文章编号:1004-0609(2014)01-0091-06

TA15钛合金的热变形微观组织与织构

李成铭,李 萍,赵 蒙,甘国强,薛克敏

(合肥工业大学 材料科学与工程学院,合肥 230009)

摘 要:

摘 要:采用X 线衍射仪和EBSD分析研究近α型TA15钛合金在不同工艺参数下的热压缩变形组织和织构演变规律。结果表明:TA15合金热变形后淬火组织中存在针状马氏体α′相;晶粒在(101)和(002)滑移面上的滑移率先达到临界分切应力,发生塑性变形,使组织细化,并最终导致变形组织的择优取向;在小应变速率(0.01 s-1)和低变形温度(950 ℃)条件下,动态再结晶分数较高,产生较强的再结晶织构;随着变形温度和应变速率的升高,材料晶粒取向性减弱。

关键词:

中图分类号:TG146 文献标志码:A

Microstructures and textures of TA15 titanium alloy after hot deformation

LI Cheng-ming, LI Ping, ZHAO Meng, GAN Guo-qiang, XUE Ke-min

(School of Materials Science and Engineering, Hefei University of Technology, Hefei 230009, China)

Abstract: The microstructures and textures of TA15 titanium alloy after hot deformation under different process parameters were investigated by X-ray diffractometry (XRD) and electron back scattering diffractometry (EBSD). The results indicate that microstructures of TA15 alloy appear obvious acicular martensite α′ phase after hot deformation and quenching. The plastic deformation is going to occur in the slip systems of (101) and (002) slip planes by first reaching the critical resolved shear stress. The strong recrystallization textures are achieved at low deformation temperature and low strain rate, which will be weakened with increasing the strain rate and temperature.

Key words: TA15 titanium alloy; hot deformation; microstructure; texture

钛合金型材零部件具有结构轻量化和强度高的特点,广泛应用于航空航天等行业中。钛及钛合金的显微组织、工艺及性能之间存在着密切关系。钛合金在塑性变形过程中,显微组织演变直观表现为晶粒形状发生改变,更深层次则表现为晶粒内部显微结构的形成。形变显微组织结构的形成恰恰是塑性变形不均匀的表现,而这种不均匀对材料的动态、静态再结晶及相变均产生不同影响[1-5]。因此,形变显微组织结构与取向演变受到国内外材料工作者们的广泛关注[6-10]。

TA15合金在常温下是近α型钛合金,六方晶体结构,滑移系较少,塑性较差,成形加工过程困难,探究该合金在的β相区(BCC)和近β相区变形机制和组织演变规律,明确织构产生的原因及织构对其性能的影响,就可以对该合金的变形加工提供理论依据,达到控制织构的目的,用以改善合金的性能以适应结构件的使用要求。通过取向成像技术,利用取向信息重构出与取向有关的微观组织结构,并可统计出亚晶结构、晶粒尺寸、织构的成分与分布等[8-9, 11-13]。因此,在金属塑性变形研究中的应用也越来越广泛[14-19]。本文作者在前期开展的TA15合金等温压缩试验基础上(见文献[20]),借助于X射线衍射仪和EBSD分析系统,深入探讨合金(α+β)/β相变点上下热变形材料微观组织演变和形变织构特征。

1 实验

实验材料为TA15钛合金,其名义化学成分(质量分数,%)为Al-6.96、V-2.31、Zr-2、 Mo-1.7,其余是Ti。在Gleeble-3500型热模拟机上进行等温恒应变速率压缩实验,具体实验方法见文献[20]。取变形后试样轴向剖面进行组织测试分析,观测区域为挤压方向RD和横向TD组成的平面,法向ND垂直于观测平 面。分别采用D/MAX2500VL/PC型X射线衍射仪进行物相分析,采用电镜上配备有SEM-EBSD系统的JSM-7001F型场发射扫描电镜进行EBSD实验。

2 结果与分析

2.1 微观组织分析

变形程度为60%时,不同应变速率和变形温度下水冷后TA15合金的显微组织如图1所示。由图1可看出,在热变形过程中,TA15合金的显微组织发生了明显的变化,随着变形温度升高,淬火组织中针片状马氏体逐渐增多。在相变点以下950 ℃压缩变形水 冷,即在(α+β)两相区热变形后水冷,发生马氏体相变,产生马氏体相α′和部分初生α相的双态组织;在相变点以上1 050 ℃压缩变形水冷后,发生马氏体相变,因为变形区由(α+β)两相区过渡到β相区,且变形后快速冷却,所以淬火组织是针状马氏体相α′[21]。观察合金在不同应变速率下的显微组织,在相变点以下,变形温度为950 ℃时,随着应变速率的降低,初生α相和马氏体组织α′相尺寸趋于长大;在相变点以上,变形温度为1 050 ℃时,随着应变速率的升高,显微组织由片层组织过渡到网篮组织。这主要是由于在应变速率较高时,变形时间短,β晶粒边界在变形过程中被破坏,不出现或仅出现少量分散分布的颗粒状晶界α,原始β晶粒内的α片变短,α束集尺寸较小,各片丛交错排列,犹如编织网篮状[21]。因此,热变形工艺可以有效影响近α钛合金组织形态和晶粒度,这可以有效解决该类合金难于热处理的问题[22]。

2.2 XRD分析

TA15合金试样等温恒应变速率压缩变形前后XRD谱如图2所示。从图2中可以看出,衍射峰强度发生变化的主要是(101)和(002)两个低指数晶面,其代表初生α相或马氏体相α′衍射面。热变形过程不会影响合金的相的组成,只会影响α相和β相的相对含量[23]。由于变形温度在(α+β)/β相变点附近,单向压缩的实验条件,故其塑性变形机制主要是滑移。衍射峰的强度在一定程度上反映了晶粒度的变化,热变形前的试样在(101)和(002)晶面上衍射峰尖而高,变形后衍射峰强度明显降低,表明有晶粒细化过程发生[24]。然而,1 050 ℃的衍射峰强度高于950 ℃时的衍射峰,说明在相变点以上的高温环境促使晶粒的长大。

图1 TA15合金不同变形条件下的微观组织

Fig. 1 Microstructures of TA15 titanium alloy under different hot deformation conditions

图2 热变形前后试样XRD谱

Fig. 2 XRD patterns of TA15 under different deformation conditions

晶面衍射峰强度的变化,主要是由于试样变形过程中受到压缩方向的压应力和横向拉应力的作用,使晶粒扭转,引起织构发生变化,导致各晶面衍射峰强度的变化。在塑性变形过程中,当晶粒受力时,率先达到临界分切应力的滑移系开始启动,随之,其他晶粒也参与运动,以保持变形协调、连续、稳定地进行。可以推测材料内部晶粒度发生变化的同时晶粒发生了转动,转至晶粒在(101)和(002)滑移面上的滑移系率先达到临界分切应力发生塑性变形,使组织细化,并最终导致了变形组织取向的改变。

2.3 极图与反极图分析

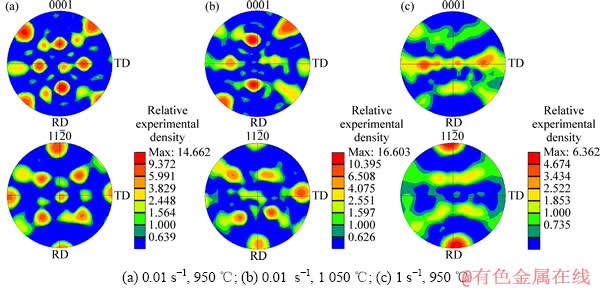

图3所示不同热变形参数下获得试样的极图。如图3(a)所示,由{0001}和{11 0}晶粒取向极图可看出,应变速率为0.01 s-1,变形温度为950 ℃时,大部分晶粒的c轴与压缩方向RD成45°或90°角关系, <11

0}晶粒取向极图可看出,应变速率为0.01 s-1,变形温度为950 ℃时,大部分晶粒的c轴与压缩方向RD成45°或90°角关系, <11 0>平行或垂直于压缩轴,变形过程发生了晶粒的择优取向;如图3(b)所示,当变形温度升高到1 050 ℃时,c轴发生一定偏转,与RD成90°角的c轴取向强度减弱,<11

0>平行或垂直于压缩轴,变形过程发生了晶粒的择优取向;如图3(b)所示,当变形温度升高到1 050 ℃时,c轴发生一定偏转,与RD成90°角的c轴取向强度减弱,<11 0>与压缩方向RD平行的取向减弱,漫散程度增加,晶粒取向性减弱;如图3(c)所示,应变速率为1 s-1,变形温度为950 ℃时,晶粒c轴与RD垂直,<11

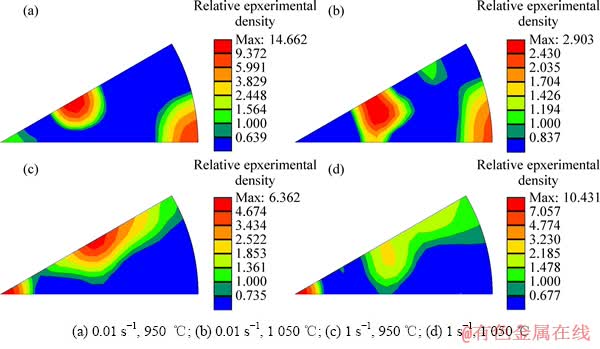

0>与压缩方向RD平行的取向减弱,漫散程度增加,晶粒取向性减弱;如图3(c)所示,应变速率为1 s-1,变形温度为950 ℃时,晶粒c轴与RD垂直,<11 0>平行于压缩方向RD。图4所示为TA15钛合金在不同热变形参数压缩后组织在法线方向ND上的EBSD 反极图。由图4可以看出,变形温度为950 ℃,法向ND大部分在<0001>和<10

0>平行于压缩方向RD。图4所示为TA15钛合金在不同热变形参数压缩后组织在法线方向ND上的EBSD 反极图。由图4可以看出,变形温度为950 ℃,法向ND大部分在<0001>和<10 0>连线之间,说明存在择优取向,如图4(a)和(c)所示;随着变形温度升高到1 050 ℃,<0001>和<10

0>连线之间,说明存在择优取向,如图4(a)和(c)所示;随着变形温度升高到1 050 ℃,<0001>和<10 0>连线之间的织构强度有所减弱,晶粒取向均匀化,图3所示的极图也反映出在相变点以上的变形过程中,材料晶粒取向较均匀,相对于低温变形条件下获得的试样具有更好的宏观各向同性。应变速率为0.01 s-1时,法向ND即压缩轴方向存在<0001>和<10

0>连线之间的织构强度有所减弱,晶粒取向均匀化,图3所示的极图也反映出在相变点以上的变形过程中,材料晶粒取向较均匀,相对于低温变形条件下获得的试样具有更好的宏观各向同性。应变速率为0.01 s-1时,法向ND即压缩轴方向存在<0001>和<10 0>连线之间的织构,随着应变速率提高到1 s-1,变形时间缩短,滑移和晶粒扭转时间减少,晶粒取向的集中性也减弱。

0>连线之间的织构,随着应变速率提高到1 s-1,变形时间缩短,滑移和晶粒扭转时间减少,晶粒取向的集中性也减弱。

图5所示为利用EBSD 分析材料热变形后晶粒尺寸分布的数据统计结果。由图5可看出,当应变速率为0.01 s-1,1 050 ℃时尺寸小于10 μm的晶粒数量多于950 ℃时的数量。从取向差的分布特点可以看出,950 ℃时小角晶界的比例比1 050 ℃时的有所增加(见图6),应变速率为1 s-1,1 050 ℃时尺寸小于10 μm晶粒数量少于950 ℃时的数量,小角晶界所占比例也少于950 ℃的小角晶界比例。这表明在变形过程中,组织发生了动态再结晶,并伴随着动态回复过程的进行,在1 050 ℃时动态回复过程更加活跃。在相同变形温度下,应变速率提高,晶粒平均尺寸降低,晶界角减小。结合对图3极图的分析可知,在小应变速率(0.01 s-1)和低变形温度(950 ℃)条件下,动态再结晶分数较高,产生较强的再结晶织构,将造成性能的各向异性[25]。

图3 TA15合金不同热变形参数下组织的极图

Fig. 3 Pole figures of microstructures of TA15 titanium alloy at different heat deformation parameters

图4 TA15合金不同热变形参数下组织的反极图

Fig. 4 Inverse pole figures of microstructures of TA15 titanium alloy under different heat deformation porameters

3 结论

1) TA15合金在(α+β)/β相变点附近热变形水冷后,发生马氏体相变,淬火组织中出现针状马氏体相α′和初生α相,随变形温度的升高,淬火组织中针状马氏体α′增多。在相变点以下,变形温度为950 ℃时,随着应变速率的降低,变形时间增加,初生α相和马氏体组织α′相晶粒长大;在相变点以上,变形温度为1 050 ℃时,随着应变速率的升高,显微组织由片层组织过渡到网篮组织。

2) 晶粒在(101)和(002)滑移面上的滑移系率先达到临界分切应力发生塑性变形,使组织细化,并最终导致了变形组织的择优取向。不同变形条件下,织构强度不同,在小应变速率(0.01 s-1)和低变形温度(950 ℃)条件下,动态再结晶分数较高,产生较强的再结晶织构,造成性能的各向异性;随着变形温度和应变速率的升高,材料晶粒取向性逐渐减弱。

图5 TA15合金不同热变形参数下晶粒尺寸

Fig. 5 Grain size of TA15 alloy under different thermal deformation parameters

图6 TA15合金不同变形参数下的晶粒取向差分布

Fig. 6 Grain misorientation distribution difference of TA15 alloy at deformation parameters

REFERENCES

[1] 李 萍, 段园培, 薛克敏, 王晓溪, 甘国强. TB8钛合金的热变形组织与织构[J]. 中国有色金属学报, 2010, 20(5): 872-877.

LI Ping, DUAN Yuan-pei, XUE Ke-min, WANG Xiao-xi, GAN Guo-qiang. Microstructures and textures of TB8 titanium alloy after hot deformation[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(5): 872-877.

[2] 段园培. TB8合金热变形组织介观尺度研究与模拟[D]. 合肥: 合肥工业大学材料科学与工程学院, 2009: 35-51.

DUAN Yuan-pei. Mesoscopic research and simulation on hot deformation microstructure in TB8 alloy[D]. Hefei: School of Materials Science and Engineering, Hefei University of Technology, 2009: 35-51.

[3] YUAN B G, YU H P, LI C F, SUN D L. Effect of hydrogen on fracture behavior of Ti-6Al-4V alloy by in-situ tensile test[J]. International Journal of Hydrogen Energy, 2010, 35(4): 1829-1838.

[4] YUAN B G, YU H P, LI C F. Influence of hydrogen content on room temperature compressive properties of Ti-6Al-4V alloy at high strain rate[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(12): 2943-2951.

[5] 陈 强. 合金加工流变学及其应用[M]. 北京: 冶金工业出版社, 2012.

CHENG Qiang. Rheology of alloys processing and its application[M]. Beijing: Metallurgical Industry Press, 2012.

[6] GLAVICIC M G, KOBRYN P A, SEMIATIN S L. Validation of an automated EBSD method to deduce the β-phase texture in Ti-6Al-4V with a colony-α microstructure[J]. Materials Science and Engineering A, 2004, 385(1/2): 372-376.

[7] ZAEFFERER S. A study of active deformation systems in titanium alloys: Dependence on alloy composition and correlation with deformation texture[J]. Materials Science and Engineering A, 2003, 344(1/2): 20-30.

[8] GLAVICIC M G, SALEM A A, SEMIATIN S L. X-ray line-broadening analysis of deformation mechanisms during rolling of commercial-purity titanium[J]. Acta Materialia, 2004, 52: 647-655.

[9] GLAVICIC M G, SEMIATIN S L. X-ray line-broadening investigation of deformation during hot rolling of Ti-6Al-4V with a colony-alpha microstructure[J]. Acta Materialia, 2006, 54: 5337-5347.

[10] SEWARD G G E, CELOTTO S, PRIOR D J, WHEELER J, POND R C. In situ SEM-EBSD observations of the hcp to bcc phase transformation in commercially pure titanium[J]. Acta Materialia, 2004, 52(4): 821-832.

[11] BERNIER J V, PARK J S, PILCHAK A L, GLAVICIC M G, MILLER M P. Measuring stress distributions in Ti-6Al-4V using synchrotron X-ray diffraction[J]. Metallurgical and Materials Transactions A, 2008, 39: 3120-3133.

[12] 曾 柯, 辛仁龙, 李 波, 汪炳叔, 黄光杰, 刘 庆. EBSD技术在稀土变形镁合金微观表征中的应用[J]. 电子显微学报, 2010, 29(1): 720-723.

ZENG Ke, XIN Ren-long, LI Bo, WANG Bing-shu, HUANG Guang-jie, LIU Qing. Application of EBSD techniques in microstructure characteristics of rare-earth magnesium alloy[J]. Journal of Chinese Electron Microscopy Society, 2010, 29(1): 720-723.

[13] 杨 平, 孙祖庆, 毛为民. 取向成像: 一种有效研究晶体材料结构、组织及取向的技术[J]. 中国体视学与图像分析, 2001, 6(1): 50-54.

YANG Ping, SUN Zu-qing, MAO Wei-min. Orientation mapping: An effective technique for revealing the morphology, crystallographic structure and orientation of crystalline materials[J]. Chinese Journal of Stereology and Image Analysis, 2001, 6(1): 50-54.

[14] GLAVICIC M G., KOBRYN P A, SPADAFORA F, SEMIATIN S L. Texture evolution in vacuum arc remelted ingots of Ti-6Al-4V[J]. Materials Science and Engineering A, 2003, 346: 8-18.

[15] GLAVICIC M G, KOBRYN P A, BIELER T R, SEMIATIN S L. An automated method to determine the orientation of the high temperature beta phase from measured EBSD data for the low temperature alpha-phase in Ti-6Al-4V[J]. Materials Science and Engineering A, 2003, 351: 258-264.

[16] GLAVICIC M G, MILLER J D, SEMIATIN S L. A method to measure the texture of secondary alpha in bimodal titanium-alloy microstructures[J]. Scripta Materialia, 2006, 54: 281-286.

[17] 李秀莲, 王茂银, 辛仁龙, 黄光杰, 刘 庆. AZ31镁合金挤压轧制过程微观织构演变[J]. 材料热处理学报, 2010, 31(5): 61-64.

LI Xiu-lian, WANG Mao-yin, XIN Ren-long, HUANG Guang-jie, LIU Qing. Texture evolution of AZ31 magnesium alloy during extrusion and rolling[J]. Transactions of Materials And Heat Treatment, 2010, 31(5): 61-64.

[18] 邓运来, 张新明, 刘 瑛, 唐建国, 周卓平. 冷轧高纯铝柱状晶粒的组织与微取向的不均匀性[J]. 中国有色金属学报, 2005, 15(8): 1173-1178.

DENG Yun-lai, ZHANG Xin-ming, LIU Ying, TANG Jian-guo, ZHOU Zhuo-ping. Inhomogeneities of microstructures and micro-orientations in cold-rolled high purity Al columnar grains[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(8): 1173-1178.

[19] 曹 鹏, 方 刚, 雷丽萍, 曾 攀. 多晶铜压缩过程中晶粒取向演化的塑性理论分析[J]. 金属学报, 2007, 43(9): 913-919.

CAO Peng, FANG Gang, LEI Li-ping, ZENG Pan. Plasticity theory analysis of grain orientation evolution of polycrystalline copper during uniaxial compression[J]. Acta Metallurgica Sinica, 2007, 43(9): 913-919.

[20] 李成铭, 李 萍, 赵 蒙, 薛克敏. TA15钛合金高温压缩变形行为与组织研究[J]. 航空材料学报, 2013, 33(3): 25-29.

LI Cheng-ming, LI Ping, ZHAO Meng, XUE Ke-min. Mechanical behavior and microstructure of TA15 titanium alloy during hot compressive deformation[J]. Journal of Aeronautical Materials, 2013, 33(3): 25-29.

[21] 赵永庆, 陈永楠, 张学敏, 曾卫东, 王 磊. 钛合金相变及热处理[M]. 长沙: 中南大学出版社, 2012.

ZHAO Yong-qing, CHEN Yong-nan, ZHANG Xue-min, ZENG Wei-dong, WANG Lei. Phase transformation and heat treatment of titanium alloys[M]. Changsha: Central South University Press, 2012.

[22] WEISS I, SEMIATIN S L. Thermomechanical processing of alpha titanium alloys—An overview[J]. Materials Science and Engineering A, 1999, 263: 243-256.

[23] 朱知寿, 王新南, 童 路, 刘东升. 新型TC21钛合金相变行为和相组成研究[J]. 稀有金属快报, 2006, 25(12): 23-27.

ZHU Zhi-shou, WANG Xin-nan, TONG Lu, LIU Dong-sheng. Phase Transformation and Composition for Novel TC21[J]. Rare Metals Letters, 2006, 25(12): 23-27.

[24] HUANG R, HAN Y. Structure evolution and thermal stability of SMAT-derived nanograined layer on Ti-25Nb-3Mo-3Zr-2Sn alloy at elevated temperatures[J].Journal of Alloys and Compounds, 2013, 554: 1-11.

[25] WANJARA P, JAHAZI M, MONAJATI H, YUEB S. Influence of thermomechanical processing on microstructural evolution in near-α alloy IMI834[J]. Materials Science and Engineering A, 2006, 416: 300-311.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51175137);安徽省自然科学基金项目(1308085JGD02)

收稿日期:2013-01-14;修订日期:2013-11-06

通信作者:李 萍,教授,博士;电话:0551-62901368;E-mail:cisi1314@sohu.com

[1] 李 萍, 段园培, 薛克敏, 王晓溪, 甘国强. TB8钛合金的热变形组织与织构[J]. 中国有色金属学报, 2010, 20(5): 872-877.

[2] 段园培. TB8合金热变形组织介观尺度研究与模拟[D]. 合肥: 合肥工业大学材料科学与工程学院, 2009: 35-51.

[5] 陈 强. 合金加工流变学及其应用[M]. 北京: 冶金工业出版社, 2012.

[12] 曾 柯, 辛仁龙, 李 波, 汪炳叔, 黄光杰, 刘 庆. EBSD技术在稀土变形镁合金微观表征中的应用[J]. 电子显微学报, 2010, 29(1): 720-723.

[13] 杨 平, 孙祖庆, 毛为民. 取向成像: 一种有效研究晶体材料结构、组织及取向的技术[J]. 中国体视学与图像分析, 2001, 6(1): 50-54.

[17] 李秀莲, 王茂银, 辛仁龙, 黄光杰, 刘 庆. AZ31镁合金挤压轧制过程微观织构演变[J]. 材料热处理学报, 2010, 31(5): 61-64.

[18] 邓运来, 张新明, 刘 瑛, 唐建国, 周卓平. 冷轧高纯铝柱状晶粒的组织与微取向的不均匀性[J]. 中国有色金属学报, 2005, 15(8): 1173-1178.

[19] 曹 鹏, 方 刚, 雷丽萍, 曾 攀. 多晶铜压缩过程中晶粒取向演化的塑性理论分析[J]. 金属学报, 2007, 43(9): 913-919.

[20] 李成铭, 李 萍, 赵 蒙, 薛克敏. TA15钛合金高温压缩变形行为与组织研究[J]. 航空材料学报, 2013, 33(3): 25-29.

[21] 赵永庆, 陈永楠, 张学敏, 曾卫东, 王 磊. 钛合金相变及热处理[M]. 长沙: 中南大学出版社, 2012.

[23] 朱知寿, 王新南, 童 路, 刘东升. 新型TC21钛合金相变行为和相组成研究[J]. 稀有金属快报, 2006, 25(12): 23-27.