Effect of coating thickness on microstructures and mechanical properties of C/Cu/Al composites

CAO Zhuo-kun(曹卓坤), YAO Guang-chun(姚广春), LIU Yi-han(刘宜汉)

School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China

Received 28 July 2006; accepted 15 September 2006

Abstract:

The different copper coatings with thickness varying from 0.3 μm to 1.5 μm were deposited on carbon fibers using either electroless plating or electroplating method. The coated fibers were chopped and composites were fabricated with melting aluminum at 700 ℃. The effect of the copper layer on the microstructure in the system was discussed. The results show that the copper layer has fully reacted with aluminum matrix, and the intermetallic compound CuAl2 forms through SEM observation and XRD, EDX analysis. The results of tensile tests indicate that composites fabricated using carbon fibers with 0.7-1.1 μm copper coating perform best and the composites turn to more brittle as the thickness of copper coating increases. The fracture surface observation exhibits good interface bonding and ductility of the matrix alloy when the thickness of copper coating is about 0.7-1.1 μm.

Key words:

carbon fiber; aluminum matrix composites; copper coating; tensile strength; interface bonding;

1 Introduction

Carbon fibers reinforced aluminum matrix composites have attractive properties for a variety of automotive and aerospace applications for their light specific mass, high modulus, high strength and stiffness [1-2]. However, the development of carbon fibers reinforced aluminum matrix composites was hindered by the weak wetting of the fiber with molten aluminum and formation of brittle reaction products at the interface [3].

In order to overcome these interface problems, the coatings can be deposited on fibers using various methods, such as electroless deposition, electroplating, vapour deposition and plasma spraying [4-6]. In particular, the copper coating deposited on carbon fibers improves the wetting ability and reduces the chemical reaction at the interface [7-8].

Alterable techniques, including electroless deposition and electroplating method, could be adopted to obtain copper coating on carbon fibers [7-9]. Electroless deposition was usually used for thinner coating due to the low deposition rate of the solution, and the copper layer is uniform and fine-grained. While a thicker coating can be obtained in an electroplating bath, which is more cost efficient [9].

Since copper was easy to dissolve into molten aluminum, it is obvious that the thickness of the copper layer would greatly affect the fabrication process and properties of the composites. However, as to C/Cu/Al system, most discussions were made on the effect of the copper coating as a metallic layer [7-8], while little comments were made on the effects of coating thickness. In this paper, both electroless and electroplating methods were realized to form copper layer with different thicknesses on carbon fibers, and the influence of the thickness of copper coating was discussed.

2 Experimental

2.1 Preparation of copper coated fibers

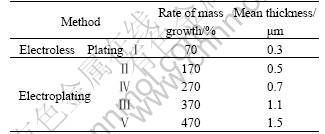

Carbon fibers used was 12 K fibers offered by Shenyang Anke Company, and its diameter was 7 μm. Thinner copper coating with thickness of about 0.3 μm was realized using an electroless plating method, which was essentially based on dipping of the fibers performs in three successive baths: sensitization, activation and coating[10]. Thicker coating was electroplated on carbon fibers in acid copper sulfate bath, and the solution was composed by 180 g/L H2SO4, 60g/L Cu2SO4 and 5mL additive agents [9]. The rate of mass growth of the fiber bundle and mean thickness of the coating are shown in Table 1.

Table 1 Properties of different copper coatings

2.2 Preparation of composites

Copper coated fibers were immersed into 2%(mass fraction) HBO3 to improve its oxidation resistance and chopped to about 3-5 mm in length after dried. The composites were prepared at 700 ℃ by a stirring-cast process. The whole stirring time was 5 min and iron mould used was preheated to 400 ℃. Several specimens containing 4%(volume fraction) carbon fibers with different copper coatings shown in Table 1 were prepared for tensile test and microstructure observation.

2.3 Characterization of composites

SXX-550 scanning electron microtelescope was used for microstructure and fracture surface observation. The tensile tests were carried out on the MTS-810 machine with the strain rate of 2 mm/min.

3 Results and discussion

3.1 Microstructure

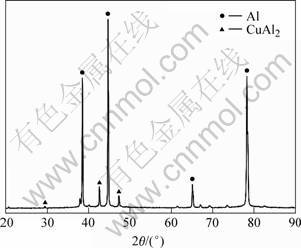

Copper as a usual element to form aluminum alloy can improve the wetting property at the interface between fibers and molten aluminum, which makes it is possible to add carbon fibers to the melt. At such a high temperature, copper is easy to dissolve into the melt and react with aluminum. XRD was used to determine the phases contained in the composites, and the XRD pattern of the sample fabricated by carbon fibers with the thickest copper coating in this study (see Table 1) is shown in Fig.1. The result indicates that there is little copper is remained after fabrication processing and almost all the copper layer turns to intermetallic compound CuAl2.

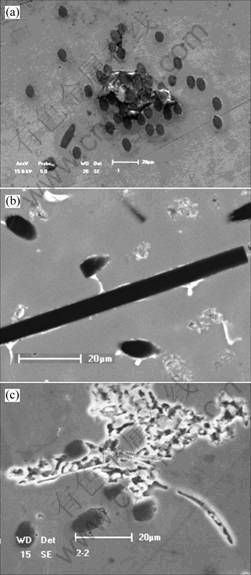

Fig.2 shows SEM images of the C/Cu/Al composites fabricated with coated fibersⅠ, Ⅲ, Ⅴ(shown in Table 1). When the coating layer is as thin as 0.3 μm, agglomeration of the fibers observed reveals bad wetting ability of the fibers towards molten aluminum because almost all copper layers are dissolved into the melt during composite process and results to direct contact of carbon and aluminum, whose contact angle is over 120?. When the coating is thicker, a uniform distribution of the fibers is observed, as shown in Figs.2(b) and (c). Thus, a certain thickness of the copper coating is needed to improve the wetting ability at the interface effectively.

Fig.1 XRD pattern of composites fabricated with 1.5 μm thickness copper coated carbon fibers

Fig.2 SEM images of composites with different coated fibers: (a) 0.3 μm; (b) 0.7 μm; (c) 1.5 μm

With the increase of the thickness of copper coating, more CuAl2 is generated and its size increases apparently. Most of this brittle phase is scattered in the matrix, while thin CuAl2 film is generated directly at the interface when the thickness of copper coating is not less than 0.7 μm, which leads to a rough interface layer and is supposed to be good for stress transfer [11]. However, thick CuAl2 layer at the interface and big CuAl2 phase in the matrix may cause brittle failure of the matrix.

3.2 Tensile properties

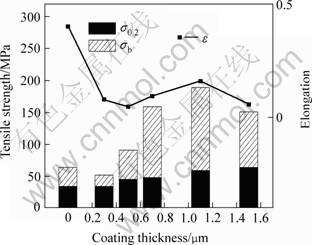

Tensile strength (σb), yield strength (σ0.2) and elongation of specimens fabricated using carbon fibers with different copper coatings shown in Table.1 are shown in Fig.3. When composites are fabricated using carbon fibers with thinner coating, the tensile strength of the composites performs no better than pure aluminum but makes the plastic property greatly decrease. Such bad performance results from the agglomerated fibers and weak interface bonding shown in Fig.2.

As the copper coating getting thicker, the tensile strength and elastic modular of the composites improve a lot. The tensile strength and elongation reach the maximum value when the thickness of coating is about 1.1 μm, the tensile strength of the composites greatly improves and the certain plastic property is remained.

When the coating is as thick as 1.5 μm, although the elastic modular is higher, the tensile strength of composites decreases with the low elongation rate, and the composites get more brittle.

Fig.3 Tensile properties of composites

3.3 Fracture analysis

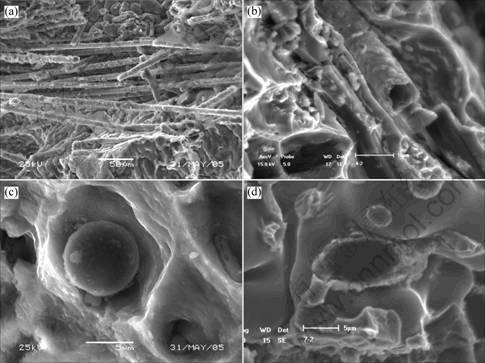

Observation results shown in Figs.4(a) and (b) confirm that the agglomerated carbon fibers and weak adherence at interface result to the failure of specimen. Fig.4(c) exhibits fine dimples and matrix adherences to the fibers located in the space between the fibers associated with the matrix and without the existence of fiber pullout, which means that a strong interface bonding is developed in the composites and the high ductility of the matrix alloy can be noted. Fig.4(d) shows

Fig.4 SEM images of fracture surface of different specimens fabricated by carbon fibers with different copper coatings: (a) 0.3 μm; (b) 0.5 μm; (c) 1.1 μm; (d) 1.5 μm

the evidence that the crack initiates and propagates through the interface and form the thick brittle phase CuAl2, which reveals the harmful effects of thick brittle phase.

Therefore, CuAl2 layer is needed at the interface to gain a good bonding condition, but the thickness should be controlled to avoid the harmful effects.

4 Conclusions

1) In order to effectively improve the wetting ability of carbon fibers to molten aluminum, the thickness of copper coating on the carbon fibers should be no less than 0.7 μm.

2) Copper coating thicker than 1.0 μm forms thick brittle layer at the interface and cause brittle failure of the composites.

3) The tensile properties of composites perform the best when the thickness of coatings is 0.7-1.1 μm. The fibers are uniformly dispersed and good bonded with the aluminum matrix, the certain plastic property is remained.

References

[1] MIRACLE D B. Metal matrix composites—From science to technological significance [J]. Composites Science and Technology, 2005, 65: 2526-2540.

[2] CLYNE T W, WITHERS P J. An Introduction to Metal Matrix Composites [M]. Cambridge: Cambridge University Press, 1993: 18.

[3] WIELAGE B, DORNER A. Corrosion studies on aluminium reinforced with uncoated and coated carbon fibres[J]. Composites Science and Technology, 1999, 59: 1239-1245.

[4] DORNERA A, WIELAGE B, SCHU?RER C. Improvement of the corrosion resistance of C/Al-composites by diamond-like carbon coatings [J]. Thin Solid Films, 1999, 355/356: 214-218.

[5] DAOUD A. Microstructure and tensile properties of 2014 Al alloy reinforced with continuous carbon fibers manufactured by gas pressure infiltration [J]. Materials Science and Engineering A, 2005, 391: 114-120.

[6] LANCIN M, MARHIC C. TEM study of carbon fibre reinforced aluminium matrix composites: Influence of brittle phases and interface on mechanical properties [J]. Journal of the European Ceramic Society, 2000, 20:1493-1503

[7] SILVAIN J F, PROULT A, LAHAYE M. Microstructure and chemical analysis of C/Cu/Al interfacial zones [J]. Composites: Part A, 2003, 34: 1143-1149.

[8] URENA A, RAMS J, ESCALER M D. Characterization of interfacial mechanical properties in carbon fiber/aluminium matrix composites by the nanoindentation technique [J]. Composites Science and Technology, 2005, 65: 2025-2038.

[9] CAO Zhuo-kun, LIU Yi-han, YAO Guang-chun. Electroplating of carbon fibers in sulfate acidic solution [J]. The Chinese Journal of Process Enginerring, 2006, 6(4): 651-655.

[10] CAO Zhuo-kun, LIU Yi-han, Yao Guang-chun. Study on copper coating on carbon fibers [J]. Journal of Guangdong Non-Ferrous Metals, 2005, 15(2/3): 496-500.

[11] BUSSCHEN A, SELVADURAI T. Mechanics of the segmentation of an embedded fiber, Part I: Experimental investigations [J]. Journal of Applied Mechanics, 1995, 62: 87-97.

(Edited by LI Yan-hong)

Foundation item: Project(204AA335010) supported by the National High-Tech Research and Development Program of China

Corresponding author: CAO Zhuo-kun; Tel: +86-24-83686462; E-mail: czkstick@163.com