J. Cent. South Univ. Technol. (2008) 15(s1): 483-487

DOI: 10.1007/s11771-008-405-0

![]()

Simulation of pipelining pours point depressant beneficiated waxy crude oil through China West Crude Oil Pipeline

LI Hong-ying(李鸿英)1, ZHANG Jin-jun(张劲军)1, LING Xiao(凌 霄)1, 2, HUANG Qi-yu(黄启玉)1,

LIN Xiao-fei(林小飞)1, JIA Bang-long(贾邦龙)1, LI Yu-guang(李宇光)1

(1. Beijing Key Laboratory of Urban Oil and Gas Distribution Technology, China University of Petroleum, Beijing 102249, China;

2. CNPC West Pipeline Company, Urumqi 830013, China)

Abstract:

Flow properties of waxy crude oils, particularly the beneficiated waxy crude oils, are sensitive to shear history that the crude oil experienced, called the shear history effect. To simulate this shear history effect accurately is vital to pipeline design and operation. It has been demonstrated by our previous that the energy dissipation or entropy generation due to viscous flow in the shear process is a suitable parameter for simulating the shear history effect. In order to further verify the reliability of this approach, experimental simulations were conducted for three PPD-beneficiated waxy crude oils transported through the China West Crude Oil Pipeline, a most complicated long-distance- crude-oil-pipeline technically and operationally so far in China. The simulations were made by using a stirred vessel and with the energy dissipation of viscous flow as the shear simulation parameter. Comparison between the flow properties of crude oils obtained from field test and experimental simulations, it is found that the gel points and viscosities from experimental simulations are in good agreement with the field data.

Key words:

waxy crude oil; flow properties; shear history effect; experimental simulation;

1 Introduction

The waxy crude oil is characterized by its high pour point/gel point, poor flowability and complex rheology[1]. To improve the flow properties of the waxy crude and hence facilitate pipeline transportation, the chemical additives called the pour point depressant (PPD) are getting more and more use. The waxy crude oil is also characterized by its high sensitive to shear history, call the shear history effect[2], particularly the PPD- beneficiated waxy crude oils[3-4].

To understand this shear history effect quantitatively is vital to oil pipeline design and operation. Experimental simulation has been a common practice, and the shear rate has been accordingly thought as the parameter for shear simulation. However, in many cases, shear rate is quite different from place to place in the flow field, i.e. in the pipe flow. This raises difficulties for shear simulation.

To account for shear effect in laminar flow for pipeline design, WARDHAUGH and BOGER[2] presented procedures to determine the locus of equilibrium flow curve by using the rotational rheometer. However, most of crude oil pipelines are operated in turbulent flow. For this case, they suggested use of shear rate at the pipe wall for shear simulation. But one should note that in turbulent flow, fluid particles moves chaotically. Shearing the crude oil with the shear rate at the pipe wall, which is the maximum shear rate within the pipe, is obviously unreasonable and make the oil over-sheared. Besides pipe flow, the crude oil is also highly sheared when passing through pumps in long distance pipelining, and in some cases the oil is also strongly sheared when flowing across throttle valves. In these cases, taking shear rate as the parameter for shear simulation no longer works. NENNIGER[5] invented a method and apparatus to simulate the shear and thermal history and measure the characteristics of waxy crude oils. However, he adopted a trial-and-error procedure, i.e. to systematically vary the control parameters (temperature, shear etc.) to discover the appropriate experimental conditions that reliably reproduce the particle characteristics observed in the field. This is undoubtedly effort and time consuming.

Our previous works[4, 6] have shown that the energy dissipation or entropy generation due to viscous flow in the shear process could be a suitable parameter for simulating the shear history effect of waxy crudes, i.e. within a certain ranges of imposed shear rate, the same energy dissipation (or entropy generation), the same shear history effect on the gel point and viscosity. In this paper, the reliability and accuracy of this simulation approach is verified once more by comparing the flow properties of crude oil obtained in experimental simulations and from the field tests in the China West Crude Oil Pipeline, the most complicated long-distance crude-oil-pipeline technically and operationally so far in China.

2 Theoretical bases for pipeline flow simulation

Essentially, the effect of shear on structure of fluids depends not only on the rate of shear, but also the shear stress. The energy dissipation rate in fluid mechanics is such a quantity that combines these two factors. It is defined as

![]() (1)

(1)

where ![]() is the energy dissipation rate, W/m3; τ is the stress tensor, Pa; D is the tensor of deformation rate, s-1.

is the energy dissipation rate, W/m3; τ is the stress tensor, Pa; D is the tensor of deformation rate, s-1.

In pipe flow, the energy dissipation rates are simplified to:

![]() (2)

(2)

where τ is the shear stress and ![]() is the shear rate. This is valid for both Newtonian and non-Newtonian fluids. For the Power Law fluids, according to Equation 2, one may yield

is the shear rate. This is valid for both Newtonian and non-Newtonian fluids. For the Power Law fluids, according to Equation 2, one may yield

![]() (3)

(3)

where K is the consistency coefficient, Pa·sn; and n is the flow behavior index.

Then the energy dissipation, which is the amount of energy dissipated in a flow process or over a period of time due to the viscous force, can be written as

![]() (4)

(4)

where ![]() is the energy dissipation, W; t is the time of fluid flowing in a specified process, s.

is the energy dissipation, W; t is the time of fluid flowing in a specified process, s.

In pipe flow, the volumetrically-average energy dissipation rate ![]() can be written as

can be written as

![]() (5)

(5)

where f is the Fanning friction factor; ρ is the density of the fluid, kg/m3; ![]() is the cross-sectional average velocity of the fluid, m/s; and d is the diameter of pipeline, m.

is the cross-sectional average velocity of the fluid, m/s; and d is the diameter of pipeline, m.

The centrifugal pump is the most-often-used pump in oil transporting pipelines. High shear in flow through a centrifugal pump may remarkably impact the flow properties of the beneficiated crude oil[4]. The average energy dissipation rate in the flow through a centrifugal pump can be derived as

![]() (6)

(6)

where H is the pump’s discharge head, m; g is the gravitational acceleration, m/s2; t′ is the time needed by a fluid element passing through the pump, s; η′=η+a, here η is the pump efficiency, which is an indication of energy dissipated in the flow within a pump. Adding constant a ranging from 0.01 to 0.03 is because not all of the energy dissipated within a pump is resulted from viscous drag.

Stirred vessels are usually used for shear simulation in laboratory[5, 7]. In a stirred vessel, almost all energy exerted by the impeller exhausts into the fluid stirred. Hence the average energy dissipation rate per unit volume of fluid can be calculated as[8]

![]() (7)

(7)

where P is the shaft power of the stirrer, W; and V is the volume of fluid stirred, m3.

3 Experimental

China West Crude Oil Pipeline, a newly constructed pipeline, was put into operation in August 2007. The main line, 1 541 km long, starts from Shanshan in northwest China’s Xinjiang Uygur Autonomous Region and ends at Lanzhou, the capital of Gansu Province. There are 10 pump stations along the pipeline, as seen in Table1 showing the mileage and elevation of each station.

Table 1 Basic information about West Crude Oil Pipeline

Several crudes with different wax contents and thus different gel points are pumped through the pipeline in batch, with the gel point ranging from -10 to 10 ℃. Since the lowest ground temperature at the depth where the pipeline is buried is as low as 2 ℃ in winter, the PPD is decided to use for reducing gel points of the pumped crude oils in order to ensure safe operation of the pipeline. To make sure that the selected PPD reduces gel point effectively, field tests were conducted[9]. The PPD was injected to the waxy crude oils at the initial station, and gel points and viscosities were measured at the initial station and several intermediate stations along the pipeline.

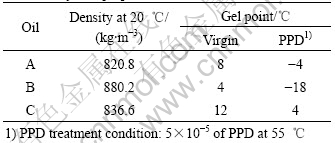

During the field test period, experimental pipelining simulations of three PPD-beneficiated waxy crude oils were conducted in the lab of the initial station in order to verify the reliability of the energy dissipation as the parameter for simulating the shear history effect of waxy crudes. Table 2 lists the basic physical properties of these three crude oils used in simulation.

Table 2 Physical properties of tested crude oils

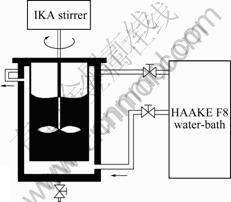

A tight stainless steel cylindrical tank with the inner diameter of 200 mm and the height of 265 mm was used for pipelining simulation. Temperature of crude oil sample was controlled by a HAAKE F8 water-bath. The crude oil was stirred by a 4-blades propeller with a diameter of 140 mm. Fig.1 shows the sketch of simulation device.

About 4.8 L PPD-beneficiated waxy crude oil taken from the discharge pipeline of the initial station, Shanshan, were filled into the stirred vessel. Then the crude oil in the stirred vessel was cooled at a rate determined by referring to the pipeline operation, and during cooling the crude oil was sheared. The shear histories was simulated according to the energy dissipation of viscous flow. When the crude oil was cooled and sheared to each sampling point, about 200 mL crude oil specimen was sampled from the sampling valve at the bottom of the stirred vessel for measuring the gel point and viscosity.

Fig.1 Sketch of simulation device

4 Results and discussion

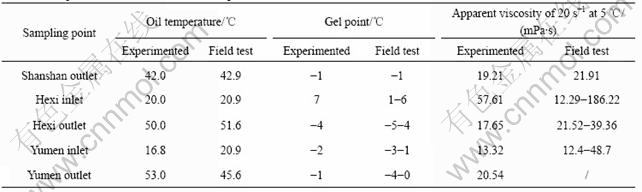

Since crude oil A was only transported to Yumen, its simulation was carried out for Shanshan to Yumen segment. Table 3 lists the comparison of field test results with experimental simulation ones for PPD-beneficiated crude oil A. It can be seen that the flow properties measured at inlet of Hexi station are worse than those at Shanshan (both gel point and viscosity increased), since there is no reheating during pipelining, this deterioration of the flow properties may be attributed to the shear effect during pipelining.

The gel points and viscosities from experimental simulation are all in the range of field test results, i.e. simulation results are in agreement with the field data.

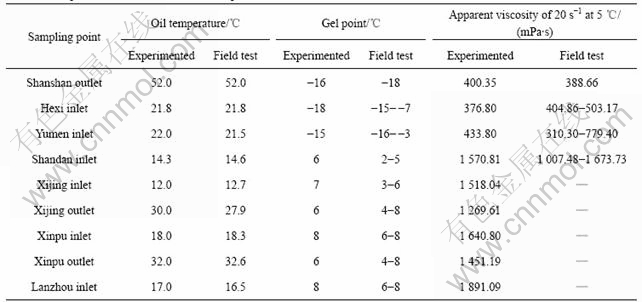

The comparison of field test results with experimental simulation ones for PPD-beneficiated crude oil B are listed in Table 4. The results also indicate that experimental simulation data are in agreement with the field data. From Table 4, one should note that the gel points from Shanshan to Yumen were all below -3 ℃, but the gel point at the inlet of Shandan rose rapidly to about 5 ℃, and the beneficiation effect of PPD lost completely. This is the result of the crude oil being reheated to 27 ℃ at the previous station, Zhangye. The

Table 3 Comparison of field test results and experimental simulation results for PPD-beneficiated crude oil A

gel points of Xijing, Xinpu and Lanzhou rose further, which all resulted from the reheating to about 30 ℃ at the previous station. The results of both lab experiments and field tests show that the reheating in certain temperature range may cause the gel point of PPD- beneficiated crude oil rise obviously, with the maximum even exceeding the gel point of the as-received virgin crude at the initial station[9].

Table 5 compares the field test results with experimental simulation ones for PPD-beneficiated crude oil C. It indicates once more that simulation results are in agreement with the field data.

Table 4 Comparison of field test results and experimental simulation results for PPD-beneficiated crude oil B

Table 5 Comparison of field test results and experimental simulation results for PPD-beneficiated crude oil C

5 Conclusions

The shear and thermal history of three PPD- beneficiated waxy crude oils transported through China West Crude Oil Pipeline were simulated by using a stirred vessel and with the energy dissipation of viscous flow as the shear simulation parameter. The comparisons of flow properties of the crude oils obtained from field tests with experimental simulation show that the gel points and viscosities from simulation are in agreement with the field data. This once more verifies the reliability and accuracy of taking energy dissipation or entropy generation as a parameter for shear simulation.

References

[1] BOGER D V. From macroscopic to microscopic flows: Something old, something new, and something very new[C]// Proceedings of XIV International Congress on Rheology. Korea, 2004: PL01.

[2] WARDHAUGH L T, BOGER D V. Flow characteristics of waxy crude oils: Application to pipeline design[J]. AIChE J, 1991, 37: 871-885.

[3] ZHANG Jin-jun, LIU Zhong-hui, ZHANG Fan, et al. Waxy crude treated with pour-point-depressants: flow behaviour and its evaluation[C]// Proc of ISMNP’97, International Acadamic Press, 1997: 7-15-7-20

[4] ZHANG Jin-jun, ZHOU Shu-hui, LI Hong-ying, et al. Entropy generation as a parameter to simulate the shear history effect of the beneficiated waxy crude oils[C]// Proceedings of the XIV International Congress on Rheology. Korea, 2004: SU39.

[5] NENNIGER J. Method and apparatus for measurement and prediction of waxy crude characteristics: US 5959194[P]. 1999.

[6] ZHANG Jin-jun, ZHANG Fan, HUANG Qi-yu, et al. Experimental simulation of the effect of shear on rheological properties of beneficiated waxy crude oils[J]. J Cent South Univ Technol, 2007, 13 (Suppl 1): 108-111.

[7] GILLIES R D, SUN R, SHOOK C A. Laboratory investigation of inversion of heavy oil emulsions[J]. The Canadian Journal of Chemical Engineering, 2000, 78: 757-763.

[8] ZHANG Jin-jun, HUANG Qi-yu, YAN Da-fan. Estimation of average shear rate in stirred vessels for pipelining shear simulation[J]. Acta Petrolei Sinica, 2003, 24: 94-96, 100. (in Chinese)

[9] LING Xiao, ZHANG Jin-jun, LI Hong-ying, et al. Transportation of waxy crudes in batch through China West Crude Oil Pipeline with pour-point-depressant beneficiation[C]// 7th International Pipeline Conference. Calgary Alberta, 2008, IPC2008-64288.

(Edited by LONG Huai-zhong)

Received date: 2008-06-25; Accepted date: 2008-08-05

Corresponding author: LI Hong-ying, Associate professor; Tel: +86-10-89733543; E-mail: lihy314@sohu.com

- Simulation of pipelining pours point depressant beneficiated waxy crude oil through China West Crude Oil Pipeline