网络首发时间: 2019-10-18 12:11

稀土La对高强IF钢中磷元素及含磷相析出的影响

内蒙古科技大学材料与冶金学院

山东钢铁集团日照有限公司钢铁研究院

内蒙古自治区新金属材料重点实验室

摘 要:

采用有无稀土镧的440 MPa高强IF钢为研究对象,分别在两种钢铸坯凝固、热轧卷取、冷轧、退火过程中取样,研究稀土镧对P元素及含P析出相析出行为的影响。对两种钢退火后组织、力学性能、析出物种类进行观察与测定。电感耦合等离子体质谱仪(ICP-MS)测定两种钢不同状态下电解出的第二相中P元素浓度,并计算得析出P占成分中P的比值。使用透射电镜加能谱(TEM+EDS)确定含P析出相种类、形貌、数量及分布。结果表明:稀土镧使得高强IF钢组织细化,抗拉强度提高;高强IF钢在铸坯凝固、热轧卷取及退火过程中稀土镧均抑制P元素析出,使成品中P的固溶量增加约12%;Nb+Ti+P高强IF钢在热轧卷取和退火过程中析出的含P相均为Fe(Nb+Ti)P复合相。对两种试样冷轧及最终成品状态中Fe(Nb+Ti)P析出相面密度和平均尺寸进行统计,结果表明,两种状态下试样1的面密度差值大于试样2,并且两种状态下试样1中Fe(Nb+Ti)P析出相的平均尺寸差值小于试样2,说明稀土镧可以减少Fe(Nb+Ti)P相析出,同时可以促使Fe(Nb+Ti)P析出相长大。稀土镧对Fe(Nb+Ti)P相的析出方式无影响,即退火前期Fe(Nb+Ti)P尺寸小且多为点状和棒状,分布较分散,随退火时间延长新的Fe(Nb+Ti)P相在之前形成的较大Fe(Nb+Ti)P相上继续形核并析出,出现串状和树枝状等复杂形貌且分布逐渐团聚;稀土镧对Fe(Nb+Ti)P形成机制无影响,高强IF钢中首先形成FeTi与FeNb混合富集相,随着热轧和退火过程进行,钢中固溶的P元素不断析出并扩散进入优先形成的FeTi与FeNb混合相中形成Fe(Nb+Ti)P相。

关键词:

高强IF钢;稀土La;磷的析出与固溶;Fe(Nb+Ti)P;

中图分类号: TG142.1

作者简介:任东(1992-),男,陕西渭南人,硕士,研究方向:高强钢组织、析出相与性能的研究,E-mail:15326722416@163.com;;*金自力,教授,电话:13190726115,E-mail:jinzl6310@126.com;

收稿日期:2019-08-25

基金:国家自然科学基金项目(50761005);内蒙古自治区科技重大专项项目(0902061701)资助;

P Element and Precipitation P-Containing Precipitate in High Strength IF Steel with Rare Earth Lanthanum

Ren Dong Jin Zili Ren Huiping Li Yuanyuan Li Yiming Zhang Jishun

School of Material and Metallurgy,Inner Mongolia University of Science and Technology

Shandong Steel Group Rizhao City Co.,Ltd.,Iron and Steel Research Institute

Key Laboratory of Advanced Metal Materials of Inner Mongolia

Abstract:

In recent years,more and more attention had been paid to the application value of rare earths in many industrial steel fields such as automobiles,military industry,and aerospace. This experiment mainly studied the role of rare earth elements in the production of high-strength IF steel. This experiment used 440 MPa high strength IF steel with or without lanthanum as the research object,the sample without lanthanum was Sample 1,and the sample with lanthanum was Sample 2. The samples were taken during solidification,hot rolling coiling,cold rolling and annealing of two kinds of steel,study on the effect of lanthanum on the precipitation behavior of P elements and P-containing precipitates. There were two annealing methods:continuous annealing and batch annealing. This experiment used batch annealing treatment,and the batch annealing process was carried out at 680 ℃,680 ℃ for 2 h,kept at 680 ℃for 2 h and cooled down with furnace,and the samples were taken out by water cooling to room temperature. The microstructure,mechanical properties,types and morphology of precipitates of two kinds of steel after batch annealing were observed and measured. The microstructure was observed by metallographic microscope(OM),the mechanical properties were measured by tensile machine,and the precipitates were observed by transmission electron microscope(TEM). Determination of P element concentration in the second phase electrolyzed by two steels under different conditions by inductively coupled plasma mass spectrometry(ICP-MS),and the ratio of phosphorus in the sample to phosphorus in the component was calculated. Determination of the type,morphology,quantity and distribution of P-containing precipitates using TEM and energy dispersive spectrometer(EDS). The results showed that:rare earth lanthanum could refine the microstructure of high strength of steel and improve the yield strength and tensile strength of the final product. In the process of solidification,hot rolling coiling and annealing of high strength IF steel,rare earth lanthanum inhibited the precipitation of P element. With the extension of the batch annealing time,the proportion of solid solution P in the two samples gradually decreased,and the proportion of solid solution P in Sample 2 was always greater than that in Sample 1. On the contrary,the proportion of precipitated P elements gradually increased,and the proportion of precipitated P in Sample 2 was always smaller than that in Sample 1. In the finished product obtained by heating at 680 ℃ for 2 h and then cooling,the proportions of precipitated P and solid solution P in Sample 1 were 57.84% and 42.16%,respectively,and the proportions of precipitated P and solid solution P in Sample 2 were 45.99% and54.01%,respectively. Comparing the changes in the proportions of precipitated P and solid solution P in the slab and the final product,the proportions of precipitated P in Sample 1 and Sample 2 increased by 49.47% and 38.11%,respectively,indicating that rare earth lanthanum made high-strength IF steel. The solid solution content of P element was increased by about 12%,and the rare earth lanthanum increased the solid solution strengthening effect of P element in high-strength IF steel. The P-containing phases precipitated during hot rolling,cold rolling and annealing of Nb+Ti+P high-strength IF steel were all Fe(Nb+Ti)P composite phases. Statistics of the areal density and average size of the Fe(Nb+Ti)P precipitates in the two cold-rolled samples and the finished product showed that the difference in areal density of Sample 1 was greater than that of Sample 2 in the two states,and the average size of Fe(Nb+Ti)P precipitates of Sample 1 was smaller than that of Sample 2. It showed that rare earth lanthanum could reduce the precipitation of Fe(Nb+Ti)P and promote the growth of Fe(Nb+Ti)P precipitates. Lanthanum had no effect on the morphology and precipitation of Fe(Nb+Ti)P phase. In the early stage of the batch annealing,Fe(Nb+Ti)P was small in size and mostly dot-like and rod-like,and its distribution was dispersed,with the increase of temperature or annealing time,the new Fe(Nb+Ti)P continues nucleated and precipitated on the large Fe(Nb+Ti)P phase formed before,and the complex morphology such as string and dendritic appears and the distribution tended to agglomerate. In this experiment,FeNb and FeTi precipitated phases were first discovered in the early stage of annealing of high-strength IF steel. With the increase of hot rolling and annealing temperature or annealing time,the solid soluble P element in high-strength IF steel continuously precipitated and diffused into the preferentially formed Fe(Nb+Ti)P mixed phase to form Fe(Nb+Ti)P phase.

Keyword:

high strength IF steel; rare earth lanthanum; precipitation and solid solution of phosphorus; Fe(Nb+Ti)P;

Received: 2019-08-25

稀土是一个国家军事装备、新型材料研发、科技发展等必不可少的战略资源。近年关于稀土在汽车、军工、航天等诸多工业用钢领域的应用价值越来越多的被发现和关注

1 实验

某钢研院真空感应炉分别冶炼两种50 kg的440 MPa高强IF钢实验钢锭,进行对比试验,冶炼得到不含稀土La的试样1和含稀土La的试样2,两种钢的具体成分如表1所示,仅为有无稀土La元素的区别。将两种钢加热到温度1250℃,在1100℃开锻,终锻温度920℃(锻造为截面尺寸为45 mm×265 mm)。板坯热轧在实验室二辊可逆式轧机上进行轧制,轧件厚度为5.0 mm,终轧温度约900℃,水冷却到600℃放进炉中进行卷曲过程的模拟。冷轧厚度为1 mm,压下率80%。

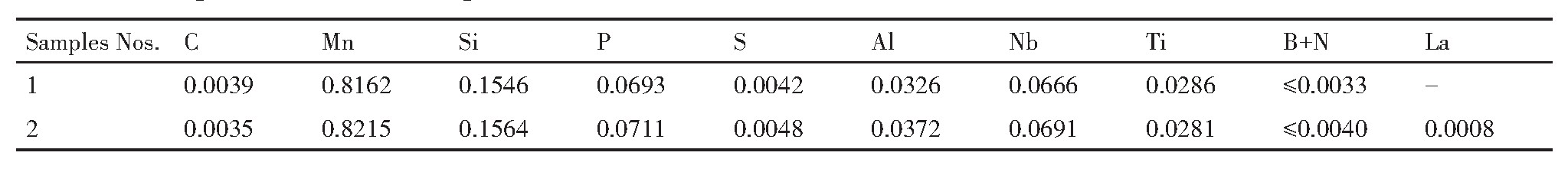

表1 实验钢的化学成分 下载原图

Table 1 Composition analysis of experimental steels(%,mass fraction)

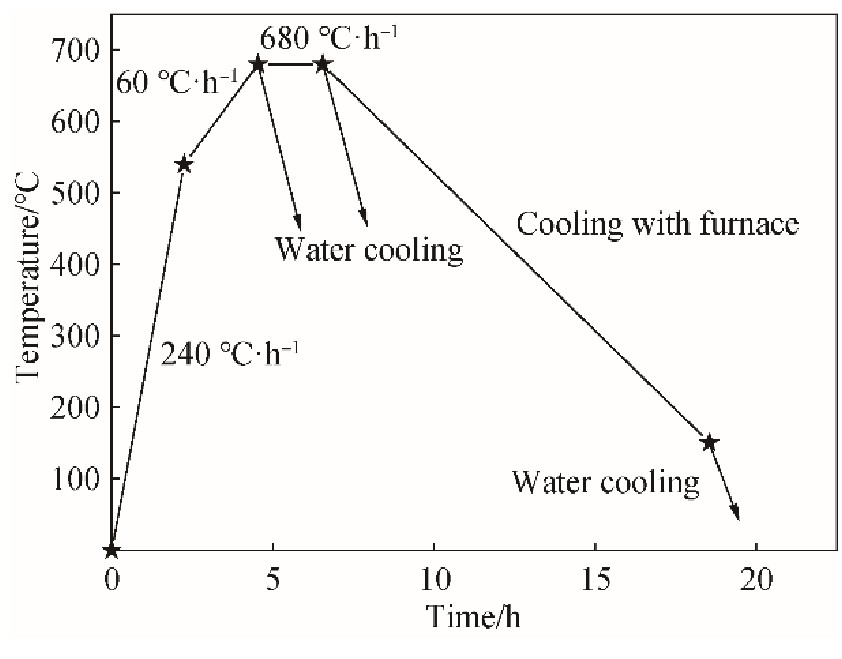

分别取铸坯状态、热轧卷取状态、冷轧状态、退火过程680℃,680℃保温2 h,680℃保温2 h随炉冷不同状态的两种试样进行试验。其中将两种钢热轧卷取板加热到1250℃保温40 min后水冷,用来模拟铸坯凝固后的状态。采用箱式电阻炉模拟罩式退火,两段式升温,540℃以下采用240℃·h-1的升温速度,540℃以上升温速度为60℃·h-1,升温至680℃保温2 h随炉冷至150℃后水冷,其退火工艺如图1所示。首先对两种钢的退火组织进行观察并通过拉伸试验测定其退火成品力学性能,以此判断稀土镧对于高强IF钢来说是否为有益元素,并为研究稀土La对高强IF钢中P元素与含P相析出的影响建立基础。通过电解法得到不同状态下两种试样中的第二相,使用电感耦合等离子体质谱仪(ICP-MS)测定所电解出的第二相中P元素浓度,并计算得到析出与固溶磷所占比例。萃取复型法制样并通过场发射透射电镜(TEM)+能谱(EDS)确定含P析出相(使用Cu网或Ni网),并观察其形状、尺寸、分布、数量及形成机制的变化。

2 结果与讨论

2.1 稀土镧对高强IF钢组织及性能的影响

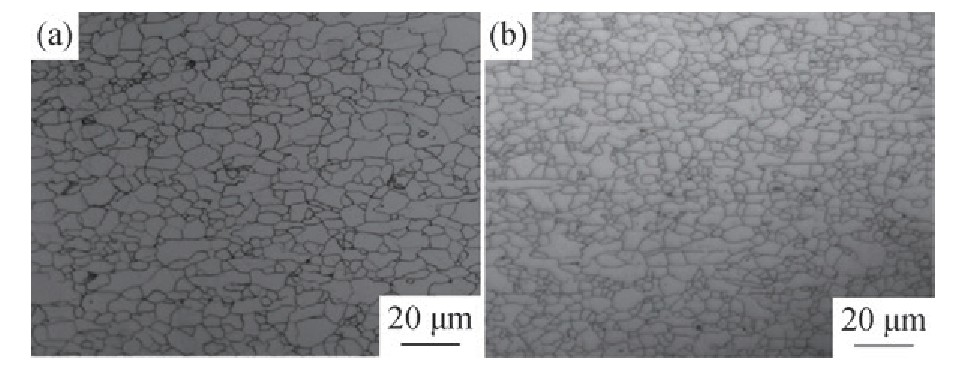

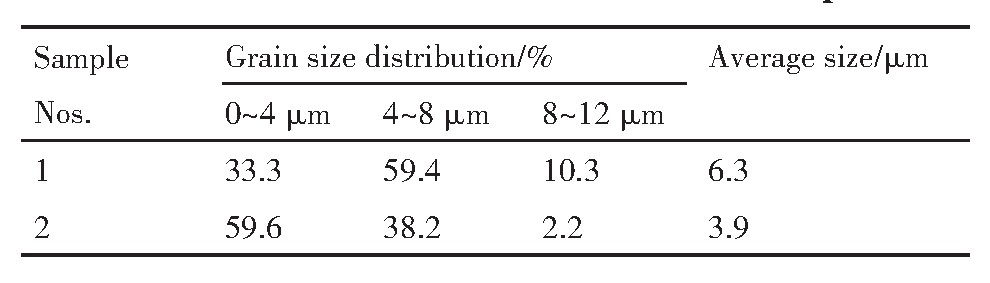

图2为680℃保温2 h随炉冷所得两种钢成品组织,可清楚看出两种钢均完全再结晶。通过对比两种钢再结晶晶粒大小,可明显看出试样1再结晶晶粒尺寸大于试样2。统计两种钢成品晶粒尺寸,结果如表2所示。表2中试样1平均晶粒尺寸大于试样2,试样1晶粒尺寸主要集中在4~8μm之间,试样2晶粒尺寸主要集中在0~4μm之间。试样1和试样2晶粒尺寸在8~12μm范围内所占比例分别为10.3%和2.2%,试样2所占比例远小于试样1。综上表明稀土镧有利于高强IF刚晶粒细化且晶粒分布更加集中。

图1 罩式退火工艺图

Fig.1 Batch annealing process diagram

图2 试样1和2的再结晶组织图(TEM)

Fig.2 Recrystallization microstructure of Sample 1 (a) and Sample 2(b)

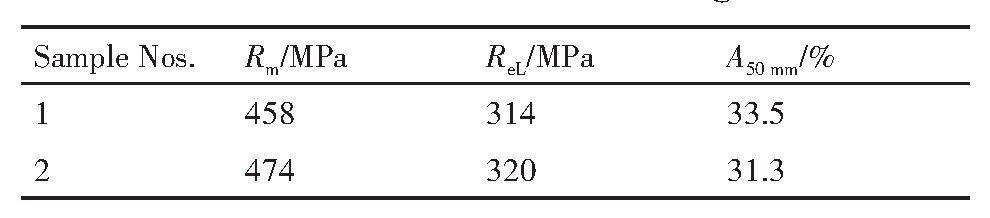

将680℃保温2 h炉冷所得成品,按照拉伸试验标准GB/T228.1-2010进行拉伸试验,结果如表3所示,其中Rm为材料的抗拉强度;Re L为材料屈服强度;A50 mm为标距为50 mm时的断后延伸率。按照宝钢企业标准Q/BQB 413-2009中规定,440 MPa高强IF钢抗拉强度大于440 MPa且伸长率大于30%,则该两种钢成品力学性能均符合标准。表3中试样2抗拉强度值较试样1大,其延伸率相差不大。表明稀土镧有助于高强IF钢抗拉强度的提高。

表2 两种钢成品晶粒尺寸统计 下载原图

Table 2 Grain size statistics of two finished steel products

查找文献可知

2.2 不同状态下稀土镧对P元素析出的影响

2.2.1 铸坯凝固与热轧卷取过程

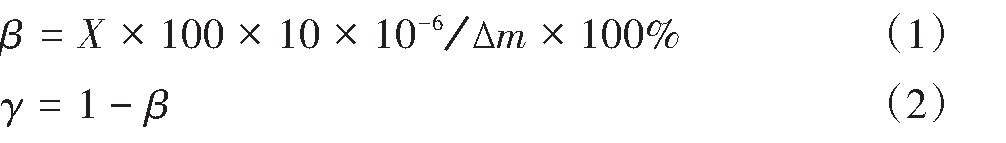

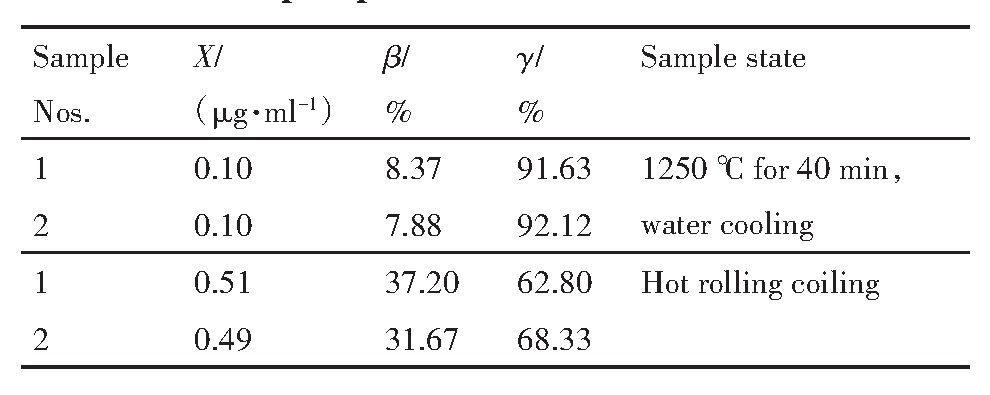

将两种钢热处理所得模拟铸坯试样与热轧卷取试样电解得到其第二相析出物,并将第二相粉末溶解、定容、稀释后进入ICP-MS测定试样电解出的析出相中P元素浓度。经下面两个公式计算可得析出与固溶P占成分中P的比值,结果如表4所示。其中析出P占成分中P的比值可作为析出P元素与含P析出相析出多少的衡量标准。

式中,X为试样电解出的第二相中所测P元素浓度(μg·ml-1);Δm为试样电解前后质量差(g);β为析出P占成分中P的比例;γ为固溶P占成分中P的比例。

Zhao等

表3 680℃保温2 h所得两种钢成品力学性能 下载原图

Table 3 Mechanical properties of finished products with680℃for 2 h with furnace cooling

表4 不同状态下析出与固溶磷占成分中磷的比例 下载原图

Table 4 Proportion of sample precipitation and solid so-lution phosphorus in different states

2.2.2 退火过程不同状态

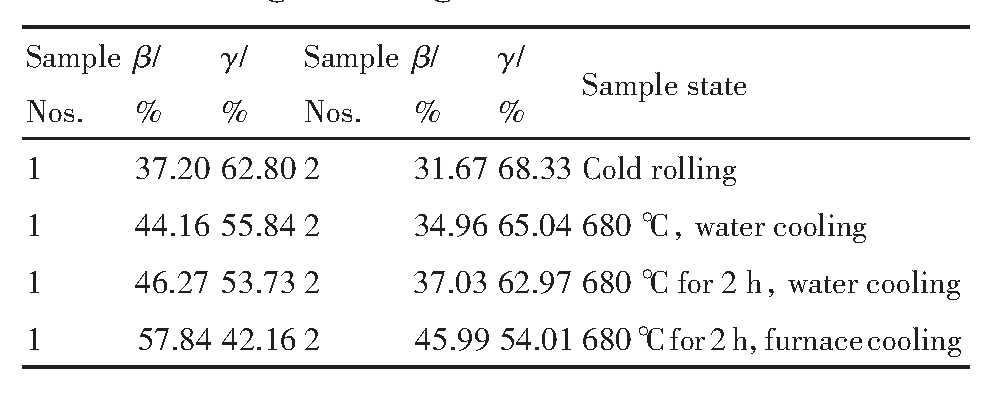

取两种钢冷轧及退火过程不同状态水冷试样,同样经ICP-MS测定电解出的第二相中P元素浓度,同理计算得表5数据。两种钢退火过程生成的含P析出相为Fe Nb(Ti)P,其中Fe∶Nb(Ti)∶P原子比约为1∶1∶1

冷轧过程不会有析出物生成,则表5中冷轧状态下有关数据和热轧卷过程所得数据相同。表5数据表明,680℃保温2 h随炉冷状态下P元素的析出量达到最大,此时钢中P元素固溶量最低。冷轧状态下两种试样析出P与成分中P的比值相差最小,随退火过程的进行,试样1中析出P占成分中P的比值远大于试样2。试样1和试样2由冷轧状态到680℃保温2 h随炉冷状态下析出P与成分中P的比值增量分别为20.64%和14.32%,试样2中P元素析出增量小于试样1,表明退火过程中稀土镧抑制P元素析出,同时说明罩式退火过程中稀土镧阻碍Fe(Nb+Ti)P析出。

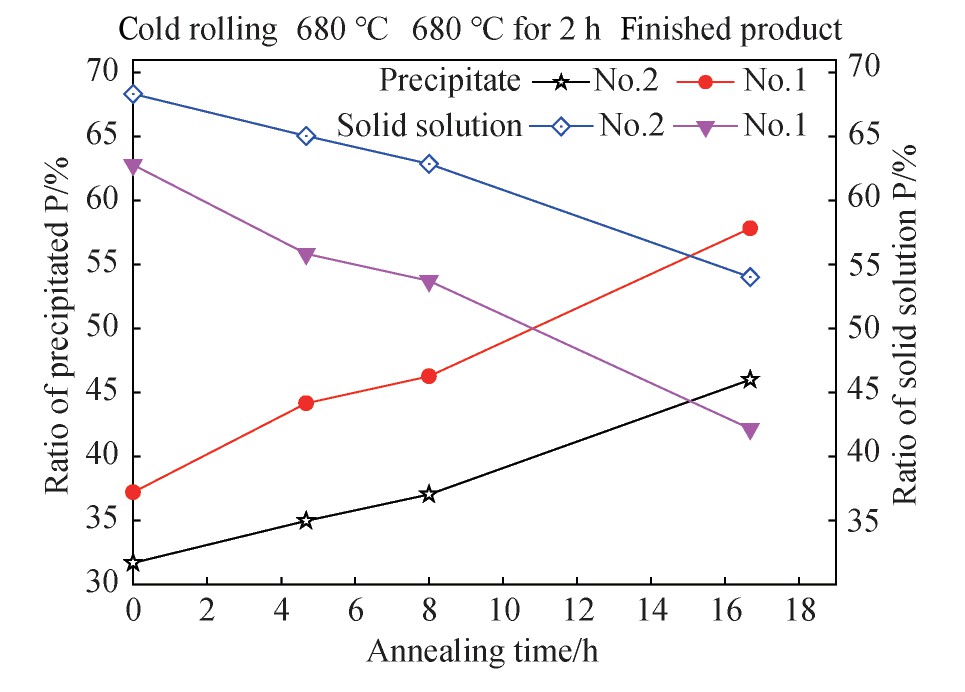

图3为退火过程不同状态下析出P或固溶P占成分中P的比值变化情况。图3横坐标时间节点分别取冷轧、680℃,680℃保温2 h,680℃保温2 h随炉冷所得成品4个状态所对应的时间。图3可清晰看出,随退火时间延长两种试样中固溶P占成分中P的比值逐渐降低,且试样2中固溶P所占比例始终大于试样1。相反析出P元素所占比值逐步递增,且试样2中析出P所占比例始终小于试样1。表5中可看出680℃保温2 h随炉冷所得成品中,试样1中析出P与固溶P占成分中P的比例分别为57.84%和42.16%,试样2中析出P与固溶P占成分中P的比例分别为45.99%和54.01%。说明高强IF钢中固溶P元素约不超过54%,析出P元素约超过46%。由铸坯到680℃保温2 h随炉冷所得成品状态下,试样1和试样2中析出P占成分中P的比值增量分别为49.47%和38.11%,表明稀土镧可使高强IF钢中P元素固溶量提高约12%,增加了P元素在高强IF钢中的固溶强化效果。

表5 退火过程中P元素析出与固溶P占成分中磷的比例 下载原图

Table 5 Proportions of P precipitation and solid solution during annealing

图3 析出P与固溶P所占比例随退火时间的变化

Fig.3 Variation of proportion of precipitated P and solid solu-tion P with annealing time

2.3 稀土镧对Fe(Nb+Ti)P相析出规律的影响

2.3.1 Fe(Nb+Ti)P相的形貌、数量与尺寸

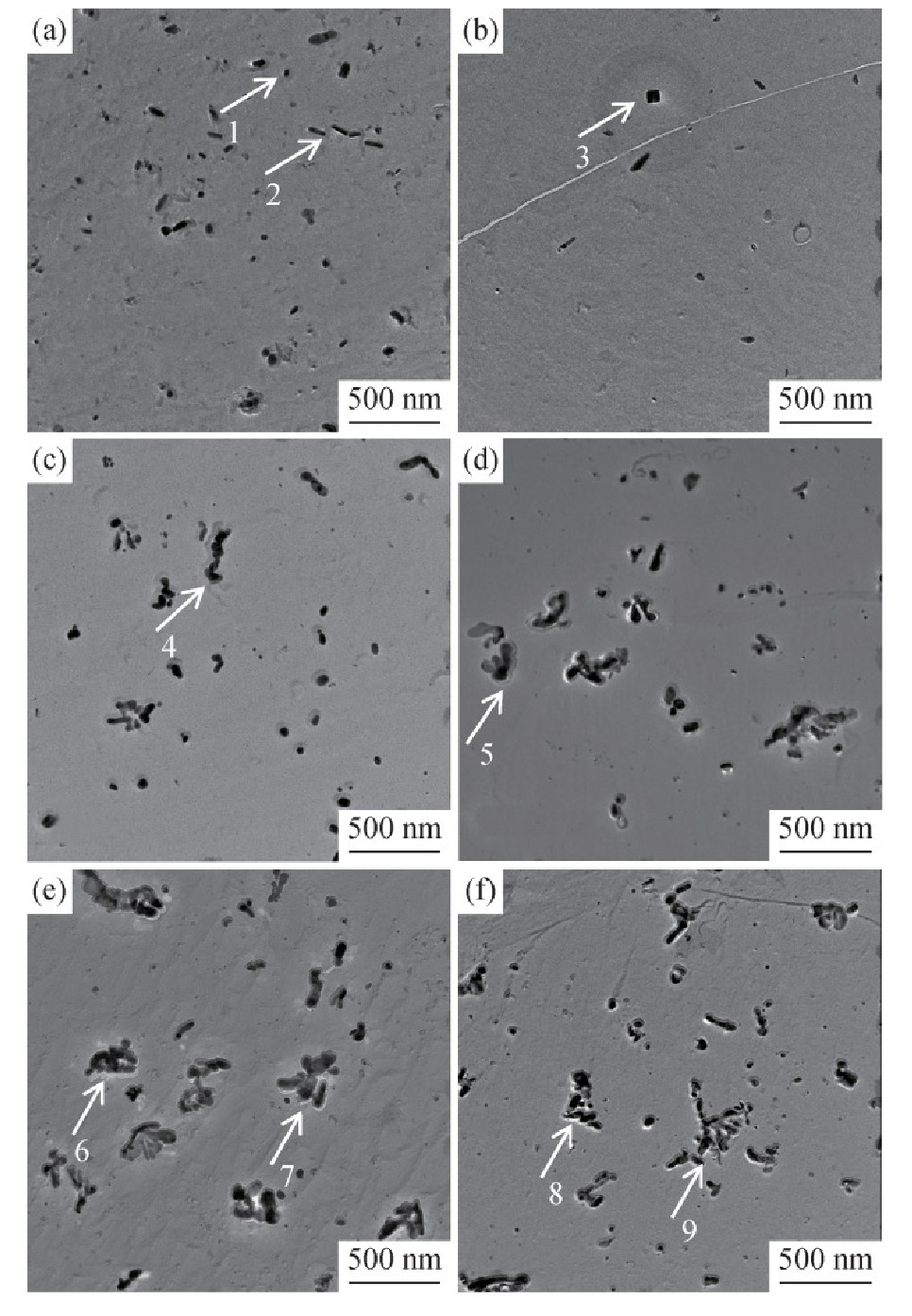

图4 退火过程中不同状态TEM照片

Fig.4 TEM images of steels with different states during an-nealing

(a)Sample 1,cold rolling;(b)Sample 2,cold rolling;(c)Sample 1,680℃for 2 h;(d)Sample 2,680℃for 2 h;(e)Sample 1,680℃for 2 h,furnace cooling;(f)Sample 2,680℃for 2 h,furnace cooling

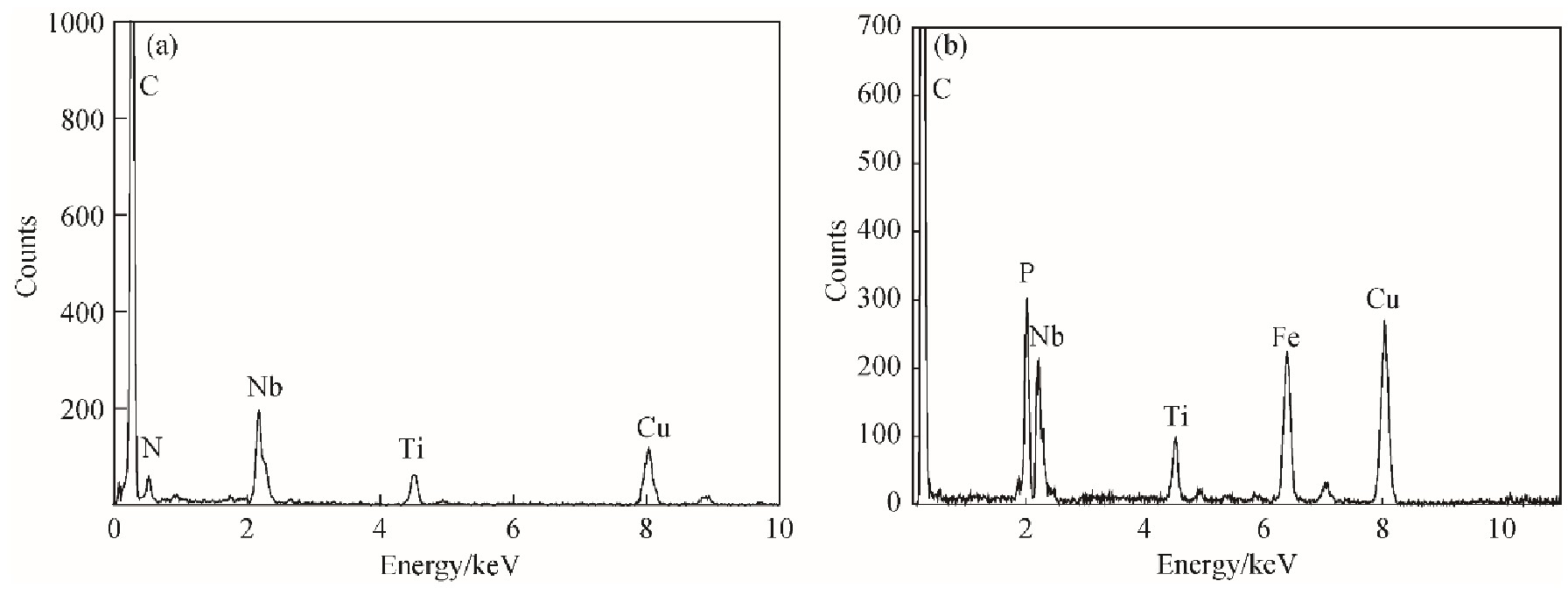

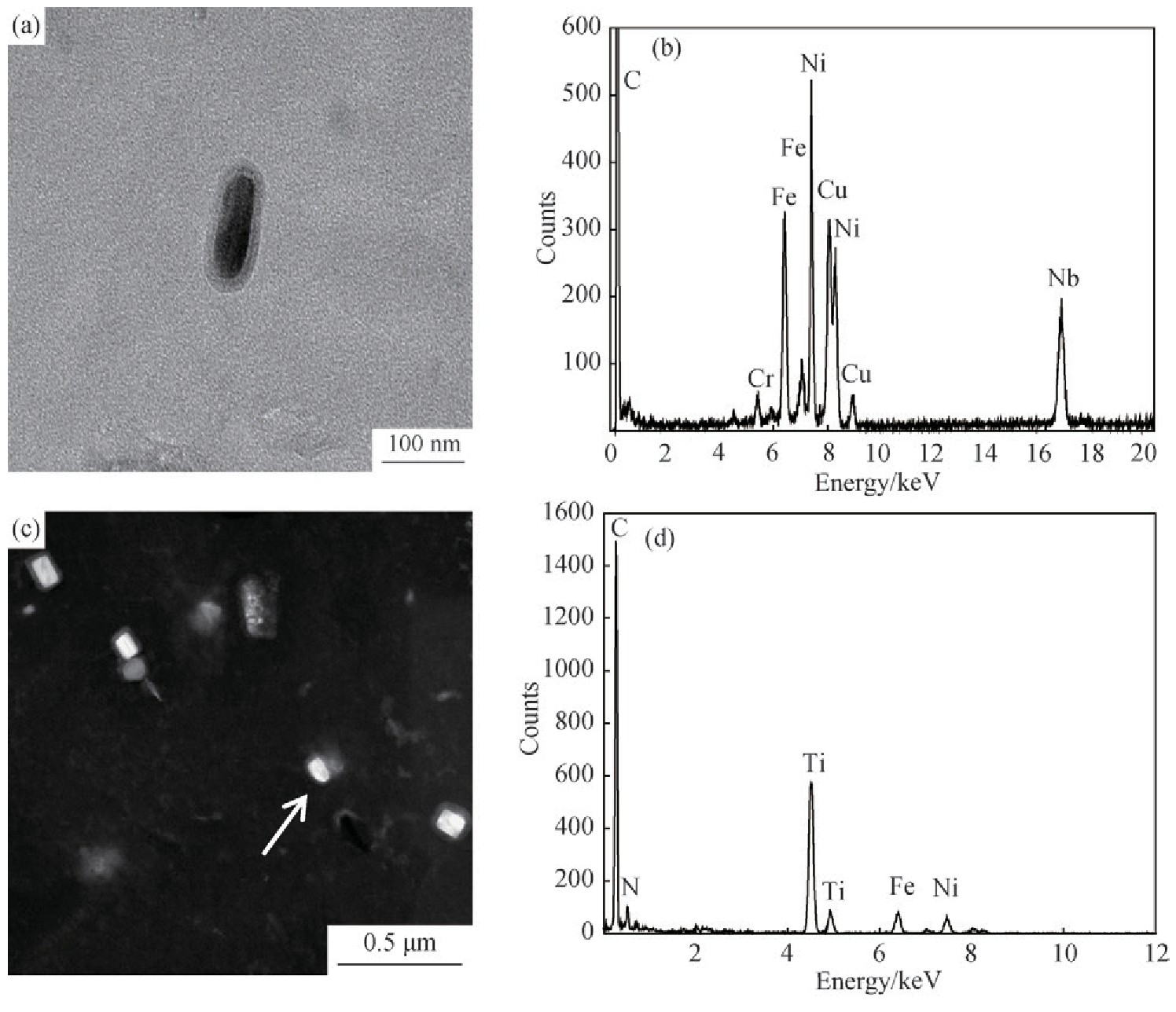

取两种钢的冷轧、680℃保温2 h后水冷、680℃保温2 h随炉冷所得成品3种状态,经透射电镜(TEM)观察结果如图4。对两种钢不同状态下的析出物进行足够多次数能谱分析,可知除了方形Nb和Ti的C,N化物(如图4(b)中3处)外全是复合相Fe(Nb+Ti)P,能谱如图5所示。整体观察可得,Fe(Nb+Ti)P形状有点状、棒状、串状、树枝状(如图4(a,c,d)中1,2,4,5处箭头所指)。在冷轧和退火初期其形状多为尺寸较小的点状和棒状,随退火温度升高或退火时间延长Fe(Nb+Ti)P形状变得复杂,出现尺寸较大的棒状、串状、树枝状等。无论试样1或2随着退火过程进行Fe(Nb+Ti)P的数量增多且尺寸逐渐增大,且其分布形式由冷轧态中的弥散分布逐渐聚集,如图4(e,f)中6~9处箭头所指。

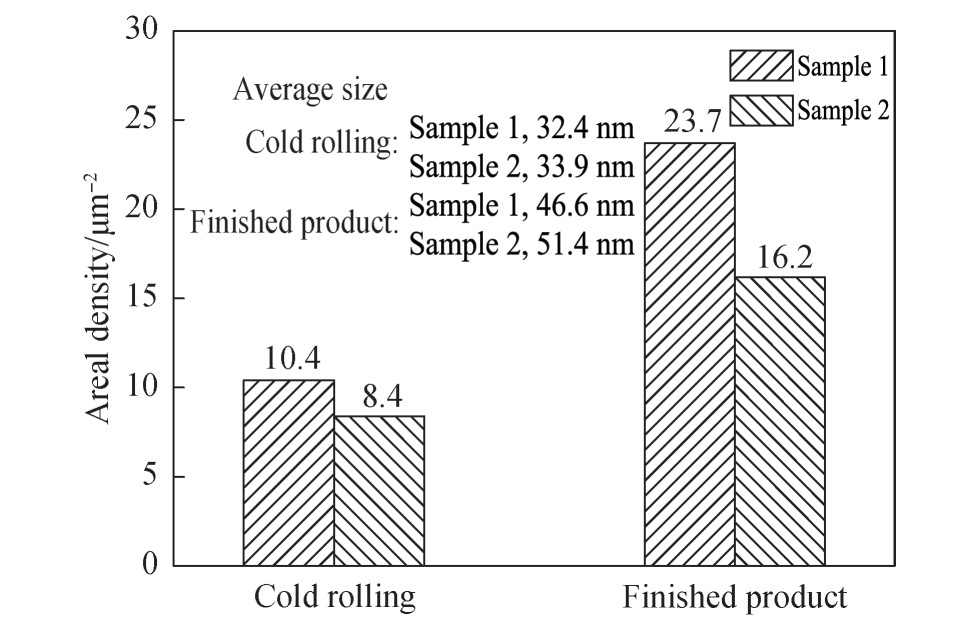

取两种钢冷轧及680℃保温2 h随炉冷所得成品钢的多张TEM照片进行Fe(Nb+Ti)P数量和尺寸统计,得该析出相面密度分布与平均尺寸如图6所示。图6中冷轧及成品两种状态下试样1中Fe(Nb+Ti)P相面密度均大于试样2,表明试样1中该析出相数量小于试样2。图6同时可以看出两种状态下试样2中该析出物尺寸大于试样1,细小弥散的析出相较粗大聚集的析出相对晶界的钉扎作用大,该析出相数量越多对成品有利织构的损害越大。则说明稀土镧可减少Fe(Nb+Ti)P的析出,并对提高440 MPa高强IF钢的综合力学性能有利。

图5 退火过程中析出物能谱(EDS)图

Fig.5 EDS results of precipitated phase in annealing process

(a)Chemical compounds of Nb,Ti and C,N;(b)EDS results of Fe(Nb+Ti)P

图6 冷轧及成品状态下Fe(Nb+Ti)P面密度分布与尺寸的变化

Fig.6 Distribution and size of Fe(Nb+Ti)P surface density in cold rolled and finished products

据图4中两种钢不同状态析出Fe(Nb+Ti)P情况与图6中不同状态下Fe(Nb+Ti)P面密度分布与尺寸的统计结果,再结合上述两种钢中析出P占成分中P的比值变化情况可得,稀土镧对Fe Nb(Ti)P相的形貌无影响,但退火过程中稀土镧对Fe Nb(Ti)P相的析出存在明显阻碍作用,且易获得尺寸较大的该析出相。

2.3.2 Fe(Nb+Ti)P相析出方式

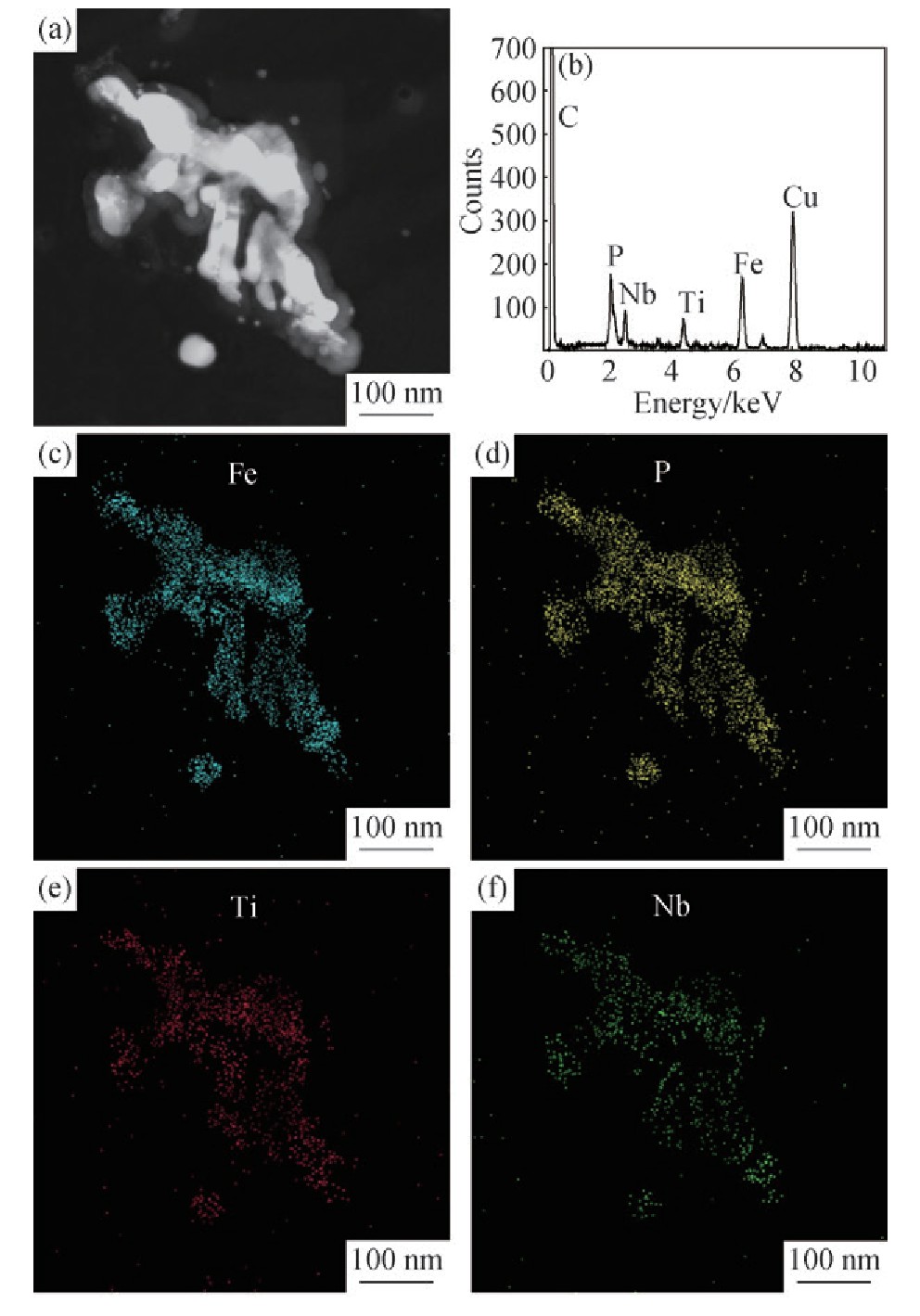

使用TEM对试样1中Fe(Nb+Ti)P聚集团进行面扫元素确认及能谱分析,如图7所示。结果表明聚集团中较大尺寸的析出物以及依附在其周围的小尺寸析出相中均只含有Fe,Nb,Ti,P这4种元素,如图7(c~f)。再结合图7(b)中能谱分析,表明该聚集团中每一个较大的Fe(Nb+Ti)P相周围依附着较小析出相均为Fe(Nb+Ti)P。由此可认为在退火过程中,随着P元素不断析出,新的细小Fe(Nb+Ti)P颗粒在之前形成的较大Fe(Nb+Ti)P颗粒上形核并长大,最终形成团聚或串状形态。则刚好解释退火初期析出相Fe Nb(Ti)P尺寸较小形状多为点状和棒状,等到退火时间延长其尺寸变的粗大且形状变为串状或者树枝状这一现象。同样对试样2中Fe(Nb+Ti)P聚集团进行面扫及能谱分析,结果与试样1完全相同。并结合图3可看出,两种试样中Fe(Nb+Ti)P相的析出方式相同,即稀土镧对Fe Nb(Ti)P相的析出方式无影响。

2.4 稀土镧对Fe(Nb+Ti)P相形成机制的影响

Fe Ti P形成机制存在两种观点,第一种观点认为溶解的Ti进入Fe2P相中形成Fe Ti P,这种观点仅从能量最小的角度计算得到,缺少试验证实

图7 团聚态Fe(Nb+Ti)P的EDS及元素分析

Fig.7 EDS and elemental analysis of aggregated Fe(Nb+Ti)P(a)TEM image;(b)EDS result;(c)Fe;(d)P;(e)Ti;(f)Nb

随退火过程的进行两种钢中Fe(Nb+Ti)P析出相数量增多,尺寸增加,形貌变得复杂且逐渐呈现团聚态。综上分析可得,这主要和其形成过程有关,P元素扩散进入优先形成的Fe Ti和Fe Nb相混合富集体形成Fe(Nb+Ti)P复合相。随着退火温度和时间的增加,P元素扩散速率增大,P元素析出量逐渐增多,因此Fe(Nb+Ti)P析出数量增多且尺寸变大。随着退火过程的进行早期形成的Fe Nb(Ti)P相具有较大的尺寸,在其身上会继续形核并长出新的Fe Nb(Ti)P相,因此最终会出现复杂的形貌和团聚态的分布,稀土镧的加入并没有影响该相的形成与析出规律。

高强IF钢铸坯凝固、热轧卷曲、退火过程中稀土镧均抑制P元素的析出,并阻碍Fe(Nb+Ti)P相析出。这是因为稀土镧对磷、钛和铌元素在钢中活度相互作用系数为负值

3 结论

1.稀土镧使得440 MPa高强IF钢组织细化且抗拉强度提高。铸坯凝固、热轧卷取及罩式退火过程中稀土镧均抑制P元素的析出,退火过程稀土镧对P元素的析出抑制程度最大。稀土镧使成品高强IF钢中P元素的固溶量提高约12%,稀土镧可明显提高P元素对高强IF钢的固溶强化效果。

2.Nb+Ti+P高强IF钢中析出的含P相为Fe(Nb+Ti)P复合相,稀土镧可有效减少高强IF钢热轧卷曲及罩式退火过程Fe(Nb+Ti)P相的析出量。稀土镧对Fe(Nb+Ti)P相的形貌及析出规律无影响,但使该相尺寸略有增大,即退火前期或初期Fe(Nb+Ti)P析出量较少,尺寸小且形状多为点状和棒状,分布较为弥散,随退火时间延长其析出数量增多,尺寸增大且形状增加串状、树枝状等,分布逐渐团聚态。

图8 不同状态所得析出相的TEM照片与能谱(EDS)图

Fig.8 TEM images and EDS results of precipitated phases obtained in different states

(a),(b)TEM image and EDS result of FeNb phase measured at 630°C;(c),(b)TEM image and EDS result of FeTi phase mea-sured by hot rolling coiling state

3.稀土镧对Fe(Nb+Ti)P相形成机制无影响,即高强IF钢中固溶的P元素不断析出,扩散进入优先形成Fe Ti与Fe Nb的混合富集相中形成Fe Nb(Ti)P相。随着退火过程进行P元素不断析出,新的Fe(Nb+Ti)P相会依附在尺寸较大的旧Fe(Nb+Ti)P相身上形核、长大,最终形成团聚态或者串状分布。

参考文献