Trans. Nonferrous Met. Soc. China 26(2016) 1620-1628

Combined effect of isothermal annealing and pre-compression on mechanical properties of Cu36Zr48Al8Ag8 bulk metallic glass

Ji GU1, Li-xin ZHANG1, Yi-han WANG1, Song NI1, Sheng-feng GUO2, Min SONG1

1. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. Faculty of Materials and Energy, Southwest University, Chongqing 400715, China

Received 1 July 2015; accepted 24 February 2016

Abstract:

The combined effects of isothermal annealing and pre-compression on the mechanical properties of Cu36Zr48Al8Ag8 bulk metallic glass (BMG) were investigated. The as-cast specimens were first annealed at 743 K for 10 min, and then pre-compressed under 800 MPa for 1, 3, 5 and 10 h, respectively. The results indicated that annealing resulted in the formation of nanocrystals with a diameter of ~10 nm in the amorphous matrix and a drastic decrease of the free volume, leading to complete loss of the plasticity of the BMG. Applying pre-compression under a stress of 800 MPa for a proper duration (5 h) resumed part of the lost free volume in the BMG matrix and therefore partially recovered the plasticity. A very long period of pre-compression (10 h) decreased the free volume again, which was caused by the excessive crystal growth.

Key words:

bulk metallic glasses; annealing; pre-compression; free volume; nanocrystal;

1 Introduction

Bulk metallic glasses (BMGs) have emerged as a new class of materials with many superior properties, including high hardness and strength, large elastic limit, and excellent corrosion and wear resistances [1-4]. However, most BMGs show negligible plasticity at room temperature, which severely restricts their structural applications. It has been well accepted that the poor plasticity is attributed to the shear localization and strain/thermal softening during deformation [3].

Previous studies [5-7] showed that the dispersion of nanocrystals in BMGs may enhance the mechanical properties, and the most effective method to introduce nanocrystals in the amorphous matrix is thermal annealing. Investigations on the effects of annealing duration and temperature on the mechanical properties and microstructural evolution of BMGs revealed that annealing usually leads to the embrittlement of BMGs due to the structural relaxation and free volume annihilation [8-17], short-range ordering and crystallization [18-22].

The effects of deformation on the structural evolution and mechanical properties of BMGs have also attracted extensive attention. The developed pre- deformation processes include quasi-constrained high pressure torsion [23], cold rolling [24,25], equal channel angular pressing [26], shot peening [27], high pressure treatment [28], lateral pre-compression treatment [29], and elastostatic compression [30-32]. It has been shown that pre-deformation treatment introduces residual stress, pre-existed shear bands and excess free volume, which lead to enhanced plasticity [23,24,27,28,33-41]. TONG et al [34] reported that significant plasticity can be recovered if a ZrCuAlNi BMG is subjected to stress during annealing, resulting in thermo-mechanical creep. CONCUSTELL et al [36] indicated that anisotropy due to anelastic strain can be erased by zero stress annealing. After annealing, the strain softening due to plastic deformation can be reversed [39], and pre-deformed samples exhibit an enhanced plasticity compared with the virgin material [40]. It should be noted that most of the previous investigations [35-41] focused on the annealing effect on the deformed samples.

Our previous study showed that the size and volume fraction of the nanocrystals in BMGs can be controlled through the variations of annealing temperature and duration [18], and that pre-compression below the yield stress introduces excess free volume and nanocrystals.

The high free volume combined with proper sized nanocrystals can effectively improve the plasticity of BMGs [42]. However, it is difficult to control the size and volume fraction of the nanocrystals via pre- compression below the yield stress. It would be a good idea to combine the thermal annealing and pre- compression processes to improve the mechanical performance of BMGs. In this work, we used a Cu36Zr48Al8Ag8 BMG to explore the combined effects of thermal annealing and pre-deformation below the yield stress on the mechanical properties and microstructural evolution.

2 Experimental

A Cu36Zr48Al8Ag8 (mole fraction, %) BMG master ingot was prepared by arc melting high-purity copper, zirconium, aluminium and silver (99.7%-99.99%) in a Ti-gettered high-purity argon atmosphere using the method described in Ref. [18]. To ensure the compositional homogeneity, the ingot was re-melted four times and stirred by a magnetic beater. Cylindrical rods with a diameter of 3 mm and a length of 70 mm were obtained by water-cooled copper mould sucking casting. The rods were cut into short rods with the length slightly longer than 4.5 mm using a low-speed diamond saw. The two ends of each short rod were carefully polished to acquire rod geometry with a length to diameter ratio of 1.5:1. The as-cast rods were sealed in vacuum quartz tubes and annealed in a preheated furnace at 743 K (56 K higher than glass transition temperature Tg) for 10 min. The quartz tubes were taken out from the furnace and cooled in air down to the room temperature. The yield strength of the as-annealed sample was (1183±102) MPa. Our previous study [42] showed that applying a pre-compressed stress of 800 MPa for proper duration can create excess free volume and effectively improve the plasticity of the BMG. Thus, the as-annealed rods were pre-compressed under a stress of 800 MPa for 1, 3, 5 and 10 h at room temperature using an Instron 3369 testing machine. The as-cast, as-annealed and pre-compressed specimens are named as S0, SA, SA1, SA3, SA5, and SA10, respectively (see Table 1 for detailed information). Cemented carbide with the hardness and strength higher than those of the BMG was used to make anvils that prevent the deformation of the anvils during the deformation processes.

Samples for Vickers hardness testing were polished to acquire a mirror-like surface using diamond lapping films (1 μm). At least five points on each rod were selected for Vickers hardness testing, which was carried out at a load of 5 kg and a dwell time of 30 s for each point. Compressive mechanical testing was conducted under a strain rate of 1×10-5 s-1 using an Instron 3369 testing machine, five samples were tested for each processing condition. An FEI Quanta FEG 250 scanning electron microscope (SEM) was used to characterize the indented areas and fracture surfaces of specimens. Transmission electron microscopy (TEM) characterization was carried out on the as-cast, as-annealed and pre-compressed specimens using a JEOL 2100F TEM. A NETASCH STA 409 differential scanning calorimeter (DSC) was used for thermal analysis under pure argon atmosphere from room temperature to ~1100 K with a heating rate of 20 K/min.

Table 1 Identification of specimens subjected to different treatments

3 Results

3.1 Hardness and shear banding

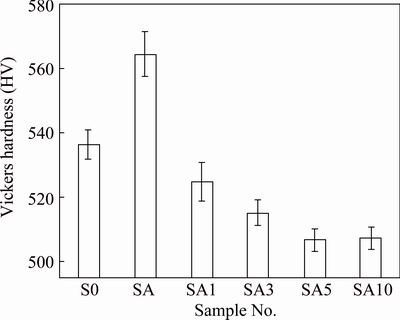

Figure 1 shows the Vickers hardness of the tested specimens. The hardness of the as-cast material was HV (537±5). After annealing at 743 K for 10 min, the Vickers hardness increased to HV (565±7). Applying pre-compression under a stress of 800 MPa led to continuous decrease of the Vickers hardness. The hardness decreased to HV (525±6), (515±4), (506±4) and (507±4) when the pre-compression durations were 1, 3, 5 and 10 h, respectively. TURNBULL and COHEN [43] indicated that large free volume exists in amorphous alloys with quenching from the liquid state. The annealing process results in the annihilation of free volume and nucleation of the nanocrystals in the amorphous matrix, leading to higher hardness [19,44]. Previous investigations [30,45] also indicated that deformation under a stress lower than the yield stress is a homogeneous deformation that produces excess free volume caused by shear-induced atomic dilatation or atomic disordering, which might substantially decrease the hardness. Thus, the hardness evolution in Fig. 1 is likely due to the irreversible structural changes during the annealing and pre-compression, and this point will be discussed later.

Fig. 1 Vickers hardness of as-cast, as-annealed and pre-compressed samples

Strain-induced hardening is normally observed in crystalline metals and alloys, while in BMGs the strain- induced softening is more common [39,46], although the opposite phenomenon was also reported [47,48]. Both phenomena have been observed in BMGs recently [23,42]. To further understand the deformation induced by indentation, SEM analysis was conducted around the indented areas. Figure 2 shows that all indents were of a regular pyramidal shape. Many shear bands were observed in the as-cast sample (Fig. 2(a)). However, only one or two shear bands are observed in the annealed sample (sample SA), indicating the severe shear localization (Fig. 2(b)). Sample SA1 (pre-compression for 1 h, Fig. 2(c)) exhibits similar shear localization to sample SA. With further increasing the pre-compression duration, more shallow shear bands can be observed in sample SA3 (Fig. 2(d)), indicating that the pre- compression processing increases the shear band nucleation and reduces shear localization. No obvious shear bands are observed in samples SA5 and SA10 (Figs. 2(e) and (f)), indicating that the samples show a more uniform deformation, with the reduction of shear localization after pre-compression for long time.

Fig. 2 SEM images of indented areas of as-cast sample (a), annealed sample (b), and pre-compressed samples under 800 MPa for 1 h (c), 3 h (d), 5 h (e) and 10 h (f)

3.2 Compression test

Figure 3 shows the compression stress–strain curves of the as-cast, as-annealed and pre-compressed samples, respectively. The compressive ductility of the as-cast material was ~2.8%, with the strength of (1958±37) MPa. After annealing at 743 K for 10 min, the material completely lost the ductility and had a decreased strength of (1183±102) MPa. Appling pre-compression under a stress of 800 MPa for 1 and 3 h on the annealed samples led to the increase of the strength to (1670±56) MPa and (1846±24) MPa, respectively. But the material still exhibited complete brittleness. Appling pre-compression under a stress of 800 MPa for 5 h on the annealed samples resulted in the recovered ductility to ~1.0% with an increased strength of (1882±36) MPa. Further increasing the pre-compression duration to 10 h led to the loss of the ductility again, accompanied by the decreased strength of (1752±40) MPa. This might be due to the decreased free volume and will be discussed later. It is clear that the annealing treatment led to dramatic embrittlement of the BMG, while applying the pre-compression with proper duration (5 h in this work) on the annealed samples partially recovered the ductility of the BMG.

Fig. 3 Stress–strain curves of as-cast, as-annealed and pre-compressed samples

Fig. 4 SEM images of fracture surfaces for as-cast sample (a), as-annealed sample (b), and samples pre-compressed for 5 h (c) and 10 h (d)

To further understand the deformation behaviors related to the annealing and pre-compression, SEM observations were conducted on the fracture surface of all the samples. Figure 4 shows the fracture morphologies of the failed samples. The as-cast sample exhibits a typical vein-like pattern on the fracture surfaces, as shown in Fig. 4(a). The vein pattern was typical for compression fracture of BMGs [49] and the fracture of the as-cast sample took place mainly along a single shear plane. On the contrary, the annealed sample was fractured into multiple fragments with various shapes and cracks, which were observed in the irregular fracture surface, as shown in Fig. 4(b). Figure 4(c) shows the fracture surface recorded from sample SA5. Two different types of zones were observed: 1) areas with a typical vein-like pattern and 2) quasi-smooth regions. The formation of the vein-like pattern is attributed to the decreased viscosity of the BMG during deformation, and the quasi-smooth regions include the propagation of some large main shear bands. A river-like pattern, which is a typical brittle fracture morphology, is apparent in sample SA10, as shown in Fig. 4(d).

3.3 Free volume

It has been reported that free volume significantly affects the plasticity of BMGs [23,42], annealing treatment leads to free volume annihilation [14,18], and the application of a stress below the yield stress can lead to irreversible structural change that creates excess free volume in BMGs [30,45]. The change in the free volume can be reflected by enthalpy change (ΔH) in BMGs [50]. Hence, DSC analysis was conducted to evaluate the effect of annealing and pre-compression on the free volume through measuring the variation of the ΔH [14]. Figure 5 compares the DSC traces of the as-cast sample (S0), as-annealed sample (SA), and two pre-compressed samples (SA5 and SA10). It is clearly seen that all the specimens have the same glass transition temperature (Tg) of ~687 K, and the same first and second crystallization onset temperatures (Tx1 and Tx2) of ~754 K and ~877 K, respectively. Compared with that of the as-cast sample, the endothermic enthalpy (ΔH) decreases drastically for the as-annealed sample, indicating that the free volume decreases dramatically after being annealed at 743 K for 10 min. Applying pre-compression stress to the annealed samples led to the increase of endothermic enthalpy (ΔH) for sample SA5 and the decrease for sample SA10. The free volume of sample SA5 is still lower than that of the as-cast sample (S0). The variation of ΔH implies that the free volume increased via pre-compression under 800 MPa for 5 h, while it decreased via pre-compression under 800 MPa for 10 h. It is commonly accepted that the annealing treatment led to the free volume annihilation in BMGs [14,18]. PARK et al [30] indicated that even under a stress below the yield stress, the excess free volume creates, and the amount of free volume reaches saturation with increasing loading time. While in our previous study [42], it was found that the free volume decreases with further increasing the pre-compression pressure and duration after reaching the maximum value. The reduction of the free volume is due to the increased structural heterogeneity, and nucleation and growth of the nanocrystals.

Fig. 5 DSC traces corresponding to as-cast sample, sample annealed at 743 K for 10 min and samples pre-compressed under 800 MPa for 5 and 10 h

3.4 TEM observation

Figure 6 shows typical TEM and high-resolution TEM (HRTEM) images and the corresponding selected area electron diffraction (SAED) or fast Fourier transformation (FFT) patterns of the as-cast sample (Fig. 6(a)), the as-annealed sample (Figs. 6(b) and (c)), and pre-compressed samples SA1 (Fig. 6(d)), SA5 (Fig. 6(e)) and SA10 (Fig. 6(f)). The as-cast sample presents a typical uniform amorphous structure, as shown in Fig. 6(a). Nanocrystals with a diameter of ~10 nm were clearly observed in Figs. 6(b) and (c) for the as-annealed sample. Pre-compression after annealing treatment led to further growth of the nanocrystals in the amorphous matrix. Nanocrystals with diameters of ~15, 30-100 and ~500 nm were observed in samples SA1, SA5 and SA10, respectively. All these results demonstrate that the annealing processing led to the structural relaxation and crystallization. Appling the pre-compression stress to the annealed samples led to further growth of the nanocrystals.

4 Discussion

It has been shown that both isothermal (below and/or above Tg) and isochronal annealing has significant effects on the microstructural evolution and mechanical properties of BMGs [9-11,22,51]. Annealing at temperature above Tg leads to dramatic embrittlement of BMGs, because of the over-sized crystalline particles and the drastic annihilation of the free volume [9,10,22]. Although a few studies [22,40,51] reported that the sub-Tg annealing can lead to the increase of both the strength and ductility due to the precipitated nanocrystals, it is more common that sub-Tg annealing also leads to the embrittlement of BMGs due to structural relaxation and decreased free volume. In this work, nanocrystals with a dimension of ~10 nm embedded in the amorphous matrix were obtained via annealing at 743 K for 10 min. The annealing processing leads to the drastic embrittlement of the BMG with the complete loss of the ductility. The significant brittleness results in the decreased strength since the samples are broken into several pieces even under a rather low applied stress. Appling the pre-compression on the annealed samples can partially relieve the annealing induced embrittlement of the BMG (sample SA5 exhibits partial recovery of strength and ductility). However, it should be noted that a very long pre-compression duration (10 h in this work) also results in a complete loss of the ductility which may be due to the over growth of the nanocrystals and the decrease of the free volume.

Fig. 6 TEM images and corresponding SAED/FFT patterns of as-cast sample (a), annealed sample (b, c) and samples pre-compressed under 800 MPa for 1 h (d), 5 h (e) and 10 h (f)

Atomic packing density, which is inversely proportional to the free volume of BMGs [30,52], is a dominant factor that affects the mechanical properties of BMGs. Annealing induced annihilation of the free volume or the increase of the atomic packing density led to the increased hardness of sample SA. In addition, the annealing-induced embrittlement led to the catastrophic failure at the very early deformation stage, and caused the decreased strength of sample SA. The pre-compression processing creates excessive free volume in the BMG, resulting in the decreased hardness of samples SA1, SA3, SA5 and SA10. Further increasing the duration, sample SA10 exhibits almost the same hardness with sample SA5, while the free volume of sample SA5 is higher than that of sample SA10. This may be attributed to the large size and volume fractioned nanocrytals in sample SA10, since the interface of the nanocrystals and amorphous matrix can act as shear band initiation sites, although the free volume of sample SA10 decreases.

Different from crystalline materials, in which the plastic deformation is mainly controlled by dislocation mechanisms and the plasticity is determined by the nucleation and motion of dislocations [53], room temperature plastic deformation of BMGs occurs via localized shear banding events [3,54]. Localized shear banding usually leads to strain softening and catastrophic failure with limited global plasticity [54]. So, the shear band initiation and propagation are very important for the plasticity of the BMGs. Shear bands are likely to nucleate at the weak points such as free volume and the interface of the amorphous matrix and nanocrystals. The annealing process annihilates the free volume that causes a complete loss of the ductility, while the pre- compression process increases the free volume due to the shear-induced atomic dilatation or atomic disordering, and thus increases the number of shear band initiation sites that de-localizes the plastic deformation [28]. Our previous investigation [42] indicated that nanocrystals can effectively inhibit the propagation of the shear bands, and nanocrystals with a very small size may not be able to effectively block the propagation of shear bands, but they can still detour the pathways of shear bands. In this study, the pre-compression process creates the excess free volume and leads to the nanocrystal growth. Sample SA5 exhibits partially recovered strength and ductility to the annealed sample (sample SA). However, it should be noted that after a very long period of pre-compression (10 h), sample SA10 loses plasticity again for the reason that excessive crystal growth consumes the free volume. Therefore, proper controlling the duration of pre-compression is critical to mechanical properties of the BMGs.

5 Conclusions

1) The combined effects of thermal annealing and pre-compression below the yield stress on the mechanical properties and microstructures of the Cu36Zr48Al8Ag8 BMG were investigated.

2) Annealing at 743 K for 10 min resulted in the annihilation of the free volume and nanocrystallization that caused a complete loss of the ductility and dramatic decrease of the strength of the BMG.

3) Pre-compression after annealing treatment led to further growth of the nanocrystals in the BMG matrix and partially resumed the lost free volume caused by the annealing. A very long period of pre-compression (10 h) decreased the free volume again, which was caused by the excessive crystal growth.

4) Properly controlling the time used for the pre-compression below the yield stress could partially recover the ductility that was lost during the thermal annealing.

References

[1] GREER A L. Metallic glasses [J]. Science, 1995, 267: 1947-1953.

[2] INOUE A. Stabilization of metallic supercooled liquid and bulk amorphous alloys [J]. Acta Mater, 2000, 48: 279-306.

[3] WANG Wei-hua. Roles of minor additions in formation and properties of bulk metallic glasses [J]. Prog Mater Sci, 2007, 52: 540-596.

[4] SCHUH C A, HUFNAGEL T C, RAMAMURTY U. Mechanical behavior of amorphous alloys [J]. Acta Mater, 2007, 55: 4067-4109.

[5] INOUE A, ZHANG W, TSURUI T, YAVARI A R, GREER A L. Unusual room-temperature compressive plasticity in nanocrystal- toughened bulk copper-zirconium glass [J]. Phil Mag Lett, 2005, 85: 221-237.

[6] STEENBERGE N V, CONCUSTELL A, SORT J, DAS J, MATTERN N, GEBERT A, SURINACH S, ECKERT J, BARO M D. Microstructural inhomogeneities introduced in a Zr-based bulk metallic glass upon low-temperature annealing [J]. Mater Sci Eng A, 2008, 491: 124-130.

[7] KATO H, YUBUTA K, LOUZGUINE D V, INOUE A, KIM H S. Influence of nanoprecipitation on strength of Cu60Zr30Ti10 glass containing μm-ZrC particle reinforcements [J]. Scr Mater, 2004, 51: 577-581.

[8] SONG Min, LIAO Xiao-zhou, HE Yue-hui. Effect of sub-Tg annealing on the mechanical properties of a ZrAlNiCuNb bulk metallic glass [J]. Phil Mag Lett, 2011, 91: 713-723.

[9] KUMAR G, RECTOR D, CONNER R D, SCHROERS J. Embrittlement of Zr-based bulk metallic glasses [J]. Acta Mater, 2009, 57: 3572-3583.

[10] RAMAMURTY U, LEE M L, BASU J, LI Y. Embrittlement of a bulk metallic glass due to low-temperature annealing [J]. Scr Mater, 2002, 47: 107-111.

[11] WU F F, ZHANG Z F, MAO S X, PEKER A, ECKERT J. Effect of annealing on the mechanical properties and fracture mechanisms of a Zr56.2Ti13.8Nb5.0Cu6.9Ni5.6Be12.5 bulk-metallic-glass composite [J]. Phys Rev B, 2007, 75: 134201.

[12] DMOWSKI W, FAN C, MORRISON M L, LIAW P K, EGAMI T. Structural changes in bulk metallic glass after annealing below the glass-transition temperature [J]. Mater Sci Eng A, 2007, 471: 125-129.

[13] SONG Min, LI Yao-qi, WU Zheng-gang, HE Yue-hui. The effect of annealing on the mechanical properties of a ZrAlNiCu metallic glass [J]. J Non-Cryst Solids, 2011, 357: 1239-1241.

[14] MURALI P, RAMAMURTY U. Embrittlement of a bulk metallic glass due to sub-Tg [J]. Acta Mater, 2005, 53: 1467-1478.

[15] LWEANDOWSKI J J. Effects of annealing and changes in stress state on fracture toughness of bulk metallic glass [J]. Mater Trans, 2001, 42: 633-637.

[16] DAS J, TANG M B, KIM K B, THEISMANN R, BAIER F, WANG W H, ECKERT J. “Work-hardenable” ductile bulk metallic glass [J]. Phys Rev Lett, 2005, 94: 205501.

[17] SONG Min, HE Yue-hui. Effect of isothermal annealing on the compressive strength of a ZrAlNiCuNb metallic glass [J]. J Alloys Compd, 2011, 509: 2606-2610.

[18] GU Ji, SONG Min, NI Song, GUO Sheng-feng, HE Yue-hui. Effects of annealing on the hardness and elastic modulus of a Cu36Zr48Al8Ag8 bulk metallic glass [J]. Mater Des, 2013, 47: 706-710.

[19] SUN Ying-ying, SONG Min, LIAO Xiao-zhou, SHA Gang, HE Yue-hui. Effects of isothermal annealing on the microstructures and mechanical properties of a FeCuSiBAl amorphous alloy [J]. Mater Sci Eng A, 2012, 543: 145-151.

[20] NIIKURA A, TSAI A P, INOUE A, MASUMOTA T. Chemical structural relaxation-induced embrittlement in amorphous Mg-Cu-Y alloys [J]. J Non-Cryst Solids, 1993, 159: 229-234.

[21] WU Hong, LIU Yong, LI Kai-yang, ZHAO Zhong-wei. Casting effect on compressive brittleness of bulk metallic glass [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(2): 385-392.

[22] HUANG Y J, ZHENG W, FAN H B, WANG D J, SHEN J, MI J. The effects of annealing on the microstructure and the dynamic mechanical strength of a ZrCuNiAl bulk metallic glass [J]. Intermetallics, 2013, 42: 192-197.

[23] WANG Y B, QU D D, WANG W H, CAO Y, LIAO X Z, KAWASAKI M, RINGER S P, SHAN Z W, LANGDON T G, SHEN J. Introducing a strain-hardening capability to improve the ductility of bulk metallic glasses via severe plastic deformation [J]. Acta Mater, 2012, 60: 253-260.

[24] LIU J W, CAO Q P, CHEN L Y, WANG X D, JIANG J Z. Shear band evolution and hardness change in cold-rolled bulk metallic glasses [J]. Acta Mater, 2010, 58: 4827-4840.

[25] STOLPE M, KRUZIC J J, BUSCH R. Evolution of shear bands, free volume and hardness during cold rolling of a Zr-based bulk metallic glass [J]. Acta Mater, 2014, 64: 231-240.

[26] LEE C M, PARK K W, LEE J C. Plasticity improvement of a bulk amorphous alloy based on its viscoelastic nature [J]. Scr Mater, 2008, 59: 802-805.

[27] ZHANG Y, WANG W H, GREER A L. Making metallic glasses plastic by control of residual stress [J]. Nat Mater, 2006, 5: 857-860.

[28] YU P, BAI H Y, ZHAO J G, JIN C Q, WANG W H. Pressure effects on mechanical properties of bulk metallic glass [J]. Appl Phys Lett, 2007, 90: 051906.

[29] YU H B, HU J, XIA X X, SUN B A, LI X X, WANG W H, BAI H Y. Stress-induced structural inhomogeneity and plasticity of bulk metallic glasses [J]. Scr Mater, 2009, 61: 640-643.

[30] PARK K W, LEE C M, WAKEDA W, SHIBUTANI Y, FALK M L, LEE J C. Elastostatically induced structural disordering in amorphous alloys [J]. Acta Mater, 2008, 56: 5440-5450.

[31] KE H B, WEN P, PENG H L, WANG W H, GREER A L. Homogeneous deformation of metallic glass at room temperature reveals large dilatation [J]. Scr Mater, 2011, 64: 966-969.

[32] LEE S C, LEE C M, YANG J W, LEE J C. Microstructural evolution of an elastostatically compressed amorphous alloy and its influence on the mechanical properties [J]. Scr Mater, 2008, 58: 591-594.

[33] TONG Y, DMOWSKI W, WITCZAK Z, CHUANG C P, EGAMI T. Residual elastic strain induced by equal channel angular pressing on bulk metallic glasses [J]. Acta Mater, 2013, 61: 1204-1209.

[34] TONG Y, DMOWSKI W, YOKOYAMA Y, WANG G, LIAW P K, EGAMI T. Recovering compressive plasticity of bulk metallic glasses by high-temperature creep [J]. Scr Mater, 2013, 69: 570-573.

[35] RITTER Y, ALBE K. Thermal annealing of shear bands in deformed metallic glasses: Recovery mechanisms in Cu64Zr36 studied by molecular dynamics simulations [J]. Acta Mater, 2011, 59: 7082-7094.

[36] CONCUSTELL A, DESMAREST S G, CARPENTER M A, NISHIYAMA N, GREER A L. Induced elastic anisotropy in a bulk metallic glass [J]. Scr Mater, 2011, 64: 1091-1094.

[37] HAJLAOUI K, BENAMEUR T, VAUGHAN G, YAVARI A R. Thermal expansion and indentation-induced free volume in Zr-based metallic glasses measured by real-time diffraction using synchrotron radiation [J]. Scr Mater, 2004, 51: 843-848.

[38] XU Y L, HAHN H, LI J G. Effects of room-temperature rolling on microstructure and crystallization behavior of Zr55Cu40Al5 metallic glass [J]. Intermetallics, 2010, 18: 2039-2043.

[39] XIE S, GEORGE E P. Hardness and shear band evolution in bulk metallic glasses after plastic deformation and annealing [J]. Acta Mater, 2008, 56: 5202-5213.

[40] KRISHNANAND K D, CAHN R W. Recovery from plastic deformation in a Ni/Nb alloy glass [J]. Scr Metall, 1975, 9: 1259-1261.

[41] MENG F Q, TSUCHIYA K, SEIICHIRO L L, YOKOYAMA Y. Reversible transition of deformation mode by structural rejuvenation and relaxation in bulk metallic glass [J]. Appl Phys Lett, 2012, 101: 121914.

[42] GU Ji, SONG Min, NI Song, LIAO Xiao-zhou, GUO Sheng-feng. Improving the plasticity of bulk metallic glasses via pre-compression below the yield stress [J]. Mater Sci Eng A, 2014, 602: 68-76.

[43] TURNBULL D, COHEN M H. On the free-volume model of the liquid-glass transition [J]. J Chem Phys, 1970, 52: 3038-3041.

[44] INOUE A, ZHANG T, KIM Y H. Synthesis of high strength bulk amorphous Zr-Al-Ni-Cu-Ag alloys with a nanoscale secondary phase [J]. Mater Trans JIM, 1997, 38: 749-755.

[45] LEE S C, LEE C M, LEE J C, KIM H J, SHIBUTANI Y, FLEURY E, FALK M L. Structural disordering process of an amorphous alloy driven by the elastostatic compression at room temperature [J]. Appl Phys Lett, 2008, 92: 151906.

[46] BHOWMICK R, RAGHAVAN R, CHATTOPADHYAY K, RAMAMURTY U. Plastic flow softening in a bulk metallic glass [J]. Acta Mater, 2006, 54: 4221-4228.

[47] WANG K, FUJITA T, ZENG Y Q, NISHIYAMA N, INOUE A, CHEN M W. Micromechanisms of serrated flow in a Ni50Pd30P20 bulk metallic glass with a large compression plasticity [J]. Acta Mater, 2008, 56: 2834-2842.

[48] JANG D C, GREER J R. Transition from a strong-yet-brittle to a stronger-and-ductile state by size reduction of metallic glasses [J]. Nat Mater, 2010, 9: 215-219.

[49] ZHENG W, HUANG Y J, WANG G Y, LIAW P K, SHEN J. Influence of strain rate on compressive deformation behavior of a Zr-Cu-Ni-Al bulk metallic glass at room temperature [J]. Metall Mater Trans A, 2011, 42: 1491-1498.

[50] van DEN BEUKEL A, SIETSMA J. The glass transition as a free volume related kinetic phenomenon [J]. Acta Metall Mater, 1990, 38: 383-389.

[51] FAN C, LI C F, INOUE A, HAAS V. Deformation behavior of Zr-based bulk nanocrystalline amorphous alloys [J]. Phys Rev B, 2000, 61: 3761-3763.

[52] PARK K W, JANG J I, WAKEDA M, SHIBUTANI Y, LEE J C. Atomic packing density and its influence on the properties of Cu–Zr amorphous alloys [J]. Scr Mater, 2007, 57: 805-808.

[53] NI S, WANG Y B, LIAO X Z, FIGUEIREDO R B, LI H Q, RINGER S P, LANGDON T G, ZHU Y T. The effect of dislocation density on the interactions between dislocations and twin boundaries in nanocrystalline materials [J]. Acta Mater, 2012, 60: 3181-3189.

[54] CHEN M W. Mechanical behavior of metallic glasses: Microscopic understanding of strength and ductility [J]. Annu Rev Mater Res, 2008, 38: 445-469.

等温退火和预压处理对Cu36Zr48Al8Ag8大块非晶合金力学性能的共同影响

顾 及1,张立鑫1,王依涵1,倪 颂1,郭胜锋2,宋 旼1

1. 中南大学 粉末冶金国家重点实验室,长沙 410083;

2. 西南大学 材料与能源学院,重庆 400715

摘 要:研究等温退火和预压处理对Cu36Zr48Al8Ag8大块非晶合金力学性能的共同影响。首先,将铸态样品在 743 K退火10 min,然后对退火后的样品进行预压处理,在800 MPa压力下分别预压1、3、5和10 h。结果表明,退火处理后在非晶基体中形成了尺寸为10 nm左右的纳米晶并极大地湮灭了自由体积,从而导致大块非晶合金完全丧失塑性。在800 MPa下预压处理合适的时间(5 h)可以部分地恢复自由体积,进而部分地恢复大块非晶合金的塑性。而过长的预压时间(10 h)将导致自由体积的再次减小,主要源于纳米晶的过分长大。

关键词:大块非晶合金;退火;预压;自由体积;纳米晶

(Edited by Wei-ping CHEN)

Foundation item: Projects (51328101, 51301142) supported by the National Natural Science Foundation of China; Project (2015JJ2206) supported by Hunan Provincial Natural Science Foundation of China

Corresponding author: Min SONG; Tel: +86-731-88877677; E-mail: msong@csu.edu.cn

DOI: 10.1016/S1003-6326(16)64270-X

Abstract: The combined effects of isothermal annealing and pre-compression on the mechanical properties of Cu36Zr48Al8Ag8 bulk metallic glass (BMG) were investigated. The as-cast specimens were first annealed at 743 K for 10 min, and then pre-compressed under 800 MPa for 1, 3, 5 and 10 h, respectively. The results indicated that annealing resulted in the formation of nanocrystals with a diameter of ~10 nm in the amorphous matrix and a drastic decrease of the free volume, leading to complete loss of the plasticity of the BMG. Applying pre-compression under a stress of 800 MPa for a proper duration (5 h) resumed part of the lost free volume in the BMG matrix and therefore partially recovered the plasticity. A very long period of pre-compression (10 h) decreased the free volume again, which was caused by the excessive crystal growth.