DOI: 10.11817/j.ysxb.1004.0609.2020-37557

NiTi40合金微观组织结构的电子显微学分析

杜志伟1, 2, 3,彭永刚1, 2, 3,韩小磊1, 2, 3,张 婧1, 2, 3,李 聪1, 2, 3,刘淑凤1, 2, 3,徐云培1, 2, 3

(1. 国标(北京)检验认证有限公司,北京 100088;

2. 国合通用测试评价认证股份公司,北京 100088;

3. 有研科技集团有限公司 国家有色金属及电子材料分析测试中心,北京 100088)

摘 要:

采用扫描电子显微分析(SEM)、电子背散射衍射分析(EBSD)、透射电子显微分析(TEM)、高分辨电子显微分析(HRTEM)、高角度环形暗场-扫描透射(HAADF-STEM)等技术手段,对NiTi40(60%Ni+40%Ti,质量分数)合金淬火态样品的微观组织结构进行分析。结果表明:NiTi40合金在950 ℃、150 min固溶水冷和1050 ℃、150 min固溶水冷的硬度值相近,为60~61 HRC,但微观组织结构有显著的区别。经950 ℃固溶水冷后,合金中的粗大第二相主要为NiTi2和Ni3Ti相,还有少量和NiTi2相互伴生的TiC相;经1050 ℃固溶水冷后,合金中的Ni3Ti相接近完全回溶的,粗大第二相主要为相互伴生的NiTi2及TiC相。随着固溶温度的升高,合金的晶粒尺寸明显增大,合金晶界处的小晶粒在1050 ℃固溶时基本消失。经950 ℃固溶处理,晶内析出相主要为10~20 nm的Ni4Ti3相;经1050 ℃固溶处理,晶内析出相主要为几十至几百纳米的Ni4Ti3相。

关键词:

NiTi40合金;固溶处理;电子显微学分析;Ni4Ti3相;

文章编号:1004-0609(2020)-03-0587-08 中图分类号:TG146.2 文献标志码:A

NiTi合金具有优异的形状记忆效应、超弹性和生物相容性,广泛应用于航空航天、航海、生物医用材料等领域[1-4]。早在20世纪60年代,BUEHLER等[1]详细描述了55NiTi(55%Ni(质量分数)或50%Ni(摩尔分数))和60NiTi(NiTi40,60%Ni(质量分数)或55%Ni (摩尔分数))的特性和工程应用。摩尔比接近1:1的55NiTi合金具有形状记忆效应和超弹性,是典型的形状记忆合金,受到了研究者广泛的关注[5-6]。NiTi40合金具有较高的强度和硬度,优异的耐腐蚀性,稳定的无磁性、低弹性模量、低密度等优点,在摩擦学应用(如轴承材料)、生物医学等领域具有广泛的应用前景[7-9]。

NiTi40合金由B2结构的NiTi基体和第二相组成,其中第二相有平衡相NiTi2和Ni3Ti,亚稳相Ni3Ti2和Ni4Ti3相[10-11],各相的空间群和晶格参数如表1所示[12-13]。NiTi和Ni3Ti是富Ni的NiTi合金的室温平衡相,Ni3Ti在NiTi基体中的固溶温度为975℃。平衡相NiTi2在984℃凝固过程中形成的[2],NiTi2易与O元素结合,形成热力学稳定的Ti2NiOx或Ti2NiO,NiTi2在固溶处理时难以回溶。NiTi40合金具有较高的强度和硬度,其主要原由于该合金析出了大密度细小的Ni4Ti3相[14]。Ni4Ti3相的析出强化了NiTi基体,提高了合金的形状记忆效应。Ni4Ti3相与马氏体相变存在强烈的耦合作用,可通过控制改变Ni4Ti3相的尺寸、密度来改变马氏体相变路径和温度[2, 15]。此外,Ni4Ti3相能影响应力场和降低基体中Ni4Ti3相周围纳米级区域Ni元素的含量[16]。

由Ni-Ti二元相图[2]可知,NiTi固溶体中,Ni元素的固溶度随着温度的升高而增加。NiTi40合金由于Ni元素的含量高,在温度降低时,更易于析出第二相,并且第二相的种类、数量和分布会随不同的热处理工艺而发生改变[10],且影响了合金的性能[11, 14, 17]。本文对NiTi40合金固溶态样品的微观组织结构进行了电子显微学分析。采用扫描电子显微分析(SEM)、电子背散射衍射(EBSD)分析、透射电子显微分析(TEM)、高分辨电子显微分析(HRTEM)、高角度环形暗场-扫描透射(HAADF-STEM)等技术手段系统研究了NiTi40挤压棒材经950 ℃、1050 ℃固溶水冷处理150 min后样品的微观组织结构,为NiTi40合金作为更有竞争力的轴承材料提供参考。

1 实验

试验所采用合金材料NiTi40名义成分为60%Ni+ 40%Ti(质量分数)。采用真空感应熔炼制备NiTi40合金铸锭;采用热挤压成形NiTi40合金棒材(挤压比为7)。NiTi40合金棒材的硬化热处理参数为到温放料(950 ℃与1050 ℃),保温150 min后水冷。试验用NiTi40合金样品由北京航空材料研究院提供。

采用JSM-7001F扫描电子显微镜观察合金中的粗大第二相分布情况,利用SEM配备的能谱仪分析相的成分,并利用SEM配备的电子背散射衍射仪对合金的晶粒尺寸分布情况进行了分析。利用JEM-2010高分辨型透射电子显微镜和Tecnai G2 F20-TWIN型热场发射透射电子显微镜观察合金的微观组织,高分辨电子显微像,并利用Tecnai G2 F20-TWIN热场发射透射电子显微镜附带的能谱仪分析相的成分。TEM制样,首先将样品制成直径为d 3 mm厚度约为50 μm的小圆片,在MTP-1A双喷仪上进行双喷,双喷液为5%(体积分数)高氯酸甲醇溶液,电压50 V,电流约为50 mA,温度约为-40℃。

2 结果与分析

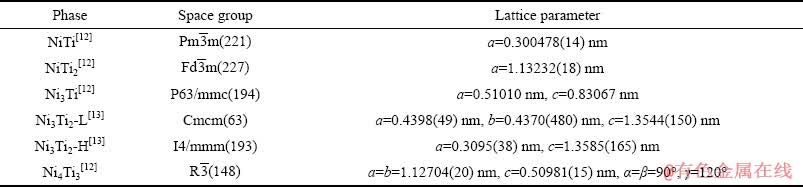

表1 NiTi40合金中各个相的空间群和晶格参数[12-13]

Table 1 Space group and lattice parameters of each phase in NiTi40 alloy[12-13]

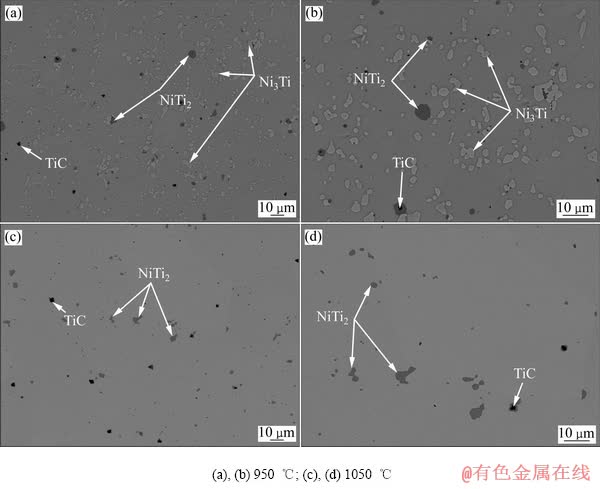

图1 NiTi40合金经950 ℃与1050 ℃固溶水冷后样品中微米尺度第二相分布

Fig. 1 BSE images of NiTi40 alloys after solid solution followed by water quenching

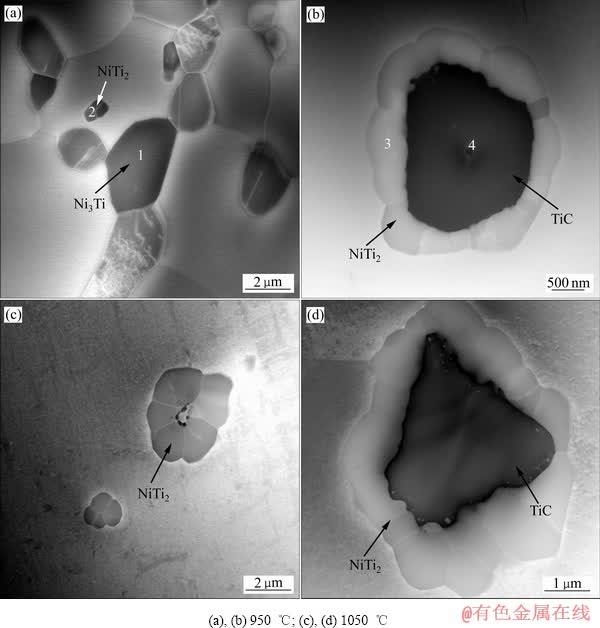

图1所示为NiTi40合金挤压棒材经不同热处理后的背散射电子(BSE)像。NiTi40合金经950 ℃固溶水冷的BSE像见图1(a)和(b),合金中存在大量尺寸在1~10 μm的第二相。根据衬度的不同,合金中除B2 结构的NiTi基体外还存在3种相,结合EDS分析结果(见表2),衬度相对基体较亮的相为Ni3Ti相,衬度相对基体较暗的相为NiTi2相,部分NiTi2相中还存在衬度接近于黑色的相为Ti的碳化物TiC。合金基体NiTi相中的Ni、Ti原子比接近于1,Ni原子略多,存在一定数量在扫描电镜不易观察到的纳米级的析出相Ni4Ti3[10-18],析出相的Ni、Ti原子比大于1。通过 HAADF-STEM像观察(见图2)和相应的EDS分析(见表3),可以发现经950 ℃固溶水冷的NiTi40合金晶粒内部以及晶界处分布大量微米尺度Ni3Ti、NiTi2以及TiC,其中TiC与NiTi2以两相伴生形式出现,如图2(b)所示。

NiTi40合金经1050 ℃固溶水冷的形貌见图1(c)、(d)。相比950 ℃固溶水冷处理,经1050 ℃固溶水冷的合金中Ni3Ti相接近完全回溶,但仍存在大量尺寸在1~10 μm成分接近于NiTi2的相和TiC相。此外,合金经1050 ℃固溶水冷后,基体中的Ni含量进一步提高,接近于NiTi40合金中Ni的理论含量。图2(c)、(d)表明粗大第二相主要为NiTi2、TiC相,未见Ni3Ti相。

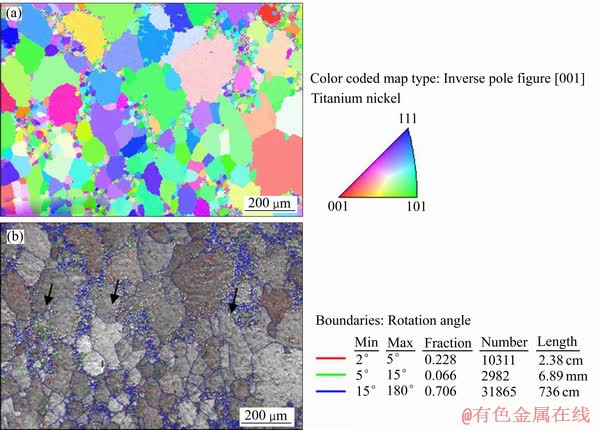

采用电子背散射衍射(EBSD)技术对两种固溶处理制度的合金进行了分析。分析区域为1200 μm×900 μm,步长为4 μm。经950 ℃和1050 ℃固溶水冷后合金的取向分布图、菊池花样质量图叠加晶界类型图分别列于图3和4。图3(b)中菊池花样质量图中白色较亮的点(用黑色箭头标出)对应于Ni3Ti相,由于其尺寸较小,较大面积范围的EBSD分析由于受步长限制未对其进行标定。由图3(b)可以看出,Ni3Ti相主要分布

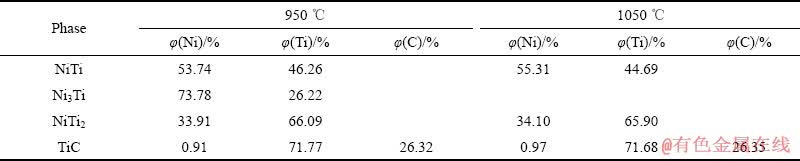

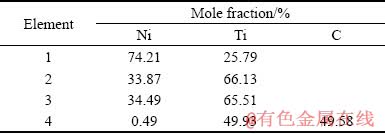

表2 图1中相应点的EDS分析结果

Table 2 EDS results of corresponding points in Fig. 1

图2 NiTi40合金中粗大第二相的HAADF-STEM像

Fig. 2 HAADF-STEM images of coarse second phases in NiTi40 alloy

表3 图2中相应点的EDS分析结果

Table 3 EDS results of corresponding points in Fig. 2

图3 NiTi40合金经950 ℃固溶水冷的取向图和菊池花样质量图叠加晶界图

Fig. 3 EBSD IPF maps(a) and IQ maps(b) of NiTi40 alloy after solid solution at 950 ℃ followed by water quenching

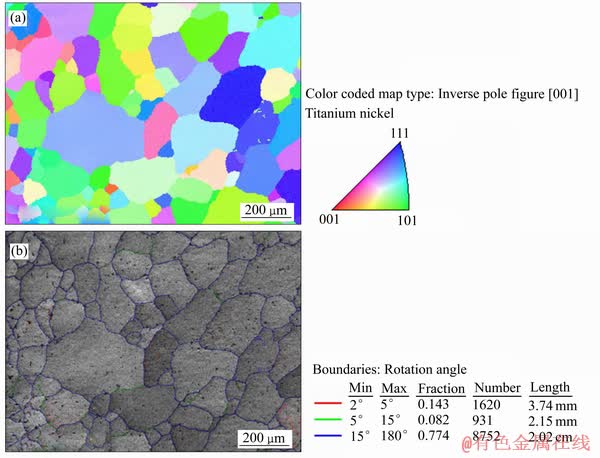

图4 NiTi40合金经1050 ℃固溶水冷的取向图和菊池花样质量图叠加晶界图

Fig. 4 EBSD IPF maps(a) and IQ maps(b) of NiTi40 alloy after solid solution at 1050 ℃ followed by water quenching

在晶界附近,在Ni3Ti聚集的位置,有一些小的晶粒存在。图4(b)中未观察到有较亮的点存在,说明经 1050 ℃固溶处理Ni3Ti相已基本回溶,与SEM观察结果相一致。经950 ℃和1050 ℃固溶水冷合金的晶粒尺寸分别为113 μm和171 μm。固溶温度升高,合金的晶粒尺寸明显增大,大角度晶界分数增加,合金晶界处的小晶粒在1050 ℃固溶时基本消失。

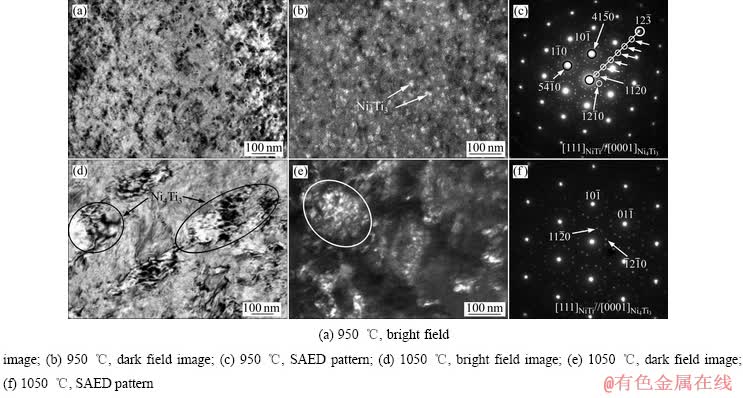

图5(a)~(c)所示为NiTi40合金经950 ℃固溶水冷样品的TEM明场像、暗场像和相应的选区电子衍射(SAED)谱。从明场像和暗场像中可以看出,该合金中存在大量的纳米级的晶内析出相,其尺寸范围为10~20 nm,图5(b)用箭头标出。析出相在明场像中具有较大的应力衬度。图5(c)所示为沿[111]NiTi方向的SAED谱,该SAED谱由基体相和两套析出相的衍射斑点叠加而成,标定结果如图5(c),与KARLIK等[12]的结果相一致。进一步确定基体为B2结构的NiTi相,晶内析出相为Ni4Ti3,析出相的Ni、Ti比应大于1,这和以上EDS分析结果相一致。从SAED谱可以看到,存在两种取向的Ni4Ti3变体,这两个变体关于B2结构NiTi基体的(110)B2镜面对称。沿着 方向观察到6个额外的衍射斑点,

方向观察到6个额外的衍射斑点, 为Ni4Ti3[19-20]。此外,NiTi基体的

为Ni4Ti3[19-20]。此外,NiTi基体的 面对应的衍射斑点和Ni4Ti3析出相的

面对应的衍射斑点和Ni4Ti3析出相的 面对应的衍射斑点重合。SAED谱表明NiTi与Ni4Ti3的取向关系为[111]NiTi//

面对应的衍射斑点重合。SAED谱表明NiTi与Ni4Ti3的取向关系为[111]NiTi// ,

, //

// 。

。

图5(d)~(f)所示为NiTi40合金经1050 ℃固溶水冷样品的TEM明场像、暗场像和相应的选区电子衍射SAED谱。从明场像和暗场像中可以看出,该合金中存在比950 ℃固溶水冷的样品明显粗大的Ni4Ti3相,且大小分布不均匀,其尺寸为几十到几百纳米,图5(b)用圆圈标出。SAED谱表明B2(NiTi)和Ni4Ti3共 存,且B2(NiTi)和Ni4Ti3的取向关系为[111]NiTi//  、

、 //

// 。

。

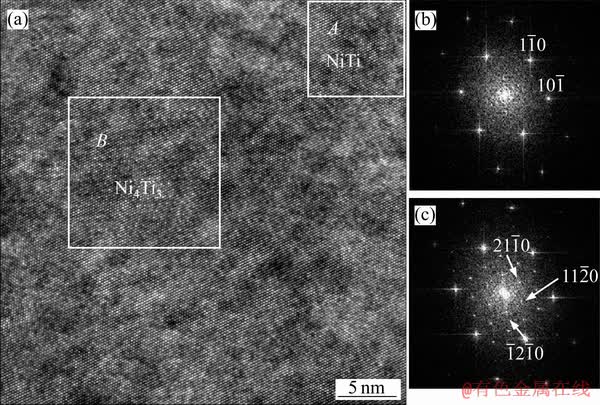

图6(a)所示为NiTi40合金经950 ℃固溶水冷的样品沿基体NiTi相[111]晶带轴(// )方向观察的高分辨电子显微像。图6(b)是区域A的快速傅里叶变换(FFT)图,为B2有序结构的NiTi基体。图6(c)是区域B的快速傅里叶变换(FFT)图,为Ni4Ti3析出相。在图6(a)中,从高分辨晶格像难以确定析出相与基体间界面,未见界面处明显的应力衬度。

)方向观察的高分辨电子显微像。图6(b)是区域A的快速傅里叶变换(FFT)图,为B2有序结构的NiTi基体。图6(c)是区域B的快速傅里叶变换(FFT)图,为Ni4Ti3析出相。在图6(a)中,从高分辨晶格像难以确定析出相与基体间界面,未见界面处明显的应力衬度。

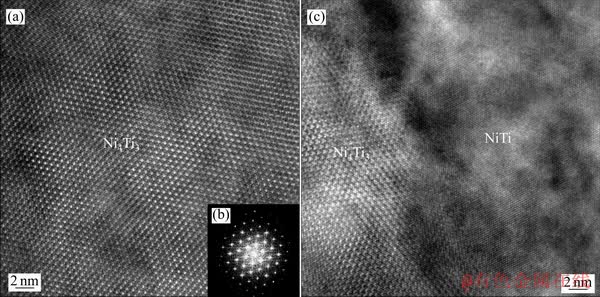

图7所示为NiTi40合金经1050 ℃固溶水冷的样品沿基体NiTi相[111]晶带轴(// )方向观察的高分辨电子显微像。由图7可知,1050 ℃固溶水冷的Ni4Ti3析出相尺寸为几十到几百纳米,在该尺寸范围,能观察到清晰的晶格像,如图7(a)所示;图7(b)所示为相应的Ni4Ti3析出相的快速傅里叶变换(FFT)图,也进一步证明图7中SAED谱由两种取向的Ni4Ti3相变体和NiTi基体的衍射谱组成。图7(c)所示为Ni4Ti3析出相和基体NiTi相界面处高分辨晶格像,能够观察到明显的相界面,界面附近存在较大的应力场。

)方向观察的高分辨电子显微像。由图7可知,1050 ℃固溶水冷的Ni4Ti3析出相尺寸为几十到几百纳米,在该尺寸范围,能观察到清晰的晶格像,如图7(a)所示;图7(b)所示为相应的Ni4Ti3析出相的快速傅里叶变换(FFT)图,也进一步证明图7中SAED谱由两种取向的Ni4Ti3相变体和NiTi基体的衍射谱组成。图7(c)所示为Ni4Ti3析出相和基体NiTi相界面处高分辨晶格像,能够观察到明显的相界面,界面附近存在较大的应力场。

图5 NiTi40合金TEM像和相应的选区电子衍射谱

Fig. 5 TEM images of NiTi40 alloy and corresponding selected area electron diffraction (SAED) patterns

图6 沿基体NiTi相[111]晶带轴(// )方向观察的高分辨电子显微像

)方向观察的高分辨电子显微像

Fig. 6 HRTEM image viewed along [111]NiTi(// )(a) and corresponding Fast Fourier Transform (FFT) patterns of Fig. 6(a) ((b), (c))

)(a) and corresponding Fast Fourier Transform (FFT) patterns of Fig. 6(a) ((b), (c))

图7 沿基体NiTi相[111]晶带轴(// )方向观察的高分辨电子显微像

)方向观察的高分辨电子显微像

Fig. 7 HRTEM images viewed along [111]NiTi(// )((a), (c)) and corresponding Fast Fourier Transform (FFT) pattern of Fig. 7(a), (b)

)((a), (c)) and corresponding Fast Fourier Transform (FFT) pattern of Fig. 7(a), (b)

经950 ℃、1050 ℃固溶水冷的NiTi40合金的硬度值分别为(60.5±0.6) HRC和(60.9±0.1) HRC。固溶水冷处理是NiTi40合金获得高硬度的关键[10-11],Ni3Ti相回溶,纳米级的Ni4Ti3相在淬火过程中迅速形核。Ni4Ti3相的析出和生长的驱动力来自于过饱和NiTi基体相与含有Ni4Ti3相的NiTi基体之间自由能差[10, 18]。纳米级的Ni4Ti3相作为强化颗粒,均匀的分布在NiTi基体中,起到弥散强化的作用。Ni4Ti3相尺寸,形貌以及与NiTi基体的界面关系对合金硬度的影响还需进一步研究。

950 ℃、1050 ℃固溶水冷的NiTi40合金的硬度值相近,但微观组织有很大的差别。合金的硬度取决于晶粒尺寸,第二相的种类、数量、尺寸和形貌等。由EBSD得出的950 ℃和1050 ℃固溶水冷合金的晶粒尺寸分别为113 μm和171 μm。根据细晶强化,Hall-Petch公式可知,晶粒越大,强度越低,晶粒尺寸大小给经950 ℃固溶水冷的NiTi40合金提供的硬度值应高于1050 ℃固溶水冷的NiTi40合金。NiTi40合金经950 ℃固溶水冷后还存在大量未溶的NiTi2和Ni3Ti相;而经1050 ℃固溶水冷后,Ni3Ti相接近完全回溶,第二相的回溶效果明显优于950 ℃固溶处理。未溶的Ni3Ti相导致了950 ℃固溶水冷的NiTi40合金中Ni4Ti3相含量的减少[18];同时,Ni3Ti相使得合金应力诱发马氏体转变发生容易,降低基体的硬度[11]。

3 结论

1) 经950 ℃固溶处理后,合金中存在大量1~10 μm的第二相,主要为相互伴生的NiTi2、TiC以及Ni3Ti相。

2) 经1050 ℃固溶处理后,相比950℃固溶,合金中的Ni3Ti相接近完全回溶,仍存在大量尺寸在1~10 μm相互伴生的NiTi2及TiC相。

3) 经950 ℃与1050 ℃固溶的晶粒尺寸分别为113 μm和171 μm。950 ℃固溶样品晶界附近Ni3Ti相周围存在尺度相对较小的晶粒。固溶温度升高,合金的晶粒尺寸明显增大,合金晶界处的小晶粒在1050 ℃固溶时基本消失。

4) 经950 ℃固溶处理,晶内析出相主要为10~20 nm的Ni4Ti3相。经1050 ℃固溶处理,晶内析出相主要为几十至几百纳米的Ni4Ti3相。从SAED谱可以看到存在两种取向的Ni4Ti3相变体。析出相Ni4Ti3和基体NiTi的取向关系为 //[111]NiTi、

//[111]NiTi、 //

// 。

。

致谢:

感谢北京科技大学姜雁斌博士在样品加工制备过程提供的支持,感谢北京航空材料研究院官磊博士在合金熔炼与热处理方面提供的技术支持。

REFERENCES

[1] BUEHLER W J, WANG F E. A summary of recent research on the nitinol alloys and their potential application in ocean engineering[J]. Ocean Engineering, 1968, 1(1): 105-108.

[2] OTSUKA K, REN X. Physical metallurgy of Ti-Ni-based shape memory alloys[J]. Progress in Materials Science, 2005, 50(5): 511-678.

[3] VELMURUGAN C, SENTHILKUMAR V, DINESH S, ARULKIRUBAKARAN D. Review on phase transformation behavior of NiTi shape memory alloys[J]. Materials Today: Proceedings, 2018, 5(6): 14597-14606.

[4] 崔 跃, 张宝祥, 马连彩, 李君涛, 缪卫东, 袁志山, 张亨金. 镍钛合金在医疗器械领域应用和表面改性研究进展[J]. 材料导报, 2017, 31(A02): 197-200.

CUI Yue, ZHANG Bao-xiang, MA Lian-cai, LI Jun-tao, MIAO Wei-dong, YUAN Zhi-shan, ZHANG Heng-jin. Research of application and surface modification of NiTi alloy in medical instruments[J]. Materials Review, 2017, 31(A02): 197-200.

[5] SITTNER P, SEDLAK P, SEINER H, SEDMAK P, PILCH J, DELVILLE R, KADERAVEK L. On the coupling between martensitic transformation and plasticity in NiTi: Experiments and continuum based modeling[J]. Progress in Materials Science, 2018, 98: 249-298.

[6] EZAZ T, WANG J, SEHITOGLU H, MAIER H J. Plastic deformation of NiTi shape memory alloys[J]. Acta Materialia, 2013, 61(1): 67-78.

[7] INGOLE S. 60NiTi alloy for tribological and biomedical surface engineering applications[J]. JOM: The Journal of the Minerals, Metals & Materials Society, 2013, 65(6): 792-798.

[8] CHRISTOPHER D C. Novel super-elastic materials for advanced bearing applications[J]. Advances in Science and Technology, 2014, 89: 1-9.

[9] CORTE C D, STANFORD M K, JETT T R. Rolling contact fatigue of superelastic intermetallic materials (SIM) for use as resilient corrosion resistant bearings[J]. Tribology Letters, 2015, 57: 26-10.

[10] XU G X, ZHENG L J, ZHANG F X, ZHANG H. Influence of solution heat treatment on the microstructural evolution and mechanical behavior of 60NiTi[J]. Journal of Alloys and Compounds, 2019, 775: 698-706.

[11] 张瑞谦, 覃秋慧, 文玉华. 热处理对铸态60NiTi合金第二相析出与硬度的影响[J]. 材料热处理学报, 2017, 38(3): 76-82.

ZHANG Rui-qian, QIN Qiu-hui, WEN Yu-hua. Effects of heat treatment on precipitation of second phases and hardness of as-cast 60NiTi alloy[J]. Transactions of Materials and Heat Treatment, 2017, 38(3): 76-82.

[12] KARLIK M, HAUSILD P, KLEMENTOVA M, NOVAK P, BERAN P, PERRIERE L, KOPECEK J. TEM phase analysis of NiTi shape memory alloy prepared by self-propagating high-temperature synthesis[J]. Advances in Materials & Processing Technologies, 2016, 3(1): 58-69.

[13] TORU H, TAKUYA O, KAZUHIRO O, MINORU N. Phase transformations and crystal structures of Ti2Ni3 precipitates in Ti-Ni alloys[J]. Mater Transactions, 1997, 38(4): 277-284.

[14] BENAFAN O, GARG A, NOEBE R D, SKORPENSKE H D, AN K, SCHELL N. Deformation characteristics of the intermetallic alloy 60NiTi[J]. Intermetallics, 2017, 82: 40-52.

[15] ZHOU N, SHEN C, WAGNER M F X, EGGELER G, MILLS M J, WANG Y. Effect of Ni4Ti3 precipitation on martensitic transformation in Ti-Ni[J]. Acta Materialia, 2010, 58(20): 6685-6694.

[16] YANG Zhi-qing, TIRRY W, SCHRYVERS D. Analytical TEM investigations on concentration gradients surrounding Ni4Ti3 precipitates in Ni-Ti shape memory material[J]. Scripta Materialia, 2005, 52(11): 1129-1134.

[17] QIN Qiu-hui, WEN Yu-hua, WANG Gai-xia, ZHANG Lan-hui. Effects of solution and aging treatments on corrosion resistance of as-cast 60NiTi alloy[J]. Journal of Materials Engineering and Performance, 2016, 25(12): 5167-5172.

[18] HORNBUCKLE B C, YU X X, NOEBE R D, MARTENS R, WEAVER M L. Hardening behavior and phase decomposition in very Ni-rich Nitinol alloys[J]. Materials Science and Engineering A, 2015, 639: 336-344.

[19] SABURI T, NENNO S, FUKUDA T. Crystal structure and morphology of the metastable X-phase in a shape memory Ti-Ni alloys[J]. Journal of the Less-Common Metals, 1986, 125: 157-166.

[20] NISHIDA M, WAYMAN C M, HONMA T. Precipitation processes in near-equiatomic TiNi shape memory alloys[J]. Metallurgical Transactions A (Physical Metallurgy and Materials, Science), 1986, 17(9): 1505-1515.

Electron microscopic analysis of microstructure of NiTi40 alloy

DU Zhi-wei1, 2, 3, PENG Yong-gang1, 2, 3, HAN Xiao-lei1, 2, 3, ZHANG Jing1, 2, 3, LI Cong1, 2, 3, LIU Shu-feng1, 2, 3, XU Yun-pei1, 2, 3

(1. Guobiao (Beijing) Testing and Certification Co., Ltd, Beijing 100088, China;

2. China United Test and Certification Co., Ltd., Beijing 100088, China;

3. National Center of Analysis and Testing for Nonferrous Metals and Electronic Materials, General Research Institute for Nonferrous Metals Group Co., Ltd, Beijing 100088, China)

Abstract: The microstructure of the quenched samples NiTi40(60%Ni+40%Ti, mass fraction) alloys was analyzed by means of scanning electron microscopy(SEM), electron backscatter diffraction(EBSD), transmission electron microscopy(TEM), high-resolution transmission electron microscopy(HRTEM) and high angle annular dark field-scanning transmission electron microscopy (HAADF-STEM). The results show that the hardness values of NiTi40 alloys after solution treatment at 950 ℃ and 1050 ℃ for 150 min are equivalent, about 60-61 HRC, but the microstructure is significantly different. After solution treatment at 950 ℃, the alloy is mainly comprised of NiTi matrix, NiTi2 and Ni3Ti precipitates, NiTi2 and TiC mutually co-existed. After solution treatment at 1050 ℃, Ni3Ti phase is completely dissolved into the matrix, and the second phase is mainly NiTi2 and TiC phase associated with each other. When the solution temperature increases, the grain size of the alloy increases significantly, and the small grains at the grain boundary of the alloy disappear substantially after solution treatment at 1050 ℃. After solution treatment at 950 ℃, the precipitation in the crystal is mainly 10-20 nm Ni4Ti3 phase, while intracrystalline precipitates are mainly dozens to hundreds of nanometer Ni4Ti3 phase after solution treatment at 1050 ℃.

Key words: NiTi40 alloy; solution treatment; electron microscopic analysis; Ni4Ti3

Foundation item: Projects(51271038, 51871195) supported by the National Natural Science Foundation of China

Received date: 2019-03-28; Accepted date: 2019-09-02

Corresponding author: DU Zhi-wei; Tel: +86-10-82241375-206; E-mail: duzhiwei@gbtcgroup.com

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51271038,51871195)

收稿日期:2019-03-28;修订日期:2019-09-02

通信作者:杜志伟,教授级高工,博士;电话:010-82241375-206;E-mail:duzhiwei@gbtcgroup.com

摘 要:采用扫描电子显微分析(SEM)、电子背散射衍射分析(EBSD)、透射电子显微分析(TEM)、高分辨电子显微分析(HRTEM)、高角度环形暗场-扫描透射(HAADF-STEM)等技术手段,对NiTi40(60%Ni+40%Ti,质量分数)合金淬火态样品的微观组织结构进行分析。结果表明:NiTi40合金在950 ℃、150 min固溶水冷和1050 ℃、150 min固溶水冷的硬度值相近,为60~61 HRC,但微观组织结构有显著的区别。经950 ℃固溶水冷后,合金中的粗大第二相主要为NiTi2和Ni3Ti相,还有少量和NiTi2相互伴生的TiC相;经1050 ℃固溶水冷后,合金中的Ni3Ti相接近完全回溶的,粗大第二相主要为相互伴生的NiTi2及TiC相。随着固溶温度的升高,合金的晶粒尺寸明显增大,合金晶界处的小晶粒在1050 ℃固溶时基本消失。经950 ℃固溶处理,晶内析出相主要为10~20 nm的Ni4Ti3相;经1050 ℃固溶处理,晶内析出相主要为几十至几百纳米的Ni4Ti3相。