- Abstract:

- 2 Experimental▲

- 3 Results and discussion▲

- 4 Conclusions▲

- References

- Figure

- Fig.1 Effect of aging period on the viscosity of asphalt binder

- Fig.2 Effects of aging process on complex shear modulus of asphalt binders

- Fig.3 Effects of aging process on phase angle of asphalt binders

- Fig.4 |G*|?sin δ of different asphalt binders

- Fig.5 Composition of creep deformation for asphalt binder suffering 30 h PAV

- Fig.6 Creep strain curves of different asphalt binders at 0 ℃

J. Cent. South Univ. Technol. (2008) 15(s1): 298-301

DOI: 10.1007/s11771-008-367-2

![]()

Rheological characteristics of aged asphalt binder

LIU Cong-hui (刘聪慧), WU Shao-peng(吴少鹏), LIU Quan-tao(刘全涛), ZHU Guo-jun(朱国军)

(Key Laboratory of Silicate Materials Science and Engineering of Ministry of Education,

Wuhan University of Technology, Wuhan 430070, China)

Abstract:

Different aging levels (RTFOT,PAV-10h, PAV-20h and PAV-30 h) of asphalt binders with various mass ratios of mineral powder to asphalt (0, 0.4, 0.8, 1.2, 1.6, 2.0) were used to investigate the rheological properties of aged asphalt binders with respect to their short and long terms aging characteristics. Viscosity test, dynamic shear test and creep test were conducted. The test results indicate that the viscosity of aged asphalt binder increases sharply with the extension of aging period. Complex shear modulus of aged asphalt increases, which indicates that the stiffness of asphalt binders can increase. The phase angle for aged asphalt binders reduces, which indicates that the elastic portion for viscoelastic property of asphalt binders increases. |G*|?sin δ increases after aging procedure which means that the fatigue resistance becomes poor. The creep test results show that creep strain curves varies remarkably for virgin and aged asphalt binders. The total strain during loading period and the permanent strain decreases significantly for aged asphalt binders, which implies that the elastic portion increases and the viscous portion decreases.

Key words:

1 IntroductionOxidative aging of asphalt is a primary cause of binder hardening in pavement, thus contributing to various forms of pavement failures. An essential element of predicting long-term pavement performance is to understand binder oxidative aging and its effect on engineering properties[1]. Two laboratory procedures were used in the superpave testing and specification system for aging of binders prior to measuring their rheological properties, namely the rolling thin film oven test (RTFOT), which simulates the aging of asphalt mixture during mixture production, laying and compaction, and the pressure aging vessel (PAV) to simulate the aging of asphalt pavement in service[2-3]. It is widely accepted that there is a trade-off within the performance of the virgin and aged asphalt, and that asphalt rheology can provide preliminary indications of the resulting asphalt mixture performance. But researches are seldom involved in the performance of aged asphalt binders with various mass ratios of mineral powder to asphalt. The objective of asphalt binder aging is to simulate the aging hardening during the construction stage (short term aging) and service period of pavement (long term aging) and then carry out rheological investigations to study the effect of aging on the asphalt binder property[4-5].

In this paper, the aged asphalt binders were prepared with different aging periods and filler concentration.

Related experiments were conducted to investigate the rheological properties of asphalt binders, including viscosity test, dynamic shear test and shear creep test. The effects of aging and mass ratios of mineral powder to asphalt on the rheological characteristics were analyzed.

2 Experimental

2.1 Raw materials

The asphalt chosen as case study for the present work is base asphalt (AH-90) provided by KOCH Asphalt Co. Ltd (Hubei Province, China). The basic properties are listed in Table 1. Limestone powder is adopted as mineral filler to prepare asphalt binder, with density of 2.83 g/cm3, major chemical compounds are CaO 51.5% and SiO2 1.76%. The particle size of filler is less than 0.075 mm.

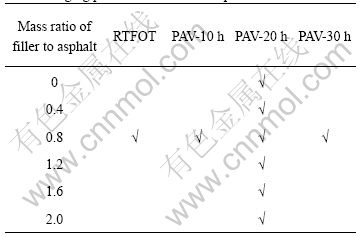

2.2 Test specimen preparation and test procedure

The asphalt binders were obtained by a stirrer at 145 ℃. The mass ratios of mineral powder to asphalt were 0, 0.4, 0.8, 1.2, 1.6, and 2.0. To obtain homogenous asphalt-filler mastics, the fillers were added slowly into the preheated pure asphalt and mixed for 1.5 h. Two aging methods used to simulate the short term and long term age hardening of asphalt binders are RTFOT and RTFOT+PAV, respectively. The aging type and procedure are presented in Tables 2-3.

Table 1 Basic properties of pure asphalt AH-90

Table 2 Test procedure for two types of aging method

Table 3 Aging procedure of various asphalt binders

A brookfield rotational viscometer is adopted to conduct the viscosity test[6]. The viscosity test temperatures are 60-175 ℃. A DSR (MCR101, Anton Paar, made in Austria) is performed and the parameters determined are the complex modulus and phase angle. Measurements are conducted at frequency range from 0.1 to 100 rad/s at 20 ℃. The test started after the temperature has remained at the desired temperature ±0.1 ℃ for at least 10 min and then conducted the frequency sweep from higher levels to the lower ones. A creep experiment is performed by DSR under a fixed imposed shear stress of 0.1 MPa and using 200 s loading time followed by 1 000 s recovery time under the test temperature of 0 ℃[7].

3 Results and discussion

3.1 Viscosity test

As is known that the increase of temperature would normally be followed by the reduction of the viscosity. The effects of aging on the viscosity of asphalt binder at different temperatures are shown in Fig.1. It can be seen that the viscosities increase with the increase of aging time. However, the increase trend of viscosity for asphalt binders becomes slower when asphalt binder suffers 20 h PAV aging and the influence of aging on the viscosity becomes lower. The reason may be that when the asphalt binders suffer aging, the molecules of asphalt binder layer has an oxidation reaction, which will increase the stiffness of asphalt binders. But the degree of oxidation reaction will decrease with the increase of asphalt binder thickness and the falling of the reacting molecules. So the discrepancy between different aging degrees becomes unobvious along with the increase of aging degree, which is similar to the aged asphalt without filler.

Fig.1 Effect of aging period on the viscosity of asphalt binder

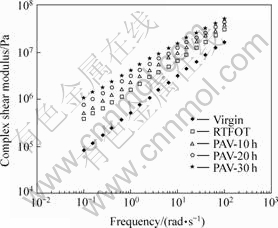

3.2 Dynamic shear rheometer test

Rheological data obtained from the DSR frequency sweep can be expressed in terms of the complex modulus |G*|, which is calculated as the ratio of maximum shear stress to the maximum shear strain. The complex shear modulus (|G*|) of asphalt binders with various aging period are shown in Fig.2. It can be observed that |G*| increase with the increase of frequency, for aged asphalt binders is consistent with the virgin one and age hardening has significant effect on the rheology of asphalt binders at low frequency region. The aging of asphalt binders affects |G*| significantly. Especially for the asphalt binders suffering RTFOT aging procedure, the growth rate of |G*| exceeds 70%. With the increase of aging time, the rising trend of |G*| between different asphalt binders becomes lower.

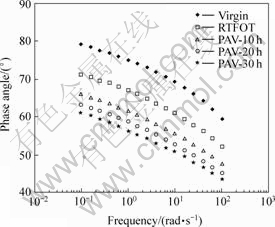

Phase angle, as a direct indicator of the elastic- viscous properties of the asphalt binder, represents the difference value between the time of stress and strain[8]. For a kind of pure elastic material or pure viscous material, the phase angle is 0? or 90?, respectively. The phase angles for asphalt binders with various aging period at 20 ℃ are shown in Fig.3.

Fig.2 Effects of aging process on complex shear modulus of asphalt binders

Fig.3 Effects of aging process on phase angle of asphalt binders

The phase angle decreases with the increase of frequency for all asphalt binders, which implies the frequency dependency of phase angle. Phase angles decreases greatly when asphalt binders suffer aging procedure, which indicates that the elastic portion of asphalt binders can be significantly improved. For asphalt binder suffering PAV-20 h aging procedure, the phase angle reduces about 15?. The reduction of phase angle will contribute the resistance to the high temperature stability for asphalt binders and mixtures.

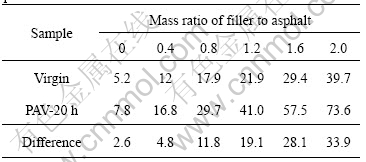

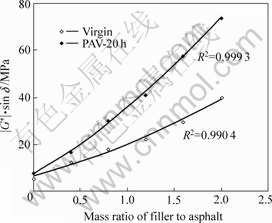

|G*|?sin δ obtained from the test is a key factor indicating the resistance to fatigue cracking. It is noted that the fatigue cracking potential increases as |G*|?sin δ increases[8]. Table 4 and Fig.4 show |G*|?sin δ for the various asphalt binders at a fixed angular frequency of 100 Hz and 20 ℃. The data for all the asphalt binders is reasonable well where |G*|?sin δ shows a quadratic law relationship with the mass ratio of filler to asphalt as Eqn.(1):

|G*|?sin δ=AF2+BF+C (1)

where |G*| is complex modulus; δ is the difference value between the time of stress and strain; F is mass ratio of filler to asphalt; A, B and C are the material regression coefficients.

Table 4 |G*|?sin δ of asphalt binders with different aging periods MPa

Fig.4 |G*|?sin δ of different asphalt binders

It can be seen that the addition of filler makes the performance of fatigue resistance decrease. Especially when the mass ratio of filler to asphalt is 1.6, |G*|?sin δ of the asphalt binder suffering PAV-20 h is one time more than that without aging.

3.3 Shear creep test

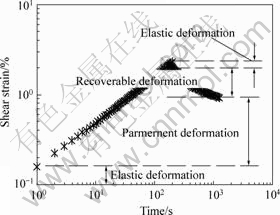

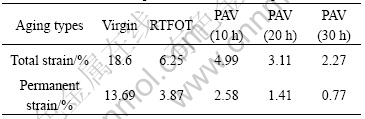

The rheological property of aged asphalt binders can also be studied by shear creep test. Fig.5 illustrates the initial elastic response and its elastic recovery of asphalt binder suffering 30 h PAV aging procedure to the applied load when the load is removed. It can be seen that the creep curve can be divided into three regions: Elastic deformation, permanent deformation and recoverable deformation. The slope of the response curve in the creep portion eventually becomes small. After the release of the applied stress, there is an immediate recovery of the elastic deformation followed by the gradual, time dependent recoverable elastic deformation. The residual strain, which exists after complete elastic recovery, is the non-recoverable permanent deformation. Shear creep test results are illustrated in Fig.6 and Table 5 for different types of aged asphalt binders with mass ratio 0.8 of mineral powder to asphalt at 0 ℃.

Fig.5 Composition of creep deformation for asphalt binder suffering 30 h PAV

Fig.6 Creep strain curves of different asphalt binders at 0 ℃

It can clearly be observed from Fig.6 that the development of creep strain curves for aged asphalt binder are varied remarkably, which confirms that the rheological characteristics of asphalt binders change. On one hand, the total strain of asphalt binders can greatly be reduced after aging procedure. On the other hand, the elastic strain and the recoverable elastic strain decrease, which result in the reduction of permanent strain of asphalt binders.

Table 5 Total strain and permanent strain for asphalt binders

It can also clearly be seen that the total strain of asphalt binder suffering PAV-30 h aging procedure is 12.2% of the virgin strain and the permanent strain is just 5.6%, which indicates that the aging procedure increases the performance of rutting resistance. At the same time the elastic strain decreases from 0.41% to 0.16% and recoverable elastic strain decreases from 4.5% to 1.34%.

4 Conclusions

1) The viscosity of asphalt binders increases with the increase of aging time, which can enhance the resistance to the flow deformation for asphalt binders, especially at high temperature.

2) As a result of the aging procedure, the mechanical properties of asphalt binders become more solid-like, as indicated by increased complex modulus and decreased phase angle, which will stiffen the asphalt binders and contribute to high resistance to permanent deformation for the binders and mixtures.

3) |G*|?sin δ increases with the increase of the aging period, which means poor fatigue resistance after aging process.

4) The total strain, permanent strain and recoverable strain reduce for aged asphalt binders during the shear creep test.

References

[1] CHEN J S, HUANG L S. Developing an aging model to evaluate engineering properties of asphalt paving binders[J]. Materials and Structures, 2000, 33(233): 559-565.

[2] BAHIA H U, KAMEL N I. Rheological evaluation of engineered asphalt binders[J]. New Materials and Methods of Repair, 1994, 804: 97-113.

[3] LU Xiao-hu, ISACSSON U. Effect of ageing on bitumen chemistry and rheology[J]. Construction and Building Materials, 2002, 16(1): 15-22.

[4] BAHIA H U, ANDERSON D A. Pressure aging vessel (PAV): A test to simulate rheological changes due to field aging[M]. ASTM Special Technical Publication, 1995: 67-88.

[5] ZHANG Zheng-qi, ZHANG Wei-ping, LI Pin. Ratio of filler bitumen of asphalt mixture[J]. Journal of Chang’an University: Natural Science Edition, 2004, 24(5): 7-10. (in Chinese)

[6] JTJ 052—2000. Standard test methods of bitumen and bituminous mixtures for highway engineering[S]. (in Chinese)

[7] COLLOP A C, AIREY G D, KHANZADA S. Creep testing of bitumens using the dynamic shear rheometer[J]. The International Journal of Pavement Engineering, 2002, 3(2): 107-116.

[8] HUANG S C, et al. Characterization of aging effect on rheological properties of asphalt-filler systems[J]. International Journal of Pavement Engineering, 2007, 8(3): 213-223.

(Edited by CHEN Can-hua)

Foundation item: Project(200631800076) supported by 2006 West Science and Technology Project of the Department of TransportationReceived date: 2008-06-25; Accepted date: 2008-08-05

Corresponding author: LIU Cong-hui, Master; Tel: +86-27-87162595; E-mail: chlaw@whut.edu.cn

- Rheological characteristics of aged asphalt binder