Trans. Nonferrous Met. Soc. China 23(2013) 711-717

Influence of FeCrAl fiber on microstructure and mechanical properties of FeCrAl(f)/HA composites

Hai-lin YANG, Jing LI, Hua-chan FANG, Xiang ZHANG, Zhong-cheng ZHOU, Xiao-yang TONG, Jian-ming RUAN

State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China

Received 29 December 2011; accepted 16 April 2012

Abstract:

FeCrAl fiber-reinforced hydroxyapatite (HA) biocomposites (FeCrAl(f)/HA) were fabricated by the hot pressing technique. The metallographic microscopy, X-ray diffractometry, scanning electron microscopy (SEM) and energy dispersive spectroscopy (EDS) were used to observe and analyze the microstructure and composition of FeCrAl(f)/HA composites, respectively. The mechanical properties of FeCrAl(f)/HA composites were measured by the three-point-bending test. The results show that the composite can be reinforced by FeCrAl fiber and enhanced gradually, and then declined with the increase of the content of FeCrAl fiber (0-11%, volume fraction) in the whole range of experiments. Both the HA matrix and FeCrAl fiber integrate very tightly and bit into each other very deeply and counter-diffusion takes place to some extent at two-phase interface. The optimum parameters of FeCrAl(f)/HA composite are diameter of 22 μm, length of 1-2 mm and of volume faction of about 7% for FeCrAl fibers.

Key words:

FeCrAl(f)/HA composites; fiber reinforcement; hot pressing technique; mechanical properties;

1 Introduction

As a promising biomedical ceramic material, hydroxyapatite (HA) is extensively employed in hard tissue replacement surgery due to its similarity to bone and its excellent ability to bond with bone [1,2]. Nevertheless, impeding HA further application in long term load-bearing environment is its brittleness and relatively insufficient mechanical properties. In order to overcome these drawbacks, metallic biomaterials, such as 316L stainless steel (316L SS) [3,4], titanium and its alloys [5-7], have been applied by clinical surgery because of their superior strength and resistance to corrosion in physiological environment. The most important advantages of these biometals over inherently weak and brittle bioactive ceramics HA are higher mechanical strength and toughness. Therefore, the combination of mechanical properties of metallic biomaterials and biocompatibility of HA bioceramics is ongoing research.

In previous investigations, it was reported that carbon fiber or stainless steel could remarkably enhance the mechanical properties of HA bioceramics [8-10]. The earlier investigations [11] indicated that 316L SS could dramatically improve the mechanical properties of HA. ANNETT et al [8] pointed out that the reinforcement of calcium hydroxyapatite with 20% (volume fraction) carbon short fibers positively improved the resistance against microabrasion. FeCrAl fiber has the merits of excellent comprehensive mechanical and corrosion resistance properties, as well as good chemical stability. So far, there are scarce investigations on reinforcing HA with FeCrAl fiber [12]. In this work, the merits of HA and FeCrAl fibers were combined, and the hot pressing technique was adopted to fabricate FeCrAl(f)/HA composites. The relative density and mechanical properties of the FeCrAl(f)/HA composites were examined, and the microstructure and toughening mechanism of the composites were analyzed.

2 Experimental

2.1 Raw materials processing

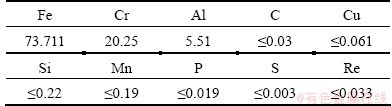

HA used in this experimental was fabricated by chemical co-precipitation process, which was described in detail in Refs. [11,12]. The average size of HA was 2.37 μm. Specific chemical contents of commercially available FeCrAl fibers (Huitong Metal Fiber Co. Ltd., China) of 22 and 12 μm in diameter are shown in Table 1. Prior to the experiment, the continuous fibers were chopped into 1-2 and 3-4 mm in length, and then drenched in 1% (mass fraction) diluted hydrochloric acid solution to make the surface coarser so as to increase the bonding with HA matrix. Thereafter, the fibers were washed by ultrasonic cleaning with distilled water, acetone and ethanol (Fig. 1).

Table 1 Chemical compositions of FeCrAl fiber (mass fraction, %)

Fig. 1 SEM image of fibers after pretreatment

2.2 Fabrication of FeCrAl(f)/HA composite

HA and FeCrAl fiber mixture powders were obtained through ball milling mixture for 6 h with alcohol as milling medium. The volume fraction of FeCrAl fibers in the composite matrix was 0, 3%, 5%, 7%, 9% and 11%, respectively. Then, the mixed powders were dried in vacuum at the constant temperature of 90 °C for 3 h. Finally, the green compacts were hot-pressing sintered at 1100 °C under a vacuum maximum of 6.67×10-2 Pa for 2 h with a heating rate of 10 °C/min and a cooling rate of 5 °C/min to prepare different FeCrAl(f)/HA composites.

2.3 Properties characterization

The density of the specimens was measured accurately by the Archimedes method on an analytical balance using distilled water at 25 °C. The relative density was calculated as follows:

(1)

(1)

where d represents the relative density, ρ is the true density and ρ0 is the theoretical density.

The phase distribution was investigated through an MeF3A metallographic microscope. Samples were ground and polished with a 2000# grid blast, and then Jeol-6360LV type SEM was used to observe the microstructure. The fracture surface of the bending samples was covered with a thin film of gold by vacuum deposition and then examined by SEM. An EDS2000 type energy dispersive X-ray analyzer (EDXA) was adopted to analyze elemental contents of the composites.

Rectangular specimens with an average size of 35 mm×6 mm×10 mm were cut from the as-prepared samples. Bending strength was tested on a material experimental machine (Instron CTM4000 type). The tests were performed at 25 °C and a crosshead speed of 0.5 mm/min. Five specimens were chosen in each experiment and the final result was the average value of the five specimens. Equation (2) was used to describe the elastic region of the load versus displacement curves:

(2)

(2)

where σmax is the bending strength (MPa), P is the load (N), L is the span length (mm), b is the specimen width (mm), and h is the specimen thickness (mm).

3 Results and discussion

3.1 Density and relative density of FeCrAl(f)/HA composites

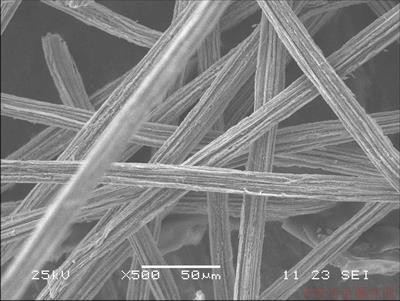

Typically, two FeCrAl fibers with diameters of 22 and 12 μm were chopped into 1-2 mm in length. The density of two sintered specimens with different diameters as function of FeCrAl fiber content is shown in Fig. 2. It can be seen from Fig. 2(a) that the density of two specimens increases from 3.1 g/cm3 to the maximum value, and then slightly decreases. For the FeCrAl fiber sample with a diameter of 22 μm, the density shows a linear function as the volume fraction of FeCrAl fiber when the volume fraction of FeCrAl fiber is below 9%. Different from FeCrAl fiber sample with a diameter of 22 μm, the density of FeCrAl fiber sample with a diameter of 12 μm shows a similar linear function as the volume fraction of FeCrAl fiber is below 7%, corresponding to the maximum density of 3.23 g/cm3. For both samples, however, the relative density decreases rapidly with the increase of volume fraction of FeCrAl fiber.

The density of FeCrAl fiber (7.15 g/cm3) is much higher than that of HA (3.16 g/cm3). But the density and relative density have almost contradictory change tendency with the increase of FeCrAl fiber contents, just as the previous investigations [13]. The true density cannot reach 90% of the theoretical density when the volume fraction of fiber is 11%. The obvious lower relative density indicates higher level porosity in the composites, and this is caused by the increase of micropores among FeCrAl fibers with the increase of FeCrAl fibers contents.

Fig. 2 Density (a) and relative density (b) as function of volume fraction of FeCrAl fiber with different diameters in FeCrAl(f)/HA composites

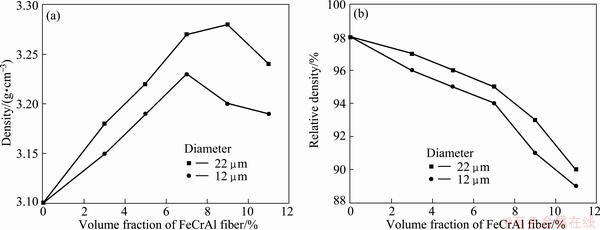

Fig. 3 Microstructures showing distribution of FeCrAl fiber with different volume factions in FeCrAl(f)/HA composites

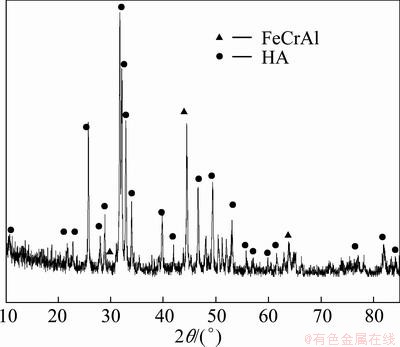

Fig. 4 XRD pattern of FeCrAl(f)/HA composite with 7% FeCrAl fiber (22 μm in diameter and 1-2 mm in length)

3.2 Metallographic and micro-component analysis of FeCrAl(f)/HA composites

FeCrAl fibers (22 μm in diameter) were adopted to investigate the distribution of FeCrAl fiber in HA matrix in this experiment. The metallographic microstructures of FeCrAl(f)/HA composite with different volume fractions of FeCrAl fibers in the matrix are shown in Fig. 3. It can be concluded that the morphologies change regularly with the volume fraction of FeCrAl fiber in the composites. The FeCrAl fibers can be homogenous in HA matrix at lower volume fraction of FeCrAl fiber (<9%). But when the volume fraction of FeCrAl fibers reaches 11%, lots of FeCrAl fibers aggregate in the HA matrix.

Typically, the XRD pattern of FeCrAl(f)/HA composite with 7% FeCrAl fiber (22 μm in diameter and 1-2 mm in length) is shown in Fig. 4. It can be clearly seen that during the hot-press sintering HA crystallization is very complete compared with the standard hydroxyapatite diffraction peak, and FeCrAl fibre can also be detected. There are no new phases, which indicates that no chimerical reaction takes place between HA and FeCrAl fiber.

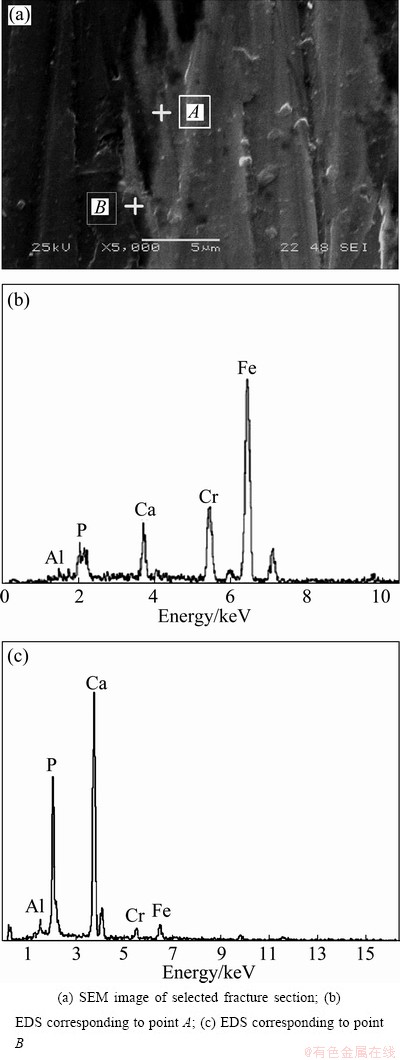

Figure 5 shows EDS analyses of 7% FeCrAl(f)/HA fiber composite (22 μm in diameter and 1-2 mm in length). It can be seen from Fig. 5(a) that the integration circumstance of the two phases is very good since there is no obvious flaw or crack in the fracture section. The phases interfaces of HA and FeCrAl fibers combine closely. Meanwhile, the interface transition region is smooth, and no obvious new interfaces form in the matrix.

The bonding between HA and FeCrAl fibers was analyzed by SEM-EDS in Figs. 5(b) and (c). EDS patterns of points A and B were selected from matrix FeCrAl fibers (point A) (Fig. 5(b)) and HA (point B) (Fig. 5(c)), respectively. It can be seen from Figs. 5(b) and (c) that the major contents of point A are Fe, Cr and Al, but trace amount of Ca and P are detected. It is indicated that Ca and P diffuse into the matrix. The major contents of point B are Ca and P, while trace amount of Fe and Al are detected, which indicates that Fe and Al diffuse into the matrix. In other words, counterdiffusion takes place between FeCrAl and HA.

Fig. 5 EDS analyses of FeCrAl(f)/HA composites with 7% FeCrAl fiber

3.3 Mechanical properties of FeCrAl(f)/HA composite

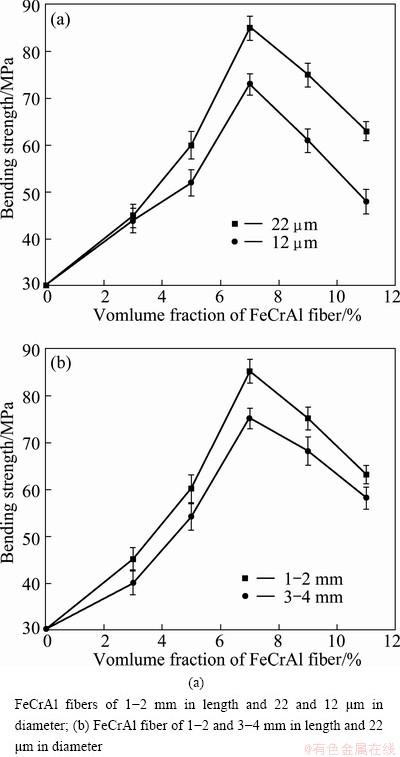

Two different FeCrAl fibers of 22 and 12 μm in diameter and 1-2 mm in length were used as toughening phase; two FeCrAl fibers with a diameter of 22 μm and chopped lengths of 1-2 and 3-4 mm were obtained as toughening phase. The relationship between the bending strength of the sintered samples and the volume fraction of the FeCrAl fiber is shown in Fig. 6. For FeCrAl fibers with different diameters (Fig. 6(a)), the addition of the FeCrAl fibers evidently improves the bending strength, meanwhile with increasing the volume fraction of FeCrAl fibers, the bending strength rapidly gets to the maximum value which corresponds to 7% FeCrAl fiber, thereafter shows a rapid decrease, which is in accordance with the change of density earlier. For FeCrAl fiber with a length of 1-2 mm and different diameters, the bending strength of the sample with a diameter of 22 μm is higher than that with a diameter of 12 μm in the whole range of volume fraction (Fig. 6(a)). Accordingly, for FeCrAl fiber with a diameter of 22 μm and different lengths, similar relationship is obeyed in the whole range of volume fraction. The bending strength of the sample with FeCrAl fiber length of 1-2 mm is higher than that of the sample with FeCrAl fiber length of 3-4 mm in the whole range of volume fraction (Fig. 6(b)).

Fig. 6 Bending strength of FeCrAl(f)/HA composite

Obviously, HA in the composite is a hard brittle phase, while FeCrAl fiber is a toughness phase. The characteristics of the composite can be determined by the interface construction and properties of the matrix. The fracture toughness of FeCrAl fiber is higher than that of the composite matrix, while there are many microporosities between FeCrAl fiber and HA. When the volume fraction of fiber is low, the microporosities are less; the strength of FeCrAl fiber takes main effect. As the volume fraction of the fibers rises up to higher level, the microporosities also go up quickly. Thus, the crack of the composite caused by microporosities increases and the mechanical properties decline.

3.4 Fracture behaviors and toughening mechanism of FeCrAl(f)/HA composite

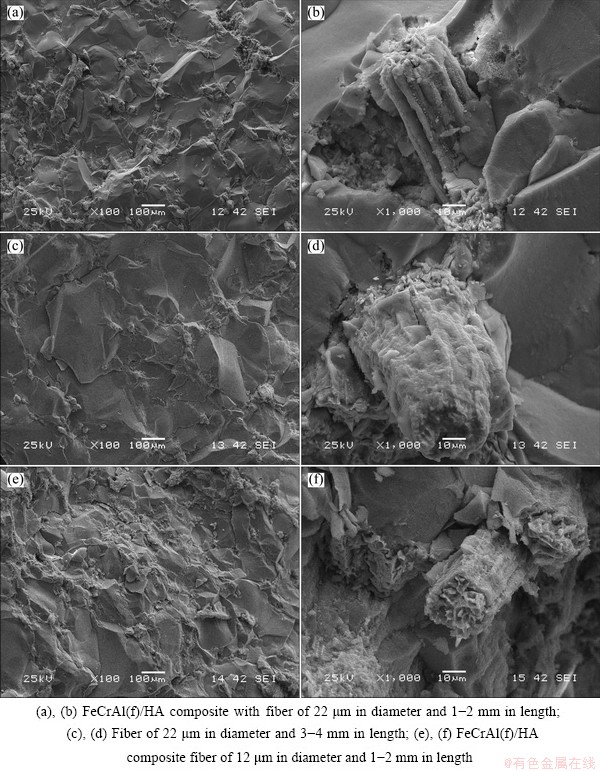

The diameter and length of toughened phase FeCrAl fiber take an important role in the properties of the composites. Figure 7 shows SEM images of FeCrAl(f)/ HA (7%) composites fracture section. Figures 7(a) and (b) show the fracture sections of FeCrAl(f)/HA composite with the fiber diameter of 22 μm and length of 1-2 mm; Figures 7(c) and (d) show fracture sections of FeCrAl(f)/ HA composite with the fiber diameter of 22 μm and a length of 3-4 mm; and Figs. 7(e) and (f) show fracture sections of FeCrAl(f)/HA composite with the fiber diameter of 12 μm and a length of 1-2 mm. It can be seen from Fig. 7 that FeCrAl fibers randomly and evenly distribute in the composites and no cracks or pores can be found in the composites, which is in accordance with the metallographic microstructures in Fig. 3. Figure 7 also shows the irregular interface of HA matrix and FeCrAl fiber. Both of the matrix and fiber integrate very tightly and bite into each other very deeply. Reinforcing mechanism is distinct when the length of the fiber changes. Reinforcing phase FeCrAl fiber pulling-out behavior can be seen in Figs. 7(b)-(f). When the FeCrAl fibers are 1-2 mm in length, the FeCrAl fibers are pulled out from the composite. But when the FeCrAl fibers are 3-4 mm in length, there are many fibers ruptured from the composites. Meanwhile, when the diameter of the fiber is 22 μm, there is no obvious change in micro- fracture compared with that of FeCrAl fibers with a diameter of 12 μm and a length of 1-2 mm, where the majority of fibers are pulled out, which can be found from Figs. 7(e) and (f).

Pure HA has a typical brittle fracture. Once the cracks under stress propagate to the FeCrAl fibers, the fibers will be pulled out or ruptured. Thus, the definite fracture energy will be exhausted and crack propagating is held back and fracture toughness is improved [14]. The more the FeCrAl fiber fraction is, the more the fracture energy is exhausted, and the more the fracture toughness is improved. Once the stress is transferred to two-phase interface, the stress can disperse onto the FeCrAl fiber, which makes the composite endure larger outside force.

The FeCrAl fibers with different diameters lead to different fracture modes of the composites. It can be seen from Figs. 7(c) and (d) that the fractures of FeCrAl fiber (12 μm in diameter) in FeCrAl(f)/HA composite are snapped, which indicates that the composite can be strengthened by the fracture of FeCrAl fiber. On the other hand, the fracture modes of FeCrAl fiber (22 μm in diameter) in FeCrAl(f)/HA composite are extracted, indicating that the disaggregation from the fiber can also strengthen the composite. According to COT theory [15], extraction energy of the fiber is an important factor during the fracture process. At the same volume faction of the fiber, the thicker fiber is not easy to be snapped, and major energy is exhausted during the extraction. So, the reinforcing effect of the composite can be promoted by the bonding of the interface between the fiber and the matrix. On the other hand, the interfaces between FeCrAl fiber and HA matrix are enhanced when the fibers are shorter. Thus, more energy is exhausted for shorter fiber compared with that of longer fiber, which makes shorter fiber strengthen the composite more obviously.

Fig. 7 SEM images of fracture sections of FeCrAl(f)/HA composite with 7% FeCrAl fiber

4 Conclusions

1) FeCrAl fiber, as a second phase, distributes evenly in the composites. Bending strength of FeCrAl(f)/HA composites can be enhanced gradually with the increase of the content of FeCrAl fiber. The interface of HA and FeCrAl fiber combines closely, and the counterdiffusion takes place to some extent in two- phase interfaces.

2) The bending strength of FeCrAl(f)/HA composite can be strengthened with the increase of the diameter of FeCrAl fiber in the composite, and declines with the increase of the length of FeCrAl fiber.

3) When the diameter of FeCrAl fibers is 22 μm, the length is 1-2 mm and the volume faction is about 7%, the properties of FeCrAl(f)/HA composite are optimum.

References

[1] DURAIA E M, HANNORA A, MANSUROV Z, BELL G W. Direct growth of carbon nanotubes on hydroxyapatite using MPECVD [J]. Materials Chemistry and Physics, 2012, 132: 119-124.

[2] RUAN Jian-ming, ZOU Jian-peng, HUANG Bai-yun. Biomaterials science [M]. Beijing: Science Press, 2004: 132-134. (in Chinese)

[3] FAN Xin, ZOU Jian-peng, WAN Qian, CHEN Jian, ZHOU Zhong-cheng, RUAN Jian-ming. Mechanical properties of HA/316L stainless steel symmetrical functionally gradient biocomposites [J]. Journal of Central South University: Science and Technology, 2009, 40(3): 632-637. (in Chinese)

[4] FAN Xin, ZOU Jian-peng, WAN Qian, CHEN Jian, ZHOU Zhong-cheng, RUAN Jian-ming. Bone-like apatite formation on HA/316L stainless steel composite surface in simulated body fluid [J]. Transactions of Nonferrous Metals Society of China, 2009, 19: 347-352.

[5] GUO Q, ZHAN Y, MO H, ZHANG G. Aging response of the Ti-Nb system biomaterials with β-stabilizing elements [J]. Materials and Design, 2010, 31: 4842-4846.

[6] XIONG J, LI Y, WANG X, HODGSON P, WEN C. Mechanical properties and bioactive surface modification via alkali-heat treatment of a porous Ti-18Nb-4Sn alloy for biomedical applications [J]. Acta Biomaterialia, 2008, 4: 1963-1968.

[7] ZHOUY L, LUO D M. Corrosion behavior of Ti-Mo alloys cold rolled and heat treated [J]. Journal of Alloys and Compounds, 2011, 509: 6267-6272.

[8] ANNETT D R, KARL B, RAINER N, KLAUS N, GUNTER M, MAGDALENA S, EBERHARD M, ANNA S. Unreinforced and carbon fiber reinforced hydroxyapatite: Resistance against microabrasion [J]. Journal of the European Ceramic Society, 2004, 24: 2131-2139.

[9] KNEPPER M, MORICCAT S, MITHORPE B K. Stability of hydroxyapatite while processing short-fibre reinforced hydroxyapatite ceramics [J]. Biomaterials, 1997, 18(23): 1523-1529.

[10] MIAO X, RUYS A J, MILTHORPE B K. Hydroxyapatite 316L fibre composites prepared by vibration assisted slip casting [J]. J Mater Sci, 2001, 36(13): 3323-3332.

[11] RUAN Jian-ming, ZOU Jian-peng, ZHOU Zhong-cheng. Hydroxyapatite-316L stainless steel fiber composite biomaterials fabricated by hot pressing [J]. Powder Metallurgy, 2006, 49(1): 62-65.

[12] TONG Xiao-yang,ZOU Jian-peng,RUAN Jian-ming, YANG Hai-lin,JIE Yun-feng. Preparation and properties of HA/FeCrAl fibers biological functional gradient materials [J]. Journal of Central South University: Science and Technology, 2011, 42(6):1 567-1572. (in Chinese)

[13] ZOU Jian-peng, HE Ze-qiang, ZHOU Zhong-cheng, RUAN Jian-ming. Microstructure and toughening mechanism of HA/316L powder asymmetrical biological functionally gradient materials [J]. Rare Metal Materials and Engineering, 2008, 37(12): 2129-2133. (in Chinese)

[14] ZOU Jian-peng, HE Ze-qiang, ZHOU Zhong-cheng, HUANG Bai-yun, CHEN Qi-yuan, RUAN Jian-ming. Fabrication, property characterization and toughening mechanism of HA-ZrO2(CaO)/316L fibre composite biomaterials [J]. Science in China Series E: Technological Sciences, 2008, 51(7): 957-967.

[15] COT H L. The elasticity and strength of paper and other fiberous materials [J]. Britain Journal of Applied Physics, 1952(3): 72-79.

FeCrAl纤维对FeCrAl(f)/HA复合材料显微结构及力学性能的影响

杨海林,李 婧,方华婵,张 翔,周忠诚,童晓阳,阮建明

中南大学 粉末冶金国家重点实验室,长沙 410083

摘 要:采用热压工艺制备FeCrAl纤维增强的FeCrAl(f)/HA生物复合材料,通过金相显微镜、X射线衍射、扫描电子显微镜(SEM)以及能谱(EDS)等测试手段对试样的微观结构及成分进行观察和表征。采用三点抗弯法测定FeCrAl(f)/HA复合材料试样的力学性能。研究结果表明:复合材料的性能随FeCrAl纤维加入得到提高,并随着纤维含量(0~11%,体积分数)的增加逐渐明显下降。HA基体和FeCrAl纤维界面结合紧密,互相咬合较深,并在两相上出现了一定程度的互扩散。FeCrAl(f)/HA生物复合材料的最优化参数如下:纤维直径22 μm,长度1-2 mm、体积分数7%左右。

关键词:FeCrAl(f)/HA复合材料;纤维增强;热压工艺;力学性能

(Edited by Wei-ping CHEN)

Foundation item: Project (50774096) supported by the National Natural Science Foundation of China; Project (2011QNZT046) supported by the Fundamental Research Funds of the Central South University, China; Project supported by the Postdoctoral Science Foundation of Central South University, China

Corresponding author: Jian-ming RUAN; Tel: +86-731-88876644; E-mail: Jianming@csu.edu.cn

DOI: 10.1016/S1003-6326(13)62520-0

Abstract: FeCrAl fiber-reinforced hydroxyapatite (HA) biocomposites (FeCrAl(f)/HA) were fabricated by the hot pressing technique. The metallographic microscopy, X-ray diffractometry, scanning electron microscopy (SEM) and energy dispersive spectroscopy (EDS) were used to observe and analyze the microstructure and composition of FeCrAl(f)/HA composites, respectively. The mechanical properties of FeCrAl(f)/HA composites were measured by the three-point-bending test. The results show that the composite can be reinforced by FeCrAl fiber and enhanced gradually, and then declined with the increase of the content of FeCrAl fiber (0-11%, volume fraction) in the whole range of experiments. Both the HA matrix and FeCrAl fiber integrate very tightly and bit into each other very deeply and counter-diffusion takes place to some extent at two-phase interface. The optimum parameters of FeCrAl(f)/HA composite are diameter of 22 μm, length of 1-2 mm and of volume faction of about 7% for FeCrAl fibers.