Roles of humidity and heat treatment temperatures on YBa2Cu3O7-x coated conductors by trifluoroacetic acid-metal organic deposition process

Seok-Hern JANG, Jun-Hyung LIM, Chang-Min LEE, Eui-Cheol PARK, Soo-Min HWANG,

Jun-Hyuk CHOI, Jong-Hyun SHIM, Jin-Hyun PARK, Won KIM, Jinho JOO

School of Advanced Materials Science and Engineering, Sungkyunkwan University, Jangan, Suwon,

Gyeonggi, 440-746, Korea

Received 18 June 2008; accepted 10 March 2009

Abstract:

YBa2Cu3O7-x(YBCO) films were fabricated on an LAO substrate using the trifluoroacetic acid-metal organic deposition (TFA-MOD) method and the effects of the humidity and heat treatment temperatures on the microstructure, degree of texture and critical properties of the films were evaluated. In order to understand the combined effects of the humidity and the calcining and firing temperatures on critical properties, heat-treatment was performed at various temperatures with the other processing variables fixed. The films were calcined at 400-430 ℃ and fired at 750-800 ℃ in a 0-12.1% humidified Ar-O2 atmosphere. The texture was determined by pole-figure analysis. The amount of the BaF2 phase was effectively reduced and a sharp and strong biaxial texture was formed under a humidified atmosphere, which led to increased critical properties. In addition, the microstructure varied significantly with firing temperature but changed little with calcining temperature. The highest IC of 40 A/cm-width, which corresponds to JC value of 1.8 MA/cm2, was obtained for the films fired at 775 ℃ (in 12.1% humidity) after calcining at 400-430 ℃. It is likely that the highest IC value is due to the formation of a more pure YBCO phase, c-axis grains, and a denser microstructure.

Key words:

humidity; metal organic deposition; pole-figure; trifluoroacetates; YBa2Cu3O7-x coated conductor;

1 Introduction

YBa2Cu3O7-x(YBCO) coated conductors(CCs) have high critical current density(JC) in a magnetic field at LN2 temperature. CCs can be successfully prepared by various methods including pulsed laser deposition(PLD) [1], metal organic chemical vapor deposition(MOCVD) [2], BaF2 process[3], and metal organic deposition (MOD)[4], etc. Among them, the MOD process has several advantages, which include precise controllability of the metal content, the wide range of coating materials that can be used, and the low cost of the process because it does not require vacuum equipment.

The critical current(IC) of CCs depends on the formability of the YBCO phase, existence of a secondary phase, texture, grain connectivity and orientation. Therefore, the processing variables should be optimized in order to obtain a uniform microstructure. The TFA-based solution forms a metal-organic containing the BaF2 phase through calcination, and the YBCO phase is prepared by hydrolysis of BaF2 during a firing heat treatment in a humid atmosphere[5]. It is well known that an incomplete reaction between the precursors results in the presence of BaF2, which reduces the purity and texture of YBCO phase, causing a decrease in the critical properties[6]. However, the effects of secondary phases formed by the incomplete reaction on the critical properties, based on the microstructural evolution, such as grain orientation, degree of texture, and grain growth, have not been studied systematically.

In addition, some studies have been carried out to understand the effects of the processing variables on microstructure and critical properties in the TFA-MOD process[7-9]. From these studies, the optimum conditions of the heating ramp, holding time, and gas flow rate have been established. On the other hand, there are a limited number of studies aimed at optimizing the heating temperature and their results were not well consistent with each other[5-6, 10-11]. In order to understand the combined effects of the calcining and firing temperatures on the microstructure and resultant critical properties, it is essential to heat-treat at various temperatures with the other processing variables fixed.

Therefore, in this study, YBCO films were deposited on an LAO substrate using the TFA-MOD method, and the effect of the humidity on the formation of a secondary phase, microstructure, texture, and resultant critical properties were evaluated. The films were calcined and fired at various temperatures to relate the microstructural evolution to a combination of the heat treatment temperatures.

2 Experimental

A solution of Y-, Ba-, and Cu-acetates in TFA at molar ratios of Y to Ba to Cu of 1?2?3 was refluxed at 74℃ for 4 h. The solution was then dried in a vacuum to evaporate the TFA and residual acetic acids, leaving a blue-colored solid residue. The residue was dissolved in methyl alcohol to produce the final solution with a total cation concentration of 3 mol/L and was coated onto a single crystalline LaAlO3 (00l) substrate using a dip-coating method. The film was dried in a vacuum at 150 ℃ for 10 min.

The heat treatment was carried out in two stages: calcination and firing. With calcination, the precursor films were slowly heated to 400 and 430 ℃ in a 12.1% humidified oxygen atmosphere with a flow rate of 170 mm/min to decompose the metal trifluoroacetates. The calcined films were fired at 750, 775, and 800 ℃ for 4 h in a dry (0%), 4.2%, and 12.1% (in volume fraction) humid Ar gas mixed with 1×10-3 oxygen. The fired films were then oxidized at 450 ℃ in a dry O2 atmosphere for 10 h to convert the tetragonal phase into a superconducting orthorhombic phase.

The microstructures of the YBCO films were characterized by scanning electron microscope (FE-SEM, JSM7000F). The crystalline phases in the films and the texture of the film were determined by X-ray diffractometer(XRD) and pole figure analyzer (BRUKER-AXS, D8 discover), respectively. The texture of the specimens was measured by obtaining four incomplete pole figures using an X-ray goniometer. The ω angle was observed in the range of 0-75?, and the φ angle in the range of 0-360? at an interval of 5?. The critical temperature(TC) measurement was made by the standard four-probe method using a cryostat. The critical current(IC) was also measured using the same method with a 1 μV/cm criterion at LN2 (77 K) in a zero field.

3 Results and discussion

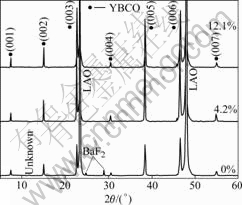

To evaluate the effect of humidity during the firing process, the coated gel films were calcined at 430 ℃ in 12.1% humidified oxygen and fired at 775 ℃ in a 0-12.1% humidified Ar gas mixed with 1×10-3 oxygen. Fig.1 shows the XRD patterns of the films, indicating that the YBCO (00l) plane is parallel to the surface and the c-axis orientation is well developed in all films. On the other hand, the intensity of the YBCO peaks is relatively low, and BaF2 and unknown phases are observed in the films fired in 0% humidity. These secondary phases disappeared when the humidity was increased to 4.2% and an almost pure YBCO phase was observed over the humidity range of 4.2%-12.1%. Therefore, firing in a humidified atmosphere has a beneficial effect on the phase formation of YBCO. In general, the overall reaction including the decomposition of the precursor and the formation of the YBCO phase can be determined from the following equation:

Y2Cu2O5+BaF2+CuO+H2O→YBa2Cu3Ox+HF(g) (1)

Fig.1 XRD patterns of films fired at 775 ℃ in 0-12.1% humid atmosphere

This indicates that the crystal growth mechanism of YBCO films is controlled by the ratio of the partial pressure of H2O gas and HF gas. Therefore, YBCO formation does not occur completely during the firing process in a low humid atmosphere[12].

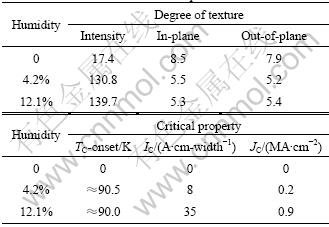

Fig.2 shows SEM images of the surface of the YBCO films. All the films have a crack-free surface and c-axis grains formed mainly (i.e., grain, in which the c-axis of the lattice is normal to the substrate), while the grain morphology is different. For the films fired in 0% humidity, the grains are very fine with many small pores and white-colored particles. These particles are characterized as BaF2 by EDS, and have disappeared at a humidity of 4.2%, which is consistent with the XRD results. As the humidity is increased, the YBCO grains grow further and the surface of the film becomes denser. The texture of the films was evaluated by measuring the intensity and full width at half maximum (FWHM) from the (113) pole-figures (Table 1). The pole intensity of the films fired in 0% humidity is low (17.4) and increases significantly to 130.8 and 139.7 for the films fired in 4.2% and 12.1% humidity, respectively. The FWHMs of the in-plane and out-of-plane textures were measured to be 8.5? and 7.9? for the films fired in 0% humidity, respectively. These values were reduced to 5.2?-5.4? when a humidity of 4.2% or 12.1% was applied. Therefore, the texture of the film is improved remarkably under a humid atmosphere and the degree of texture does not vary in the humidity range of 4.2%-12.1%. The poor texture in 0% humidity is probably due to the presence of BaF2 phase and the less dense microstructure.

Fig.2 SEM micrographs of films fired at 775 ℃ in dry (0%) (a), 4.2% (b) and 12.1% (c) humid Ar-O2 gas atmospheres

Table 1 also shows the measured TC, IC, and JC values. The TC and IC were undetectably small in the films fired in 0% humidity. When the humidity was increased to 4.2%, the corresponding TC (zero) and TC (onset) increased to 90.5 K and 92.0 K, respectively. Similar TC values with a sharp transition range were also obtained for the films fired at a higher humidity (about 12.1%). This suggests that the use of a humid atmosphere during firing enhances the formation of a YBCO phase with a high oxygen content. In addition, the IC increases with increasing humidity and reaches a peak of 35 A/cm-width (corresponding JC?0.9 MA/cm2) at a humidity of 12.1%. Based on the XRD pattern, pole-figure, and SEM images, it is likely that the highest IC value is due to the existence of pure YBCO, a strong biaxial texture, and large grain size with a dense microstructure.

Table 1 FWHM, intensity, and critical properties of films fired at 775 ℃ in 0-12.1% humid atmosphere

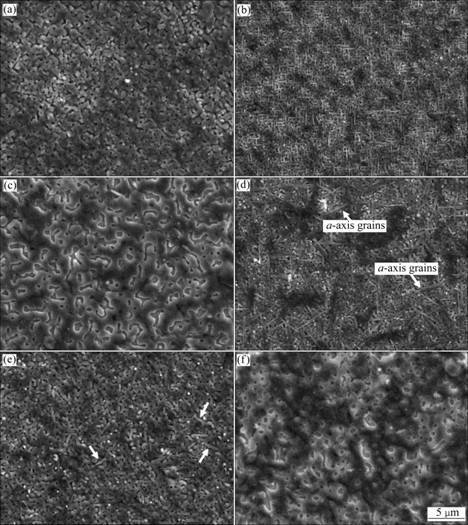

In order to determine the effect of the calcining and firing temperature, the precursor films were fired at 750-800 ℃ for 4 h in 12.1% humidity after calcination at 400-430 ℃ in 12.1% humidified oxygen. Figs.3(a)- (f) show SEM images of the corresponding YBCO films. The grain size and density of the films increase with increasing firing temperature for the films calcined at 400 ℃ and 430 ℃. For both films fired at 750 ℃, the grains are very fine, pores are frequently observed, the microstructure becomes denser and the grains grows further with increasing the firing temperature. Similar microstructures are observed for the films fired at the same temperature, regardless of the calcining temperature. This indicates that the calcination temperature does not affect the film morphology, which is in contrast to the firing temperature.

Fig.3 SEM micrographs of films fired at 750 ℃, 775 ℃, and 800 ℃ after calcining at 400 ℃ and 430 ℃, respectively: (a) Fired at 750 ℃, calcined at 400 ℃; (b) Fired at 775 ℃, calcined at 400 ℃; (c) Fired at 800 ℃, calcined at 400 ℃; (d) Fired at 750 ℃, calcined at 430 ℃; (e) Fired at 775 ℃, calcined at 430 ℃; (f) Fired at 800 ℃, calcined at 430 ℃

In addition, the grain orientation varies according to the firing temperature. For the films fired at 750 ℃, there are needle-shaped grains that appear to be a-axis grains (in which the a-axis of the lattice is normal to the substrate). The fraction of a-axis grains decreased with increasing the firing temperature to 775 ℃, and had disappeared at 800 ℃, suggesting that the grains consist mainly of c-axis grains. This variation in the grain orientation with the firing temperature can be explained by lattice mismatch between the film and substrate[13]. Since the thermal expansion coefficient of the a-axis (α= 9.6×10-6/K) is smaller than that of the c-axis (α=17.6×10-6/K), the mismatch between the a-axis and LAO substrate becomes smaller than that between the c-axis and the substrate with increasing firing temperature. This means that the formation of the a-axis parallel to the substrate (i.e., the c-axis grain) becomes energetically favorable at higher firing temperatures. This observation is consistent with another report[6].

Fig.4 shows the variations in the IC of the YBCO film as a function of the calcining and firing temperatures. At a firing temperature of 750 ℃, the IC value was undetectably small, which is probably related to the presence of an a-axis grain and poor YBCO phase formability because of the low diffusion kinetics at this temperature. Moreover, additional XRD analysis indicates that this film contains BaF2 and other unknown phases. As the firing temperature increases, the IC increases and reaches a peak of 40 A/cm-width (corresponds to a JC value of 1.8 MA/cm2) at 775 ℃ and then decreases at 800 ℃. It is likely that the increased IC at 775 ℃ is due to the formation of a more pure YBCO phase, c-axis grain, and denser microstructure. The decrease in the IC at 800 ℃ is not clearly understood because the microstructural observation indicating the texture, phase purity, and porosity is similar to that at 775 ℃. It was reported that the YBCO phase was partially decomposed at 780 ℃ and a secondary phase formed resulting in a decrease in IC[6]. The secondary phase was identified by Raman spectroscopy to be BaCuO2 in a study where YBCO films were fabricated on LAO using a similar method[6]. Therefore, further study will be needed to relate the IC value and the microstructural evolution in more detail.

Fig.4 Dependence of critical current on calcining and firing temperatures

4 Conclusions

1) It is found that the critical properties depended significantly on the humidity. The BaF2 phase is effectively removed under a humid atmosphere and a sharp and strong biaxial texture forms, leading to increase in TC and IC.

2) The IC varies remarkably with the firing temperature (750-800 ℃) but little with the calcining temperature (400-430 ℃). As the firing temperature increases from 750 ℃, the IC increases and reaches a peak of 40 A/cm-width (corresponding to a JC value of 1.8 MA/cm2) at 775 ℃ and then decreases at 800 ℃.

3) The highest IC value at 775 ℃ is due to the formation of a more pure YBCO phase, c-axis grains, and a denser microstructure.

Acknowledgement

This work was supported by Samsung Research Fund, Sungkyunkwan University, 2006.

References

[1] CANTORO M, COPPEDE N, CAMPOSEO A, ANDREONI E, LABARDI M, PARDI L, FUSO F, ALLEGRINI M, ARIMONDO E. Near-field microscopy investigation of laser-deposited coated conductors [J]. Applied Surface Science, 2003, 208/209: 599-603.

[2] KIM C J, JUN B H, KIM H J, CHOI J K, LEE S H, YOO J M. Comparative study of YBCO film growth in the cold wall type and hot wall type MOCVD processes [J]. Physica C, 2005, 426/431: 915-919.

[3] YOO J, LEONARD K J, HSU H S, HEATHERLY L, LIST F A, LEE D F, GAPUD A A, MARTIN P M, COOK S, PARANTHAMAN M, GOYAL A, KROEGER D M. The growth of YBCO films with high critical current at reduced pressures using the BaF2 ex situ process [J]. Superconductor Science and Technology, 2004, 17: 1209-1214.

[4] JEE Y A, LI M, MA B, MARONI V A, FISHER B L, BALACHANDRAN U. Comparison of texture development and superconducting properties of YBCO thin films prepared by TFA and PLD processes [J]. Physica C, 2001, 356(4): 297-303.

[5] TAKESHI A, IZUMI H. Review of a chemical approach to YBa2Cu3O7-x-coated superconductors-metalorganic deposition using trifluoroacetates [J]. Superconductor Science and Technology, 2003, 16: R71-R94.

[6] JEE Y A, MARONI M B, LI V A, FISHER M, BALACHANDRA U B L. Texture development and superconducting properties of YBa2Cu3Ox thin films prepared by a solution process in low oxygen partial pressure [J]. Superconductor Science and Technology, 2001, 14: 285-291.

[7] TERANISHI R, FUJI H, HONJO T, NAKAMURA Y, IZUMI T, SHOHARA Y, SHIBATA J, YAMAMOTO T, IKUHARA Y, YOSHIMURA M. Growth mechanism of Y123 film by MOD-TFA process [J], Physica C, 2002, 1033/1038: 378-381.

[8] DAWLEY J T, CLEM P G, BOYLE T J, OTTLEY L M, OVERMYER D L, SIEGAL M P. Rapid processing method for solution deposited YBa2Cu3O7-δ thin films [J]. Physica C, 2004, 402: 143-151.

[9] PUIG T, GONZALEZ J C, POMAR A, MESTRES N, CASTANO O, COLL M, GAZQUEZ J, SANDIUMENGE F, PINOL S, OBRADORS X. The influence of growth conditions on the microstructure and critical currents of TFA-MOD YBa2Cu3O7 films [J]. Superconductor Science and Technology, 2005, 18: 1141-1150.

[10] ZHAO B, SUN Z Y, SHI K, YANG J, SUN Y P, HAN Z H. Preparation of YBa2Cu3O7-δ films by MOD method using trifluoroacetate as precursor [J]. Physica C, 2003, 386: 342-347.

[11] SMITH J A, CIMA M J, SONNENBERG N. High critical density thick MOD-derived YBCO films [J]. IEEE Trans Appl Supercond, 1999, 9: 1531-1534.

[12] MCINTYRE P C, MICHAEL J, CIMA J A, SMITH J, ROBERT B H, MICHAEL P S. Effect of growth conditions on the properties and morphology of chemically derived epitaxial thin films of Ba2YCu3O7-x on (001) LaAlO3 [J]. J Appl Phys, 1991, 71: 1868- 1877.

[13] SINGH R K, NARAYAN J. Nature of epitaxial growth of high-Tc laser-deposited yttrium barium copper oxide films on (1100) strontium titanate substrates [J]. J Appl Phys, 1990, 67: 3448-3451.

Corresponding author: Jinho JOO; Tel: +82-31-290-7358, 7385; E-mail: jinho@skku.edu; jinhojoo@hanmail.net

DOI: 10.1016/S1003-6326(08)60385-4