Effect of thermal processing on microstructure and mechanical properties of AZ80 magnesium alloy

XU Hong-yan(徐宏妍)1, 2, WANG Qiang(王 强)2, ZHANG Zhi-min(张治民)2

1. National Key Laboratory for Electronic Measurement Technology, North University of China,

Taiyuan 030051, China;

2. School of Materials Science and Engineering, North University of China, Taiyuan 030051, China

Received 12 June 2008; accepted 5 September 2008

Abstract:

The influences of deformation temperature and deformation degree on the microstructure and mechanical properties of AZ80 magnesium alloy were investigated by the adoption of isothermal plain strain compression experiment. The results show that thermal compression processing can refine the grain size and the tensile strength of all the deformed AZ80 magnesium alloys is increased to the maximum of 320 MPa. With the increasing of deformation temperature, the tensile strength decreases; with the increasing of the deformation degree, the tensile strength increases significantly in the temperature range of 200-300 ℃ and becomes stable at temperature higher than 300 ℃. During the compression processing of AZ80 magnesium alloys, at lower temperature (<300 ℃), dynamic recrystallization is incomplete and a certain hardening effect is preserved, which makes great effect of deformation degree on the properties. At higher temperature (>300 ℃), dynamic recrystallization is complete and refined grain strengthening is dominant, leading to little effect of deformation degree on mechanical properties.

Key words:

AZ80 magnesium alloy; thermal deformation; microstructure; mechanical properties;

1 Introduction

Magnesium alloys have been paid great attention in application in the automobile, 3C and navigation/defense industries for their excellent properties, such as lightweight, high specific strength, superior damping characteristics, and good electromagnetic shielding performance[1-2]. One of the challenges for wide application is their low absolute strength and elongation. Recently, many efforts have been paid to improve the properties of magnesium alloys[3-5].

By affecting the process of dynamic recovery and dynamic recrystallization, the thermal processing will determine the sub-structure and grain size of magnesium alloys. With deformation temperature increasing, the microstructures of hot compression deformed AZ70 magnesium alloy are transformed from mixed crystal and uncompleted strip-shaped recrystallization to completed recrystallization[6]. It is also found that grain size decreases with increasing extrusion ratio in AZ80 alloy [7]. The smaller the grain size, the better the integrated mechanical properties[8]. So, the change of process parameters affects the mechanical properties of deformed magnesium alloy products[9]. It is believed that important parameters in deformation process influencing grain refinement are deformation temperature and deformation degree[7].

In this work, AZ80 magnesium alloys were deformed at different deformation temperatures and deformation degrees by isothermal plain strain compression experiment, and the influence of thermal process on the microstructure and mechanical properties was investigated.

2 Experimental

The studied material was AZ80 Mg alloy with chemical compositions listed in Table 1. The as-cast AZ80 Mg alloy bars were first homogenized at 450 ℃ for 16 h, and then cut along the axial direction to plates with the size of 150 mm in length, 17 mm in width and different thickness of 2, 4, 6, 8 and 10 mm. These plates were deformed isothermally at 200, 250, 300, 350 and 400 ℃ under compression to the thickness of 1 mm, with the corresponding deformation degree of 0.69, 1.39, 1.79,2.08 and 2.30, respectively. After the compression deformation, all specimens were cooled in the water to room temperature, followed by aging (T5) treatment.

Table 1 Chemical compositions of AZ80 magnesium alloys (mass fraction, %)

The microstructure and mechanical properties of the as-cast, homogenized and different isothermally deformed AZ80 magnesium alloys were studied by optical microscope and tensile test.

Following standard metallographic procedures, the polished surfaces of the samples were etched using a solution of 2% oxalic acid + 2% nitric acid, and their microstructures were examined with Image MAT A1 optical microscope. The examined surface of deformed samples was perpendicular to the compression direction.

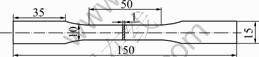

The tensile tests were performed, according to the standard of GB/T228—2002, by WAW-Y500A electronic testing machine. And the schematic diagram of the tensile sample is shown in Fig.1.

Fig.1 Schematic diagram of tensile sample (mm)

3 Results and discussion

3.1 Effect of thermal processing on microstructure of AZ80 alloy

Fig.2(a) shows the microstructure of the as-cast AZ80 ingot. It is clearly shown that the grain size of the as-cast alloy is 80-100 μm, and the second phase β(Mg17Al12) is accumulated at the grain boundary of α-Mg matrix[10]. During the solidification of AZ80, the segregation of second-phase β(Mg17Al12) and strain are induced by the fast cooling and non-equilibrium crystallization, which will lead to the decrease of thermoplasticity and deterioration of processing performance, so the cast ingots are often homogenized before thermal plastic process[11]. By homogenization at 450 ℃ for 16 h, the stress and segregation in crystals are eliminated and the texture is modified, as shown in Fig.2(b). While compared with the as-cast alloy, the grain size of homogenized AZ80 alloy is coarser.

Microstructures of T5 treated AZ80 alloys are shown in Fig.3. These alloys were compressed at temperatures of 200, 250, 350 and 400 ℃ with the same deformation degree of 1.79. By comparing Fig.3 with

Fig.2 Microstructures of AZ90 alloy: (a) As-cast; (b) Homo- genized

Fig.2, the microstructures are greatly refined after thermal deformation. The refined equiaxed grains have already been observed in AZ80 magnesium alloy after multiple forging processing[12].

Small size grains are found at low deformation temperatures (Figs.3(a) and 3(b)), which means that the dynamic recrystallization occurs[13-14]. The distribution of secondary phase β(Mg17A112) particles in the α-matrix indicates that the dynamic recrystallization is incomplete. At higher temperatures (350 ℃ and above), the dynamic recrystallization is complete and a homogeneous microstructure is obtained, as shown in Figs.3(c) and 3(d).

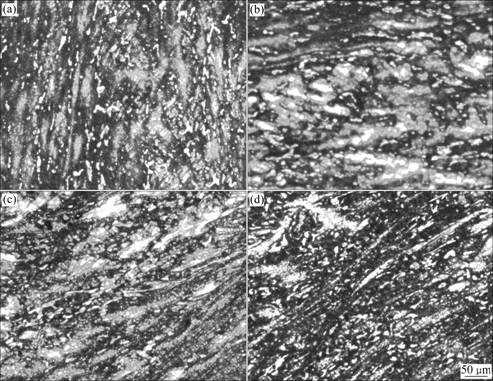

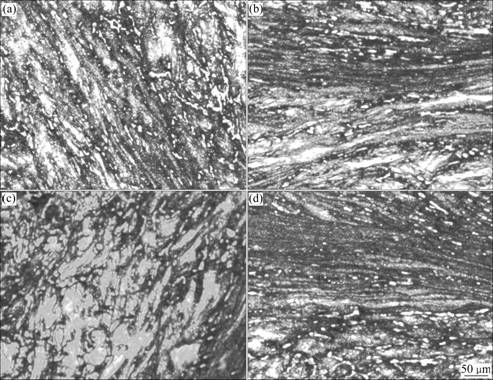

At the deformation temperature of 300 ℃, the microstructures of T5 treated AZ80 alloy with different deformation degrees are shown in Fig.4.

It can be clearly seen that fine equiaxed grains are scattered along the parallel streamline with the retaining of some deformed texture crushed along the direction perpendicular to the pressure (Fig.4(a)), which indicates that the dynamic recrystallization occurs partially. With increasing deformation degree, dynamic crystallization becomes successively, grain size is refined and the volume fraction of new grains increases, but a certain of deformed textures still retains (Fig.4(b)). With the continuous increase of deformation degree, the re- crystallization textures become abundant and new grains without distortion are formed inside and along the boundaries of the original grains (Figs.4(c) and 4(d)). Most of the new grains have recrystallization texture.

Fig.3 Microstructures of AZ80 alloys deformed at different temperatures: (a) 200 ℃; (b) 250 ℃; (c) 350 ℃; (d) 400 ℃

Fig.4 Typical microstructures in AZ80 alloys (T5) deformed at 300 ℃ with different deformation degrees: (a) 0.69; (b) 1.39; (c) 1.79; (d) 2.08

It is obvious that, during the isothermal compression deformation, when the deformation degree is greater than a certain critical value, dynamic recrystallization begins to take place. With continuous increase of deformation degree, the recrystallization is accelerated, and the coarse grains and segregation in as-cast alloy are eliminated effectively. At the same time, refined and equiaxed crystal tissues are obtained without distortion. It has been found that large strain on hot rolled AZ61A magnesium alloy produces a more homogenous and equiaxed grains[15].

3.2 Mechanical properties of deformed AZ80 alloy

The tensile strength and elongation of the as-cast AZ80 alloy are measured as 155 MPa and 4%, respectively. Compared with the as-cast one, the mechanical properties of homogenized AZ80 alloy are changed. The tensile strength decreases to 140 MPa, and elongation increases to 5%. The tensile strength of deformed AZ80 samples after T5 treatment is shown in Fig.5.

Fig.5 Tensile strength of Z80 alloys deformed by isothermal plain strain compression: (a) Effect of deformation degree; (b) Effect of deformation temperature

The effect of deformation degree on the tensile strength is varied in different range of deformation temperature (Fig.5(a)). In the two-phase zone (200-300 ℃), the tensile strength increases obviously with the increasing of deformation degree; while in single-phase zone (350-400 ℃), the effect curves show “M” type. The tensile strength increases first with deformation degree to the maximum at deformation degree of 1.39, followed by decreasing at deformation degree of 1.79, increasing at deformation degree of 2.08 and decreasing slowly again at deformation degree of 2.30.

In the temperature range of 200-250 ℃, the change in tensile strength with increasing temperature is indistinctive. In the range of 300-400 ℃, the effect of deformation temperature is evident, and the greatest tensile strength falling appears in the samples with deformation degree of 2.08 and 2.30 (Fig.5(b)).

When AZ80 is deformed in lower temperature range (200-300 ℃, two-phase zone), the dynamic crystallization is incomplete and second phase strengthening mechanism is dominant. In higher temperature range (350-400 ℃, single-phase zone), a full dynamic recrystallization takes place and fine-grain strengthening mechanism is dominant, which leads to the little effect of deformation on the mechanical properties of AZ80 alloys. The mechanical behavior of AZ80 alloys is analogous to that of AZ31 alloys[15]. Therefore, the mechanical properties of hot-deformed AZ80 alloys at room temperature are directly dependent on their microstructures, and deformation degree has no direct effects on the tensile strength.

4 Conclusions

1) The grain size of AZ80 alloys is refined by thermal compression process. With the increasing of deformation temperature, the grain size is first refined and then becomes coarse. While with the increasing of deformation degree, grain size decreases and the texture becomes more uniform.

2) Tensile strength of the deformed AZ80 alloys is increased obviously by thermal compression. When AZ80 alloy is deformed at 350 ℃ with deformation degree of 2.30, the tensile strength of AZ80 alloy reaches the maximum of 320 MPa. This is due to the preserving of deformation strengthening effect together with the refined grain size.

References

[1] ALVES H, KOSTER U, AGHION E, ELIEZER D. Environmental behavior of magnesium and magnesium alloys [J]. Material Technology, 2001, 16(2): 110-126.

[2] BAGHNI I M, WU Y S, Li J Q, DU C W, ZHANG W. Mechanical properties and potential applications of magnesium alloys [J]. Trans Nonferrous Met Soc China, 2003, 13(6): 1253-1259.

[3] MORDlKE B L, EBERT T. Magnesium properties—applications— potential [J]. Materials Science and Engineering A, 2001, 302: 37-45.

[4] MUELLER K, MUELLER S. Severe plastic deformation of the magnesium alloy AZ31 [J]. Journal of Materials Processing Technology, 2007, 187/188: 775-779.

[5] HSIANG S H, KUO J L. An investigation on the hot extrusion process of magnesium alloy sheet [J]. Journal of Materials Processing Technology, 2003, 140: 6-12.

[6] GUAN Shao-kang, WU Li-hong, WANG Li-guo. Flow stress and microstructure evolution of semi-continuous casting AZ70 Mg-alloy during hot compression deformation [J]. Trans Nonferrous Met Soc China, 2008, 18(2): 315-320.

[7] UEMATSU Y, TOKAJI K, KAMAKURA M, UCHIDA K, SHIBATA H, BEKKU N. Effect of extrusion conditions on grain refinement and fatigue behaviour in magnesium alloys [J]. Materials Science and Engineering A, 2006, 434(1/2): 131-140.

[8] EL-MORSY A, ISMAIL A, WALY M. Microstructural and mechanical properties evolution of magnesium AZ61 alloy processed through a combination of extrusion and thermomechanical processes [J]. Materials Science and Engineering A,2008, 486(1/2): 528-533.

[9] HSIANG S H, LIN Y W. Investigation of the influence of process parameters on hot extrusion of magnesium alloy tubes [J]. Journal of Materials Processing Technology, 2007, 192/193: 292-299.

[10] GUO Qiang, YAN Hong-ge, CHEN Zhen-hua, ZHANG Hui. Fracture behaviors of AZ80 magnesium alloy during multiple forging processes [J]. Trans Nonferrous Met Soc China, 2006, 16: 922-926.

[11] ZHANG Hui, YAN Yun-qi, WENG Wen-ping, ZHONG Hao, CHEN Qi. Effects of hot extrusion and annealing treatment on microstructures properties and texture of AZ31 Mg alloy [J]. Trans Nonferrous Met Soc China, 2006, 16: s1732-s1735.

[12] GUO Q, YAN H G, CHEN Z H, ZHANG H. Grain refinement in as-cast AZ80 Mg alloy under large strain deformation [J]. Materials Characterization, 2007, 58: 162-167.

[13] BAI Jing, SUN Yang-shan, XUE Feng, XUE Shan, QIANG Jing, TAO Wei-jian. Effect of extrusion on microstructures, and mechanical and creep properties of Mg-Al-Sr and Mg-Al-Sr-Ca alloys [J]. Scripta Materialia, 2006, 55: 1163-1166.

[14] BEN-HAROUSH M, BEN-HAMU G, ELIEZER D, WAGNER L. The relation between microstructure and corrosion behavior of AZ80 Mg alloy following different extrusion temperatures [J]. Corrosion Science,2008, 50(6): 1766-1778.

[15] ZHANG Zhi-min, WANG Qiang, LI Bao-cheng. Effect of warm forming on the mechanical properties of AZ31 magnesium alloy [J]. Materials Science and Technology, 2005, 13(6): 637-639.

(Edited by YANG Bing)

Corresponding author: XU Hong-yan; Tel: +86-351-3557485; E-mail: xuhongyan@nuc.edu.cn