Cu含量对2:17型SmCo永磁体磁畴结构和矫顽力的影响

钢铁研究总院高温材料研究所

摘 要:

采用粉末冶金的方法制得2∶17型SmCo永磁体, 通过对磁体进行X射线衍射 (XRD) 、振动样品磁强计 (VSM) 和磁力显微镜 (MFM) 等分析, 较为系统地研究了Cu含量对Sm (Co bal Fe0.20Cu x Zr0.03) 7.5 (x=0.06, 0.08) 永磁体的磁畴结构及矫顽力的影响。研究结果表明, 2∶17型SmCo永磁体属于多磁畴晶体, 其磁畴结构主要表现为波纹畴结构, 磁畴宽度约12μm, 畴宽远小于晶粒尺寸。Cu含量对磁体的X射线衍射谱没有明显影响, 但对磁畴宽度和内禀矫顽力i H c影响很大, 且磁畴宽度与内禀矫顽力i H c具有一定的对应关系。磁体的X射线衍射谱上显示了2∶17相和1∶5相特征峰, 没有出现会影响磁体磁性能相的特征峰。Cu含量增大, X射线衍射谱并未出现明显的变化。随Cu含量增加, 磁体磁畴宽度由2μm减小到1μm, 1∶5胞壁相的畴壁能降低, 内禀矫顽力i H c相应增大, 表明畴壁钉扎是吸引型钉扎。内禀矫顽力i H c在室温时为2473 kA·m-1, 到450℃时减小为457 kA·m-1, 热激活能是内禀矫顽力i H c随温度升高而逐渐降低的主要因素。高温下Cu含量越高的磁体的2∶17主相和1∶5胞壁相间畴壁能差越大, 从而使矫顽力随温度的升高衰减减缓。

关键词:

中图分类号: TM273

作者简介:王倩 (1987-) , 女, 北京人, 硕士;研究方向:功能材料、高温合金. (E-mail:crystalxuanyuan@sina.com) ;

收稿日期:2013-06-21

基金:国家自然科学基金项目 (51071010);国家科技部高技术研究发展计划项目 (2010AA03A401) 资助;

Effects of Cu on Domain Structures and Intrinsic Coercivity of 2:17-Type SmCo Permanent Magnets

Wang Qian Wang Yanbo Li Yang Li Peijia Zhang Xin Li Juntao

High Temperature Materials Division, Central Iron and Steel Research Institute

Abstract:

The effects of Cu content on the domain structures and the intrinsic coercivity of 2∶ 17-type Sm ( Co bal Fe0. 20Cu x Zr0. 03) 7. 5 ( x =0. 06, 0. 08) magnets prepared by powder metallurgy process were systematically studied by X-ray diffractometry ( XRD) , vibration sample magnetometer ( VSM) and magnetic force microscopy ( MFM) . The results showed that 2∶ 17-type SmCo permanent magnets had multi-domain structures, which were mainly corrugated domains with the width of 1 ~ 2 μm and far thinner than the cell size. Cu content had little effects on XRD measurements, but had obvious effects on the width of the domain and the intrinsic coercivity i H c.Meanwhile, there was the corresponding relation between the width of the domain and the intrinsic coercivity i H c. There were 2∶ 17 and1∶ 5 phases but no characteristic peaks of hazardous phase for magnetic properties on the X-ray spectrum and no significant changes on the X-ray spectrum when Cu content increased. With raising Cu content, the width of the domain changed from 2 to 1 μm and the domain wall energy of 1∶ 5 boundary phase decreased while the intrinsic coercivity i H c increased which indicated the attractive domain wall pinning. The intrinsic coercivity was 2473 kA·m- 1at room temperature and 457 kA·m- 1at 450 ℃ and the thermal activation energy was the main factor which led to the reduction of the intrinsic coercivity i H c. At high temperature, the higher the Cu content was, the greater the energy difference was between 2∶ 17 phase and 1∶ 5 phase, thus caused slower decrease of the intrinsic coercivity i H c with temperature increasing.

Keyword:

SmCo permanent magnets; domain structure; coercivity; magnetic properties;

Received: 2013-06-21

2∶17型Sm Co永磁体的磁性能高、居里温度高、剩磁温度系数低、耐蚀性及热稳定性好, 在永磁材料中具有不可替代的作用, 尤其在航空航天、交通运输、微波通讯技术等领域得到了广泛的应用[1,2,3,4,5]。

2∶17型Sm Co永磁体具有长菱形的胞状结构, 易磁化轴沿c轴。胞内为Th2Zn17型Sm2 (Co, Fe) 17三方晶系富Fe主相, 胞壁是Ca Cu5型Sm (Co, Cu) 5六方晶系富Cu相, 两相呈共格关系。Th2Ni17型六方晶系片状富Zr相镶嵌于胞状结构之中, 与c轴相垂直。均匀的胞状组织为磁性能提供了保障, 永磁体的磁化强度主要来自2∶17主相, 同时时效过程中主相中的Cu通过片状相进入胞壁, 形成富Cu胞壁相, 对畴壁形成强的钉扎[6]。目前对于钉扎类型有两种观点, 且尚不统一。Liu等[7]认为含Cu量越多, 1∶5相的畴壁能越低, 2∶17相与1∶5相的能差增大, 矫顽力提高, 所以Sm Co永磁体是吸引型钉扎。Kronmuller等[8]认为没有Cu富集的1∶5相的磁晶各向异性常数K1高, 胞壁表现为排斥型钉扎。Xiong等[9]也认为含Cu量低的磁体, 经高温淬火后表现为排斥型钉扎。国内外学者对磁畴结构进行了一定研究。Hubert等[10]通过采用TEM方法观察磁畴结构来研究畴壁钉扎, 但薄片TEM样品的磁畴结构与块体的不尽相同, 说明TEM方法不能很好的反映块状样品的磁畴结构。也有学者[11,12,13]通过MFM研究2∶17型Sm Co永磁体, 但用MFM研究Cu含量对磁畴结构影响的研究尚少。近些年, 基于美国航空航天领域对永磁材料高温环境的应用需求, 最高使用温度高于500℃的高温永磁材料逐渐成为研究热点, 而2∶17型Sm Co永磁体的矫顽力对Cu含量及其敏感, 所以研究Cu含量对Sm Co永磁体的矫顽力的影响非常重要。

本文设计了不同Cu含量的Sm (CobalFe0.20CuxZr0.03) 7.5 (x=0.06, 0.08) 磁体实验, 采用X射线衍射测试、磁滞回线测试和磁畴观察的方法, 探索Cu含量对磁体的磁畴结构及磁性能的影响, 并分析磁体的室温和高温矫顽力机制。

1 实验

本实验所用的原材料是纯度为99.9%以上的Sm, Co, Cu, Fe和Zr, 配制目标成分Sm (CobalFe0.20Cu0.06Zr0.03) 7.5和Sm (CobalFe0.20Cu0.08Zr0.03) 7.5的合金, 为了控制Sm在熔炼和后续制备过程中的烧损, 增加6%的烧损, 在非自耗式真空电弧炉中熔炼。在真空手套箱中手工粗破碎合金铸锭后过80目筛, 再以丙酮溶液为介质球磨1 h。在5 T磁场下给磁粉取向, 再以冷等静压压制成型。在真空管式炉中以1170~1210℃的温度下烧结1~3 h, 在1130~1200℃的温度下固溶处理1~3 h。在800~860℃的温度下时效12~24 h, 以0.5~1.0℃·min-1的速率冷却到400~450℃, 保温2~10h, 淬火得到样品。将样品用电火花线切割机切成Φ3 mm×3 mm的圆柱状, 用于测量磁滞回线, 剩下的样品用胶木粉热镶嵌后先经过200#砂纸粗磨, 接着依次在800#, 1000#, 1500#, 2000#金相砂纸上细磨, 然后进行机械抛光, 用于MFM测试。

采用JDAW-2000C型振动样品磁强计 (VSM) 测量样品从室温到450℃下的磁性能, 采用FZ-T-10000-H-VI-P-SH型多功能物理性能测量系统 (PPMS) 测量了部分样品的室温磁滞回线作为校正。采用Nanoscope型磁力显微镜 (MFM) 表征样品的磁畴结构。MFM的磁探针是以Si为骨架, 外层镀有Co-Cr磁性薄膜, 垂直向上磁化永磁体, 磁畴结构中的黑区表示磁针和样品之间是吸引作用, 白区表示两者为排斥作用[14]。物相分析由D/max2200PC自动X射线衍射分析仪进行表征。

2 结果与讨论

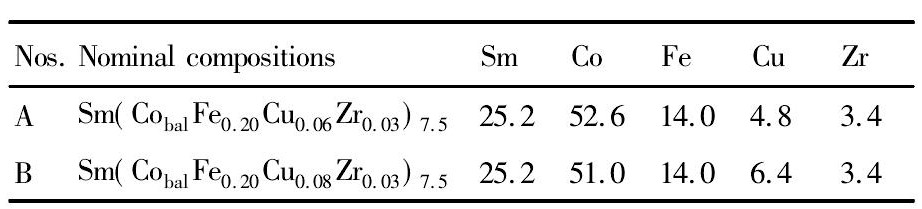

表1为烧结磁体A:Sm (CobalFe0.20Cu0.06Zr0.03) 7.5和B:Sm (CobalFe0.20Cu0.08Zr0.03) 7.5的名义成分。两种磁体具有相同的Fe含量14.0%, 磁体A的Cu含量为4.8%, 磁体B的Cu含量为6.4%。

表1 Sm (CobalFe0.20Cu0.06Zr0.03) 7.5和Sm (CobalFe0.20Cu0.08Zr0.03) 7.5永磁体的名义成分 (%, 质量分数) Table 1Nominal compositions of Sm (CobalFe0.20Cu0.06Zr0.03) 7.5and Sm (CobalFe0.20Cu0.08Zr0.03) 7.5permanent magnets (%, mass fraction) 下载原图

表1 Sm (CobalFe0.20Cu0.06Zr0.03) 7.5和Sm (CobalFe0.20Cu0.08Zr0.03) 7.5永磁体的名义成分 (%, 质量分数) Table 1Nominal compositions of Sm (CobalFe0.20Cu0.06Zr0.03) 7.5and Sm (CobalFe0.20Cu0.08Zr0.03) 7.5permanent magnets (%, mass fraction)

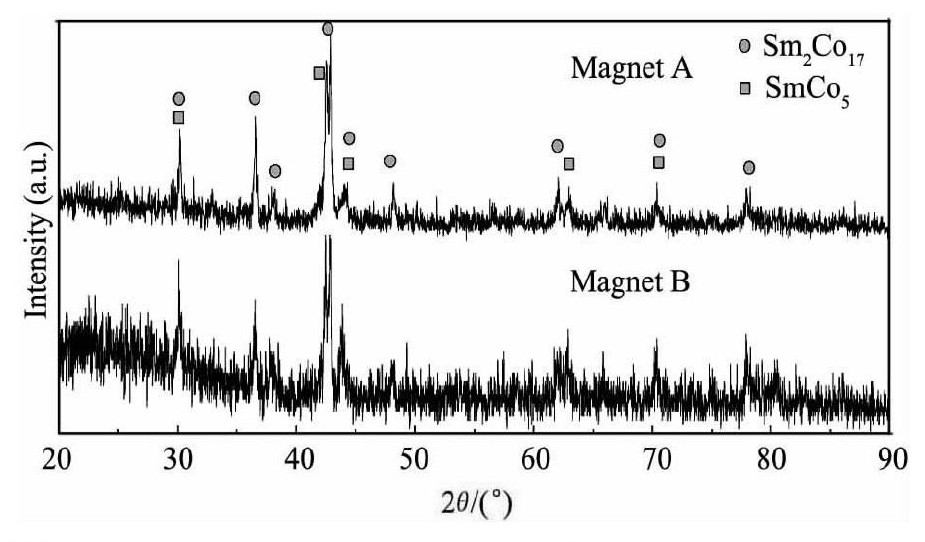

图1是烧结磁体A:Sm (CobalFe0.20Cu0.06Zr0.03) 7.5和B:Sm (CobalFe0.20Cu0.08Zr0.03) 7.5的X射线衍射图。从图1可以看出2个磁体都出现了2∶17相和1∶5相的特征峰, 并没有出现明显的可能会影响磁体性能的相的特征峰, 如:1∶3相, 2∶7相或Fe-Co软磁相, 可见少量的Cu含量的变化对磁体的相结构影响不大。

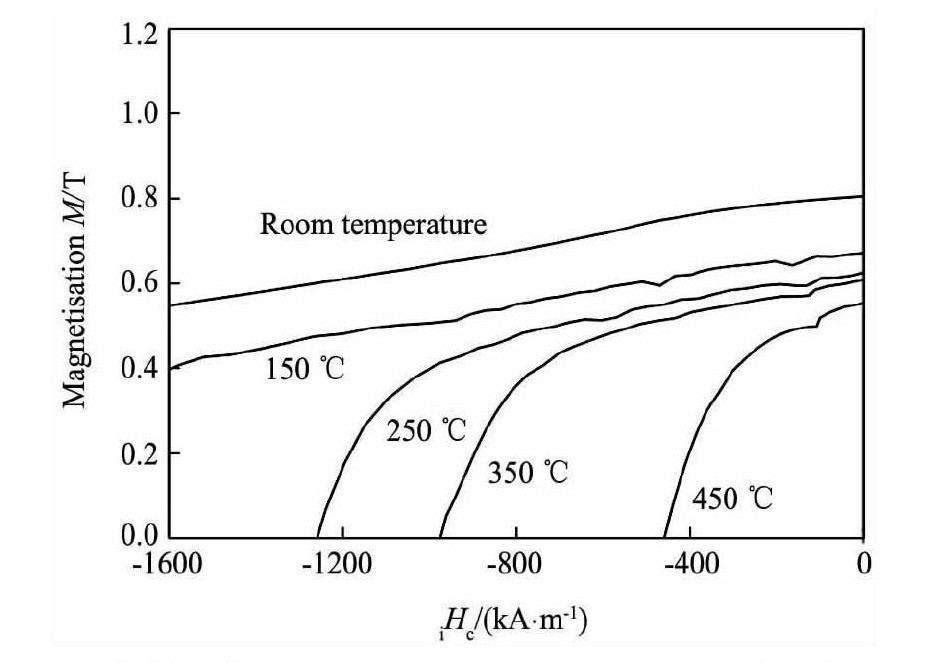

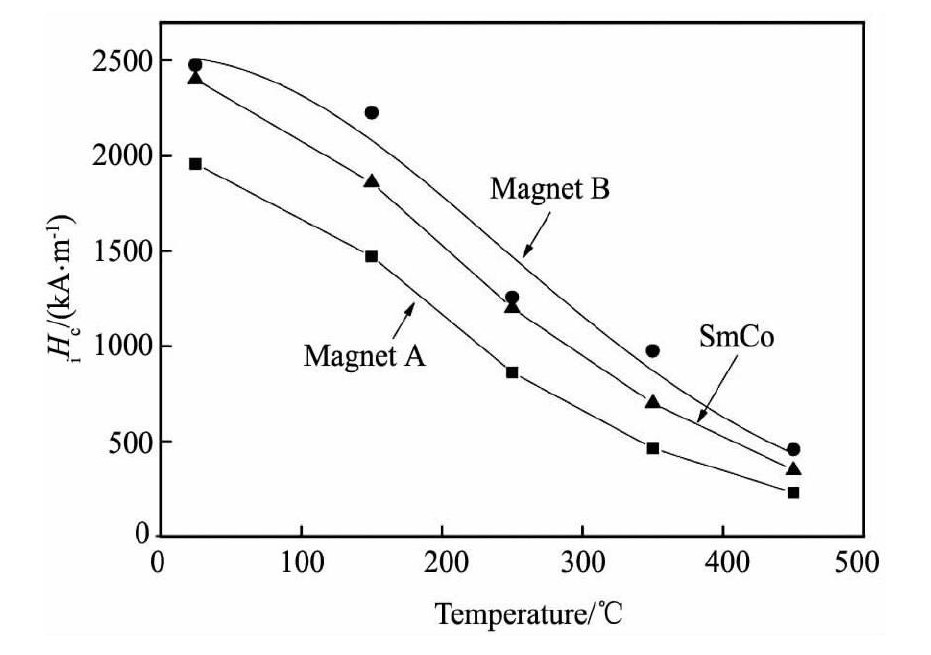

图2为磁体A与B以及文献[1]中商用2∶17型Sm Co磁体的内禀矫顽力iHc随温度变化的曲线。室温下, 当Cu含量由0.06增加到0.08时, 内禀矫顽力iHc增长近500 k A·m-1, 说明iHc随Cu含量的增加而增加, 随着温度的升高而逐渐降低, 且磁体B从室温到450℃的性能都优于商用2∶17型Sm Co永磁体。

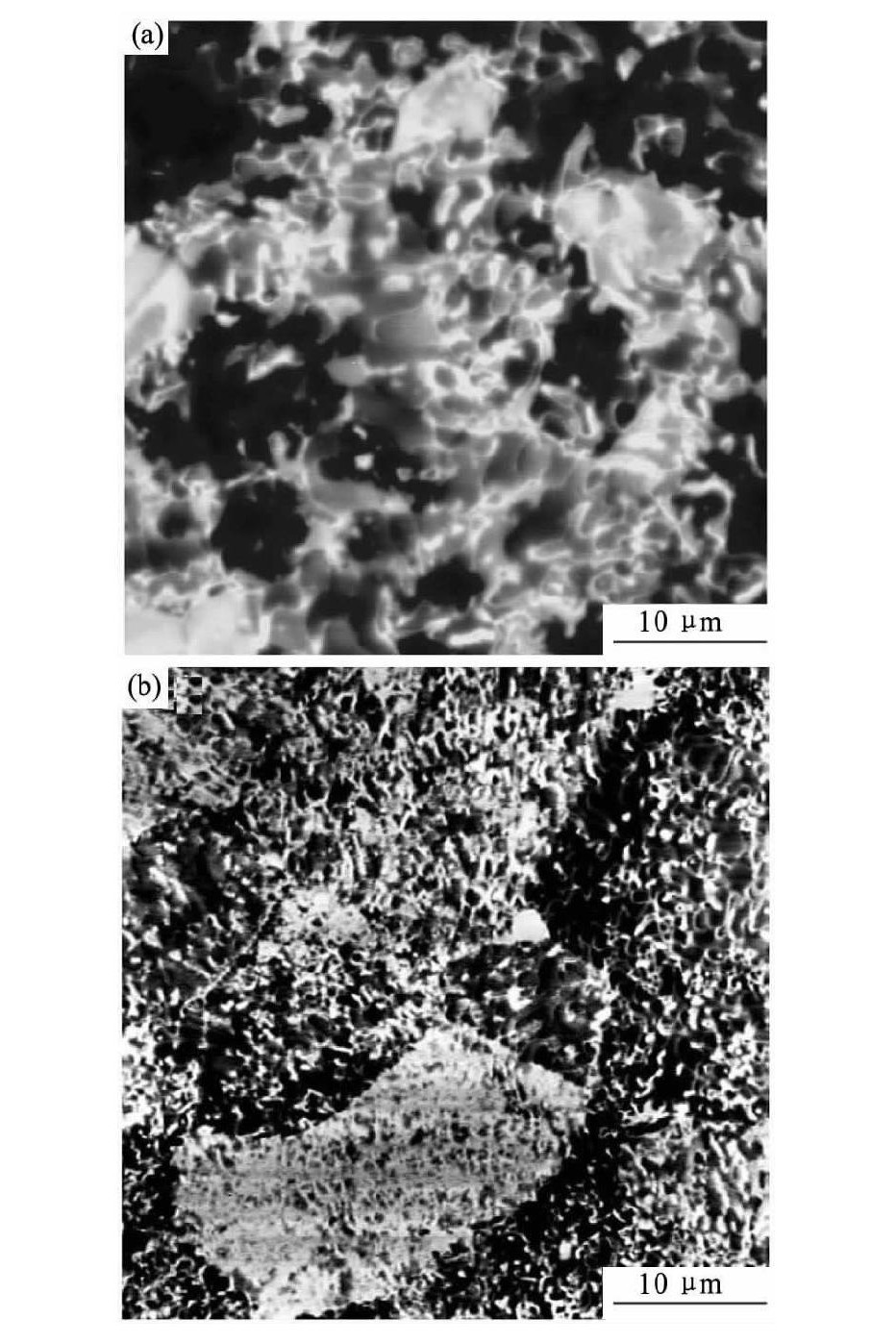

图3是热退磁状态下的永磁体A和B的磁畴结构图。由图可见, 两个磁体表面为明显的波纹畴结构。2∶17型Sm Co永磁体作为一种单轴磁晶各向异性材料, 当易磁化轴c轴垂直于样品表面时, 为减小表面退磁能而形成的磁畴结构。磁体的畴壁被胞壁钉扎, 磁畴分布均匀、大小相近且磁畴边界比较模糊, 说明两个磁体的易磁化轴都近似垂直于试样表面, 即磁化强度方向基本垂直于试样表面[15,16]。

图1 Sm (CobalFe0.20Cu0.06Zr0.03) 7.5和Sm (CobalFe0.20Cu0.08Zr0.03) 7.5烧结磁体的X射线衍射图Fig.1 XRD patterns of A:Sm (CobalFe0.20Cu0.06Zr0.03) 7.5and B:Sm (CobalFe0.20Cu0.08Zr0.03) 7.5sintered magnets

图2磁体A: (Sm (CobalFe0.20Cu0.06Zr0.03) 7.5) 与磁体B: (Sm (CobalFe0.20Cu0.08Zr0.03) 7.5) 以及商用2∶17型Sm Co磁体的内禀矫顽力iHc随温度的变化关系Fig.2 Comparisons of temperature dependence of intrinsic coercivity for magnet A: (Sm (CobalFe0.20Cu0.06Zr0.03) 7.5) , magnet B: (Sm (CobalFe0.20Cu0.08Zr0.03) 7.5) , and commercial 2∶17-type Sm Co permanent magnet

两种磁体具有相同的Fe含量14.0%, 磁体A的Cu含量为4.8%而磁体B的Cu含量为6.4%。由图3 (a) 可知, 磁体A的磁畴宽度约2μm, 而经热处理后的2∶17型Sm Co永磁体的胞状结构大小约为60~100 nm, 说明磁畴远小于晶粒尺寸。对比磁畴图可知, 磁体B比A的畴细, 即当Fe含量相同而Cu含量增加时, 磁畴变细, 宽度由2μm变到1μm。由图2可知, 室温时磁体B的内秉矫顽力高于磁体A近520 k A·m-1, 说明磁畴变细, 内秉矫顽力iHc提高。

2∶17型Sm Co永磁体为高磁晶各向异性单轴晶体, 磁畴多为条形畴 (或波纹畴) 结构, 其磁畴结构的畴宽表达式[17]为:

图3 热退磁状态下的Sm (CobalFe0.20CuxZr0.03) 7.5永磁体的MFM磁畴Fig.3 Domain structures observed by magnetic force microscopy (MFM) of thermally demagnetized Sm (CobalFe0.20CuxZr0.03) 7.5magnets

(a) Magnet A, x=0.06; (b) Magnet B, x=0.08

式中, d为畴宽, γ为1∶5相畴壁能, Ms为永磁体的饱和磁化强度, L为晶体的厚度, 对于2∶17型Sm Co永磁体特殊的显微结构, 此处的L就是指晶粒大小。当Cu含量从0.06提高到0.08时, 对磁体的晶粒大小L和饱和磁化强度Ms影响不大, 所以可以视为畴宽d∝γ1/2。众所周知, 内禀矫顽力iHc是由富Cu胞壁相对磁畴的钉扎作用形成的, 而iHc∝ΔE (ΔE为2∶17相和1∶5相之间的畴壁能差) 。当Cu含量增大, 畴宽d减小, 1∶5相畴壁能γ降低, 内禀矫顽力iHc相应提高, 由此明确表明了畴壁应是吸引性钉扎。

为了使畴壁钉扎富Cu的1∶5相胞壁相, 需要获得足够的能量以通过1∶5相和2∶17相之间的势阱, 磁场提供了所需要的能量, 高温下的热激活过程明显的促进了这个过程。因此2∶17型Sm Co永磁体的退磁过程也是一个热激活过程。

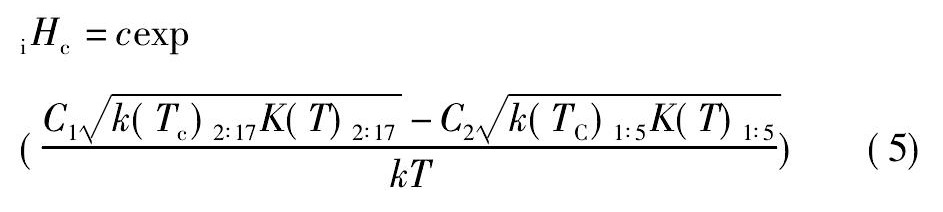

磁体的内禀矫顽力和温度有如下的关系[18]:

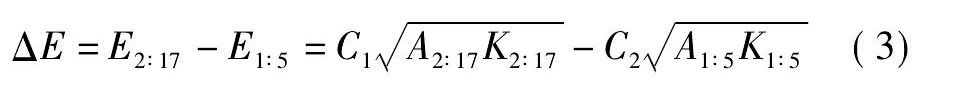

其中, T表示绝对温度, k为玻尔兹曼常数, c为常数。2∶17相和1∶5相间的畴壁能差ΔE可以表示为:

其中, C1, C2为常数, A为交换积分常数, K为磁晶各向异性常数。交换积分常数A与居里温度Tc有如下关系:

所以内禀矫顽力可表示为:

如图2所示, 磁体的内禀矫顽力随着温度的提高而逐渐降低, 说明了热激活作用使磁体发生了退磁过程。

富Cu的1∶5相的居里温度和磁晶各向异性都比2∶17主相低, 当温度升高时, 1∶5相的畴壁能比2∶17相下降的更多, 即2∶17相和1∶5相之间的畴壁能差增大, 从而使内禀矫顽力提高, 一定程度上补偿了由于热激活作用而造成的iHc降低。而Cu含量提高, 1∶5相的居里温度TC降低, 使含Cu量高的磁体的1∶5相畴壁能随温度的提高而降低更快, 两相的畴壁能差更大而内禀矫顽力提高。这就解释了图2中磁体B的Cu含量比磁体A高, 磁体B的内禀矫顽力虽然随温度降低, 但始终比磁体A高。磁体450℃时的性能降低很快是因为磁体在此温度下晶粒变大, 胞状组织不再完整, 1∶5相胞壁相也相应破坏, 对畴壁的钉扎作用减弱。同时温度增加使热激活作用增强, 甚至使Sm, Co在晶格上的位置发生变化[19]。

图4是永磁体B在25, 150, 250, 350和450℃的退磁曲线。由图可见, 试样从25℃升到450℃, 磁滞回线保持较好的方形度, 第二象限的退磁曲线也没有恶化, 较为光滑的退磁曲线表示磁体具有细而均匀的晶粒尺寸[20], 但随温度的升高, 磁滞回线逐渐变狭窄, 内禀矫顽力iHc和剩磁Br都随温度的增加线性递减, 内禀矫顽力在室温时为2473 k A·m-1, 到450℃时减小为457 k A·m-1。而350℃时磁体的iHc达到975 k A·m-1, 且方形度较好, 说明磁体B在350℃下依然保持较好的磁性能。

含Cu量高的永磁体不论在室温还是高温时都具有较高的矫顽力iHc, 说明Cu的增加促进了Cu扩散到1∶5相胞壁中, 使2∶17相和1∶5相之间的畴壁能差增大, 矫顽力提高。

图4 烧结磁体Sm (CobalFe0.20Cu0.08Zr0.03) 7.5不同温度下的退磁曲线Fig.4Demagnetization curves of sintered Sm (CobalFe0.20Cu0.08Zr0.03) 7.5magnet at different temperatures

3 结论

1.用粉末冶金法制备Sm (CobalFe0.20CuxZr0.03) 7.5 (x=0.06, 0.08) 烧结磁体的磁畴结构表现为波纹畴结构, 2∶17型Sm Co属多畴晶体, 磁畴远小于晶粒尺寸。

2.磁畴宽随Cu含量的增加而减小, 内禀矫顽力iHc随Cu含量的增加而增大, 明确表明其畴壁钉扎是吸引型钉扎。

3.随温度增加, 内禀矫顽力iHc降低, 其在高温下的衰减主要是热激活作用导致的, 含Cu量高的磁体的矫顽力随温度的升高衰减较慢。

参考文献

[17] Zhong W D.Ferromagnetism[M].Beijing:Science Press, 2000.116. (钟文定.铁磁学[M].北京:科学出版社, 2000.116.)