J. Cent. South Univ. (2017) 24: 1762-1766

DOI: https://doi.org/10.1007/s11771-017-3584-8

High-temperature acoustic properties of porous titanium fiber metal materials

LIU Shi-feng(刘世锋)1, 2, LI An(李安)1, ZHANG Zhao-hui(张朝晖)1, LI Dong-feng(李东峰)1

1. School of Metallurgical Engineering, Xi’an University of Architecture and Technology, Xi’an 710055, China;

2. State Key Laboratory for Powder Metallurgy (Central South University), Changsha 410083, China

Central South University Press and Springer-Verlag GmbH Germany 2017

Central South University Press and Springer-Verlag GmbH Germany 2017

Abstract:

The high-temperature acoustic absorption performance of porous titanium fiber material was investigated in terms of sample thickness, porosity, temperature, air-cavity thickness and double-layer structure arrangement. The effects on absorption coefficient were systematically assessed. The results show that the sound absorption performance is improved by increasing the sample porosity and/or thickness, and/or increasing the air-cavity thickness. Meanwhile, increasing the temperature gives better acoustic absorption performance in the low frequency range but also lowers the performance in the high frequency range, while double-layer structure enables better acoustic absorption performance.

Key words:

porous titanium fiber material; acoustic absorption; heat transfer; pool boiling;

1 Introduction

Nowadays, noise is one of the three major environmental pollution problems, which not only causes great disturbance in our daily life and impairs our auditory as well as nervous systems, but also accelerates aging of architectural and mechanical structures and impacts sensitivity, accuracy and service duration of instruments and equipment [1-4]. Noise absorption and reduction have attracted increasingly attention and become an urgent issue in environment management. The main solution is to use porous material with homogeneously distributed internal fine through-open pores to absorb the noise [5-8]. Porous metal materials possess many new excellent features, such as large specific surface area, good permeability, high- temperature resistantance, corrosion resistant, recyclable, process able and machinable, as well as retain the metal characteristics, being solderable, electro conductive, and ductile, which makes them an ideal choice for noise absorption [9-13]. However, there are few theoretical and experimental studies on the noise absorption performance of porous metallic fibre materials under high temperature [14-18]. Therefore, porous titanium fiber material was prepared in this work, and the effects of sample thickness, porosity, temperature, air-cavity (behind the porous sample) thickness and double-layer structure arrangement on the sound absorption performance at high temperature were assessed.

2 Experimental

The titanium fiber porous samples were sintered at 1250 °C and then cut into d50 mm plates for acoustic absorption study, as shown in Fig. 1. The test was conducted under atmospheric pressure using a self-made high temperature acoustic test system. The acoustic absorption coefficient of titanium fiber porous material was measured by the stationary wave method as per GB J85-1985, named as standard measurement method of acoustic absorption coefficient and acoustic impedance by standing wave tube. A 4206 double-microphone impedance measurement tube (B & K Company, Danish) was used. The effects of sample porosity, thickness, air-cavity (behind the sample) thickness and double-layer structure arrangement on the acoustic absorption properties were studied. Sample conditions for high- temperature acoustic absorption performance assessment are listed in Table 1.

3 Results and discussion

3.1 Effect of porosity on acoustic absorption performance

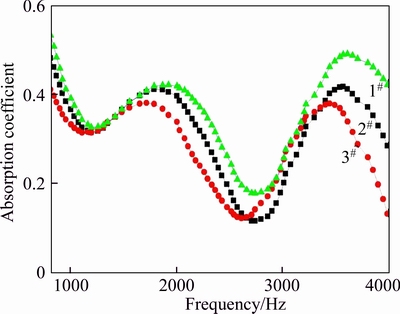

Figure 2 shows the acoustic absorption curves of samples 1# (porosity, 40%), 2# (porosity, 45%) and 3# (porosity, 50%) at 300 °C. Generally, the acoustic absorption performance increases with increasing the sample porosity, and the acoustic absorption peaks were shifted to higher frequency as well. The absorption coefficient is in the range of 0.3-0.45 at a low frequency region and gradually decreases to the lowest valley of 0.4-0.8 at the intermediate frequency region, then the absorption coefficient increases again at the high frequency region, approaching the highest absorption coefficient at 0.54 with 50% sample porosity. The first resonance acoustic absorption peak (1700-2000 Hz) and the second peak (3300-3700 Hz) shift toward higher frequency when increasing the porosity. This can be attributed to the fact that increasing the porosity will make the sample surface acoustic resistance closer to the air resistance, resulting in less energy reflected back into the air. Acoustic wave raises the vibration frequency of air particles within internal pores, which causes more viscous loss between air and pore wall, so the acoustic absorption performance is enhanced at high frequency. In addition, the higher the porosity is, the more tortuous the internal channels are. Therefore, more energy is consumed inside the sample, when other parameters keep identical. However, further increasing porosity does not make absorption performance better, because the vibration speed caused by sound wave will be lowered and the number of second or third reflection is reduced. The energy consumption is lowered by the decreased friction and viscous drag between air and pore wall, so the acoustic absorption performance becomes worse. Transmission might occur at this occasion. On the other hand, if the porosity is too small, the material is too dense to let the sound wave transfer inside, which will also makes the acoustic absorption performance poorer. Therefore, there exists an optimal porosity value. Relevant research will be conducted in our future work.

Fig. 1 Sample of porous titanium fiber material (d50 mm)

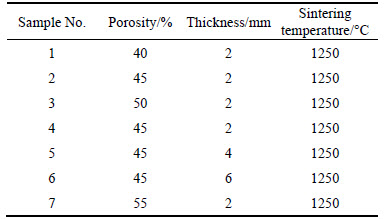

Table 1 Conditions for high-temperature acoustic absorption test

Fig. 2 Effect of porosity on acoustic absorption performance

3.2 Effect of sample thickness on acoustic absorption performance

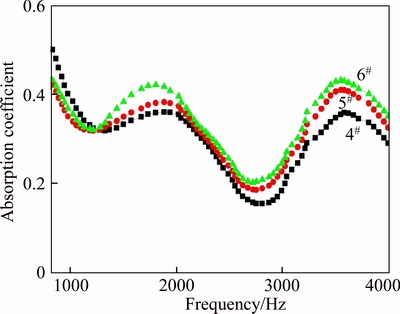

Figure 3 shows the relative-high-temperature (300 °C) acoustic absorption curves of the samples with an identical porosity (i.e. 45%) but different thicknesses, namely 2 mm (4#), 4 mm (5#) and 6 mm (6#), respectively. The average absorption coefficient of titanium fiber porous material increases with increasing the thickness. The first absorption peak moves toward lower frequency in the range of 1000-2000 Hz. This move is due to the fact that the first resonant frequency is inversely proportional to the material thickness, which leads to the thicker sample’s first absorption peak appears at the lower frequency region. In the higher frequency range of 3000-4000 Hz, the second peak absorption coefficient value increases and the acoustic absorption band is broadened when the sample becomes thicker. In the thicker samples, longer time is needed for acoustic wave to pass through, which increases the blocked acoustic wave number by the tortuous channel and then more energy is lost, which makes the sound absorption performance better. However, the influence of sample thickness on the acoustic absorption performance depends on the temperature. Acoustic wave travel speed becomes faster at higher temperatures. In this case, dwelling time of acoustic wave within the sample is shortened, thus the energy loss is lowered and the absorption performance is deteriorated.

Fig. 3 Effect of sample thickness on acoustic absorption performance

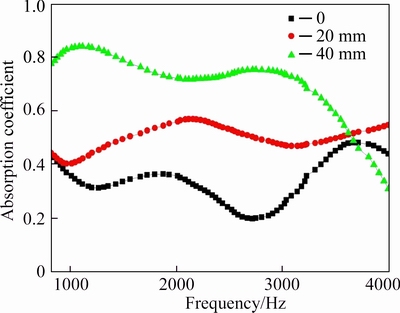

3.3 Effect of air-cavity thickness on acoustic absorption performance

Figure 4 shows the sound absorption coefficient curves of sample 5# with different air-cavity thickness, 0, 20 and 40 mm, respectively. Increasing the cavity thickness significantly increases the sound absorption performance at the low frequency range. The absorption coefficient is 0.85 when the cavity thickness is 40 mm at 1200 Hz. In the high frequency region (over 3500 Hz), however, cavity thickness exhibits little effect on the sound absorption performance, even worsens the absorption performance at certain occasions. The sound absorption coefficient is only 0.3 when the cavity thickness is 40 mm at the frequency of 4000 Hz. When the cavity thickness is odd times of 1/4 wavelength of the incident wave, the acoustic absorption performance is the best, while the acoustic absorption performance is the poorest when the cavity thickness is integral multiple of1/2 wavelength. Acoustic absorption performance at the intermediate and low frequency region is improved by keeping an air cavity behind of porous samples. The absorption coefficient is close to that when the cavity is filled with porous sample. The amount of the porous material used in industrial applications would be reduced in this way.

Fig. 4 Effect of air-cavity thickness on acoustic absorption performance

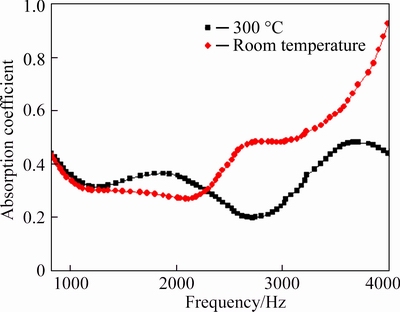

3.4 Effect of temperature on acoustic absorption performance

Figure 5 shows the acoustic absorption performance curves of sample 5# at room temperature and 300 °C, respectively. Apparently, the average sound absorption coefficient at high temperatures is smaller than that at room temperature, although both the sound absorption curves display an upward trend versus frequency. At room temperature, the first absorption peak does not appear within the frequency range of 0-2000 Hz, but shifts to around 2600 Hz. The highest acoustic absorption coefficient obtained is 0.95 at about 3900 Hz in the current frequency range. When temperature is raised to 300 °C, the acoustic absorption performance in the frequency range of 1500-2400 Hz is better than that at room temperature. The first absorption peak shifts to lower frequency and laid at 1750 Hz, where the acoustic absorption coefficient is 0.38. According to equations, the air viscosity coefficient is proportional to the temperature. The air viscosity coefficient increases when increasing the temperature, which then increases the flow resistance. In this occasion, the acoustic resistance increases while the sound absorption coefficient decreases. In addition, acoustic wave movement through porous material becomes unstable at high temperatures, which results in larger fluctuations of the energy loss. Furthermore, high temperature increases wave speed, which increases the wavelength at high frequency. The acoustic wave becomes more reflective, so the absorption coefficient will be decreased.

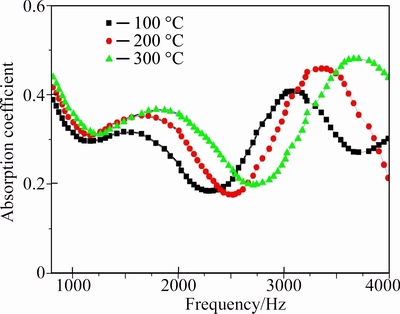

Figure 6 shows the acoustic absorption curves of sample 5# at 100, 200 and 300 °C, respectively. The sound absorption coefficient increases with increasing temperature in the frequency range of 1500-2500 Hz, in which the first absorption coefficient peak can be observed and shifts to higher frequencies. Acoustic absorption performance at the low frequency region is enhanced by increasing temperature, which is consistent with the result in Fig. 5. The sound absorption coefficient becomes worse with increasing temperature in the frequency range of 2500-3200 Hz. The main reason may contribute to the fact that increasing temperature will increase air viscosity coefficient and the flow resistance is increased, thus the sound absorption performance would be reduced. When the frequency is higher than 3200 Hz, the absorption curve will change considerably. This can be attributed to the following three factors: 1) at high temperatures, the local stiffness and strength of titanium fiber become weak, weakening the supporting capability of original rigid skeleton; 2) as the sample is heated while the sound source is kept cool, a temperature gradient exists in the impedance tube and this would deform the acoustic absorption curve; 3) at high temperatures, as a result of the thermal boundary layer existing inside the impedance tube, the cross-sectional temperature isothermal surface would show a parabola shape. The wave surface within the impedance tube will be distorted, resulting in further deformation of the sound absorption curve.

Fig. 5 Acoustic absorption performance at room temperature and 300 °C

Fig. 6 Effect of temperature on acoustic absorption performance

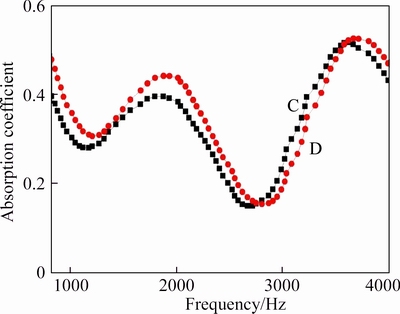

3.5 Acoustic absorption performance of double layer composite structure

Figure 7 shows the high-temperature sound absorption curves of the double-layer structures C and D (shown in Table 2), the second layer of which both the porosity and thickness are the same, being 45% and 2 mm, respectively. The first layer porosity of structure C and structure D is 40% and 50%, respectively. The absorption performances of these two structures are comparable. In the frequency region below 2750 Hz, the absorption performance of structure C is better than that of structure D; over 2750 Hz, structure D becomes better. On average, structure D holds higher sound absorption coefficient than structure C. Therefore, a double-layer structure with a high porosity in the first layer has better acoustic absorption performance when the second layer porosity is the same.

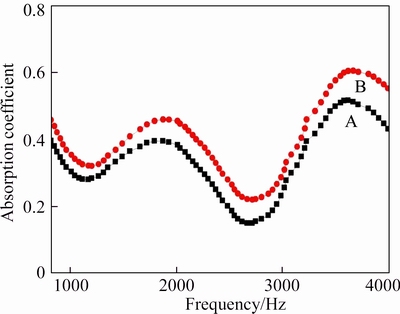

Figure 8 shows the acoustic absorption coefficient curves of the double-layer structures of A and B (shown in Table 2) where both the second layers are with different porosity, i.e., 40% (structure A) and 45% (structure B), respectively. These two structures display a similar trend versus frequency, and structure B with a second layer of higher porosity gives higher absorption coefficient. The first absorption peak appears around1800 Hz with the absorption coefficient higher than 0.4. The second absorption peak can be observed at about 3700 Hz with absorption coefficient over 0.52. The highest absorption coefficient structure B obtained is 0.62. Overall, a double-layer structure gives better absorption performance in the whole frequency range. Increasing the porosity of the second layer will deliver higher absorption coefficient, especially in the high frequency range.

Fig. 7 Acoustic absorption frequency curves of double-layer structures C and D

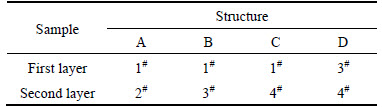

Table 2 Arrangements of double-layer structure

Fig. 8 Acoustic absorption frequency curves of double-layer structures A and B

4 Conclusions

1) At high temperature of 300 °C, the acoustic absorption coefficient increases with increasing the porosity of porous titanium fiber material, and the sound absorption peak is shifted to higher frequencies.

2) Increasing the sample thickness can improve the acoustic absorption performance and broadens the absorption frequency band.

3) Increasing the air-cavity thickness enhances the acoustic absorption coefficient particularly in the frequency range of 1000-3000 Hz, where the absorption coefficient reaches its maximum value over 0.85.

4) The acoustic absorption coefficient curve displays an upgrade trend versus frequency at temperatures investigated. Increasing the temperature improves the acoustic absorption coefficient in the lower frequency range and shifts the absorption peak to the lower frequency region, while the acoustic absorption performance is deteriorated between 2500 and 3200 Hz.

5) Double-layer structure gives better acoustic absorption performance. The highest absorption coefficient achieved by structure B is 0.62.

References

[1] LI Yao-zhong, LI Dong-sheng. Noise control techniques [M]. Beijing, China: Chemical Industry Press, 2008. (in Chinese)

[2] SUN Peng, GUO Zhan-cheng. Sintering preparation of porous sound-absorbing materials from steel slag [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(7): 2230-2240.

[3] WANG Jian-zhong, XI Zheng-ping, TANG Hui-ping, HUANG Wei-dong, ZHU Ji-lei, AO Qing-bo. Research status of sound absorption property of porous materials by metal fiber [J]. Rare Metal Materials and Engineering, 2012, 41(2): 405-408. (in Chinese)

[4] DUAN Cui-yun, CUI Guang, LIU Pei-sheng. Present research and prospect of porous absorption materials [J]. Metallic Functional Materials, 2011, 18(1): 60-65. (in Chinese)

[5] LIU P S, QING H B, HOU H L. Primary investigation on sound absorption performance of highly porous titanium foams [J]. Materials and Design, 2015, 85: 275-281.

[6] SUN Fu-gui, CHEN Hua-ling, WUJiu-hui, FENG Kai. Sound absorbing characteristics of fibrous metal materials at high temperatures [J]. Applied Acoustics, 2010, 71(3): 221-235.

[7] ZHANG Ling. Research status and prospect on sound absorption materials and structure [J]. Popular Science and Technology, 2012, 14(11): 55-56. (in Chinese)

[8] RU Jin-ming, KONG Bo, LIU Yao-guang, WANG Xiao-lin, FAN Tong-xiang, ZHANG Di. Microstructure and sound absorption of porous copper prepared by resin curing and foaming method [J]. Materials Letters, 2015, 139: 318-321.

[9] ZHANG Bo, CHEN Tian-ning. Calculation of sound absorption characteristics of porous sintered fiber metal [J]. Applied Acoustics, 2009, 70(2): 337-346.

[10] QIN Jun-hua, CHEN Qing, YANG Chun-yan, HUANG Yong. Research process on property and application of metal porous materials [J]. Journal of Alloys and Compounds, 2016, 654: 39-44.

[11] LU Tian-jian, HE De-ping, CHEN Chang-qing, ZHAO Chang-ying, FANG Dai-ning, WANG Xiao-lin. The multi-functionality of ultra-light porous metals and their applications [J]. Advances in Mechanics, 2006, 36(4): 517-534. (in Chinese)

[12] HE Dong-lin, GUO Zhan-cheng, LIAO Hong-qiang, YUE Chang-sheng, Sainbaatar, YU Guang-wei. Research progress and development trend of porous absorption materials [J]. Materials Review, 2012, 26(19): 303-306. (in Chinese)

[13] SUN Fu-gui, CHEN Hua-ling, WU Jiu-hui. High-temperature acoustic properties of porous metal materials measuring and research [J]. Journal of Vibration Engineering, 2010, 23(5): 502-507. (in Chinese)

[14] ZHOU Han, WU Jiu-hui, HU Zhi-ping. Sound absorbing property of porous metal material at high temperature and high sound pressure level [J]. Chinese Journal of Theoretical Applied Mechanics, 2013, 45(2): 229-234. (in Chinese)

[15] SUN Fu-gui, CHEN Hua-ling, WU Jiu-hui. Coupled acoustic- structure research of the fibrous metal materials at high temperatures [J]. Chinese Journal of Applied Mechanics, 2010, 27(2): 326-332. (in Chinese)

[16] LIU Shi-feng, XI Zheng-ping, TANG Hui-ping, YANG Xin, ZHANG Zhao-hui. Compressive behavior of porous titanium fibers materials [J]. Journal of Iron and Steel Research, International, 2014, 21(8): 793-796.

[17] LIU Shi-feng, XI Zheng-ping, TANG Hui-ping, YANG Xin, ZHANG Zhao-hui. Sintering behavior of titanium fiber porous materials [J]. Journal of Iron and Steel Research, International, 2014, 21(9): 849-854.

[18] PAN Zhong-lin, ZHAI Guo-qing. Noise control techniques [M]. Beijing, China: Chemical Industry Press, 2006. (in Chinese)

(Edited by FANG Jing-hua)

Cite this article as:

LIU Shi-feng, LI An, ZHANG Zhao-hui, LI Dong-Feng. High-temperature acoustic properties of porous titanium fiber metal materials [J]. Journal of Central South University, 2017, 24(8): 1762-1766.

DOI:https://dx.doi.org/https://doi.org/10.1007/s11771-017-3584-8Foundation item: Projects(51671152, 51304153) supported by the National Natural Science Foundation of China

Received date: 2016-09-22; Accepted date: 2017-03-17

Corresponding author: LIU Shi-feng, Associate Professor, PhD; Tel: +86-29-82202933; E-mail: liushifeng66@126.com

Abstract: The high-temperature acoustic absorption performance of porous titanium fiber material was investigated in terms of sample thickness, porosity, temperature, air-cavity thickness and double-layer structure arrangement. The effects on absorption coefficient were systematically assessed. The results show that the sound absorption performance is improved by increasing the sample porosity and/or thickness, and/or increasing the air-cavity thickness. Meanwhile, increasing the temperature gives better acoustic absorption performance in the low frequency range but also lowers the performance in the high frequency range, while double-layer structure enables better acoustic absorption performance.