J. Cent. South Univ. Technol. (2011) 18: 1891-1896

DOI: 10.1007/s11771-011-0919-8![]()

Rheological properties of

polyvinyl butyral/Pluronic F127/PEG200 blend systems

OUYANG Wei(欧阳伟), QIU Yun-ren(邱运仁)

School of Chemistry and Chemical Engineering, Central South University, Changsha 410083, China

? Central South University Press and Springer-Verlag Berlin Heidelberg 2011

Abstract:

The influence of temperature and mass fraction of Pluonic F127 on the rheological properties of polyvinyl butyric (PVB)/Pluronic F127/polyethylene glycol (PEG) 200 blend systems was investigated by a rotational rheometer with parallel plates. The results show that the blend systems approach homogeneous state at 140, 150 and 160 °C while the rheological properties of the blend systems significantly deviate from the homogeneous systems at 120 °C. Shear thinning behavior is observed for all the blend systems at different temperatures and is enhanced by increasing Pluronic F127 content. The complex viscosity, storage modulus, loss modulus, zero-shear activation energy and flow recovery of the blend systems increase with the increase of Pluronic F127 content. There is a crossing point for the loss modulus and the storage modulus of each sample at high frequency, which is called specified frequency (SF). The loss modulus is larger than the storage modulus when the frequency is less than the SF, and when frequency is more than SF, the loss modulus is smaller than the storage modulus.

Key words:

polyvinyl butyral; amphiphilic copolymer; polyethylene glycol; dynamic rheological properties;

1 Introduction

Membrane fouling is a major obstacle to the widespread applications of microfiltration and ultrafiltration. There are some methods to increase the hydrophilicity of membrane [1]. Thus, many techniques such as coating, blending, plasma treatment and surface grafting have been used to increase the hydrophilicity of the membrane [2]. Polymer blends provide an efficient way to satisfy new requirements for material properties, in which improved process ability and properties are achieved by combining the individual properties of each pure component [3]. The study of the evolution of polymer blend morphology during processing receives more and more attentions and different techniques have been used in order to obtain improved knowledge on this subject [4].

Polyvinyl butyral (PVB) has been extensively used in laminated safety glass and surface treatments. In addition to an innocuous and tasteless polymeric material, PVB can endure low temperature, light, change in humidity, bacteria, microorganism, alkali and diluents acid [5]. Moreover, it is regarded as a random copolymer of vinyl butyral and vinyl alcohol units. The vinyl alcohol unit is polar and hydrophilic and the vinyl butyral unit is hydrophobic. Therefore, PVB seems to be an attractive material for preparing the membrane, though very few literatures have been reported on the preparation of PVB microfiltration and ultrafiltration membranes [5-6]. Pluronic F127 is an amphiphilic copolymer. The hydrophobic polypropylene oxide (PPO) segments in Pluronic F127 ensure the Pluronic copolymers to be firmly anchored in the polymer matrix, while the hydrophilic polyethylene oxide (PEO) segments in Pluronic F127 endow the membranes surface with higher hydrophilicity. Since the PEO segments of Pluronic are highly hydrophilic, Pluronic 127 is an attractive modifier for the increase of the hydrophilicity of the membrane [7]. Our previous researches [8-9] indicate that Pluronic F127 can exist in the polymer matrix and increase the hydrophilicity of the membrane.

PVB/Pluronic F127 blend hydrophilic hollow fiber membranes were prepared via thermally induced phase separation (TIPS). In the TIPS process, PVB and Pluronic F127 were dissolved in PEG200 at high temperature, and then extruded from the spinneret into water bath to induce phase separation and solidify the membrane. The structure and properties of the hollow fiber membranes are affected by the shear rate during extrusion. From the rheological perspective, the intensive regions in fiber formation are the shear flow during extrusion through the spinneret and elongational flow in the air gap region prior to immersion into the coagulation bath. The molecular orientation in the fiber structure is affected by the dynamic rheological properties of this blend system. Therefore, detailed rheological studies are important to the behavior of PVB/F127/PEG200 blend systems extruded from the spinneret and the final properties of the PVB/Pluronic F127 blend hydrophilic hollow fiber membranes via TIPS. However, there is so far no report on the rheological properties of the PVB/F127/PEG200 blend systems. The present work focuses on the effect of temperature and mass fraction of F127 on the rheological properties of the blend systems. The rheological properties such as shear viscosity, storage and loss modulus, melt miscibility and flow recovery characteristics were obtained from the oscillatory shear measurements.

2 Experimental

2.1 Materials

Polyvinyl butyral (PVB) with vinyl butyral part of 45%-49%, was purchased from Sinopharm Chemical Reagent Co., China. Pluronic F127 (abbreviated as F127 in figures) with relative molecular mass of 12 600 used as additive was purchased from Anqiushi Lu-xing Chemistry Co., China. Polyethylene glycol (PEG, Mr= 200) used as diluent was supplied from Sinopharm Chemical Reagent Co., China. All the chemicals were used without further purification.

2.2 Preparation of blend systems

PVB/F127/PEG200 blend systems were prepared by melt blending on the Haake Rheocord 90 with Rheomix 600 mixer at 160 °C and 40 r/min. The mixing continued until a constant torque was reached. The mass fraction of F127 in the blend systems was varied from 1% to 7% as indicated in Table 1, and the samples were denoted as F0, F1, F3, F5 and F7, respectively. The samples for rheological testing were prepared by compression molding at 160 °C for about 1 h in the form of 40 mm diameter disks with 1.5 mm in thickness. To avoid water absorption, the samples obtained were stored in a vacuum oven at 80 °C for at least 2 d before use.

Table 1 Compositions of PVB/F127/PEG200 blend systems

2.3 Rheological testing

The rheological behaviors of the blend systems were measured with a rotational rheometer (AR2000, TA instruments) using parallel plates with a diameter of 40 mm and a gap of 1.0 mm. The specimen was melted at 160 °C between the parallel plates and kept for 3 min at the temperature to remove the residual stress. Dynamic frequency sweeps were performed over the range of 0.05-600 rad/s at 120, 140, 150 and 160 °C, using strain values determined with a dynamic strain sweep to lie within the linear viscoelastic region. To avoid any oxidative degradation of the samples, all measurements were conducted under nitrogen atmosphere.

3 Results and discussion

3.1 Effect of temperature on rheological properties

Small amplitude oscillatory shear experiments were carried out to determine the rheological characteristics of the PVB/F127/PEG200 blend systems. From these experiments, insights were gained into the processing characteristics of these blend systems. Figure 1 shows the storage modulus (G′) and loss modulus (G″) of the F5 samples against frequency at 120, 140, 150 and 160 °C. As shown in Fig.1(a), the samples show a typical terminal behavior with a slope of about 2.0, i.e. G′∝2 lg ω at low frequencies at 140, 150 and 160 °C. However, the storage moduli of the blend systems significantly deviate from classical terminal behavior at 120 °C. This behavior is well-documented in Ref.[10] and represents a fingerprint for the presence of phase-separated domains. The pronounced elasticity is attributed to the concentration fluctuation near the phase boundary and interfacial tension in phase-separated regions [11]. In contrast to G′, the loss modulus G″ remains almost unchanged and shows no anomalous terminal response, as illustrated in Fig.1(b). G″ is either insensitive or very weakly sensitive to phase separation.

Fig.1 Plots of storage modulus G′ (a) and loss modulus G″ (b) vs frequency for F5 sample at different temperatures

Figure 2 shows the master curves of G′ and G″ of the F5 sample. Each curve of G′ and G″ in Fig.2 was shifted onto the curve at a reference temperature of 160 °C, assuming that the time–temperature superposition (tTS) principle constructs the master curves. Only horizontal shifting along the frequency axis was performed. In the case of heterogeneous polymer materials, in particular polymer blends, the different phase domains of the material generally display different temperature dependent rheology, so the tTS will not hold for blends. That is why the failure of the tTS was often used for characterizing phase separation [11]. As shown in Fig.2, tTS principle holds well for the samples at 140, 150 and 160 °C while an obvious split of master curves of G′ at low frequencies is observed at 120 °C.

Fig.2 Master curves of G′ (a) and G″ (b) of F5 sample at reference temperature of 160 °C

G′ versus G″ plots were compared to further investigate the miscibility of the blend systems. Plots comparing the elastic (G′) and the viscous (G″) behavior are often used to detect phase separation due to differences in structural units. Figure 3 shows the logarithmic plots of G′ versus G″′ (so-called Han plot). As shown in Fig.3, the samples examined show a temperature independent behavior and similar curves with slopes of about 1.9 over all the frequencies at 140, 150, 160 °C. This value is similar to the slope (2.0) of most isotropic and homogeneous systems reported previously [12]. On the other hand, the slope of the curve deviates gradually from 2 at 120 °C. This result indicates that the PVB/F127/PEG200 blend systems show an upper critical solution temperature (UCST) behavior. The sample approaches homogeneous state irrespective of shear force at 140, 150 and 160 °C while the phase separation occurs at 120 °C.

Fig.3 Han plots for F5 sample at different temperatures

3.2 Effect of mass fraction of F127 on rheological properties

Figure 4 shows the angular frequency (ω) dependence of the complex viscosity (η*) of F0, F1, F3, F5 and F7 samples at 150 °C. For these samples, the complex viscosity of the blend systems increases with increasing mass fraction of F127. The higher η* could be attributed to higher relative molecular mass of F127. Shear thinning behavior is observed for all the blends (decrease in viscosity with increasing frequency of the test). Shear thinning of the polymer occurs when the chains begin to disentangle and slip past each other. This slippage allows for the orientation of the polymer in the flow direction, leading to a lowering of the viscosity [13-14]. The rate at which shear thinning occurs for a polymer melt is of great importance during polymer processing. To quantify the effects of F127 on shear-thinning behavior, the power-law expression [15], given by Eq.(1), was fitted to the viscosity data at high shear rates:

![]() (1)

(1)

where a is the consistency index and n is the power-law exponent, which indicates the degree of non-Newtonian behavior. This model generally predicts well the viscosity behavior for many polymers in the high shear rate region, but lacks a parameter to estimate the zero-shear viscosity. The power-law exponents at 150 °C for all the blend systems are listed in Table 2. The n values decrease with the increase of mass fraction of F127. This trend suggests that increasing F127 content can enhance the shear thinning. Estimates for the zero-shear viscosity of the polymers are obtained from the Cross model. The Cross model is a modification of the power-law to include parameters to account for the Newtonian behavior of the polymer in the low shear rate region. The equation of the Cross model is shown below by Eq.(2):

![]() (2)

(2)

where ω is the oscillation angular frequency; η0 is the zero shear viscosity; τ is the characteristic relaxation time; m is a dimensionless exponent that is independent of temperature. The characteristic time of the material is the reciprocal of the shear rate at which the zero-shear viscosity occurs. In the low shear rate region, the viscosity of a polymer generally approaches a constant value where the viscosity is independent of the shear rate. The zero shear viscosities obtained from cross fitting are listed in Table 2. As shown in Table 2, η0 increases with the increase of mass fraction of F127.

Fig.4 Complex viscosity η* vs frequency for different samples at 150 °C

Table 2 Rheological properties of different samples at 150 °C

The flow activation energy Ea is obtained by applying the shift factor aT [16], which is calculated from zero shear viscosities according to Eq.(3):

![]() (3)

(3)

where T0 is the reference temperature.

The factor is correlated to temperature through the Arrhenius-type equation, given by Eq.(4):

![]() (4)

(4)

where R is the gas constant; T is the absolute temperature; Ea is the zero-shear activation energy.

Table 2 shows the apparent zero-shear activation energies for the samples. It can be seen that zero-shear activation energies increase with the increase of mass fraction of F127.

Comparison of the storage modulus with frequency can also provide more insight into the polymer microstructure. The storage modulus (G′) and loss modulus (G″) of the blend systems are plotted against frequency in Fig.5. As shown in Fig.5, the storage modulus increases with increasing the frequency. This behavior is similar to that of polymer in the solid-state. At low frequencies, the chains can rearrange amongst themselves but, as the frequency increases, they have less time to relax and become glassy. For these blend systems, the viscous response and elastic response depend on the composition of the blend systems. Both the elastic and loss properties increase with increasing the mass fraction of F127. Typical terminal behavior at low frequencies is observed for all the samples at 150 °C. This indicates that all the samples are homogeneous at 150 °C.

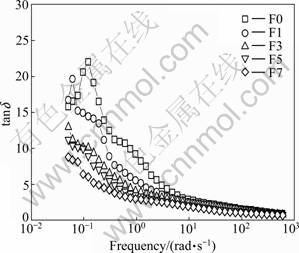

Figure 6 compares the tan delta (tan δ) behavior of the blends at 150 °C. The tan δ(G″/G′) quantifies the balance of the loss and elastic properties. A high value of tan δ indicates that the polymer material has poor recovery characteristics since the chains relax slowly after being stressed. From a processing point of view, this value can indicate how well a material will recover after being deformed. As the content of F127 increases, the tan δ decreases. The flow recovery of the blends increases with the increase of F127 content due to the high relative molecular mass of the F127. The flow recovery also increases with the increase of frequency. There is a crossing point (tan δ=1) for G′ and G″ of each sample, where the frequency is called specified frequency (SF). The loss modulus G″ is larger than the storage modulus G′ when frequency is less than SF, under which the viscous component dominates the viscoelastic properties. However, when angular frequency is more than SF, the elasticity component becomes a dominating factor.

Fig.5 Plots of storage modulus G′ (a) and loss modulus G″ (b) vs frequency for different samples at 150 °C

Fig.6 Flow recovery of different samples at 150 °C

4 Conclusions

1) The PVB/F127/PEG200 blend systems show an upper critical solution temperature (UCST) behavior. The blend systems approach homogeneous state at 140, 150 and 160 °C while the rheological properties of the blend systems significantly deviate from homogeneous systems at 120 °C. In homogeneous region, the blends of different compositions behave as a classical polymer melt. On the other hand, in phase-separated region, deviations from the classical scaling laws are observed.

2) Shear thinning behavior is observed for all the blend systems and enhanced by increasing the mass fraction of Pluronic F127. For these blend systems, the viscous response and elastic response depend on the composition of the blend systems, and the complex viscosity, storage modulus, loss modulus, and zero-shear activation energies increase with the increase of F127 content.

3) The flow recovery of the blends increases with the increase of F127 content due to the high relative molecular mass of the F127. The flow recovery also increases with the increase of frequency.

4) There is a crossing point (tan δ=1) for G′ and G″ of each sample. The loss modulus G″ is larger than the storage modulus G′ when the angular frequency is less than SF, under which the viscous component dominates the viscoelastic properties. However, when the angular frequency is more than SF, the elasticity component becomes a dominating factor.

References

[1] Huisman I H, Prádanos P, Hernández A. The effect of protein–protein and protein–membrane interactions on membrane fouling in ultra filtration [J]. J Membr Sci, 2000, 179(1/2): 79-90.

[2] Suk D E, Chowdhury G, Matsuura T, Narbaitz R M, Santerre P, Pleizier G, Deslandes Y. Study on the kinetics of surface migration of surface modifying macromolecules in membrane preparation [J]. Macromolecules, 2002, 35(8): 3017- 3021.

[3] Sung Y T, Han M S, Hyun J C, Kim W N, Lee H S. Rheological properties and interfacial tension of polypropylene–poly (styrene-co-acrylonitrile) blend containing compatibilizer [J]. Polymer, 2003, 44(5): 1681-1687.

[4] Tyagi S, Ghosh A K. Morphology development during blending of immiscible polymers in screw extruders [J]. Polym Eng Sci, 2004, 42(6): 1309-1321.

[5] SHEN Fei, LU Xiao-feng, BIAN Xiao-kai, SHI Liu-qing. Preparation and hydrophilicity study of poly (vinylbutyral)-based ultrafiltration membranes [J]. J Membr Sci, 2005, 265(1/2): 74-84.

[6] Fu Xun-yao, Matsuyama H, Teramoto M, Nagai H. Preparation of hydrophilic poly(vinyl butyral) hollow fiber membrane via thermally induced phase separation [J]. Sep Purif Technol, 2005, 45(3): 200-207.

[7] Singh B M, Shweta S. Influence of hydrophobicity on the mixed micelles of Pluronic F127 and P103 plus cationic surfactant mixtures [J]. Colloids Surf A: Physicochem Eng, 2006, 276(1/2/3): 146-154.

[8] QIU Yun-ren, Matsuyam H, GAO Guo-ying, OUYANG Wei, MIAO Chang. Effects of diluent molecular weight on the performance of hydrophilicpoly (vinyl butyral)/Pluronic F127 blend hollow fiber membrane via thermally induced phase separation [J]. J Membr Sci, 2009, 338(1/2): 128-134.

[9] QIU Yun-ren, Rahman N A, Matsuyam H. Preparation of hydrophilic poly (vinyl butyral)/Pluronic F127 blend hollow fiber membrane via thermally induced phase separation [J]. Sep Purif Technol, 2008, 61(1): 1-8.

[10] DU Mao, GONG Jian-huan, ZHENG Qiang. Dynamic rheological behavior and morphology near phase-separated region for a LCST-type of binary polymer blends [J]. Polymer, 2004, 45(19): 6725-6730.

[11] LI Run-ming, YU Wei, ZHOU Chi-xing. Phase behavior and its viscoelastic responses of poly (methyl methacrylate) and poly (styrene-co-maleicanhydride) blend systems [J]. Polymer Bulletin, 2006, 56(4/5): 455-466.

[12] Han S, Im S S, Kim D K. Dynamic mechanical and melt rheological properties of sulfonated poly (butylene succinate) ionomers [J]. Polymer, 2003, 44(23): 7165-7173.

[13] ZHAO Cai-xian, ZHANG Ping, CHEN Guang-bing, WANG Xia-yu. Rheological behavior of novel polyamide 6/silica nanocomposites containing epoxy resins [J]. Journal of Central South University of Technology, 2008, 15(Suppl 1): 76-79.

[14] MENG Ling-wei, KANG Wan-li, ZHOU Yang, WANG Zhi-wei, LIU Shu-ren, BAI Bao-jun. Viscoelastic rheological property of different types of polymer solutions for enhanced oil recovery [J]. Journal of Central South University of Technology, 2008, 15(Suppl 1): 126-129.

[15] WANG Wen-jun, YE Zhi-bin, FAN Hong, LI Bo-geng, ZHU Shi-ping. Dynamic mechanical and rheological properties of metallocene-catalyzed long-chain-branched ethylene/propylene copolymers [J]. Polymer, 2004, 45(16): 5497-5504.

[16] Vega J F, Santamaría A, Mu?oz-Escalona A, Lafuente P. Small-amplitude oscillatory shear flow measurements as a tool to detect very low amounts of long chain branching in polyethylenes [J]. Macromolecules, 1998, 31(11): 3639-3647.

(Edited by HE Yun-bin)

Foundation item: Project(20776161) supported by the National Natural Science Foundation of China

Received date: 2010-09-16; Accepted date: 2010-12-16

Corresponding author: QIU Yun-ren, Professor; Tel: +86-731-88876675; E-mail: qiu_yunren@yahoo.com.cn

Abstract: The influence of temperature and mass fraction of Pluonic F127 on the rheological properties of polyvinyl butyric (PVB)/Pluronic F127/polyethylene glycol (PEG) 200 blend systems was investigated by a rotational rheometer with parallel plates. The results show that the blend systems approach homogeneous state at 140, 150 and 160 °C while the rheological properties of the blend systems significantly deviate from the homogeneous systems at 120 °C. Shear thinning behavior is observed for all the blend systems at different temperatures and is enhanced by increasing Pluronic F127 content. The complex viscosity, storage modulus, loss modulus, zero-shear activation energy and flow recovery of the blend systems increase with the increase of Pluronic F127 content. There is a crossing point for the loss modulus and the storage modulus of each sample at high frequency, which is called specified frequency (SF). The loss modulus is larger than the storage modulus when the frequency is less than the SF, and when frequency is more than SF, the loss modulus is smaller than the storage modulus.