1 000 MPa以上,塑性提高到15%~20%;同时,塑性阶段出现应力平台,表现为稳态塑性变形。因此,通过合理的热处理工艺可以在保证合金高强度的同时提高塑性。