网络首发时间: 2015-05-11 08:38

热处理对掺镓直拉单晶硅中缺陷及少子寿命的影响

河北工业大学化工学院

河北工业大学材料科学与工程学院

摘 要:

抑制p型单晶硅太阳能电池的光致衰减现象是光伏科技领域的热点和难点。掺镓直拉硅单晶工艺的突破以及在晶硅电池上的应用破解了这一难题,成功地抑制光致衰减。因为镓原子与硼原子共价半径的差异以及在太阳能电池制备过程中单晶硅片仍会经历不同条件的热处理,所以探究不同热处理条件对掺镓单晶硅中缺陷以及少子寿命的影响是非常有必要的。本文使用专利工艺技术制备掺镓硅单晶,并对掺硼和掺镓两种不同单晶硅片进行不同温度和时间的退火实验,对比分析不同样品的氧含量和少子寿命。结果发现:退火温度的升高、时间的延长以及预热处理都会降低两种硅片中的间隙氧含量以及少子寿命,同时促进了两组硅片中氧沉淀的形成。通过两组不同硅片对比表明,在相同条件下的退火处理,原子半径差异导致掺镓硅单晶硅的间隙氧含量下降速度更快,易形成更多的氧沉淀。

关键词:

中图分类号: TM914.4

作者简介:丰云恺(1988-),男,天津人,硕士研究生,研究方向:半导体材料,E-mail:fengyunkai0725@126.com,;任丽,教授,电话:13821163689,E-mail:liren@hebut.edu.cn;

收稿日期:2014-09-18

基金:国家科技部高技术研究发展计划(863计划)项目(2012AA05031);河北省自然科学基金项目(F2012202090)资助;

Defects and Minority Lifetime of Ga Doped Cz-Si Single Crystal with Heat Treatment

Feng Yunkai Li Ning Ren Li Ren Bingyan

School of Chemical Engineering,Hebei University of Technology

School of Materials Science and Engineering,Hebei University of Technology

Abstract:

The inhibition of light-induced degradation of p-type silicon solar cell was hot spot and difficulty in field of photovoltaic technology. The breakthrough in gallium-doped Czochralski silicon technology and the application in crystalline silicon cells solved this problem,successfully suppressing the light-induced degradation. Because of the difference in radius between boron and gallium and different heat treatment conditions in solar cell manufacturing process,it was very necessary to explore the impact of different heat treatment conditions on interstital oxygen and minority carrier lifetime of gallium-doped silicon single crystal. The silicon single crystal doped with gallium was fabricated by patented technology,boron-doped and gallium-doped silicon wafers were heat-treated at different annealing temperatures and different time,and the interstitial oxygen content and the minority carrier lifetime of different samples were comparatively analyzed. The results showed that the interstitial oxygen content and the minority carrier lifetime decreased,but the precipitation of oxygen increased when the annealing temperature rose and the time increased; the radius difference of gallium and boron caused the interstitial oxygen content of gallium-doped monocrystalline silicon to decrease faster and the precipitates of oxygen to form more easily than those of boron-doped silicon under the same annealing conditions.

Keyword:

solar cell; light-induced degradation; minority lifetime; annealing;

Received: 2014-09-18

以硼掺杂的p型单晶硅已经被广泛应用于太阳电池的基底,但是,有报道指出,该类电池在AM1.5的光线下照射12 h,其效率将呈指数下降(一般衰减达3%~8%),然后达到一个饱和值,退火处理后,电池的性能又得到了完全的恢复,这就是现在常被提及的“光致衰减”现象[1,2,3]。对于晶体硅太阳电池的光致衰减,受到业界的普遍关注。

在掺镓直拉单晶硅中不会形成与氧有关的亚稳态复合体,继而抑制了太阳电池的光致衰减,但是在掺镓直拉单晶硅生长过程中,氧杂质的引入还是不可避免的。在太阳电池生产工艺中,氧杂质在热处理条件下会发生转化,最终对太阳电池的效率产生影响。氧沉淀的存在会使直拉单晶硅太阳电池的效率下降5%左右,是直拉单晶硅效率提升的一个很大限制因素[4,5]。而对掺镓直拉单晶硅中氧的热行为的研究,对提高掺镓直拉单晶硅太阳电池的效率也是至关重要的。因此,本文研究了不同热处理条件对掺镓单晶硅的缺陷及少子寿命的影响。

1 实验

本实验所需掺镓单晶硅样品均在CZ-90单晶炉内生长,采用Φ20″复合式热系统完成。掺镓、掺硼单晶硅均为<100>晶向,直径Φ165 mm,在硅棒相邻位置分别取厚片(1200±10)μm和薄片(450±10)μm两种,电阻率为0.5~3.0Ω·cm,掺镓单晶硅中间隙氧含量为7.86×1017cm-3,碳含量为1×1016cm-3,少子寿命为65.74μs;掺硼单晶硅中间隙氧含量为8.44×1017cm-3,碳含量为1×1016cm-3,少子寿命为45.86μs。将制备好的掺镓、掺硼单晶硅片放进常规热处理炉中做退火处理。热处理工艺如下:

单步退火工艺:对掺镓单晶硅片和掺硼单晶硅片分别在650,750,850,950,1050℃温度下进行退火处理,每个温度下退火时间分别为4,6,8,10 h。

两步退火工艺:对掺镓、掺硼单晶硅片先做650℃4 h的预处理,再进行750,850,950,1050℃各4 h的退火处理。

采用傅立叶变换红外光谱仪(FT-IR)测量退火前后掺硼、掺镓单晶硅中间隙氧含量;采用WT-1000B少子寿命测试仪测试硅片中的少子寿命;将退火后的掺硼、掺镓单晶硅片解理,随后用Wrigh腐蚀液对其进行腐蚀,最后用光学显微镜(OM)观察硅片解理面上氧沉淀情况。

2 结果与讨论

2.1 退火温度对单晶硅中氧沉淀形成的影响

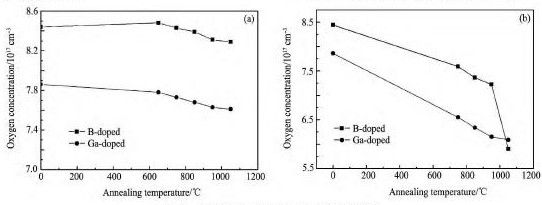

如图1(a)和(b)为不同温度下单步退火6 h以及两步退火后掺镓单晶硅和掺硼单晶硅间隙氧含量的变化。对比图1(a)和(b)可以看出,无论是掺镓单晶硅还是掺硼单晶硅,经过两步退火后硅片间隙氧含量下降明显。在单步退火过程中,随着退火温度的升高,直拉单晶硅片中的氧原子易扩散,促进了氧沉淀形核后的长大过程[6,7,8]。经过650℃4 h预处理的硅片中形成了很多氧沉淀的核心,随着第二步退火温度升高,氧杂质的扩散能力也增强,有利于第一步低温退火中形成氧沉淀的核心的长大,故消耗间隙氧原子急剧增多,从而在硅片中形成了很多氧沉淀。

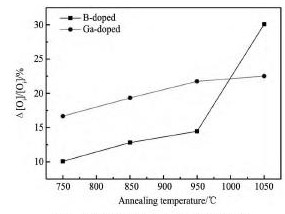

图2是不同掺杂样品经历两步退火后间隙氧含量降低率对比图,纵坐标中[Oi]表示退火前的间隙氧含量,Δ[Oi]表示退火前后间隙氧含量之差。从图2中可以看出,掺镓样品在经历两步退火后间隙氧含量降低率普遍高于掺硼单晶硅,虽然两种掺杂样品经历的退火条件相同,但初始间隙氧含量不同,且两种单晶中的杂质缺陷含量也不同。掺镓单晶硅的初始间隙氧含量要小于掺硼单晶硅,且在硅中镓的掺入会引入晶格畸变[9,10,11],从而影响氧沉淀的形成数量和形成速率,这些都是导致两步退火后掺镓单晶硅中间隙氧含量降低率高于掺硼单晶硅的因素。掺镓直拉单晶硅片和掺硼直拉单晶硅片在经历650℃4 h预处理后,再分别经历750,850,950,1050℃4 h退火处理,其间隙氧含量大幅下降,降低率都在10%以上,最高降低率出现在对掺硼样品进行1050℃4 h的热处理后,间隙氧含量的降低率达到了30.1%。

图1 间隙氧含量与热处理温度的变化关系Fig.1 Variation relationship between interstitial oxygen concentration in Cz-Si and annealing temperature

(a)One-step annealing for 6 h;(b)Two-step annealing

图2 两步退火后间隙氧含量的降低率Fig.2 Reduction rate of interstitial oxygen concentration(Δ[Oi]/[Oi])in Cz-Si after two-step annealing

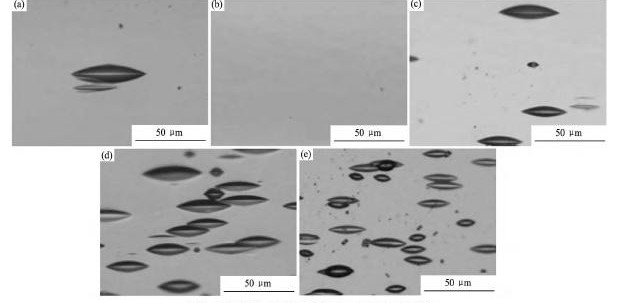

图3和4为经过不同温度热处理过程的掺镓单晶硅片和掺硼单晶硅片再经Wright腐蚀液腐蚀后解理面的显微照片。从图3可以看出,单步退火后掺镓硅片中氧沉淀腐蚀坑的密度比较低。从低温(650和750℃),中温(850和950℃)、高温(1050℃)图样对比发现,掺镓直拉单晶硅片在低温退火时,氧沉淀密度很小;中温退火,氧沉淀尺寸大且密集;高温退火时,氧沉淀腐蚀坑密度大,但尺寸稍小于低温和中温退火下的腐蚀坑尺寸。同样,对比来看,图4中掺硼单晶硅在低温和中温单步退火下腐蚀坑的尺寸较大且有一定的密集度,而在高温单步退火下的氧沉淀腐蚀坑尺寸稍小但密度大。

2.2 退火时间对单晶硅中氧沉淀形成的影响

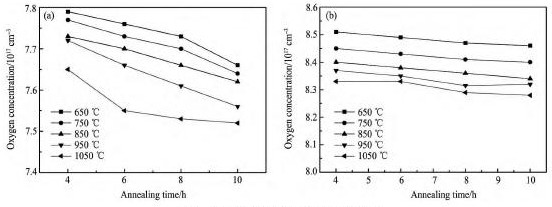

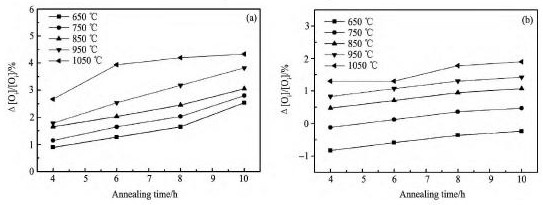

经过不同温度、不同时间退火后,掺镓直拉单晶硅片和掺硼直拉单晶硅片的间隙氧含量变化如图5所示。在同一热处理温度下,随着退火时间延长,掺镓直拉单晶硅片和掺硼直拉单晶硅片的间隙氧含量均下降。这是因为随着退火时间的延长,硅片中形成的氧沉淀数量增多,消耗间隙氧原子增多,则硅片的间隙氧含量逐渐降低。图6是不同掺镓样品经历单步退火后间隙氧含量降低率对比图,纵坐标中[Oi]表示退火前的间隙氧含量,Δ[Oi]表示退火前后间隙氧含量之差。掺镓单晶硅中的镓原子和掺硼单晶硅中的硼原子在原子尺寸上存在着差别,两种不同掺杂单晶硅的初始间隙氧含量也不同,这就造成了随热处理温度变化间隙氧含量变化的不同。

图3 掺镓样品经历不同条件热处理后的缺陷形貌Fig.3 OM images of Ga-doped silicon wafers annealed under different conditions

(a)650℃,6 h;(b)750℃,6 h;(c)850℃,6 h;(d)950℃,6 h;(e)1050℃,6 h

图4 掺硼样品经历不同条件热处理后的缺陷形貌Fig.4 OM images of B-doped silicon wafers annealed under different conditions

(a)650℃,6 h;(b)750℃,6 h;(c)850℃,6 h;(d)950℃,6 h;(e)1050℃,6 h

图5 间隙氧含量与退火时间的变化关系Fig.5 Variation relationship between interstitial oxygen concentration in Cz-Si and annealing time

(a)Ga-doped silicon;(b)B-doped silicon

图6 单步退火后间隙氧含量的降低率Fig.6 Reduction rate of interstitial oxygen concentration(Δ[Oi]/[Oi])in Cz-Si after one-step annealing

(a)Ga-doped silicon;(b)B-doped silicon

从图6可以明显看出,在同一温度条件下退火,随着时间的延长,掺镓单晶硅间隙氧含量的下降率要大于掺硼单晶硅。掺硼单晶硅片经历650℃4 h退火后,间隙氧含量有所增加,其原因是初始单晶硅中存在原生氧沉淀,经过退火处理后,氧沉淀熔解,使间隙氧含量有所增加[11,12,13]。在同一温度条件下退火,随着时间的延长,掺镓单晶硅和掺硼单晶硅的间隙氧含量降低率都上升,说明随着退火时间的延长,消耗的间隙氧含量不断增加,每种温度条件在经历10 h后消耗的间隙氧含量最多。

2.3 热处理对直拉单晶硅片少子寿命的影响

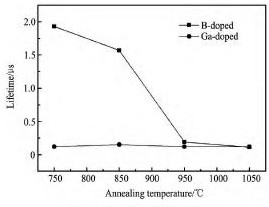

单步退火后少数载流子的寿命变化如图7所示,对应同一退火时间,随着退火温度的升高,掺镓直拉单晶硅片和掺硼直拉单晶硅片的少子寿命都下降,高温1050℃退火少子寿命最低。比较而言,低温(650和750℃)退火少子寿命明显降低,而中温(850和950℃)和高温(1050℃)退火少子寿命的变化不大。这是由于在低温退火过程中,随着退火温度的升高,不断有氧沉淀及相关缺陷的产生,这些与氧相关的缺陷作为缺陷中心对载流子有很强的复合作用,导致硅片少子寿命的下降[14,15,16]。而随着温度的继续上升,过量的间隙硅原子重新填充了一些空位,使硅片的少子寿命变化较小;高温下少子寿命变化小的原因也可能是在产生氧沉淀的同时也熔解了一部分,使硅片内少子复合中心保持稳定。同样,在同一温度下退火,随着退火时间的延长,少子寿命也下降,且在低温(650和750℃)下,随着退火时间的延长下降更为明显,而在中温(850和950℃)和高温(1050℃)退火下,少子寿命基本没有什么变化。

图7 单步退火后的少子寿命Fig.7 Lifetime of Cz-Si after one-step annealing

(a)Ga-doped silicon;(b)B-doped silicon

两步退火后少数载流子的寿命变化如图8所示。两步退火后,无论是掺镓单晶硅还是掺硼单晶硅,低温单步退火后少子寿命比两步退火的变化幅度大。对比单步退火和两步退火,在低中温(650℃4 h+950℃4 h)条件下,两步退火比单步退火少子寿命下降得多,这是由于在650℃4 h预退火条件下,增加了氧沉淀的形核中心以至于在第二步退火中产生了大量的氧沉淀和缺陷复合体,成为少数载流子的复合中心,导致了硅片少子寿命的降低;而在高温(1050℃4 h)单步退火条件下,由于部分氧外扩散或者是体内原生缺陷的分解导致分散的复合中心大大减少,从而使硅片的少子寿命稍高于两步退火。

图8 两步退火后的少子寿命Fig.8 Lifetime of Cz-Si after two-step annealing

3 结论

1.在单步退火过程中,随着退火温度的升高,掺镓单晶硅和掺硼单晶硅中间隙氧含量都下降,掺镓单晶硅中间隙氧含量下降速率更快;氧沉淀腐蚀坑都增多,掺镓单晶硅的腐蚀坑尺寸小于掺硼单晶硅;少子寿命均下降,且低温退火下降速率更快。随着退火时间的延长,掺镓单晶硅和掺硼单晶硅中间隙氧含量继续下降同时氧沉淀腐蚀坑密度增加,而少子寿命变化不大。

2.两步退火过程中,随着第二步退火温度的升高,掺镓单晶硅和掺硼单晶硅中间隙氧含量和少子寿命下降速率都明显加快。

参考文献