J. Cent. South Univ. (2017) 24: 2260-2265

DOI: https://doi.org/10.1007/s11771-017-3636-0

Evaluation of granulability and absorbtivity of biomass in agglomeration mixture

Jozef,

Jozef,  Jaroslav,

Jaroslav,  Zuzana,

Zuzana,  ,

,  , Legemza Jaroslav

, Legemza Jaroslav

Institute of Metallurgy, Faculty of Metallurgy, Technical University of  ,

,  , 042 00, Slovakia

, 042 00, Slovakia

Central South University Press and Springer-Verlag GmbH Germany 2017

Central South University Press and Springer-Verlag GmbH Germany 2017

Abstract:

The granulability and absorbtivity of sawdust and coke breeze were investigated. These properties are important within the preparation of agglomeration charge. They have a significant impact on plynodynamic batch conditions. Ability of materials to wet is a fundamental condition of granulability of materials. Wettability and water absorption of wood with liquids is generally significantly affected by their chemical structure. The important factors affecting the wetting process are undoubtedly the wood moisture content, the value of the surface tension of liquid media and their chemical composition. With increasing moisture content of wood, the time to equilibrium rises. Determination of water absorption and granulability of sawdust was conducted to seek their possible use as a partial replacement of coke dust in the production of the agglomerate. Experiments have been realized with alder, oak and pine sawdust and reference material-coke breeze. These materials were divided to four classes of granularity: supplied material, 1-2 mm,0.5-1 mm and less than 0.5 mm. And different liquid media were used: water 16 °C, water 60 °C, soapy water, lime milk and surfactant.

Key words:

agglomeration; biomass; coke breeze; granulability; absorbtivity;

1 Introduction

Pig iron production is the energy-intensive industry, which depends mainly on use of fossil fuels, forming below the Earth surface for millions of years. The process of fossil fuels formation still continues, but its consumption far exceeds its production. Fossil fuels belong among the critical raw materials, therefore it is necessary to gradually reduce their consumption. The energy source for production of this valuable raw material is coke breeze.

At present, the research in the area of the agglomeration process is focused on reducing the majority of energy consumption, reducing pollutants and the increase of the production of agglomerate. This leads to a reduction in operating costs and a partial reduction of environmental impacts [1-4].

One of the possibilities to reduce the consumption of fossil fuels in the agglomerate production can be its partial substitution by renewable energy source, which is environmentally acceptable.

Based on our knowledge in the research area, our attention was focused on the wood waste material. However, biomass must meet requirements for agglomeration fuel therefore, it must undergo treatment before use.

The basic condition is the ability to create binding forces at the contact points between the components of the agglomeration mixture, which help producing raw granules. Agglomeration mixture is composed of agglo- ore, concentrates, slag additives and basic fossil fuel-coke breeze. Water is most commonly used as a binder for the production of raw granules. The components of agglomeration charge to be granulated belong to hydrophilic dispersion systems that are characterized by intensive interaction with water.

During a wetting of solid matter by fluids, properties of the phases relating to the wettability of the solid surface and the wetting properties of the liquid come into play.

Wetting of solid matter by a liquid is caused by the action of a force between the solid and the liquid phases. Wetting is significantly affected by the surface tension of the liquid, surface free energy, interfacial tension at the interface, the chemical structure of the surface of the solid phase, temperature etc [5, 6].

The surface tension is the most important measurable quantity that characterizes the surface of the liquid. It is influenced by the composition of the liquid phase, the temperature and, to a small extent the pressure, or electric charge phase interface [7].

The surface tension of liquids arises between the liquid and gaseous media due to increased cohesion among molecules of the liquid medium [8].

For the surface tension of water in the temperature range 0-30 °C applies the interpolation Eq. (1):

γ=75621-0.15t-10266×10-4t2 (1)

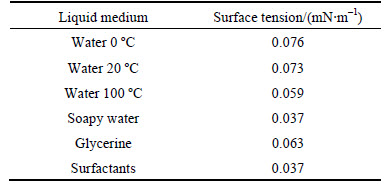

where t is the temperature in °C and γ is the surface tension in mN/m [7]. Table 1 shows the values of surface tension for different liquids.

Table 1 Surface tension of various liquids [9, 10]

To determine the sawdust wettability, liquid media with different values of the surface free energy are commonly used, which wet wood to a certain extent. Formation and nature of the boundary between wood and the liquid depends on the differences in the chemical composition of fluids used. Wettability and penetration of liquids into the intergranular spaces of sawdust are influenced by the structure of wood. The wood structure is characterized by porous-capillary structure, which is expressed in a change of the phase boundary nature, values of surface free energy of the liquid and its components at the phase boundary [11-18].

2 Materials and methods

The aim of the experiment was to determine absorptivity and granulability of hardwood and softwood sawdust and coke breeze of four granularity classes using two methods: capillary soaking method and free drop method. Coke breeze was used as a reference material, as alternative fuel selected sawdust from Scots pine (Pinus sylvestris), pedunculate oak (Quercus robur) and common alder (Alnus glutinosa).

All materials were used in the dry state. Drying of the investigated materials was carried out at 110 °C to constant mass. Subsequently, a portion of sawdust was subjected to screening on the vibrating pendulum grader KVT-U-2. Screening of materials resulted in grain size classes listed in Table 2. Analysis of materials was carried out on the sample of 100 g. Because testing of materials for industry was also used fraction named “as supplied”, this fraction has not been screened and contained all grain sizes. Fraction >2 mm was used only in “as-supplied” part of the experiment.

Table 2 Granulometry of selected materials

Liquid media, used in experiment, to determine absorbtivity and granulability of the materials, were water at 16 °C and 60 °C. Physical properties of water, which significantly affect wettability of the materials include a surface tension, which decreases as temperature increases and density which increases from 0 to 3.98 °C, and then decreases with increasing temperature [19-21].

Along with density, the behavior of water is significantly affected also by its viscosity, which decreases with increasing temperature as well as in the case of density [20, 21].

Another liquid medium used in the present study was the 10% aqueous suspension of calcium hydroxide Ca(OH)2, which is usually identified as milk of lime Ca(OH)2(aq). The density of milk of lime is around 2040 kg/m3 at 20 °C [22].

Assessment of granulability and absorbtivity of sawdust and coke breeze was also carried out with tensides, and there are surface active substances which are readily adsorbed at the phase interface even at low concentrations, reducing the surface tension of liquid, which may facilitate wetting of materials [6]. The each molecule consists of the hydrophilic and hydrophobic parts. The hydrophilic polar group (e.g., COOH) is oriented toward the water molecule. The non-polar hydrophobic group is a hydrocarbon chain (C8 and above), which is directed towards the non-polar part of wettable surface. This leads to a reduction of the surface tension [6].

The first surfactant used was an anionic tenside (soap). Function groups of the hydrophilic part of the molecule of anionic tensides (soaps) may be —COOH, —SO3H. The surface of the material obtains negative charge by the action of the anion. The effect of anionic surfactants increases with increasing temperature and mechanical action.

Anionic tenside (soap) was prepared as a 0.1% aqueous solution. The value of 0.1% was determined on the basis of completed experiments and theoretical knowledge [7, 23].

The second tenside was a nonionic industrial surfactant. The solubility of nonionic surfactants is given by a strong hydrating properties of their polar hydrophilic group. The hydrophobic portion of these surfactants is composed of an aliphatic hydrocarbon chain, optionally alkylphenol chain. The chemical composition of the surfactant which was used in the experiment indicated by the manufacturer as follows: <5% non-ionic surfactants, 20%-22% ethanol, 1%< ammonia. The density of the surfactant is about 0.965 to 0.985 g/cm3 (in the experiment, the value was found to be 0.975 g/cm3) [6, 24].

The experiment was carried out by capillary soaking method and free drop method. These methods are commonly used to assess granulability and water absorptivity of fine-grained materials.

The methodology for measuring the height of capillary soaking is based on the methodology described by  [24] and its implementation was carried out as follows: studied material was poured into the tube of 11 mm diameter, with a wire mesh bottom. The material was freely poured into the capillary, it was not compacted. The tube was mounted on the holder so that its lower end touched the studied fluid. The height of capillary soaking increases over time. The criterion for assessing capillary soaking in the case of present laboratory study was set as a value achieved after 15 min.

[24] and its implementation was carried out as follows: studied material was poured into the tube of 11 mm diameter, with a wire mesh bottom. The material was freely poured into the capillary, it was not compacted. The tube was mounted on the holder so that its lower end touched the studied fluid. The height of capillary soaking increases over time. The criterion for assessing capillary soaking in the case of present laboratory study was set as a value achieved after 15 min.

The determination of granulability of materials was carried out as follows: on the solid surface, the studied material was freely poured and leveled a 15 mm layer. A measured amount (0.8 mL) of water or other liquid, to penetrate the material, was added on the surface of dry pre-sorted material by dispensing device. After penetration of liquid into the bulk material, solid granules are formed. The degree of water penetration into the material depends on the size of pores between the particles, grain size of the material and the amount of water added. The duration of the penetration by liquid was 60 s. After this period, the mass of the granules was determined [24].

3 Results and discussion

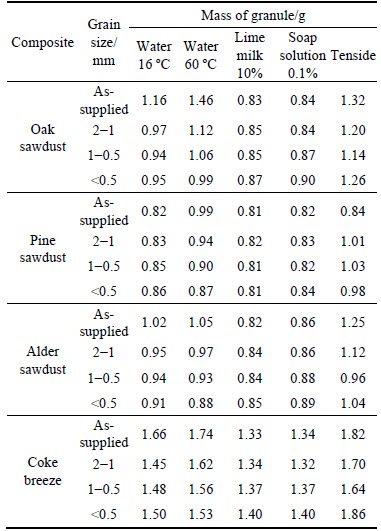

The results of measuring the height of capillary soaking and mass of raw granules formed without the action of mechanical forces and agitation are shown in Table 3.

These masses indicate that oak, pine and alder sawdust achieve minimum wetting by water at 16 °C. Mass of granules ranged from 0.82 to 1.16 g, as shown in Table 3. The largest mass has been measured in the case of oak sawdust as-supplied (1.16 g), and the lowest mass was found in the case of pine sawdust as-supplied(0.82 g). Overall, wetting of wood sawdust with water of 16 °C temperature has reached lower values than in the case of wetting coke breeze. The maximum cake masses for all studied materials were measured on “as-supplied” materials. During sawdust wetting, liquid did not penetrate into the volume of the sawdust, particles of material remained exclusively on the surface of drops (Fig. 1).

Table 3 Masses of sawdust and coke breeze granule

Fig. 1 Wetting of Oak sawdust (fraction 0.5-1 mm, diameter 18 mm)

Subsequently, the 10% milk of lime was used as wetting medium. In the case of milk of lime, the lowest granule masses were measured. Already the early experiments showed that this medium does not wet sawdust. The wettability of coke was lower compared to water at 16 °C, which is confirmed by the values. In this case, the best results were achieved with oak sawdust, fraction <0.5 mm. Mass of granules was 0.87 g. The next was alder sawdust, and the lowest mass had granules of pine sawdust. The highest mass had again the granules of coke breeze, as shown in Table 3. As in the previous case, sawdust was minimally wetted and no penetration of liquid into the volume of sawdust occurred. The grains of the material accumulated on the lower section of a droplet surface (Fig. 2).

Fig. 2 Wetting of alder sawdust (fraction 0.5-1 mm, diameter 15 mm)

Self-granulating ability of sawdust was then tested with water at 60°C. Granulating of different kinds of sawdust with water at 60°C has noticeably improved as confirmed by data given in Table 3. It can be presumed that it was mainly due to the lower surface tension of water, which supported the actions occurring at the interface, that is, liquid absorption by solid matter, in this case sawdust. Top mass, i.e., 1.46 g, was obtained with oak sawdust in as-supplied state. Lower values were measured with sawdust of alder and the lowest, when wetting pine sawdust (0.87 g, fraction <0.5 mm). Granules of coke breeze had about 50 % higher mass. Resulting granules were solid and suitable for further manipulation (Fig. 3).

Mass of granules using 0.1% soap solution differed only marginally for each type of sawdust. The best results were achieved with oak sawdust, fraction <0.5 mm (0.90 g) and the worst results were measured with pine sawdust in as-supplied state, from 0.5 to 1mm (0.82 g), shown in Table 3. In this case, sawdust granules achieved quality comparable with the wetting of water at 60 °C, but below that of the non-ionic industrial surfactant shown in Figs. 4 and 5.

Based on these results, it can be concluded that the most suitable liquid medium for sawdust granulating is industrial surfactant, followed by water at 60°C, water at 16 °C and 0.1% soap solution. The worst results were obtained in the case of 10 % milk of lime.

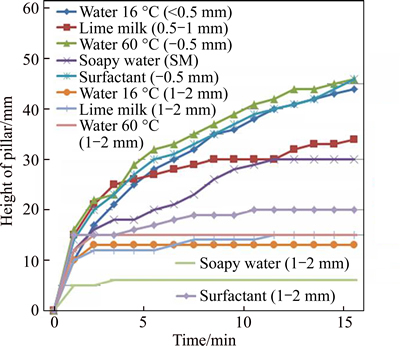

To assess granulability of tested materials, capillary soaking method was also performed, which is commonly used to assess granulability of fine-grain materials.

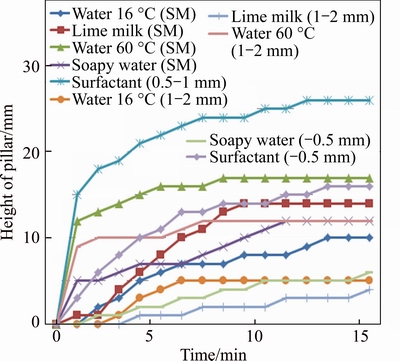

The same or comparable results were achieved for oak sawdust using capillary soaking, as in the case of free drop method. The highest water absorption was achieved using a surfactant (26 mm) (Fig. 6), followed by water at 60 °C, and water at 16 °C. The lowest values were measured in the case of soaking with 10% milk of lime (5 mm).

The highest values obtained by the capillary soaking with pine sawdust were achieved using a surfactant and water at 60 °C (Fig.7). The results differed only marginally and values reached about 16 mm. The results were worse in comparison with oak sawdust by approximately 10 mm. The lowest values were measured using milk of lime (1 mm), and of water at 16 °C (2mm).

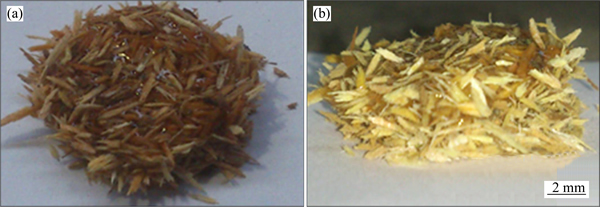

Fig. 3 Granules of alder sawdust (fraction 1–0.5 mm, diameter 15 mm, top (a) and side (b) view)

Fig. 4 Granules of alder sawdust (fraction 2-1 mm, diameter 15 mm, top (a) and side (b) view)

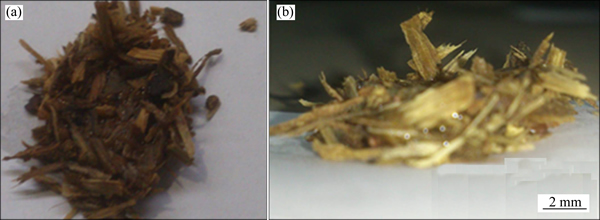

Fig. 5 Granules of pine sawdust (fraction <0.5 mm, diameter 15 mm, top (a) and side (b) view)

Fig. 6 Capillary soaking curves of oak sawdust

Fig. 7 Capillary soaking curves of pine sawdust

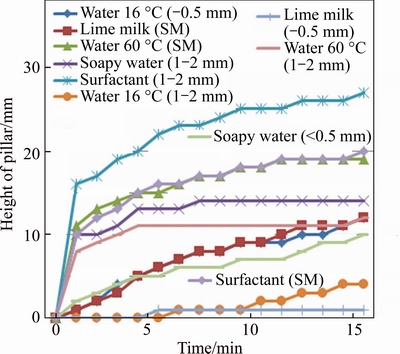

The soaking values for alder fluctuated around those of oak sawdust. The highest value of capillary soaking was achieved with the use of surfactant (Fig. 8), around 26 mm. Slightly worse results were obtained using water at 60 °C, about 20 mm, and soapy water (14 mm). The values obtained using a 10% milk of lime (1 mm) were the lowest.

The highest values were achieved in the case of the reference material, coke breeze, soaking. The maximum values of the capillary soaking were about 55.5% higher compared to oak sawdust or alder sawdust. The highest values were again obtained using a surfactant and values fluctuated around 45 mm (Fig. 9). Comparable results are obtained using water at 60 °C, with values of the capillary soaking reaching 44 mm. The lowest values of the wet column height achieved 12 mm, except for 0.1% sodium soap solution, which were about 5 mm, which is still a higher value than that in the case of sawdust.

Fig. 8 Capillary soaking curves of alder sawdust

Overall, we can conclude that in the case of capillary soaking, the best results among the studied sawdusts were achieved in the case of oak sawdust, followed by alder sawdust. The worst values were measured in the case of pine sawdust. For evaluation of the liquid medium, it can be concluded that the critical parameter was surface tension and thus the best results were obtained using industrial surfactant. The second best results were obtained with water at 60 °C and water at 16 °C. The worst results were obtained using a 0.1% sodium soap solution and 10% milk of lime. An important role in the granulability of sawdust, similarly to coke breeze, plays the type of sawdust and its granulometry.

Fig. 9 Capillary soaking curves of coke breeze

4 Conclusions

1) The key factors that influenced granulability and absorbtivity were surface tension of liquids, the type and particle size of sawdust.

2) Application of sawdust as a replacement for coke breeze in the agglomeration process is possible and justified. However, it is necessary to examine it further and look for possibilities of its optimization. There are several possibilities: pretreatment of materials, optimum combination of alternative fuels, and last but not least, finding a suitable medium for soaking in full-scale operation.

Acknowledgements

This work was supported by Slovak Research and Development Agency (APVV), Slovak Republic, No. APVV-0405-11 and Slovak research and development agency (SRDA), Slovak republic, No. VEGA- 1/0847/16.

References

[1] LONG Ho-ming, LI Jia-xin, WANG Ping. Influence of dioxin reduction on chemical composition of sintering exhaust gas with adding urea [J]. Journal of Central South University, 2012, 19(5): 1359-1363.

[2] JIANG Y, HUANG Z C, XU B, JIANG T. Lower fuel consumption model and air-flow segregation feeding system for sintering [J]. Journal of Central South University of Technology, 2011, 18(6): 1917-1923.

[3] FAN Xiao-hui, YU Zhi-yuan, GAN M, CHEN Xu-ling, JI Zhi-yun. Combustion behavior and influence mechanism of CO on iron ore sintering with flue gas recirculation [J]. Journal of Central South University, 2014, 21(6): 2391-2396.

[4] FAN X H, GAN M, JIANG T, YUAN L S, CHEN X L. Influence of flux additives on iron ore oxidized pellets [J]. Journal of Central South University of Technology, 2010, 17(4): 732-737.

[5]  J. Effect of biomass addition in the production of iron ore agglomerate on the environment [J]. Acta Metallurgica Slovaca-conference, 2014, 4(1): 66-73.

J. Effect of biomass addition in the production of iron ore agglomerate on the environment [J]. Acta Metallurgica Slovaca-conference, 2014, 4(1): 66-73.

[6]  Anton. Tenzidy [M]. Bratislava : Alfa,1977. (in Slovak)

Anton. Tenzidy [M]. Bratislava : Alfa,1977. (in Slovak)

[7]  Marie. Physical chemistry of surface and colloid systems [M]. Praha :

Marie. Physical chemistry of surface and colloid systems [M]. Praha :  , 2005.(in Czech)

, 2005.(in Czech)

[8]  hydrobiologie [M]. Praha:

hydrobiologie [M]. Praha:  , 2003. (in Czech)

, 2003. (in Czech)

[9] ATKINS Peter. Physical chemistry [M]. Oxford: W.H. Freeman & Company, 1982: 1095

[10]  Peter. Laboratory exercises of physical chemistry [M]. Bratislava: STU vBratislave, 1998. (in Slovak)

Peter. Laboratory exercises of physical chemistry [M]. Bratislava: STU vBratislave, 1998. (in Slovak)

[11] GARDNER D J. Application of the Lifshitz – van der Waals acid – base approach to determine wood surface tension components [J]. Wood and Fiber Science, 1996, 28(4): 422-428.

[12] GINDL Milojka, TSCHEGG Stefanie. Significance of the acidity of wood to the surface free energy components of different wood species [J]. Langmuir, 2002, 18(8): 3209-3212.

[13]  Magnus. Wetting phenomena on wood–factors influencing measurements of wood wettability. [D]. Stockholm: KTH–Royal Institute of Technology, 2000.

Magnus. Wetting phenomena on wood–factors influencing measurements of wood wettability. [D]. Stockholm: KTH–Royal Institute of Technology, 2000.

[14] SCHULZE Hans-Joachim. Physico-chemical elementary processes in flotation: Analysis from the point of view of colloid science including process engineering considerations (developments in mineral processing) [M]. Amsterdam: Elsevier, 1984.

[15] GRAY V Robert. Wetting, adhesion and penetration of surface coatings on wood [J]. Journal of the Oil and Colour Chemists’ Association, 1961, 44(1): 756-786.

[16] NGUYEN Thien, JOHNS E. William. Polar and dispersion force contributions to the total surface free energy of wood [J]. Journal of Wood Science, 1978, 2(1): 63-74.

[17] ZHANG H J, GARDNER D. J, WANG J Z, SHI Q S. Surface tension, adhesive wettability and bondability of artificially weathered CCA treated southern pine [J]. Forest Product Journal, 1997, 47(10): 69-72.

[18] GINDL Milojka, SINN Gerhard, GINDL Wolfgang, REITERER Alexander, TSCHEGG Stefanie. A comparison of different methods to calculate the surface free energy of wood using contact angle measurements [J]. Colloids and Surfaces. A: Physicochemical and Engineering Aspects, 2001, 181(3): 279-287.

[19] MILES T R. Alkali deposits found in biomass power plants. A preliminary investigation of their extend and nature [R]. Colorado: National Renewable Energy Laboratory, 1995.

[20]  Z. Physical tables [M]. Liberec: TUL, 2001. (in Czech)

Z. Physical tables [M]. Liberec: TUL, 2001. (in Czech)

[21] EALY J B, EALY J L. Visualizing chemistry, investigations for teachers [M]. Washington, DC: The American Chemical Society, 1995.

[22] MOHAMMADI Z, DUMMER M H P. Properties and applications of calcium hydroxide in endodontics and dental traumatology [J]. International Endodonic Journal, 2011, 44(8): 697-730.

[23] CULLUM D C. Introduction to surfactant analysis [M]. New York: Blackie Academic, 1994.

[24]  . Pelletizing of fine-grained materials [M]. Bratislava: ALFA, 1976. (in Slovak)

. Pelletizing of fine-grained materials [M]. Bratislava: ALFA, 1976. (in Slovak)

(Edited by HE Yun-bin)

Cite this article as:

Jozef,

Jozef,  Jaroslav,

Jaroslav,  Zuzana,

Zuzana,  ,

,  , Legemza Jaroslav. Evaluation of granulability and absorbtivity of biomass in agglomeration mixture [J]. Journal of Central South University, 2017, 24(10): 2260–2265.

, Legemza Jaroslav. Evaluation of granulability and absorbtivity of biomass in agglomeration mixture [J]. Journal of Central South University, 2017, 24(10): 2260–2265.

Received date: 2016-05-05; Accepted date: 2016-12-23

Corresponding author: Hudák Jozef, PhD; Tel: +421-55-602-3165; E-mail: jozef.hudak.2@tuke.sk

Abstract: The granulability and absorbtivity of sawdust and coke breeze were investigated. These properties are important within the preparation of agglomeration charge. They have a significant impact on plynodynamic batch conditions. Ability of materials to wet is a fundamental condition of granulability of materials. Wettability and water absorption of wood with liquids is generally significantly affected by their chemical structure. The important factors affecting the wetting process are undoubtedly the wood moisture content, the value of the surface tension of liquid media and their chemical composition. With increasing moisture content of wood, the time to equilibrium rises. Determination of water absorption and granulability of sawdust was conducted to seek their possible use as a partial replacement of coke dust in the production of the agglomerate. Experiments have been realized with alder, oak and pine sawdust and reference material-coke breeze. These materials were divided to four classes of granularity: supplied material, 1-2 mm,0.5-1 mm and less than 0.5 mm. And different liquid media were used: water 16 °C, water 60 °C, soapy water, lime milk and surfactant.

[6] Anton. Tenzidy [M]. Bratislava : Alfa,1977. (in Slovak)

[7] Marie. Physical chemistry of surface and colloid systems [M]. Praha : , 2005.(in Czech)

[8] hydrobiologie [M]. Praha: , 2003. (in Czech)

[9] ATKINS Peter. Physical chemistry [M]. Oxford: W.H. Freeman & Company, 1982: 1095

[20] Z. Physical tables [M]. Liberec: TUL, 2001. (in Czech)

[23] CULLUM D C. Introduction to surfactant analysis [M]. New York: Blackie Academic, 1994.

[24] . Pelletizing of fine-grained materials [M]. Bratislava: ALFA, 1976. (in Slovak)