- Abstract:

- 1 Introduction▲

- 2 MDO for POS in air...▲

- 3 Implementation of ...▲

- 4 Simulation and ana...▲

- 5 Conclusions▲

- References

- Figure

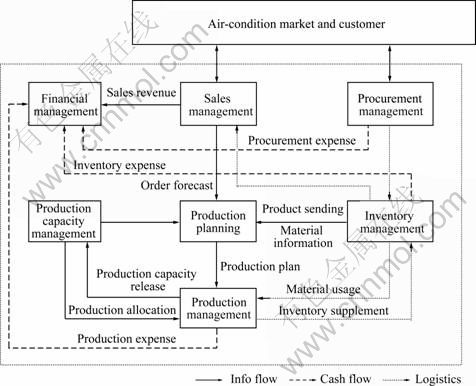

- Fig. 1 Model of air-condition enterprise production operation

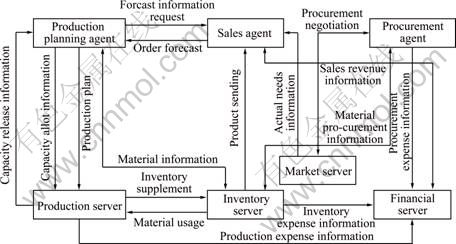

- Fig. 2 Simulation model of enterprise production operation based on multi-agent technique

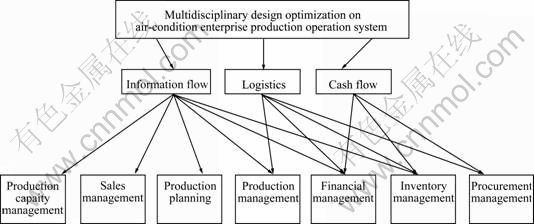

- Fig. 3 Grading structure of multidisciplinary optimization design

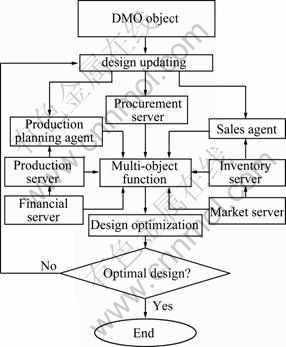

- Fig. 4 MDO process of air-condition enterprise production operation system

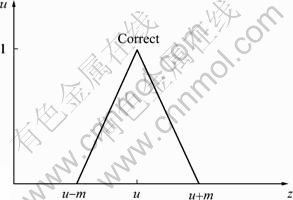

- Fig. 5 Triangle membership function

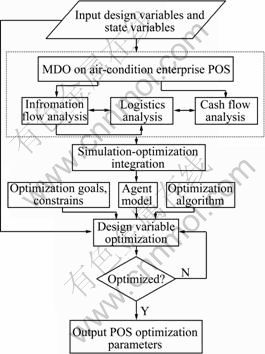

- Fig. 6 Flow chart of design and optimization of air-condition enterprise production operation system

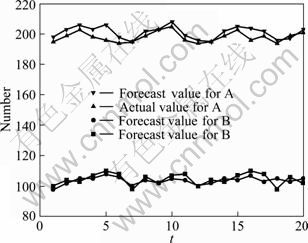

- Fig. 7 Sales forecast and actual demands of air-condition

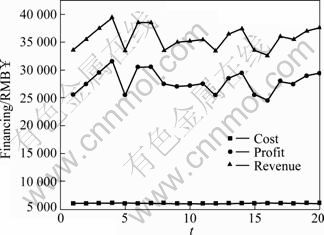

- Fig. 8 Optimization results of demands and income, cost and profit of air-condition enterprise

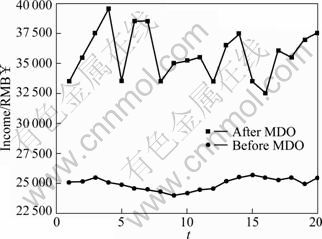

- Fig. 9 Comparison of air-condition enterprise income before and after multidisciplinary design optimization

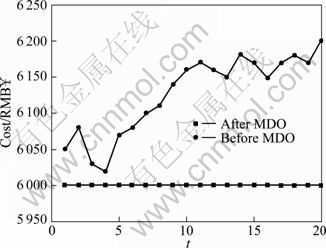

- Fig. 10 Comparison of air-condition enterprise cost before and after multidisciplinary design optimization

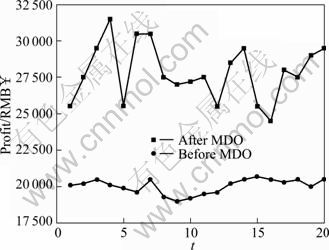

- Fig. 11 Comparison of air-condition enterprise profit before and after multidisciplinary design optimization

J. Cent. South Univ. (2012) 19: 527-536

DOI: 10.1007/s11771-012-1036-z![]()

Multidisciplinary design optimization for air-condition production system based on multi-agent technique

YANG Hai-dong(杨海东)1, E Jia-qiang(鄂加强)2, QU Ting(屈挺)1

1. Department of Mechatronics Engineering, Guangdong University of Technology, Guangzhou 510006, China;

2. College of Mechanical and Vehicle Engineering, Hunan University, Changsha 410082, China

? Central South University Press and Springer-Verlag Berlin Heidelberg 2012

Abstract:

In order to guarantee the overall production performance of the multiple departments in an air-condition production industry, multidisciplinary design optimization model for production system is established based on the multi-agent technology. Local operation models for departments of plan, marketing, sales, purchasing, as well as production and warehouse are formulated into individual agents, and their respective local objectives are collectively formulated into a multi-objective optimization problem. Considering the coupling effects among the correlated agents, the optimization process is carried out based on self-adaptive chaos immune optimization algorithm with mutative scale. The numerical results indicate that the proposed multi-agent optimization model truly reflects the actual situations of the air-condition production system. The proposed multi-agent based multidisciplinary design optimization method can help companies enhance their income ratio and profit by about 33% and 36%, respectively, and reduce the total cost by about 1.8%.

Key words:

1 Introduction

Intensified competition among enterprises has, to a large extent, led to the expansion of production scale as well as applications of new production equipments and control systems. It not only makes the enterprises discrete, uncertain, dynamic and complex, but also makes the enterprise manufacturing process decentralized and heterogeneous, which has brought certain difficulties for the production operation. Thus, the enterprise production modeling and simulation techniques have gradually attracted the attention of enterprise operators and academic researchers [1]. The simulation blocks in traditional simulation method [2] lack initiative and autonomy and the department level blocks also lack responsibility for the whole model system in the processing of air-condition enterprises operation system. However, in practice, each part of the air-condition enterprise is intelligent, and they can analyze the internal and external information and make decisions accordingly. Such cooperation capability of departments is based on the collaboration of each department, as well as the comprehensive analysis of their own information and decision-making. When the traditional simulation methods are applied to intelligent air-condition enterprises, they only consider operation process, the logistics and information flow of the enterprise, and do not take the changes of market and the cash flow impacting on business operations into account. Hence, the traditional simulation methods are certainly not suitable for applications in task allocation, decomposition, production planning and scheduling, as well as resource planning in the production process of the air-condition enterprises.

Since distributed artificial intelligent agents can run independently under certain environments, they have their own attributes, behaviors, goals and knowledge, as well as their characteristics in initiative, intelligence, responsiveness, interaction, etc. Therefore, the multi-agent technique is attractive simulation tool for the enterprise production systems [3-7].

In the modern management of production systems, it is necessary to take information like logistics, information flow and fund flow, into account. The organization of enterprise becomes more and more complex, and the operation process becomes more and more complicated. Therefore, it is necessary for the optimization modeling of enterprise production system to be systematic and general. With the rapid improvement of computer performance, the increasing complexity of the enterprise production system and higher demands for the properties of products, a new method for modeling and optimization of enterprise production operation system (POS) is proposed based on the multidisciplinary design optimization (MDO) [8-10] recently.

2 MDO for POS in air-condition enterprise

2.1 POS model for air-condition enterprise

The production operation process of modern air-condition enterprises emphasizes the collaboration between internal functional departments and external environments. Each department is responsible for making its own decision according to different information, and the production operation tasks will be completed through the collaboration of all related departments. As depicted in Fig. 1, the order fulfillment is taken as the essential objective in the production operation process. The production plan is made mainly based on the sales forecast. The production plan department is responsible for coordinating the production resources and arranging the production activities in air- condition enterprises. The inventory department is responsible for managing raw materials and ultimate products in air-condition enterprises. The procurement department organizes procurement based on business needs of the air-condition enterprise, but the actual procurement is determined by the market fluctuation. The production department carries out ordered products according to the production plans.

2.2 Simulation model based on multi-agent

As shown in Fig. 2, by combining the model of air-condition enterprise production operation system shown in Fig. 1 and the multi-agent technology, knowledge on enterprise production operation can be fed to the production plan agent, marketing agent and procurement agent. The necessary external environment for the production planning agent, sales agent and procurement agent is created by the production server, inventory server, sales server and financial server. Each individual functional department mentioned above should possess certain properties and characteristics of realizing the operation of air-condition enterprise department and can respond accordingly to different decisions made by production plan agent, marketing agent and procurement agent. High-level strategies for the operations of production planning agent, sales agent and procurement agent are achieved by reasoning and decision-making based on necessary information in the simulation system.

1) The production planning agent makes the production plan based on the demand information forecast by the sales agent, under the consideration of the current raw materials and production capability levels of enterprise and other information.

2) The sales agent forecasts the demands of air-conditioners based on the historical demand data and the market trends. When receiving the actual demands of air-conditioners, it notifies the warehouses to deliver air-conditioners.

Fig. 1 Model of air-condition enterprise production operation

Fig. 2 Simulation model of enterprise production operation based on multi-agent technique

3) The procurement agent firstly evaluates the suppliers with the fuzzy analytic hierarchy process (AHP) method, selecting those of good performance and negotiating the order details. After receiving the supplied raw materials, the procurement agent conducts a quality test and then records the performance of the suppliers to the knowledge base for future evaluation.

4) The inventory server records the changes of raw material and ultimate product inventory. It responds to the queries of the production planning agent about current raw material and the queries of the sales agent about current ultimate product.

5) The production server arranges the raw materials and production capacities for production according to the production plan. During the production process, it records the real-time production capacity information of the enterprise. After the complement of production, the occupied production capacity is set free, and the air-conditioners are sent to warehouses. All the material transaction processes will be recorded.

6) The finance server records the income and cost information of the enterprise, estimates the profits to facilitate the decision-making for the managers.

7) The market server provides external environment for the operation of the system: 1) Describing market conditions of raw materials, and providing the raw material demands according to the market changes; 2) Describing the actual air-conditioner demand information.

2.3 MDO for air-condition POS

Multidisciplinary design optimization (MDO) is a methodology to design complex system and sub-system through exploring and using the interactional synergistic mechanism in system. The main idea of MDO for the production operation system (POS) is to integrate the multidisciplinary knowledge through the whole process of the complex system design. The air-condition enterprise POS is designed and optimized based on the multi-agent technique and utilization of effective design, optimization strategies and distributed computer network system. The optimum design results of the air-condition enterprise POS are obtained by making use of synergistic effect generated by interaction among subjects (sub-systems). The MDO framework of the air-conditioner enterprise POS is shown in Fig. 3.

The MDO is carried out on three levels of the air-condition enterprise POS: system level, interaction level (information flow, logistics and cash flow) and department level (production capacity management, sales management, production planning management, production management, finance management, inventory management and procurement management). The objective function of global optimization for air-condition enterprise POS is to minimize the overall production cost, and to maximize the profits of the POS. Meanwhile, it distributes indicators to the interaction level under the constrained conditions that the indicators of the system level are same to those of the component level. It takes the minimization on the difference between indicators of distribution of optimization design for the component level and that of the system level as the objective function of the component level optimization design, and it distributes indicators to its own departments under the constrained conditions of the component level.

By adjusting the geometric structure size of component, it causes constrained condition of each subject in the department level to be met. Through the above three-level optimization, coordination is achieved among the departments and enterprise. In other words, the complex coupling relationships among the departments and enterprise are decomposed through the consistency constraints, and the comprehensive optimum design scheme would be found through it. In the above process, if an upper-level system contains too many lower-level systems, one or more intermediate levels could be added if necessary. For example, a unit level optimization can be added between the interaction level and department level.

Fig. 3 Grading structure of multidisciplinary optimization design

2.4 MDO model of air-condition enterprise POS

Based on the above-mentioned MDO framework, the process of themultidisciplinary design optimization on air-condition enterprise production operation system is designed and depicted in Fig. 4, including the production planning agent, sales agent, procurement agent, production server, inventory server, market server and financial server of the POS.

The problem of the MDO on POS can be expressed as a mathematical programming optimization problem:

min f(X, Y, Z) (1)

s.t. gi(X, Y, Z)≤0 (i=1, 2, …, n)

where f(X, Y, Z) is the objective function.

f(X, Y, Z)=W1f1(X, Y, Z)/f10(X, Y, Z)+

W2f2(X, Y, Z)/f20(X, Y, Z)+W3f3(X, Y, Z)/

f30(X, Y, Z)+W4 f4(X, Y, Z)f40(X, Y, Z)+

W5f5(X, Y, Z)/f50(X, Y, Z)+W6f6(X, Y, Z)/

f60(X, Y, Z)+W7 f7(X, Y, Z)/f70(X, Y, Z)

where f1(X, Y, Z) is the objective function of production planning agent, f2(X, Y, Z) is the objective function of sales agent, f3(X, Y, Z) is the objective function of procurement agent, f4(X, Y, Z) is the objective function of production server, f5(X, Y, Z) is the objective function of inventory server, f6(X, Y, Z) is the objective function of market server, f7(X, Y, Z) is the objective function of financial server; f10(X, Y, Z) to f70(X, Y, Z) are the initial values before MDO of production planning agent, sales agent, procurement agent, production server, inventory server, market server, financial server respectively; W1, W2, W3, W4, W5, W6 and W7 are the weighted coefficients of the objective functions of the production planning agent, the sales agent, the procurement agent, the production server, the inventory server, the market server and the financial server in the total objective planning, respectively, and W1+W2+W3+W4+W5+W6+W7=1; X=(X1, X2, …, Xi, …, XI)T, is the information flow variable; Y=(Y1, Y2, …, Yj, …, YJ)T is the logistics variable;Z=(Z1, Z2, …, Zk, …, ZK)T is the cash flow variable; gi(X, Y, Z) is the constrained condition.

Fig. 4 MDO process of air-condition enterprise production operation system

2.5 Self-adaptive chaos immune optimization algorithm with mutative scale

2.5.1 Selection of chaos model

It has been proven in Ref. [11] that the one-dimensional self-mapping described in Eq. (2) has infinite folds. It has infinite fixed points and zero points in [-1, 1], and has more obvious chaos characteristics than the logistic model:

![]() (2)

(2)

2.5.2 Parallel chaos immune clustering algorithm

In the artificial immune algorithm, matching algorithm or evolution algorithm is used to accomplish data training and immune memory. Evolution algorithm has better performance than matching algorithm. The parallel chaos immune clustering algorithm in this work can be described as follows.

Step 1: Input the antigen {g} and normalize it. Choose Eq. (1) as a chaos model, and randomly generate N initial antibodies {b} in interval (0, 1).

Step 2: Operate on each antigen gi as follows:

1) Use Eq. (3) to calculate the appetency aij between antibody bi and antigen gi:

![]() (3)

(3)

2) Select m pieces of antibodies with the highest appetency as the network cells.

3) Operate cloning on the m pieces of selected network cells. The higher the appetency, the larger the cloning times, Nc.

4) Use equation C=C-α(C-X) to carry out mutation operation for the cloned cells, where C is the clonal anti- body cell, X is the clonal antigen cell, and α is the mutation rate.

5) Re-calculate the appetency of C after mutation.

6) Select the best appetency, ξ, as the partial memory cell dataset Mp.

7) Use Eq. (4) to calculate the similarity sij between antibody bi and antibody bj and abandon the individual whose similarity sij is greater than the threshold value ss in Mp:

![]() (4)

(4)

Step 3: Combine Mp to the memory dataset M which is already obtained.

Step 4: Refine chaos search for better individual.

We suggest to select 10% individuals with better appetency in the memory base for refined chaos search. Suppose the better individuals are X=(X1, X2, …, Xk), the search interval of the chaos variable can be narrowed, and it can be described as

![]() (5)

(5)

where φ∈(0, 0.5), is the narrowing factor.

To guarantee that the new interval is not out of bounds, the following steps are needed: if ![]() <>i, then

<>i, then ![]() =ai , and if

=ai , and if ![]() >bi, then

>bi, then ![]() =bi.

=bi.

After reverted in the new interval [![]() ,

, ![]() ], Xi is changed to Yi, which can be determined by

], Xi is changed to Yi, which can be determined by

![]() (6)

(6)

Use the linear combination of Yi and Xi, n+1 as a new chaos variable for a new search:

![]() (7)

(7)

where 0<βi<1, is a self-adaptive accommodation coefficient.

It is determined by

![]() (8)

(8)

where m is a integer depending on the objective function (it is selected as 2 in this work), and K is the iterations (it is selected as evolution algebra in this work).

Then, remove those 10% individuals whose similarity is greater than σs in the memory base.

Step 5: Use Eq. (1) to generate N individuals in (0,1), substitute them for those with bad affinity, and put these individuals together with the memory dataset M as the antibody of next generation immune calculation. Return to Step 2 until network converges.

The stop condition of this algorithm is that the iteration is out of the pre-set max evolution generation number or the mean distance between the immune network cells of two near generations or the network size do not change (or the change is small enough).

After the optimum solutions W1, W2, W3, W4, W5, W6 and W7 are obtained, they are recorded into the memory.

3 Implementation of MDO on air-condition enterprise POS based on multi-agent technique

Java agent development framework (JADE) is used as the development tool for the air-condition enterprise POS. After it starts, a management agent will be created to manage the registration and cancellation of the POS and record the information such as names, addresses of the production planning agent, sales agent and procurement agent in the POS. A DF agent is also created to manage the services provided by the above three agents. The detailed implementation of the air-condition enterprise POS is discussed.

3.1 Multi-objective function design of air-condition enterprise POS

3.1.1 Objective function of production planning agent

If the current resources of the air-conditioner enterprise can meet the requirement of production, the production server will be notified directly to start its production activity. Otherwise, a decision is made based on the current limited raw materials and production capacity:

max f1(X1, Y1, Z1)=z11x11+z12x12 (9)

s.t. y11x11+y12x12≤y13

y13x11+y14x12≤b2

x11≥0, x12≥0

where f1(X1, Y1, Z1) is the expected max profit of the air-conditioner enterprise. X1 contains different air-conditioning products: x11 and x12. Y1 contains material consumptions of different air-conditioning products: y11, y12, y13 are the materials of the air-condition enterprise, y14 and y15 are the production capacity consumptions of different air-conditioning products, and y16 is the total production capacity of the enterprise. Z1 contains expected profits of different air-conditioner products: z11 and z12.

3.1.2 Objective function of sales agent

Based on the real historical data in the knowledge database of sales agent, a forecasting model f2(X2, Y2, Z2) is established by using the time series forecasting method:

![]() (10)

(10)

where f2(X2, Y2, Z2)t+1 is the forecasted value at cycle (t+1), wi is the weight at cycle i, f2(X2, Y2, Z2)i is the actual demand at cycle i, and n is the total weight of the forecasting cycle.

3.1.3 Objective function of procurement agent

Suppliers with best performance are selected by using the fuzzy AHP and taking into account of the factors such as the date of delivery of the supplier x31, supplier reputation x32, amount of air-conditioning products or raw materials y31, price of air-conditioning products or raw materials z31.

1) Confirmation of weights of different factors by AHP

The method of determining weights by AHP [4] can be described as follows:

Construct a judgment matrix C=(cij)n×n with the following properties: (1) cij>0; (2) cij=cji; (3) ci=j =1. The relative weight Wi can be expressed as

![]()

![]() (11)

(11)

2) Establishment of fuzzy judgment matrix

Based on the conditions of the procurement agent, some evaluation levels are selected to form a evaluation set: U={excellent, good, medium, poor, bad}. The specialist-scored method is used for the evaluation, whose detailed procedure is that for each evaluative index of the procurement agent. Each expert gives a score which must range in (0, 1), and the sum of the scores is 1 [12-14].

Currently, most methods on determining the membership function are still in a stage that the final goals are achieved relying on the experience and adjustment of knowledge through evaluating the feedbacks from practice. In many cases, it is the easiest method that expresses the fuzzy variables by using common distribution functions such as membership functions. Figure 5 shows the triangular membership function used for the fuzzy possibility distribution calculation of the procurement agent.

Fig. 5 Triangle membership function

Equation (12) shows how to calculate the membership using the mean value of the procurement agent:

(12)

(12)

where zijk is the k evaluation value of the j-th procurement agent in class i; uij is the mean value of the j-th procurement agent in class i; mij is the boundary of the fuzzy subset, which is a necessary condition to determine the membership of the procurement agent and can be self-adaptively adjusted based on its applications; usually mij=2σij and σij is the square error of the corresponding evaluation value given by

![]() (13)

(13)

According to the above method, the fuzzy judgment matrix can be constructed as

where μij is the risk indicator score evaluated by the expert, 0≤i≤m, 0≤j≤n.

3) Establishment of evaluation matrix of different factors

The evaluation matrixes of different factors Bi=Wij·Ri(0≤i≤m)are calculated and normalized.

4) Establishment of objective matrix

The objective matrix B=(B1T, B2 T, …, BiT) T is constructed.

5) Overall fuzzy evaluation

Carry out the overall fuzzy evaluation to get the result set, that is, the fuzzy subset f3(X3, Y3, Z3) which is combined by weight vector W and fuzzy matrix B:

f3(X3, Y3, Z3)=W·B

where X3 includes the date of delivery x31 and corporate reputation x32, Y3 includes the amount of air-conditioning products or raw materials y31, Z3 includes the prices of air-conditioning products or raw materials z31.

The evaluation value of the procurement agent is obtained from f3(X3, Y3, Z3)=W·B. The suppliers’ performance evaluated by experts-grading-method is stored into the knowledge base for later evaluation and selection.

The procedure of negotiation with the suppliers is a quadruple notation áx31, x32, y31, z31?. If any disagreement on the quadruple notation appears in the process of negotiation, a new negotiation scheme should be carried out.

3.1.4 Objective function of inventory server

The ultimate air-conditioner products are received by the inventory server. When there is a market demand, the products are sent to the market. The equivalent inventory record of renewed products from cycle t to cycle t+1 can be obtained:

f4(X4, Y4, Z4) =y41+y42-y43+(y41+y42-y43)/α (15)

where Y4 includes the amount of finished air- conditioning products at cycle t+1, y41, amount of the sold air-conditioning products at cycle t+1, y42, amount of remained air-conditioning products at cycle t, y43, amount of purchased raw materials at cycle t+1, y44, amount of raw materials sent to production at cycle t+1, y45, and amount of remained raw materials at cycle t, y46. α is the required raw materials for one air-conditioner product.

3.1.5 Objective function of production server

This server is used for the simulation of machine malfunction in the air-conditioner enterprise and provides information of real-time production capacity status for the production planning of air-conditioner. The machine malfunction in cycle t will obey the Weibull distribution as

f5(X5, Y5, Z5)=1-exp{-[(t-x53)/x52]x51} (16)

where X5 includes the shape parameter x51, the scale parameter x52, the position parameter x53, all of which can be obtained from historical malfunction information of the machine.

3.1.6 Objective function of financial server

The financial server is used to simulate the profit obtained by the enterprise, as well as the cost and expense information. The profit at cycle t is calculated:

f6(X6, Y6, Z6)=z61-z62-z62-z63 (17)

where Z6 includes z61, z62, z63, and z64, which are the sales profit, procurement cost, inventory cost and production cost at cycle t in the air-condition enterprise, respectively.

3.1.7 Objective function of market server

This server is used to simulate the actual demand information on air-conditioning products of the market. It simulates the demand information of air-conditioner on different periods in segments:

(18)

(18)

where Y7 includes y71, y72 and y73, and y71 is the demand quantity of air-conditioner of class i which is in the initial period t1, y72 is the demand quantity of air- conditioner of class i which is in the developing period t2, y73 is the demand quantity of air-conditioner of class i which is in the recession period t3, and n is the total type number of the air-conditioning productions.

4 Simulation and analysis for MDO on air-condition enterprise POS

4.1 Procedure of MDO simulation

The parametric modeling of the air-conditioner enterprise POS is implemented in the following procedure. Firstly, by using a self-customized program, the self-customized and formatted parameter files are operated to generate the numeric documents which are suitable for the information flow, logistics and cash flow analysis. Then, the information flow software, the logistics software, the cash flow software and the above self-customized program are integrated together into the optimization platform, where the MDO is accomplished. The relationships among the information flow, the logistics flow and the cash flow are depicted in Fig. 6, which includes the flow chart of the simulation integration.

Fig. 6 Flow chart of design and optimization of air-condition enterprise production operation system

4.2 Results of MDO

The MDO procedure of an air-conditioner enterprise based on multi-agent technique can be described as follows. Firstly, the fulfillment process of a forecast order is simulated, and one forecast order is generated by the sales agent during each simulation period. The production planning agent establishes the production plan based on the received order, supposing that the total production capacity of the enterprise is 800 units. The production server simulates the production activity based on the production plan received. The inventory server sets the maximal stock of raw materials to be 1000 units and the safety stock to be 300 units and sets the fixed quantity of product A to be 200 units and product B to be 100 units in a period based on the historical experience of enterprise. According to the above setting condition, the simulated MDO results of the air-conditioner enterprise are shown in Fig. 7 and Fig. 8.

The changes of air-conditioner sales forecast and actual demand in every simulation cycle are shown in Fig. 7. It can be seen from Fig. 7 that the error between the sales forecast and actual demand is small, and the actual demand fluctuation for air-conditioner can be correctly reflected. The actual demand of air-conditioner and the cost, profits and revenues information of the air-condition enterprise in every simulation cycle are shown in Fig. 8. It can be seen in Fig. 8 that in order to guarantee the normal running of the enterprise, the sales agent should forecast the market demand in every cycle based on the actual demand fluctuation for air-conditioner, the production planning agent should establish a reasonable and accurate production plan based on the result of demand forecast and the procurement agent should purchase raw materials of adequate quantity and quality with right price at the right time through negotiation with the suppliers. In this way, the procurement of the enterprise and the costs for production can be largely reduced, and the actual demands of the air-conditioner can be largely met.

Fig. 7 Sales forecast and actual demands of air-condition

Fig. 8 Optimization results of demands and income, cost and profit of air-condition enterprise

The comparisons among the revenue, cost and profit of the enterprise before and after the MDO simulation under the same actual air-conditioner demands are shown in Figs. 9-11.

It is shown in Figs. 9-11 that after the MDO simulation based on the multi-agent technology, the revenue of the enterprise can be increased by at least 33%, the cost can be decreased by at least 1.8% and the profit can be increased by at least 36%. The reason is that before applying MDO based on the multi-agent simulation technique, the air-conditioner enterprise cannot accurately obtain the demand information from the market, but only fix the production quantity of product A to be 200 units, product B to be 100 units based on historical sales record, which will lead to the fact that the enterprise cannot flexibly establish its production plan based on the fluctuation of the market demand. This leads to a low income for the air-condition enterprise. Because there is a lack of interaction before MDO, the enterprise has no negotiation with the suppliers, which would definitely increase the procurement cost of enterprise. In addition, because of the lack of effective control in the production process, the cost of production and inventory cost of articles increase. In contrast, after applying the MDO based on the multi-agent simulation technology, the forecast model of the sales agent could forecast the market needs preferably. Based on the forecasting results, the production plan is able to be made. In this way, the enterprise could grasp the expected needs in each cycle and decrease the inventory cost largely. Moreover, the negotiation of the procurement agent with the suppliers can also largely reduce the procurement cost and in the meanwhile guarantee the quality of the raw materials and the delivery deadline, which will guarantee the continuous operation of the enterprise. Therefore, the proposed MDO method is close to the actual situation of the air-conditioner enterprise. It can effectively reduce the costs of enterprise, meet the actual needs of the air-conditioner market, and also enable the enterprise to get higher revenues and profits with lower cost.

Fig. 9 Comparison of air-condition enterprise income before and after multidisciplinary design optimization

Fig. 10 Comparison of air-condition enterprise cost before and after multidisciplinary design optimization

Fig. 11 Comparison of air-condition enterprise profit before and after multidisciplinary design optimization

5 Conclusions

1) By using the multi-agent technology proposed, the model of MDO on air-condition enterprise POS is established based on the objective function of production planning agent, sales agent, procurement agent, production agent, inventory agent, market agent and financial agent. The self-adaptive multi-scale chaos immune optimization algorithm is adopted to establish the MDO on the air-condition enterprise POS. The simulation results show that the proposed approach can reflect the actual operation situation of the air-conditioner enterprise. The revenue of the enterprise is increased by at least 33%, the cost is decreased by at least 1.8% and the profit is increased by at least 36%.

2) Under the situation that traditional design methods can hardly get more satisfactory POS modeling results for air-conditioner enterprise, MDO method is used for the overall optimization of the POS. Through fully considering the coupling effects among the information flow, logistics and cash flow, the revenues and profits can be increased while the costs are reduced. This new approach is applicable for the overall optimization of the air-conditioner enterprise POS. It can be predicted that it will have very broad application prospects for the MDO on overall optimization and control of air-condition enterprise POS.

References

[1] XU Xiao-fei, XU Yin-qiu, TAN Ying-zi. Simulation and implementation in enterprise production operation system based on multi-agent [J]. System Simulation Technology, 2009, 5(2): 116-121. (in Chinese)

[2] HU Dai-ping, WANG Huan-chen. Approaches for implementation of forecasting model agents [J]. Journal of Systems Engineering, 2001, 6(5): 330-334. (in Chinese)

[3] LEI Xing-hui, SU Tao-yong. Research on inventory management in SCOR model based on agent technology [J]. Journal of Tongji University: Natural Science, 2006, 34(2): 270-274. (in Chinese)

[4] ZHAI Li-li, YU Rui-xue, FAN Jun-tao. Research on production operational management of virtual enterprise based on multi-agent [J]. Science Technology and Management, 2007, 9(1): 17-20. (in Chinese)

[5] JIANG Jin-ju, LIN Jie. Agent-based simulation for supply chain [J]. Journal of System Simulation, 2004, 16(12): 2847-2850. (in Chinese)

[6] LIN Jie, FENG Ling, YOU Jian-xin. Research on simulation methods of supply chain operation based on intelligent agent [J]. Industrial Engineering and Management, 2005(4): 40-44. (in Chinese)

[7] LO Wei-shuo, HONG Tzuing pei, RONG Jeng. A framework of E-SCM multi-agent systems in the fashion industry [J]. International Journal of Production Economics, 2008, 114(2): 594-614.

[8] AGARWAL H, RENAUD J E, PRESTON E L, PADMANABHAN D. Uncertainty quantification using evidence theory in multidisciplinary design optimization [J]. Reliability Engineering & System Safety, 2004, 85(1/3): 281-294.

[9] XIE Chang-qing, E Jia-qiang, PENG Yu, GONG Jin-ke, ZHAO Yan-ming. Multidisciplinary design optimization of electric braking resistor [J]. Journal of the China Railway Society, 2008, 30(5): 119-124. (in Chinese)

[10] YUAN Wen-hua, E Jia-qiang, GONG Jin-ke, WANG Chun-hua, PENG Yu. Multidisciplinary design optimization for fuel nozzle of high pressure common-rail injection system based on self-adaptive particle swarm optimization algorithm [J]. Chinese Internal Combustion Engine Engineering, 2009, (5): 63-67. (in Chinese)

[11] YANG Hai-dong, E Jia-qiang. An adaptive chaos immune optimization algorithm with mutative scale and its application [J]. Control Theory & Applications, 2009, 26 (10): 1069-1074. (in Chinese)

[12] HUANG Guo-quan, QU Ting. Extending analytical target cascading for optimal configuration of supply chains with alternative autonomous suppliers [J]. International Journal of Production Economics, 2008, 115(1): 39-54.

[13] QU Ting, HUANG Guo-quan, CUNG V D, MANGIONE F. Optimal configuration of assembly supply chains using analytical target cascading [J]. International Journal of Production Research, 2010, 48(23): 6883-6907.

[14] QU Ting, HUANG Guo-quan, ZHANG Ying-feng, DAI Qing-yun. A generic analytical target cascading optimization system for decentralized supply chain configuration over supply chain grid [J]. International Journal of Production Economics, 2009, 127(2): 262-277.

(Edited by YANG Bing)

Foundation item: Project(60973132) supported by the National Natural Science Foundation of China; Project(2010B050400005) supported by the Science and Research Program of Guangdong Province, China

Received date: 2010-11-29; Accepted date: 2011-04-18

Corresponding author: YANG Hai-dong, Professor, PhD; Tel: +86-13926036043; E-mail: yanghd@yeah.net

Abstract: In order to guarantee the overall production performance of the multiple departments in an air-condition production industry, multidisciplinary design optimization model for production system is established based on the multi-agent technology. Local operation models for departments of plan, marketing, sales, purchasing, as well as production and warehouse are formulated into individual agents, and their respective local objectives are collectively formulated into a multi-objective optimization problem. Considering the coupling effects among the correlated agents, the optimization process is carried out based on self-adaptive chaos immune optimization algorithm with mutative scale. The numerical results indicate that the proposed multi-agent optimization model truly reflects the actual situations of the air-condition production system. The proposed multi-agent based multidisciplinary design optimization method can help companies enhance their income ratio and profit by about 33% and 36%, respectively, and reduce the total cost by about 1.8%.

- Multidisciplinary design optimization for air-condition production system based on multi-agent technique