J. Cent. South Univ. (2012) 19: 1132-1137

DOI: 10.1007/s11771-012-1119-x![]()

Improved slope safety analysis by new Druker-Prager type criterion

ZHU Jun-gao(朱俊高)1, 2, PENG Kai(彭凯)1, 2, J. F. Shao3, LIU Han-long(刘汉龙)1, 2

1. Key Laboratory of Geo-mechanics and Embankment Engineering of Ministry of Education, Hohai University, Nanjing 210098, China;

2. Geotechnical Research Institute, Hohai University, Nanjing 210098, China;

3. Laboratoire de Mécanique de Lille, UMR CNRS 8107, Equipe Mécanique des Géomatériaux Cohérents, Polytech’Lille, Cité Scientifique, 59655 Villeneuve d’Ascq, France

? Central South University Press and Springer-Verlag Berlin Heidelberg 2012

Abstract:

Based on Mohr-Coulomb (M-C) criterion, the parameters of Druker-Prager (D-P) criterion for geomaterial were determined under non-associated flow rule, and thus a new D-P type criterion was presented. Two assumptions were employed during the derivation: 1) principal strains by M-C model and D-P model are equal, and 2) the material is under plane strain condition. Based on the analysis of the surface on π plane, it is found that the proposed D-P type criterion is better than the D-P criterion with M-C circumscribed circle or M-C inscribed circle, and is applicable for stress Lode angle less than zero. By comparing the predicted results with the test data of sand under plane strain condition and other D-P criteria, the proposed criterion is verified and agrees well with the test data, which is further proved to be better than other D-P type criteria in certain range of Lode angle. The criterion was compiled into a finite difference package FLAC3D by user-subroutine, and was used to analyze the stability of a slope by strength reduction method. The predicted slope safety factor from the proposed criterion agrees well with that by Spencer method, and it is more accurate than that from classic D-P criteria.

Key words:

yield criterion; non-associated flow rule; dilatancy angle; plastic potential function;

1 Introduction

A yield condition or yield criterion describes a material failure in structural plasticity. It defines the threshold state of a material between elastic and plastic or brittle failure deformations. It is very important to adopt a proper yield criterion in the design of a structure. The estimated load-bearing capacity of structures may be significantly affected by the choice of different yield criteria.

Mohr-Coulomb (M-C) criterion has been widely used in geotechnical engineering for decades. Though they can reflect tension-compression behavior of geomaterial, numerical calculation does not converge due to singular point of yield surface on 3-dimensional stress space. By rounding of hexagon on π plan [1-5], a number of revised M-C criteria have been presented to solve this problem. In addition, based on the Mohr- Coulomb criterion, many other yield functions were set up with associated flow rule [6-7] or non-associated flow rule [8-9]. These solutions, however, often give too complicated formula to apply.

Different from M-C and its revised criterion, classic Druker-Prager (D-P) criterion [10] is inscribed circle of M-C criterion on π plan and is convenient for numerical calculation due to its brief description. The predicted plasticity zone is, however, generally too large, if it is used to analyze the stress-strain relationship of geomaterial structures. There are other D-P criteria, such as circumscribed circle [11], M-C equivalent area circle [12], and other extension of the classical Drucker- Prager-type function in order to overcome the numerical difficulties in the tensile stress range [13-16], but they result in errors in some cases. For example, compared with limit equilibrium method, the deviation of slope safety factor determined by M-C equivalent area circle criterion is around 6% [17].

Although the geomaterial is generally taken as a material subjected to Druker’s postulate and associated flow rule, as pointed out by LIU [18], there criteria not applicable for geomaterial. Therefore, a number of researchers paid attention to the study of non-associated flow rule [19-21].

With non-associated flow rule, ZHANG et al [22] deduced a D-P criterion, and it was verified better than the conventional D-P criterion with circumscribed circle.

In view of the above mentioned results, a new D-P yield criterion is presented. The influence on yield surface due to plastic volumetric strain is considered in the criterion, and the increment of plastic volumetric strain as well as the equivalent plastic strain increment derived from this D-P criterion are compared with those of M-C criterion.

2 New D-P yield criterion

In plasticity theory, M-C yield criterion and D-P yield criterion are widely used. As previously mentioned, these two criteria have their advantages and limitations. Thus, they will be used to derive a new D-P yield criterion.

These two criteria are briefly introduced firstly as follows:

When σ1≥σ2≥σ3, M-C yield criterion can be expressed in the form of principal stress as

![]() (1)

(1)

where c and φ refer to the cohesion and internal friction angle of geomaterial, respectively.

Using invariants of stress tensor, D-P criterion is given by

![]() (2)

(2)

where I1 and J2 are the first and second invariants of stress tensor, and αf and k are material parameters.

In this work, yield means either plastic strain for elasto-plastic material or failure for elastic perfectly- plastic material.

For M-C elasto-plastic model under non-associated flow rule, it may be assumed that the plastic potential function QMC is similar to the yield function F, i.e. Eq. (1), and is written as

![]() (3)

(3)

where ψ is the so-called dilatancy angle.

On the other hand, for D-P elasto-plastic model under non-associated flow rule, the plastic potential function QDP may also be assumed to take a similar form to Eq. (2), that is,

![]() (4)

(4)

where αψ refers to material parameter, which is a function of ψ.

According to the plasticity theory, the plastic strains for the two models may be given by

![]()

![]() (5)

(5)

where ![]() (i=1, 2, 3; j=1, 2, 3) is component of increment of plastic strain, σij is component of stress tensor, and dλ is coefficient of proportionality.

(i=1, 2, 3; j=1, 2, 3) is component of increment of plastic strain, σij is component of stress tensor, and dλ is coefficient of proportionality.

Assuming the increments of principal strains determined from M-C model and D-P model are equal, from Eq. (5), we can get

![]() (6)

(6)

According to Eqs. (3) and (4), the derivation of plastic potential function to principal stress can be found, and then Eq. (6) can be written as

(7)

(7)

where si (i=1, 2, 3) are the principal values of the deviatoric stress tensor. According to continuum mechanics, the following expression can be obtained:

s1+s2+s3=0 (8)

From Eqs. (7) and (8), the following equation can be obtained:

![]() (9)

(9)

Under non-associated flow rule, the dilatancy angle can be expressed as ψ=φ/2 [23]. Substituting it into Eq. (9) leads to

![]() (10)

(10)

To determine the parameters of ![]() and k in Eq. (2), it is needed to assume the plane strain condition.

and k in Eq. (2), it is needed to assume the plane strain condition.

As well known, under plane strain condition, it is required that ![]()

![]() and s23= σ23=0. According to the definition of the second invariant J2 of stress tensor, in plane strain condition, J2 is written as

and s23= σ23=0. According to the definition of the second invariant J2 of stress tensor, in plane strain condition, J2 is written as

![]() (11)

(11)

From Eqs. (4) and (5), ![]() is found and then using

is found and then using ![]() (plane-strain condition), the deviatoric stress s33 can be determined by

(plane-strain condition), the deviatoric stress s33 can be determined by

![]() (12)

(12)

According to the definition of s33, i.e., s33=σ33-I1/3, the stress component σ33 is then obtained:

![]() (13)

(13)

Substituting Eq. (13) into I1=σ11+σ22+σ33 leads to

![]() (14)

(14)

Substituting Eq. (13) into Eq. (14), J2 is written as

![]() (15)

(15)

Let

![]() (16)

(16)

where R is just equal to the radius of the Mohr circle.

Substituting Eqs. (14)-(16) into Eq. (2), it gives

![]() (17)

(17)

Rearranging Eq. (17) leads to

![]() (18)

(18)

According to M-C criterion, in the state of failure, the radius of Mohr circle can be expressed as

![]() (19)

(19)

Let the first term of the right side in Eq. (18) equal to that in Eq. (19), and it leads to

(20)

(20)

In a similar manner, for the second term of right side in Eqs. (18) and (19), we may obtain

(21)

(21)

Substituting Eq. (10) into Eq. (20) and Eq. (21), respectively, the parameters ![]() and k in Eq. (2) in the state of failure are then obtained:

and k in Eq. (2) in the state of failure are then obtained:

(22)

(22)

It should be pointed out that the parameters ![]() and k in Eq. (22) are obtained in the state of failure and the plane strain condition. Using Eq. (22) and Eq. (2) as a failure criterion should, therefore, meet the plane strain condition. As an approximate use, of course, it can also be used in non-plane-strain condition.

and k in Eq. (22) are obtained in the state of failure and the plane strain condition. Using Eq. (22) and Eq. (2) as a failure criterion should, therefore, meet the plane strain condition. As an approximate use, of course, it can also be used in non-plane-strain condition.

It should be mentioned that if Eqs. (2) and (4) are taken as yield function and plastic potential function for a elasto-plastic constitutive model, the D-P yield function should not be used with hardening. The material is always assumed to be elastic perfectly-plastic, except for cap hardening. This implies that the yield function (yield criterion) is in fact a failure criterion.

It is known that when plastic volumetric strain is zero, there is ψ=0. From Eq. (9), we can get aψ=0. Substituting it into Eq. (20) and Eq. (21), respectively, it leads to

![]()

![]() (23)

(23)

Equation (23) is the Mohr matching D-P criterion of ZHANG et al [22].

3 Discussion and verification

3.1 Discussion on D-P criterion

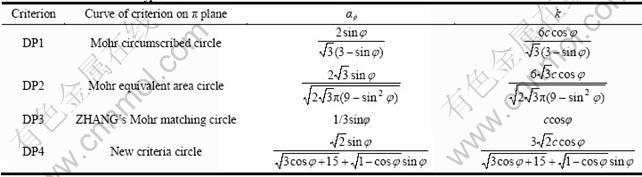

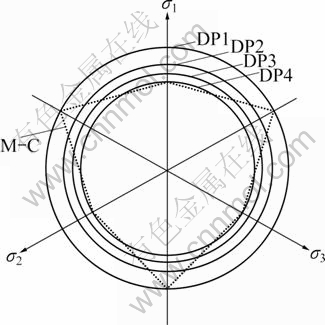

So far, a number of D-P type yield criteria have been presented. The parameters of ![]() and k for them are listed in Table 1, and those of the DP4 criterion presented in this work are also given for comparison. For convenient comparison, the M-C criterion and D-P type criteria on π plane are shown in Fig. 1.

and k for them are listed in Table 1, and those of the DP4 criterion presented in this work are also given for comparison. For convenient comparison, the M-C criterion and D-P type criteria on π plane are shown in Fig. 1.

As can be seen in Fig. 1, on π plane, the surface of DP4 of the proposed D-P criterion, is slightly larger than that of M-C criterion in the range of the Lode angle θ near to -30°, if θ is defined in the range from -30° to 30°. On the other hand, the deviation between M-C surface and the proposed D-P surface is relatively large in the range of Lode angle θ near to 30°. It is noted that for soil in plane strain condition, the parameter b (b= (σ2-σ3)/(σ1-σ3)) is in the range from 0.2 to 0.3 [24-25], and thus θ is in the range from -13.0° to -19.1°. This implies that the proposed D-P criterion is better to be used in condition with θ<0 for a good accuracy.

Although for soil the failure stress state can be expressed by the M-C surface fairly, it is well known that the test data seem to be slightly greater than the M-C surface on π plane [26] when the Lode angle is near to -30°. The surface of the proposed D-P criterion is just greater that of M-C criterion on π plane in this range. The D-P criterion presented in this work, therefore, is better than the D-P criterion with Mohr inscribed circle.

As for the D-P criterion with Mohr circumscribed circle, it is much greater than M-C criterion on π plane. It is applicable to the case with the stress state that θ is about 30°.

Based on the above analysis, the proposed criterion is better than the D-P criteria with Mohr inscribed circle and with Mohr circumscribed circle theoretically.

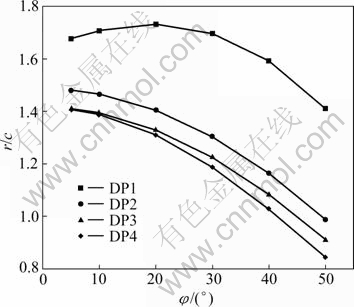

Figure 2 indicates the change of radii on π plane under different criteria with friction angle φ. As shown in Fig. 2, r refers to the radius of the criterion circle on π plane; c is the cohesion; r/c is a non-dimensional parameter. On the whole, DP3 is parallel with DP2. When 5°≤φ≤20°, DP3 is close to DP4, and the deviation between them increases with the increase of φ. The radius of DP1 circle is much larger than that of DP2 and DP4.

Table 1 Parameters of D-P type criteria

Fig. 1 M-C criterion and D-P type criteria on π plane

Fig. 2 Relationship between r/c and φ

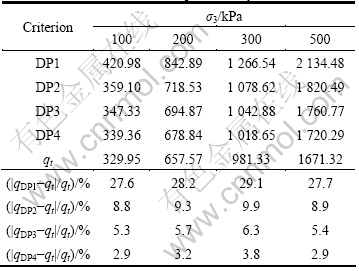

3.2 Verification I: Failure in plane-strain test of sand

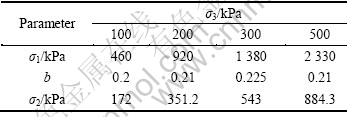

Using the experimental data in Ref. [27], the proposed criterion is verified. A kind of sand was tested under plane strain state in Ref. [27]. The size of the sample was 51 mm × 42 mm × 88 mm. In the tests, consolidation pressures (σ3) were 100, 200, 300 and 500 kPa, respectively, and during the test, σ3 was kept constant and σ1 was increased until the sample fails. The stresses of the samples at failure under plane-strain testing condition are listed in Table 2. In Table 2, the parameter b refers to the Bishop constant, and is defined as b=(σ2-σ3)/(σ1-σ3), where σ1, σ2 and σ3 are principal stresses. As seen in Table 2, the ratio of σ1 to σ3 is 4.6, and b is in the range from 0.2 to 0.23 in the failure state for the sand tested.

Table 2 Stresses of sample at failure under plane-strain condition

The generalized shear stress (q=![]() ) is related to the distance from the failure surface to the origin on π plane for an element at failure state, and it is employed to verify the D-P criteria.

) is related to the distance from the failure surface to the origin on π plane for an element at failure state, and it is employed to verify the D-P criteria.

Using Eq. (2), mean stress of the test and parameters in Table 1, J2 can be calculated, and qDP is then determined. On the other hand, by using σ1, σ2 and σ3 in the test of failure, qt ![]() can be directly determined, as listed in Table 3. It is obvious that if qDP is closer to qt, which implies that the D-P criterion is better.

can be directly determined, as listed in Table 3. It is obvious that if qDP is closer to qt, which implies that the D-P criterion is better.

The predicted values of qDP by D-P criterion of Eq. (2) are used to calculated the deviation of different D-P criteria, |qDP-qt|/qt, and they are listed in Table 3. It is found from Table 3 that, qt predicted by the DP1 is the largest, and the error is about 30%. The deviation is around 10% and 6% for DP2 and DP3 criteria, while the error is only about 3% for the proposed criterion DP4. The results indicate that the new criterion is better than other D-P criteria for the sand in the stress-state tested.

3.3 Verification II: Slope stability analysis

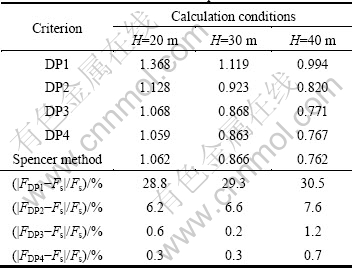

The validity of the proposed criterion is verified further by comparing it with other D-P type criteria. The proposed criterion is implemented into a finite different package FLAC3D by user-subroutine, and then the strength reduction method [28] is employed to analyze the stability of a simple slope.

Table 3 Generalized shear stress predicted by different criteria

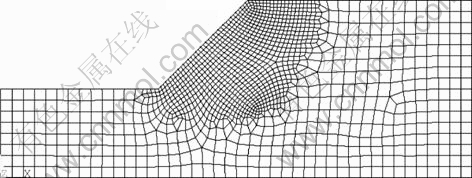

The height of the slope is H=20 m, slope gradient is 45°, and unit mass of soil is γ=25 kN/m3. The parameters are cohesion c=42 kPa, internal friction angle φ=17°, elastic modulus E=1 000 kPa, and Poisson ratio υ=0.3. The mesh is shown in Fig. 3.

In order to make a comparison, the slopes with

different heights are employed for analyzing, and the Spencer method is also used to calculate the stability of the slopes. The results are listed in Table 4. To analyze the difference between the safe factors from D-P type models and Spencer method, the relative error is calculatedby |FDP-Fs|/Fs, where FDP is safe factor obtained from D-P type model, and Fs is that from Spencer method.

Fig. 3 Mesh for analysis of slope stabilization

Table 4 Calculated safe factors of slopes

As shown in Table 4, compared with the results of Spencer method, the safe factors obtained from DP1 are the largest, and the error is about 30%. The deviation is around 6% when DP2 (M-C equivalent area circle) is adopted. It is still a little larger than that from Spencer method. The deviation is around 1% when DP3 (ZHANG et al’s criterion) is applied.

When the new criterion (DP4) proposed in this work is employed in the analysis, the deviation is only around 0.5%, and can almost be neglected.

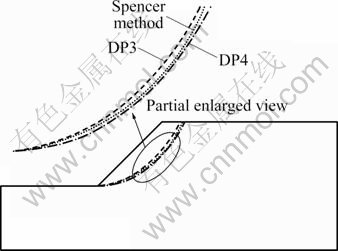

Figure 4 shows the dangerous slip surfaces which correspond to the lower limit of the plastic zone in the state of instability obtained from different D-P criteria and that of Spencer method. It is found that the slip surfaces by Spencer method and strength reduction method are basically similar. The slip surface from DP4 criterion is a little deeper than that of DP3 criterion, and the shape is relatively closer to that of Spencer method.

Fig. 4 Slip surfaces by Spencer and strength reduction method

4 Conclusions

1) With non-associated flow rule by matching M-C criterion, a new D-P yield criterion is presented. The parameters ![]() and k of this criterion are derived under plane strain condition.

and k of this criterion are derived under plane strain condition.

2) Compared to the M-C criterion, for the D-P type criteria, the deviation between M-C surface and D-P surface on π plane depends on the Lode angle. The new criterion presented is fairly better than other criteria with circumscribed circle and inscribed circle theoretically.

3) On the basis of the test data under plane strain condition of sand, the predicted generalized shear stresses of different D-P criteria are compared with those of test. The generalized shear stress predicted by the proposed criterion is very close to the test results, and the error can almost be neglected.

4) Compared with the classic D-P criterion and ZHANG et al’s M-C matching criterion, in slop stabilization analysis, safety factor from the proposed criterion is fairly close to that calculated by Spencer method.

5) The proposed yield criterion is assumed to be elastic perfectly-plastic, and it dose not consider the hardening of the materials. It can be used for ultimate analysis such as slope stability and foundation bearing capacity. In the case of cap-hardening model for elasto-plastic analysis, it can only be used as a failure criterion.

References

[1] KOITER W T. Stress-strain relations, uniqueness and variational theorems for elasto-plastic materials with a singular yield surface [J]. Quarterly of Applied Mathematics, 1953, 11(3): 350-354.

[2] CHEN W F. Limit analysis and soil plasticity [M]. Amsterdam: Elsevier Scientific Press, 1975: 637-639.

[3] LADE P V, NELSON R B. Incrementalization procedure for elasto-plastic constitutive model with multiple, intersecting yield surfaces [J]. International Journal for Numerical and Analytical Methods in Geomechanics, 1984, 8(4): 311-323.

[4] GUDEHUS G A comprehensive constitutive equation for granular materials [J]. Soils and Foundations, 1996, 36(1): 1-12.

[5] MATSUOKA H, SAKAKIBARA K A. A constitutive model for sands and clays evaluating principal stress rotation [J]. Soils and Foundation, 1987, 27(4): 73-88.

[6] FAKHARIAN K, EVGIN E. Elasto-plastic modeling of stress-path-dependent behavior of interface [J]. Int J Number Analyt Method Geomech, 2000, 24(2): 183-199.

[7] DOVE J E, JARRETT B. Behavior of dilative sand interface in a geotribology framework [J]. Journal of Geotech and Geoeviron Eng, 2002, 125(7): 545-555.

[8] DEJONG J T, WESTGATE Z J. Role of overconsolidation on sand-geomembrane interface response and material damage evolution [J]. Geotxtilesand and Geomembranes, 2005, 23(6): 486-512.

[9] SAID I, DEGENNARO V, FRANK R. Axisymmetric finite element analysis of pile loading test [J]. Computers and Geotechnics, 2009, 36(1/2): 6-19.

[10] DRUNKER D C, PRAGER W. Soil mechanics and plastic analysis in limit design [J]. Quarterly of Applied Mathematics, 1952, 10(2): 157-165.

[11] WANG Fu-shou, CHEN Ching-ben, HWANG J H, CHANG Pai-chi, CHEN Wei-fang. Models for evaluating the revolving cutter profile of circular-arc end mills [J]. Int J Adv Manuf Technol, 2006, 28(3/4): 228-235.

[12] XU Gan-cheng, ZHENG Ying-ren. Study on application of yield criterions in geotechnical engineering [J]. Chinese journal of Geotechnical Engineering, 1990, 12(2): 93-99. (in Chinese)

[13] RAMEZANI S, NAGHDABADI R, SOHRABPOUR S. An additive theory for finite elastic-plastic deformations of the micropolar continuous media [J]. Acta Mechanica, 2009, 206()1/2: 81-93.

[14] ARSLAN H, STURE S. Finite element analysis of localization and micro–macro structure relation in granular materials [J]. Acta Mechanica, 2008, 197(3/4): 153-171.

[15] LAMBRECHT M, MIEHE C, STUTTGART, GERMANY. Two non-associated istotropic elastoplastic hardening models for frictional materials [J]. Acta Mechanica, 1999, 135(1/2): 73-90.

[16] PALLAR?S F J, AG?ERO A, IVORRA S. A comparison of different failure criteria in a numerical seismic assessment of an industrial brickwork chimney [J]. Materials and Structures, 2009, 42(2): 213-226.

[17] GONG Xiao-nan. Geotechnical computer analysis [M]. Beijing: Building Industry Press, 2000: 222-226. (in Chinese)

[18] LIU Yuan-xue. Study of several basic problems in constitutive theory of geomaterials [J]. Chinese Journal of Geotechnical Engineering, 2001, 23(1): 45-48. (in Chinese)

[19] YANG Xiao-li, HUANG Fu. Slope stability analysis considering joined influences of nonlinearity and dilation [J]. Journal of Central South University of Technology, 2009, 16(2): 292-296.

[20] GANJIAN N, ASKARI F, FARZANEH O. Influences of non-associated flow rules on three-dimensional seismic stability of loaded slopes [J]. Journal of Central South University of Technology, 2010, 17(3): 603-611.

[21] LAVASAN A A, GHAZAVI M. Influence of interference on failure mechanism of closely constructed circular footings on reinforced sand [C]// Proceedings of the 4th Aasia Regional Conference on Geosynthetics. Shanghai: Zhejiang University Press, 2008: 311-317.

[22] ZHANG Lu-yu, SHI Wei-min, ZHENG Ying-ren. The slope stability analysis by FEM under the plane strain condition [J]. Chinese Journal of Geotechnical Engineering, 2002, 24(4): 487-490. (in Chinese)

[23] ZHENG Ying-ren, WANG Jing-lin, ZHU Xiao-kang. Discussion on velocity of slip line theory for geotechnical materials [J]. Journal of Hydraulic Engineering, 2001, 32(6): 1-7. (in Chinese)

[24] LI Guang-xin, HUANG Yong-nan, ZHANG Qi-guan. The principal stress of soil in the direction of plane strain [J]. Chinese Journal of Geotechnical Engineering, 2001, 23(3): 358-361. (in Chinese)

[25] KHALID A, HEATH S W. A true triaxial apparatus for soil testing with mixed boundary conditions [J]. Geotechnical Testing Journal, 2005, 28(6): 534-543.

[26] LADE P V, DUNCAN J M. Cubical triaxial tests on cohesionless soil [J]. Journal of the Soil Mechanics and Foundations Division, 1973, 99(SM10): 793-812.

[27] LI Guang-xin, ZHANG Qi-guan, HUANG Yong-nan. Study on transforming of principal stresses in constant stress ratio plane strain tests [J]. Rock and Soil Mechanics, 2006, 27(11): 1867-1872. (in Chinese)

[28] HUANG Mao-song, JIA Cang-qin. Strength reduction FEM in stability analysis of soil slopes subjected to transient unsaturated seepage [J]. Computers and Geotechnics, 2009, 36(1): 93-101.

(Edited by HE Yun-bin)

Foundation item: Project(2010B14814) supported by the Fundamental Research Funds for the Central Universities of China; Project(200801133) supported by the Ministry of Water Resources of China for Public Welfare Profession; Project(50809023) supported by the National Natural Science Foundation of China

Received date: 2011-02-27; Accepted date: 2011-06-30

Corresponding author: ZHU Jun-gao, Professor; Tel: +86-25-83787217; E-mail: zhujungao@hhu.edu.cn

Abstract: Based on Mohr-Coulomb (M-C) criterion, the parameters of Druker-Prager (D-P) criterion for geomaterial were determined under non-associated flow rule, and thus a new D-P type criterion was presented. Two assumptions were employed during the derivation: 1) principal strains by M-C model and D-P model are equal, and 2) the material is under plane strain condition. Based on the analysis of the surface on π plane, it is found that the proposed D-P type criterion is better than the D-P criterion with M-C circumscribed circle or M-C inscribed circle, and is applicable for stress Lode angle less than zero. By comparing the predicted results with the test data of sand under plane strain condition and other D-P criteria, the proposed criterion is verified and agrees well with the test data, which is further proved to be better than other D-P type criteria in certain range of Lode angle. The criterion was compiled into a finite difference package FLAC3D by user-subroutine, and was used to analyze the stability of a slope by strength reduction method. The predicted slope safety factor from the proposed criterion agrees well with that by Spencer method, and it is more accurate than that from classic D-P criteria.