J. Cent. South Univ. (2019) 26: 3200-3212

DOI: https://doi.org/10.1007/s11771-019-4246-9

Experimental investigation on boiling heat transfer and pressure drop of R245fa in a horizontal micro-fin tube

WANG Zhi-qi(王志奇)1, HE Ni(贺妮)1, XIA Xiao-xia(夏小霞)1, 2, LIU Li-wen(刘力文)1

1. School of Mechanical Engineering, Xiangtan University, Xiangtan 411005, China;

2. School of Energy Science and Engineering, Central South University, Changsha 410083, China

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2019

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2019

Abstract:

An experimental investigation on the boiling heat transfer and frictional pressure drop of R245fa in a 7 mm horizontal micro-fin tube was performed. The results show that in terms of flow boiling heat transfer characteristics, boiling heat transfer coefficient (HTC) increases with mass velocity of R245fa, while it decreases with the increment of saturation temperature and heat flux. With the increase of vapor quality, HTC has a maximum and the corresponding vapor quality is about 0.4, which varies with the operating conditions. When vapor quality is larger than the transition point, HTC can be promoted more remarkably at higher mass velocity or lower saturation temperature. Among the four selected correlations, KANDLIKAR correlation matches with 91.6% of experimental data within the deviation range of ±25%, and the absolute mean deviation is 11.2%. Also, in terms of frictional pressure drop characteristics of flow boiling, the results of this study show that frictional pressure drop increases with mass velocity and heat flux of R245fa, while it decreases with the increment of saturation temperature. MULLER-STEINHAGEN-HECK correlation shows the best prediction accuracy for frictional pressure drop among the four widely used correlations. It covers 84.1% of experimental data within the deviation range of ±20%, and the absolute mean deviation is 10.1%.

Key words:

Cite this article as:

WANG Zhi-qi, HE Ni, XIA Xiao-xia, LIU Li-wen. Experimental investigation on boiling heat transfer and pressure drop of R245fa in a horizontal micro-fin tube [J]. Journal of Central South University, 2019, 26(11): 3200-3212.

DOI:https://dx.doi.org/https://doi.org/10.1007/s11771-019-4246-91 Introduction

It is a major topic to improve energy utilization of energy conversion systems due to environmental pollution and energy shortage. As an effective solution, organic Rankine cycle (ORC), which converts waste heat into electricity, has attracted growing interest [1-4]. For ORC systems, R245fa is a quite suitable working fluid due to its excellent thermophysical and environmental properties [5, 6]. In addition, the evaporator is a key component to ORC system performance since it causes the highest energy loss [7]. Therefore, it is important to investigate heat transfer and pressure drop characteristics of R245fa to improve the design of these units.

TIBIRICA et al [8] investigated boiling heat transfer of R245fa in a 2.3 mm stainless steel tube with mass velocity of 100-400 kg/(m2·s), heat flux of 10-60 kW/m2 and saturation temperature of 30 °C. They found that HTC is closely linked with heat flux, mass velocity and vapor quality. Besides, the test results agreed well with LIU-WINTERTON correlation [9]. CHARNAY et al [10] carried out a visualization research of flow boiling of R245fa in a 3.00 mm tube. The data were obtained at saturation temperature between 60 and 80 °C, while mass velocity varied from 100 to 1500 kg/(m2·s) and heat flux was 10 to 50 kW/m2. It demonstrated that GUNGOR-WINTERTON correlation [11] showed the best agreement with experimental data. PIKE-WILSON et al [12] conducted an experimental study of boiling heat transfer and pressure drop using R245fa in a 1.1 mm stainless steel, brass and copper tube. The mass velocity was varied from 100 to 400 kg/(m2·s), heat flux was varied from 10 to 60 kW/m2 and inlet pressures was 1.8 to 2.4 bar. They concluded that there was no clear link between the surface roughness and the changes in the HTC and pressure drop. REVELLIN et al [13] measured the two-phase frictional pressure drops in a 0.79 mm glass tube and reported that the best-agreement correlation was MULLER- STEINHAGEN-HECK [14]. SANDLER et al [15] presented a detailed review on the most recognized heat transfer models during small-scale flow boiling and an experimental database on R236fa and R245fa. The comparison of the predicted results with experimental datasets revealed that the model by SAITOH et al [16] is recommendable for general purpose because it is characterized by the lowest mean absolute percentage error (MAPE) and fairly low standard deviation, σSD. However, the above studies mainly focused on the characteristics of boiling heat transfer in a smooth tube.

Compared with smooth tubes, micro-fin tubes provide higher HTCs realized by increase of heat transfer area and turbulence generated by the fins. Many studies have experimentally investigated flow boiling characteristics in micro-fin tubes in the past decades. LONGO et al [17] measured HTCs and pressure drops during R245fa flow boiling inside a mini micro-fin tube with an inner diameter at the fin top of 4.2 mm. Tests were run at a constant mean saturation temperature of 30 °C, by varying the vapor quality from 0.15 to 0.95, the mass velocity from 100 to 300 kg/(m2·s), at two imposed heat fluxes, 30 and 60 kW/m2. Moreover, DIANI et al correlation [18] demonstrated to be satisfactory consistent with the experimental results. LALLEM et al [19] measured boiling HTC of R22 and R407C in 12.7-mm horizontal micro-fin tubes. The mass velocity and heat flux were ranged from 100 to 300 kg/(m2·s) and 10 to 30 kW/m2, respectively. Results indicated that HTC was strongly influenced by the heat flux at the low vapor quality region. WU et al [20] presented the experimental results of HTC and pressure drop of CO2 in a zero helix angle micro-fin tube. The mass velocity was ranged from 100 to 600 kg/(m2·s), heat flux was from 1.67 to 8.33 kW/m2 and saturation temperature was from 1 to 15 °C. As increase of vapor quality, HTC increased first and then decreased at vapor quality around 0.2-0.4. On the other hand, pressure drops increased with mass velocity and heat flux, while decreased with the increment of saturation temperature. DIANI et al [18] investigated the flow boiling mechanisms of R1234ze(E) in a 2.4 mm micro-fin tube. The saturation temperature was 30 °C, while mass velocity and heat flux were ranged from 375 to 940 kg/(m2·s) and 10 to 50 kW/m2, respectively. The test data demonstrated that nucleate boiling and convective boiling were dominated at different conditions, which was similar to the conclusion of CUI et al [21]. Besides, the correlations proposed by DIANI et al [18] showed reasonable agreement with their HTC and frictional pressure drop data. JIANG et al [22] compared boiling characteristics of four refrigerants in a 9.52 mm micro-fin tube with mass velocity of 50-450 kg/(m2·s), heat flux of 5-20 kW/m2 and saturation temperature of 5 °C. The results indicated that the HTC and pressure drop were quite different from each other. HAN et al [23] discussed the influence of oil concentration on HTC of R1234 in a 7 mm micro-fin tube at mass velocity of 100-400 kg/(m2·s), heat flux of 4-12 kW/m2 and saturation temperatures of 5-15 °C. The results showed that lubricant oil was a major factor that affected the HTC and pressure drop. ZHANG et al [24] compared the HTC and pressure drop of R417A in different micro-fin tubes. They concluded that the fin root distance was an important factor for flow boiling heat transfer characteristics. PADOVAN et al [25] performed a study on flow boiling of R134a and R410A in a micro-fin tube with saturation temperature of 30-40 °C, mass velocity of 80-600 kg/(m2·s) and heat flux of 14-83.5 kW/m2. They demonstrated that nucleate boiling heat transfer was dominant and the model by CAVALLINI et al [26] had the highest accuracy for predicting HTC. AKHAVAN- BEHABADI et al [27] compared the HTC of R134a in a micro-fin tube with different inclination angles. They found that the highest HTC was obtained at the inclination angle of 90°, and HTC was strongly influenced by inclination angle at low mass flux and vapor quality. Based on the measured HTC of R22 and R124 with reduced pressure of 0.15, flow quality of 0.1-0.9, mass flux of 100-400 kg/(m2·s) and heat flux of 5-20 kW/m2 in micro-fin tubes, CHIOU et al [28] proposed a correlation with standard deviation of 25%. COLOMBO et al [29] investigated flow boiling characteristics of R134a in two micro-fin tubes with different fin numbers. The evaporation temperature was 5 °C and mass velocity was ranged from 100 to 340 kg/(m2·s). They observed that micro-fin tube effectively enhanced heat transfer at low mass velocities. TANG et al [30] proposed a new heat transfer model to predict the database containing 2221 data points covering nine refrigerants, and the involved operation conditions are as follows: mass velocity 47-835 kg/(m2·s), vapor quality 0.05-0.98, heat flux 3.9-85.2 kW/m2, and fin-root diameter 2.64-11.98 mm. The results showed that the new model can predict 82.1% of the data points within the ±30% error band and 95.0% within ±50% error band. While it was still difficult to access a suitable correlation for HTC and pressure drop in micro-fin tube taking into account different geometrical parameters.

Although a lot of studies on flow boiling heat transfer characteristic have been performed, there were little investigations on the boiling heat transfer characteristics of R245fa in micro-fin tube. In addition, there were no general correlations for the prediction of HTC and pressure drop of different refrigerants in micro-fin tubes. Therefore, this paper presents the experimental data of heat transfer characteristics of R245fa in a 7-mm horizontal micro-fin tube. In addition to collecting experimental data, another purpose of this work is to search for suitable correlations, which can provide accurate predictions of HTC and pressure drop for the design of evaporators in ORC systems.

2 Experimental apparatus and data reduction

2.1 Experimental apparatus

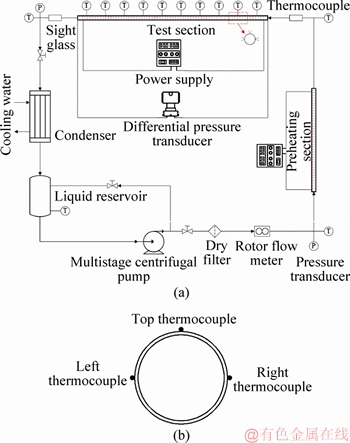

Figure 1 shows the schematic diagram of the experimental apparatus used for flow boiling heat transfer of R245fa, and it consists of a refrigerant circuit, a cooling water loop, an electric heating system and a data acquisition system.

Figure 1 Schematic diagram of experimental apparatus (a), location of thermocouples around perimeter of micro-fin tube (b)

In the refrigerant circuit, a multistage centrifugal pump drives R245fa stored in the liquid reservoir through the circulation. The refrigerant flow rate is measured by a rotor flow meter with a nominal flow range of 0-100 L/h. It is adjusted by the bypass pipe to the reservoir and the speed of multistage centrifugal pump controlled by a frequency controller. An electrical preheater is used to trigger two-phase flow and to achieve the desired condition at the inlet of the test section (micro-fin tube), where the input power is controlled by adjusting the voltage of a power supply. Then, additional heat transfer occurs between the two-phase mixture and the test section, which is also electrically heated by another power supply. Two sight glasses are installed at the inlet and outlet of the test section to observe the refrigerant flow patterns. Finally, the two-phase refrigerant is cooled by cooling water in a plate heat exchanger and flows to the liquid reservoir.

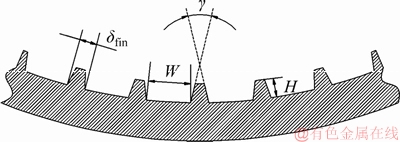

The test section is a micro-fin cooper tube with length of 1.5 m and outside diameter of 7.0 mm. Its cross-sectional structure and main geometrical parameters are shown in Figure 2 and Table 1, respectively.

Figure 2 Schematic diagram of micro-fin tube structure

Table 1 Geometry of micro-fin tube

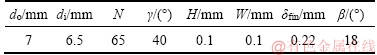

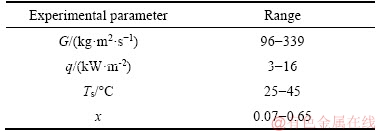

The preheating section and test section are heated by electric heating tape which is uniformly wrapped around the external surface of the tube. The distance between the preheating section outlet and the test section inlet is less than 15 cm. Additionally, the preheating section and test section were wrapped with glass wool and rubber foam on the heater. By controlling the voltage to the heating tape, it is possible to adjust the heat flux, obtain a set-up vapor quality at the test section inlet and control the variation range of vapor quality of the test section to within 0.2. The voltage and current are measured by a voltmeter and an amperometer, respectively. Resistance temperature sensors (PT100, accuracy ±0.1 °C) are used to measure refrigerant temperature at the inlet and outlet of preheating section and test section. The local outside wall-temperature of the test section is measured by T-type thermocouples with the precision of ±0.2 °C after being calibrated by a standard mercury thermometer. There are 10 measurement locations along the axis with intervals of 150 mm. At each location, thermocouples are positioned at top, right and left direction to prevent uneven temperature distribution in the circumferential direction. The pressure at inlet of preheating section and outlet of test section is measured by a pressure sensor with the precision of 0.25%. The pressure drop of test section is obtained by a differential pressure sensor with an accuracy of 0.25%. The rotor flow meter has an accuracy of 2.5%. During the experiment, the data of temperature and pressure are collected by the VX8140R/C2/U paperless recorder, the measurement period is fixed at 1 s and the sampling period is set to 2 s. When the parameter variation range is within ±0.1, the experimental conditions can be considered to be stable. The main parameters and uncertainties of measuring instruments are shown in Table 2, while the experimental conditions are presented in Table 3.

Table 2 Main parameters and uncertainties of measurement devices

Table 3 Experimental conditions

2.2 Data processing method

The two-phase HTC of R245fa in the micro-fin tube is determined as:

(1)

(1)

where A is the external surface area of the test section calculated by do; q is the heat flux in the test section; Tw,i and Ts are inside wall temperature of micro-fin tube and saturation temperature of R245fa, respectively. The saturation temperature is defined by the following:

(2)

(2)

The inside wall temperature can be calculated according to one-dimensional conduction equation:

(3)

(3)

where do and di is the outer diameter and inside diameter of micro-fin tube, respectively; L is effective length of test section; λw is the thermal conductivity of the cooper tube; Tw,o is the average exterior wall temperature of all thermocouples located along the test section and it is calculated by:

(4)

(4)

The temperature difference between internal and external surfaces is lower than 0.02 °C.

Based on energy balance equation, the inlet vapor quality of test section can be calculated as follows:

(5)

(5)

where is and r are the specific enthalpies of the saturated liquid and latent heat of vaporization, respectively.

In the test section, the outlet specific enthalpy and variation of the vapor quality can be expressed as:

(6)

(6)

(7)

(7)

where x is the vapor quality and m is the mass flow rate of the refrigerant.

In these experiments, the frictional pressure drop is calculated as follows:

(8)

(8)

where △p is total pressure drop of test section, while △pmomand △psta are the momentum and static pressure drops, respectively. For a horizontal test section, the static pressure drop is null.

The momentum pressure drop can be obtained by:

(9)

(9)

where ρ is the density of refrigerant and ε is the void fraction which is determined by ROUHANI- AXELSSON correlation [31]:

(10)

(10)

where σ is the surface tension and G is the mass velocity, which is calculated as follows:

(11)

(11)

where Anet is the net cross-section area calculated based on the internal diameter.

The mean vapor quality is defined as the average value of inlet and outlet vapor qualities.

(12)

(12)

2.3 Uncertainty analysis

The MOFFAT [32] error propagation is introduced to analyze the uncertainties of the heat transfer coefficient, frictional pressure drop and other calculated parameters, and the analysis results are showed in Table 4.

Table 4 Uncertainty of experimental parameters

3 Results and discussion

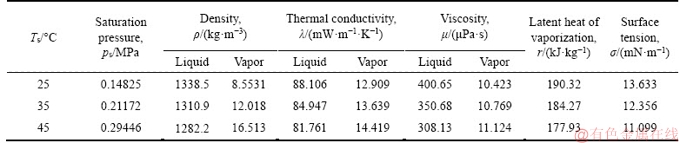

This section presents the experimental results collected during flow boiling of the R245fa inside the micro-fin tube. Table 5 lists the main thermos- physical properties of the R245fa at three different saturation temperatures.

Table 5 Thermos-physical properties of R245fa

3.1 Experimental results and validation

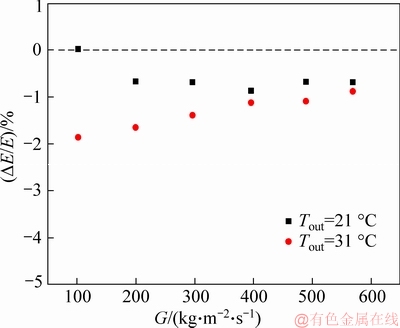

Single-phase heat transfer experiments of R245fa in a smooth tube were performed in order to evaluate the effective rate of heat losses (△E/E) and validate the presents experimental results. Effective rate of heat losses is defined as follows:

(13)

(13)

where iin and iout are the refrigerant enthalpies at the

preheater inlet and test section outlet, respectively. Q is the electrical power supplied to the heated sections.

As one can see in Figure 3, effective rate of heat losses of the test data is less than 2%, indicating that the influence of heat losses on the measurement of experimental data is negligible.

Figure 3 Evaluation of heat losses for single-phase

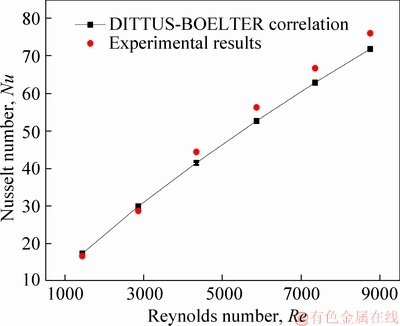

In addition, single-phase heat transfer experiments results were compared against the results provided by DITTUS-BOELTER correlation as shown in Figure 4. It demonstrates that the experimental data agree reasonably well with the predicted data.

3.2 Boiling heat transfer characteristics

The effect of the vapor quality on the boiling heat transfer coefficient of R245fa is given in Figure 5. The latter shows that the HTC increases first and then decreases with the increment of the vapor quality. It means that there is a transition point of vapor quality where HTC reaches the maximum, which changes with the experimental conditions. This decreasing trend might be addressed to a transition of two-phase flow regimes from the annular flow to the mist flow. When mass flux is 339 kg/(m2·s), the transition point of vapor quality is about 0.4. Compared with the HTC at x=0.4 (4711 W/(m2·K)), it decreases by 70.7% at x=0.07 and 15.8% at x=0.6, respectively. As the boiling gradually increases, gas fraction of R245fa becomes large and the disturbance generated at the meantime helps to enhance the convection boiling heat transfer; moreover, the increase of the vapor quality can contribute to more nucleation sites. As the vapor quality increases to a high region, a large number of bubbles contact with the heating surface which prevents refrigerant to constantly wet the surface. Consequently, the HTC decreases after the transition point of vapor quality.

Figure 4 Comparison between experimental single-phase heat transfer experiments Nu and values predicted by DITTUS-BOELTER correlation

Figure 5 Variation of boiling heat transfer coefficient with vapor quality

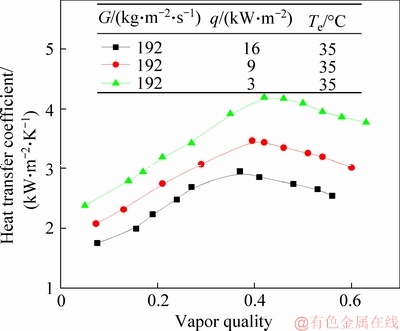

The effect of heat flux and vapor quality on the boiling heat transfer coefficient is described in Figure 6. It demonstrates that the HTC decreases with the increment of heat flux. When the vapor quality is 0.38, it decreases by 30.6% as heat flux ranges from 3 kW/m2to 16 kW/m2. The temperature difference between wall and refrigerant increases with the heat flux. At low mass velocities, higher heat flux accelerates more bubbles grow and detach from micro-fin surface, which causes intermittent dry-out on the micro-fin surface, further reducing the average heat transfer coefficient.

Figure 6 Variation of boiling heat transfer coefficient with heat flux

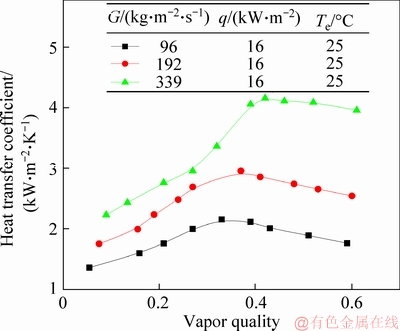

With an increase of mass velocity, fluid movement near the heating surface is intensified, leading to the enhancement of HTC, as is shown in Figure 7. The effect of mass velocity on heat transfer is small at low vapor quality, while it is significant when vapor quality is higher than 0.4. With mass velocity increases from 96 kg/(m2·s) to 339 kg/(m2·s), HTC at x=0.3 increases by 52.6%, while it increases by 151.4% at x=0.5. It is probably due to the enhancement of the convective heat transfer at high vapor quality region. When vapor quality is higher, more bubbles can lead to initiate a higher flow speed and a stronger disturbance on the boundary layer. Therefore, the boiling heat transfer coefficient is enhanced.

Figure 7 Variation of boiling heat transfer coefficient with mass velocity

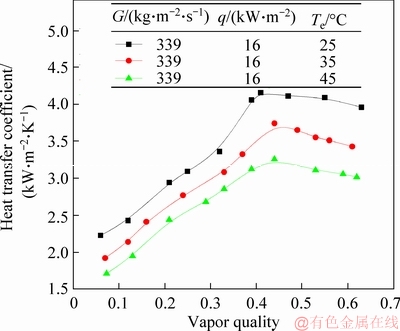

The effect of saturation temperature on the HTC is shown in Figure 8. A negative effect of saturation temperature on heat transfer coefficient, especially in the high vapor quality region, can be found. When the saturation temperature ranges from 25 °C to 45 °C, the HTC decreases by 13.5% at x=0.3, while it decreases by 36.7% at x=0.5. For the same heat flux, the temperature difference between wall and refrigerant increases with the decrease of saturation temperature. It leads to easier bubble formation and higher HTC.

Figure 8 Variation of boiling heat transfer coefficient with saturation temperature

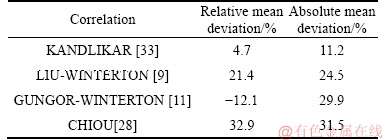

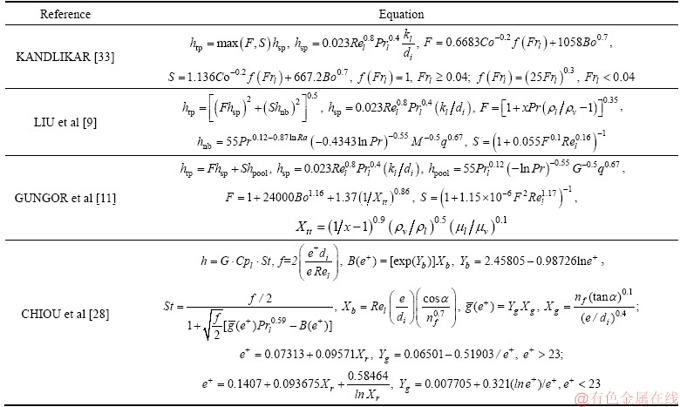

The comparisons of the present test results with the correlations of GUNGOR-WINTERTON [11], LIU-WINTERTON [9], CHIOU [28], and KANDLIKAR [33] are shown in Figures 9(a)-(d) respectively. The deviation between experimental results and predicted results by the above correlations is listed in Table 6. Additionally,Table 7 presents the detailed equations of these correlation.

Based on the results shown in Figure 9 and Table 6, the predicting results achieved by KANDLIKAR [33] correlation have the best agreement, where 91.6% of experimental data falls in the range of ±25% and the absolute mean deviation and relative mean deviation are 11.2% and 4.7%, respectively. The predicted heat transfer coefficients with LIU-WINTERTON [9] and CHIOU [28] correlations tend to overestimate the experimental data, providing mean absolute deviations of 24.5% and 31.5%, respectively. On the other hand, the correlation introduced by GUNGOR-WINTERTON [11] underestimates most of the experimental data, and the mean absolute deviation is about 30%.

Figure 9 Comparison of experimental results with four heat transfer correlations:

Table 6 Deviation between experimental and predicted results

3.3 Frictional pressure drop characteristics

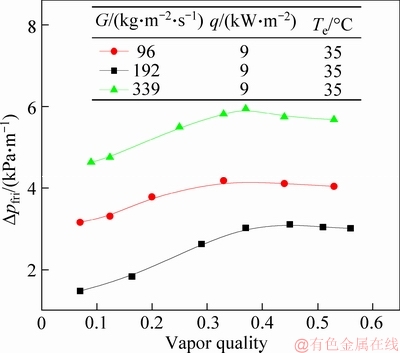

The effect of mass velocity on the frictional pressure drop of R245fa is presented in Figure 10. Figure 10 demonstrates that the frictional pressure drop increases sharply with mass velocity. There is an increase of 124.8% in frictional pressure drop as the mass velocity increases from 96 kg/(m2·s) to 339 kg/(m2·s) when heat flux is 9 kW/m2, saturation temperature is 35 °C and vapor quality is 0.2. The increment of mass velocity leads to the increase of flow velocity in the micro-fin tube. Therefore, higher mass velocity results in higher frictional pressure drop.

Figure 11 depicts the effect of heat flux on the frictional pressure drop. A positive effect of heat flux on frictional pressure drop was found. Frictional pressure drop at x=0.15 increases by 22.4% as heat flux ranges from 3 kW/m2 to 16 kW/m2. Due to the increase of heat flux, the frequency of bubble formation and detachment increases. As result, the friction between vapor and liquid increases, then leading to the increase of frictional pressure drop.

Figure 12 indicates that the frictional pressure drop of R245fa decreases with the increment of saturation temperature. When saturation temperature is changed from 25 °C to 45 °C, the frictional pressure drop at x=0.2 is 5.59 kPa/m and 4.75 kPa/m, respectively. There is a decrease of 17.7% in frictional pressure drop as saturation temperature increases from 25 °C to 45 °C. It can be attributed to the variation of thermodynamic properties of R245fa at different saturation temperatures. The increase of saturation temperature results in the decrease of viscosity. Consequently, higher saturation temperature leads to lower frictional pressure drop.

Table 7 Description of four heat transfer correlations

Figure 10 Variation of frictional pressure drop with mass velocity

Figure 11 Variation of frictional pressure drop with heat flux

Figure 12 Variation of frictional pressure drop with saturation temperature

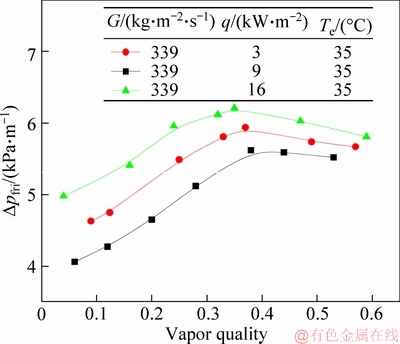

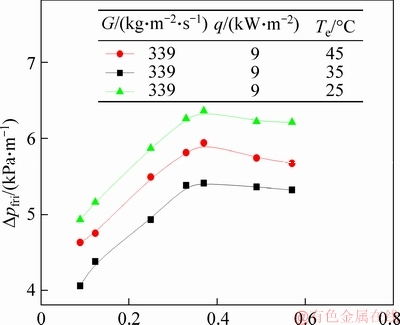

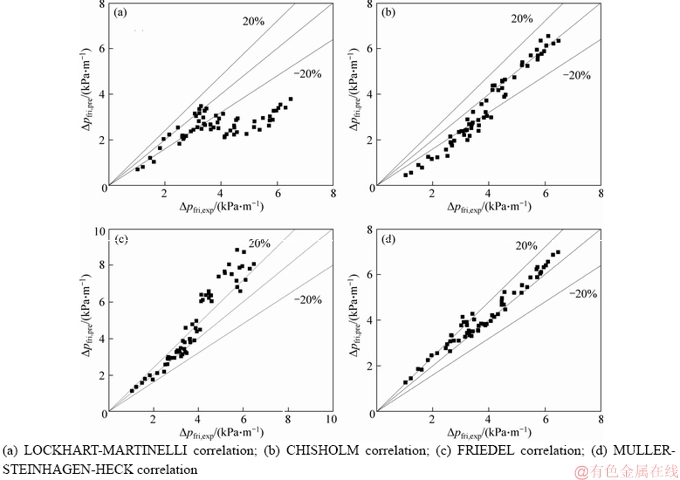

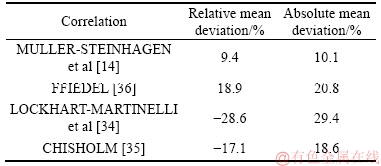

The comparisons of experimental results with the correlations of LOCKHART-MARTINELLI et al [34], CHISHOLM [35], FFIEDEL [36], and MULLER-STEINHAGEN et al [14] are shown in Figures 13(a)-(d) respectively. Table 8 lists the deviation between experimental and predicted results by the above correlations.

Figure 13 Predicted against experimental results for four different frictional pressure drop correlations:

As shown in Figure 13 and Table 8, MULLER-STEINHAGEN et al [14] correlation shows the lowest relative mean deviation and absolute mean deviation as well as the best prediction. In addition, 80.6% of the experimental data points can be predicted within ±20% error bands. CHISHOLM [35] and LOCKHART- MARTINELLI et al [34] correlation tends to underestimate the experimental data points, and both the relative mean deviation and absolute mean deviation of the latter are up to 30%. FFIEDEL [36] correlation is prone to overestimate the experimental data, and it provides a prediction with the relative mean deviation of 18.9% and absolute mean deviation of 20.8%.

Table 8 Deviation between experimental and predicted results for frictional pressure drop

4 Conclusions

An experimental investigation of R245fa boiling heat transfer in a 7.0-mm outer diameter horizontal micro-fin tube has been carried out as a function of vapor quality ranging from 0.07 to 0.65, saturation temperature ranging from 25 to 45 °C, mass velocity ranging from 96 to 339 kg/(m2·s) and heat flux ranging from 3 to 16 kW/m2. The heat transfer and frictional pressure drop characteristics in different conditions are obtained and the main conclusions are the following:

1) There is a transition point of vapor quality for boiling heat transfer of R245fa. The HTC increases first and then decreases with the increment of the vapor quality.

2) The HTC increases with the mass velocity, while it decreases with the increment of saturation temperature and heat flux. Moreover, the effect of mass velocity and saturation temperature on the heat transfer coefficient is enhanced in the region of high vapor qualities.

3) With absolute mean deviation of 11.2%, KANDLIKAR correlation shows the best agreement when predicting the HTC with the experimental results among the four correlations.

4) The frictional pressure drop of R245fa decreases with the increment of saturation temperature, while it increases with the mass velocity and heat flux. The experimental results of frictional pressure drop agree well with the MULLER-STEINHAGEN-HECK correlation and the absolute mean deviation is 10.1% .

Nomenclature

Roman symbols

A

Area, m2

d

Diameter, m

E

Heat transfer rate, W

G

Mass velocity, kg/(m2·s)

h

Heat transfer coefficient, W/(m2·K)

H

Fin high, mm

i

Specific enthalpy, kJ/kg

L

Effective length, m

m

Mass flow rate, kg/s

N

Fin number

△p

Pressure drop, kPa

q

Heat flux, kW/m2

Q

Total heat input, kW

r

Latent heat of vaporization, kJ/kg

T

Temperature, °C

W

Fin space, mm

x

Vapor quality

Greek symbols

β

Helix angle, (°)

γ

Apex angle of micro-fin, (°)

△

Difference

λ

Thermal conductivity, W/(m·K)

ρ

Density, kg/m3

σ

Surface tension, N/m

σSD

Standard deviation

△

Thickness, mm

μ

Viscosity, Pa·s

Subscripts

f

Fluid

fri

Frictional

g

Gas

i

Interior

in

Inlet

l

Liquid

mom

Momentum

o

Out

out

Outlet

pre

Predicted

s

Saturation

sta

Static

t

Test section

w

Wall

Acronyms

HTC

Heat transfer coefficient

ORC

Organic rankine cycle

MAPE

Mean absolute percentage error

References

[1] TCHANAHE B F, LAMNRINOS G, FRANGOUDAKIS A. Low-grade heat conversion into power using organic Rankine cycles-a review of various applications [J]. Renewable and Sustainable Energy Reviews, 2011, 15(8): 3963-3979. DOI:10.1016/j.rser.2011.07.024.

[2] WANG Zhi-qi, ZHOU Nai-jun, GUO jing. Fluid selection and parametric optimization of organic Rankine cycle using low temperature waste heat [J]. Energy, 2012, 40(1):107-115. DOI: 10.1016/j.energy.2012.02.022.

[3] XIA Xiao-xia, WANG Zhi-qi, HU Yan-hua, ZHOU Nai-jun. A novel comprehensive evaluation methodology of organic Rankine cycle for parameters design and working fluid selection [J]. Applied Thermal Engineering, 2018, 143: 283-292. DOI:10.1016/j.applthermaleng.2018.07.061.

[4] SUN Wen-qiang, YUE Xiao-yu, WANG Yan-hui, CAI Jiu-ju. Energy and exergy recovery from exhaust hot water using organic Rankine cycle and a retrofitted configuration [J]. Journal of Central South University, 2018, 25: 1464-1474. DOI: https://doi.org/10.1007/s11771-018-3840-6.

[5] YANG Fu-bin, ZHANG Hong-guang, SONG Song-song, BEI Chen, WANG Hong-jin, WANG En-hua. Thermoeconomic multi-objective optimization of an organic Rankine cycle for exhaust waste heat recovery of a diesel engine [J]. Energy, 2015, 93(2): 2208-2228. DOI: 10.1016/j.energy.2015.10.117.

[6] KANG S H. Design and experimental study of ORC (organic Rankine cycle) and radial turbine using R245fa working fluid [J]. Energy, 2012, 41(1): 514-524. DOI: 10.1016/ j.energy.2012.02.035.

[7] SAFARIAN S, ARAMOUN F. Energy and exergy assessments of modified organic rankine cycles (ORCs) [J]. Eenrgy Report, 2015, 1: 1-17. DOI: 10.1016/j.egyr.2014. 10.003.

[8] TIBIRICA C B, RIBATSKI G. Flow boiling heat transfer of R134a and R245fa in a 2.3 mm tube [J]. International Journal of Heat and Mass Transfer, 2010, 53(11): 2459-2468. DOI: 10.1016/j.ijheatmasstransfer.2010.01.038.

[9] LIU Z, WINTERTON R H S. A general correlation for saturated and subcooled flow boiling in tubes and annuli, based on a nucleate pool boiling equation [J]. International Journal of Heat and Mass Transfer, 1991, 34(11): 2759-2766. DOI: 10.1016/0017-9310(91)90234-6.

[10] CHAMAY R, BONJOUR J, REVELLIN R. Experimental investigation of R245fa flow boiling in minichannels at high saturation temperatures: Flow patterns and flow pattern maps [J]. International Journal of Heat and Fluid Flow, 2014, 46(4): 1-16. DOI: 10.1016/j.ijheatfluidflow.2013.12.002.

[11] GUNGOR K E, WINTERTON R H S. Simplified general correlation for saturated flow boiling and comparisons with data [J]. Chemical Engineering Research and Design, 1987, 65(2): 148-156.

[12] PIKE-WILSON E A, KARAYANNIS T G. Flow boiling of R245fa in 1.1 mm diameter stainless steel, brass and copper tube [J]. Experimental Thermal and Fluid Science, 2014, 59: 166-183. DOI:10.1016/j. expthermflusci.2014.02.024.

[13] REVELLIN R, THOME J R. Experimental investigation of R134a and R245fa two-phase flow in microchannels for different flow conditions [J]. International Journal of Heat and Fluid Flow, 2007, 28(1): 63-71. DOI: 10.1016/ j.ijheatfluidflow.2006.05.009.

[14] MULLER-STEINHAGEN H, HECK K. A simple friction pressure drop correlation for two-phase flow in pipes [J]. Chemical Engineering and Processing Process Intensification, 1986, 20(6): 297-308. DOI: 10.1016/0255-2701(86) 80008-3.

[15] SANDLER S, ZAJACZKOWSKI B, KROLICKI Z. Review on flow boiling of refrigerants R236fa and R245fa in mini and micro channels [J]. International Journal of Heat and Mass Transfer, 2018, 126: 591-617. DOI: 10.1016/ j.ijheatmasstransfer.2018.05.048.

[16] SAITOH S, DAIGUJI H, HIHARA E. Correlation for boiling heat transfer of R134a in horizontal tubes including effect of tube diameter [J]. International Journal of Heat and Mass Transfer, 2007, 50(25): 5215-5225. DOI: 10.1016/ j.ijheatmasstransfer.2007.06.019.

[17] LONGO G A, MANCIN S, RIGHETTI G, ZILIO C. R245fa flow boiling inside a 4.2 mm ID microfin tube [J]. International Journal of Physics: Conference Series, 2011(1): 012016. DOI: 10.1016/j.ijrefrig.2014.07.018.

[18] DIANI A, MANCIN S, ROSSETTO L. R1234ze(E) flow boiling inside a 3.4 mm ID microfin tube [J]. International Journal of Refrigeration, 2014, 47: 105-119. DOI: 10.1016/j.ijrefrig.2014.07.018.

[19] LALLEM M, BRANESCU C, HABERSCHILL P. Local heat transfer coefficients during boiling of R22 and R407C in horizontal smooth and micro-fin tubes [J]. International Journal of Refrigeration, 2001, 24(1): 57-72. DOI: 10.1016/S0140-7007(00)00064-5.

[20] WU Xiao-min, ZHU Yu, TANG Ying-jie. New experimental data of CO2 flow boilinginminitubewithmicrofinsofzero helix angle [J]. International Journal of Refrigeration, 2015, 59: 281-294. DOI: 10.1016/j.ijrefrig.2015.08.002.

[21] CUI Wen-zhi, LI Long-jian, XIN Ming-dao, JEN T C. A heat transfer correlation of flow boiling in micro-finned helically coiled tube [J]. International Journal of Heat and Mass Transfer, 2006, 49(17): 2851-2858. DOI: 10.1016/ j.ijheatmasstransfer.2006.02.020.

[22] JIANG Guo-bao, TAN Jin-tian, NIAN Qu-xing, TAO Wu-qing. Experimental study of boiling heat transfer in smooth/micro-fin tubes of four refrigerants [J]. International Journal of Heat and Mass Transfer, 2016, 98(7): 631-642. DOI: 10.1016/j.ijheatmasstransfer.2016.03.024.

[23] HAN Xiao-hong, LI Peng, YUAN Xiao-rong, WANG Qin, CHEN Guang-ming. The boiling heat transfer characteristics of the mixture HFO-1234yf/oil inside a micro-fin tube [J]. International Journal of Heat and Mass Transfer, 2013, 67(12): 1122-1130. DOI: 10.1016/j.ijheatmasstransfer.2013. 08.083.

[24] ZHANG Xiao-yan, ZHANG Jin, JI Hai-wei, ZHAO Deng-yu. Heat transfer enhancement and pressure drop performance for R417A flow boiling in internally grooved tubes [J]. Energy, 2015, 86(15): 446-454. DOI: 10.1016/j.energy. 2015.04.054.

[25] PADOVAN A, DSLCO D, ROSSETTO L. Experimental study on flow boiling of R134a and R410A in a horizontal microfin tube at high saturation temperatures [J]. Applied Thermal Engineering, 2011, 31(17): 3814-3826. DOI: 10.1016/j.applthermaleng.2011.07.026.

[26] CAVALLINI A, DEL COL D, ROSSETTO L. Flow boiling inside microfin tubes: Prediction of the heat transfer coefficient [C]// Proceedings of ECI International Conference on Boiling Heat Transfer. Spoleto, Italy, 2006.

[27] AKHAVAN BEHABADIM A, MOHSENI S G, RAZAVINASAB S M. Evaporation heat transfer of R-134a inside a micro-fin tube with different tube inclinations [J]. Experimental Thermal and Fluid Science, 2011, 35(6): 996-1001. DOI: 10.1016/j.expthermflusci.2011.01.020.

[28] CHIOU Chen-bao, LU Deng-chao, CHEN Ceng-cong. Heat transfer correlations of forced convective boiling for pure refrigerants in micro-fin tubes [J]. Applied Thermal Engineering, 2011, 31(5): 820-826. DOI: 10.1016/ j.applthermaleng.2010.10.031.

[29] COLOMBO L P M, LUCCHINI A, MUZZIO A. Flow patterns, heat transfer and pressure drop for evaporation and condensation of R134A in microfin tubes [J]. International Journal of Refrigeration, 2012, 35(8): 2150-2165. DOI: 10.1016/j.ijrefrig.2012.08.019.

[30] TANG Wei-yu, LI Wei. A new heat transfer model for flow boiling of refrigerants in micro-fin tubes [J]. International Journal of Heat and Mass Transfer, 2018, 126: 1067-1078. DOI: 10.1016/j.ijheatmasstransfer.2018.06.066.

[31] ROUHANI Z, AXEISSON E. Calculation of void volume fraction in the subcooled and quality boiling regions [J]. International Jouranal of Heat Mass Transfer, 1970, 13(2): 383-393. DOI: 10.1016/0017-9310(70)90114-6.

[32] MOFFAT R J. Describing the uncertainties in experimental results [J]. Experimental Fluid Thermal Science, 1998, 1(1): 3-17. DOI: 10.1016/0894-1777(88)90043-x.

[33] KANDLIKAR S G. A general correlation for saturated two-phase flow boiling heat transfer inside horizontal and vertical tubes [J]. Journal of Heat Transfer, 1990, 112(1): 219-228. DOI: 10.1115/1.2910348.

[34] LOCKHART R W, MARTINELLI R C. Proposed correlation of data for isothermal two-phase two-component flow in pipes [J]. Chem Eng Prog, 1949, 45(1): 39-45.

[35] CHISHOLM D. A theoretical basis for the Lockhart- Martinelli correlation for two-phase flow [J]. International Journal of Heat and Mass Transfer, 1967, 10(12): 1767-1778. DOI: 10.1016/0017-9310(67)90047-6.

[36] FFIEDEL L. Improved friction pressure drop correlation for horizontal and vertical two-phase pipe flow [J]. Proc of European Two-phase Flow Group Meet. Ispra, Italy, 1979.

(Edited by YANG Hua)

中文导读

水平微肋管内R245fa沸腾换热及压降的实验研究

摘要:本文对R245fa在7 mm水平微肋管内的沸腾传热特性和摩擦压降特性进行了实验研究。结果表明,在流动沸腾传热特性方面,沸腾传热系数(HTC)随着R245fa质量速度的增加而增大,随着饱和温度和热流密度的增加而减小。随着干度的增加,HTC存在最大值,对应的干度约为0.4,其值随工作条件的变化而变化。当干度大于过渡点时,较高的质量速度或较低的饱和温度下可以显著增加HTC。在所选四个关联式中,KANDLIKAR的预测值与91.6%实验值的偏差在±25%以内,绝对平均误差为11.2%。此外,关于流动沸腾的摩擦压降特性,本研究结果表明,摩擦压降随着R245fa的质量速度和热流密度的增加而增加,随着饱和温度的升高而减小。在四种常用的关联式中,MULLER- STEINHAGEN-HECK对R245fa摩擦压降值的预测最准确,预测值与84.1%的实验值偏差在±20%以内,绝对平均误差为10.1%。

关键词:沸腾传热;摩擦压降:预测关联式;微肋管;R245fa流体

Foundation item: Project(51606162) supported by the National Natural Science Foundation of China; Project(2018JJ2399) supported by the Natural Science Foundation of Hunan Province, China

Received date: 2018-08-02; Accepted date: 2019-06-17

Corresponding author: WANG Zhi-qi, PhD, Associate Professor; Tel: +86-731-58292215; E-mail: wangzhiqi@xtu.edu.cn; ORCID: 0000-0001-5541-7936

Abstract: An experimental investigation on the boiling heat transfer and frictional pressure drop of R245fa in a 7 mm horizontal micro-fin tube was performed. The results show that in terms of flow boiling heat transfer characteristics, boiling heat transfer coefficient (HTC) increases with mass velocity of R245fa, while it decreases with the increment of saturation temperature and heat flux. With the increase of vapor quality, HTC has a maximum and the corresponding vapor quality is about 0.4, which varies with the operating conditions. When vapor quality is larger than the transition point, HTC can be promoted more remarkably at higher mass velocity or lower saturation temperature. Among the four selected correlations, KANDLIKAR correlation matches with 91.6% of experimental data within the deviation range of ±25%, and the absolute mean deviation is 11.2%. Also, in terms of frictional pressure drop characteristics of flow boiling, the results of this study show that frictional pressure drop increases with mass velocity and heat flux of R245fa, while it decreases with the increment of saturation temperature. MULLER-STEINHAGEN-HECK correlation shows the best prediction accuracy for frictional pressure drop among the four widely used correlations. It covers 84.1% of experimental data within the deviation range of ±20%, and the absolute mean deviation is 10.1%.