含锆锶Al-Zn-Mg-Cu系高强铝合金热处理工艺的优化

江苏大学机械工程学院

江苏大学先进制造与现代装备技术工程研究院

摘 要:

采用硬度与电导率测试、拉伸试验、金相(OM)观察、X射线衍射(XRD)分析、晶间腐蚀和剥落腐蚀(EXCO)试验,研究了不同热处理工艺(固溶-T6时效,固溶-预压缩-T6时效,预回复-固溶-预压缩-T6时效和预回复-固溶-预压缩-T76时效)对含锆锶复合微合金化的Al-10.78Zn-2.78Mg-2.59Cu-0.221Zr-0.0465Sr高强铝合金组织与性能的影响。结果表明:在T6(120℃×24 h)时效制度下,预回复和预压缩均能提高位错强化,并且预回复能显著抑制再结晶;与固溶-预压缩-T6相比,预回复-固溶-预压缩-T6工艺能在不降低强度的情况下,提高抗晶间和剥落腐蚀性能(最大晶间腐蚀深度从125μm减少到91μm,剥落腐蚀从EB级提高到EA级);预回复-固溶-预压缩-T76状态下,合金强度低至600 MPa,但电导率高达31.58%ICAS,较T6时效下的抗腐蚀性能明显改善。经研究表明,Al-10.78Zn-2.78Mg-2.59Cu-0.221Zr-0.0465Sr高强铝合金挤压材在预回复-固溶-预压缩-T6时效工艺下的综合性能最佳。

关键词:

中图分类号: TG166.3

作者简介:张香丽(1989-),女,山东定陶人,硕士研究生,研究方向:先进材料制造与性能表征;E-mail:15751010200@163.com;;许晓静,教授;电话:13952877885;E-mail:xjxu67@ujs.edu.cn;

收稿日期:2015-03-20

基金:国家自然科学基金项目(51074079);江苏省工业科技支撑计划项目(BE2008118);江苏省高校研究生科研创新计划项目(CXLX110563)资助;

Optimization of High-Strength Al-Zn-Mg-Cu Series Aluminum Alloy with Zr and Sr Additions by Heat Treatment

Zhang Xiangli Xu Xiaojing Ling Zhiyong Wu Yao Sun Liangsheng Fan Yazhou

School of Mechanical Engineering,Jiangsu University

Institute of Advanced Manufacturing and Modern Equipment Technology Engineering,Jiangsu University

Abstract:

The effect of solid solution-T6,solid solution-pre-compression-T6,pre-recovery-annealing-solid solution-T6 and pre-recovery-annealing-solid solution-pre-compression-T76 aging treatment on microstructure and mechanical properties of the experimental high strength Al-10. 78Zn-2. 78Mg-2. 59Cu-0. 221Zr-0. 0465 Sr aluminum alloy extrusions were investigated by hardness and electrical conductivity tests,tensile test,optical microscope( OM),X-ray diffraction( XRD) analysis and corrosion experiment. The results showed that under the T6( 120 ℃ × 24 h) aging treatment system,pre-recovery-annealing and pre-compression could improve the dislocation strengthening,and pre-recovery-annealing could significantly inhibit recrystallization. Compared with the solid solution-precompression-T6,pre-recovery-annealing-solid solution-pre-compression-T6 process could improve the corrosion resistance( the maximum corrosion depth was reduced from 125 to 91 μm,exfoliation corrosion rating increased from EB to EA) without reducing the strength. Under the condition of pre-recovery-annealing-solid solution-pre-compression-T76 aging treatment,the strength of the alloy was as low as 600 MPa,but the electrical conductivity reached as high as 31. 58% ICAS,which significantly improved the corrosion resistance compared to T6 aging treatment. Studies showed that the experimental high-strength aluminum alloy extrusion presented the optimal comprehensive performance under the condition of pre-recovery-annealing-solid solution-pre-compression-T6.

Keyword:

high-strength aluminum alloy; microstructure; mechanical properties; optimization;

Received: 2015-03-20

超高强铝合金作为一种高性能材料,加上自身质轻、成本低、易制造、耐蚀性能好等一系列优点,被广泛应用于航空航天、武器装备、交通运输、建筑等领域

Al-Zn-Mg-Cu系铝合金是一种可热处理强化型合金,通过对热处理工艺的合理制定,从而调控铝合金的性能,达到提高其综合性能的目的。

本文通过对含微量锆锶元素的高强Al-10.78Zn-2.78Mg-2.59Cu-0.221Zr-0.0465Sr铝合金挤压材时效热处理工艺的研究,优化出该超高强铝合金的最佳热处理工艺制度,以期为后续高强铝合金的研究提供一定的参考依据。

1实验

合金制备以A00工业纯Al(99.79%)、工业纯Zn(99.9%)、工业纯Mg(99.9%)和Al-50%Cu、Al-4%Zr及Al-10%Sr中间合金为熔炼原材料,熔炼温度为700~740℃,浇注在直径为220mm的铸铁模具中,铸锭重量约为28 kg,实验合金的实际成分在德国SPECTRO上测试,其实际测量成分见表1。对该合金铸锭进行多级均质化退火和挤压变形处理,均质化退火工艺为400℃×6 h+420℃×6 h+440℃×6 h+460℃×12 h,挤压比为10∶1,挤压成直径为Φ35 mm的棒料。该合金4种不同的时效热处理工艺详见表2和3。

拉伸性能参照GB/T 228-2002标准

金相试样经磨平、抛光后,采用Graff Sargent试剂(1 ml HF+16 ml HNO3+3 g Cr O3+83 ml蒸馏水)浸蚀。晶间腐蚀试验按照GB/T 7998-2005标准

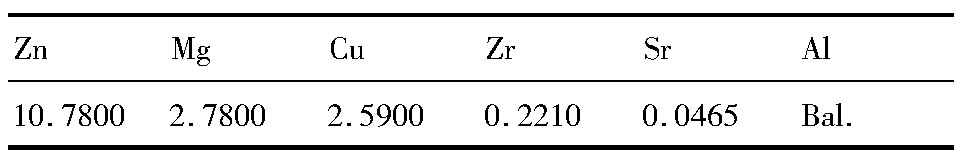

表1 实验铝合金的化学成分Table 1 Chemical composition of experimental aluminum alloys(%,mass fraction) 下载原图

表1 实验铝合金的化学成分Table 1 Chemical composition of experimental aluminum alloys(%,mass fraction)

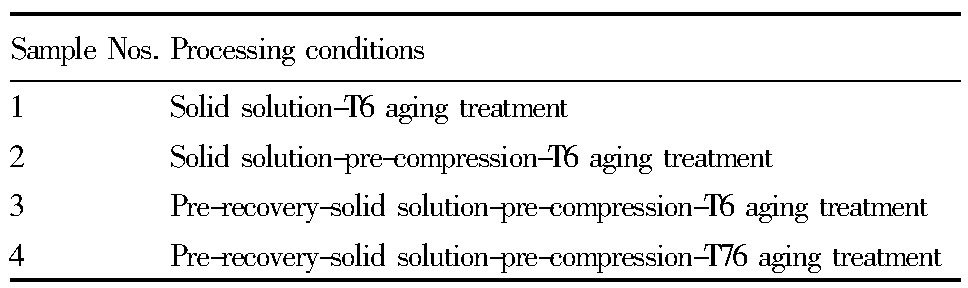

表2 实验合金在不同热处理工艺下的编号Table 2 Label of experimental alloys under different heat treatment processes 下载原图

表2 实验合金在不同热处理工艺下的编号Table 2 Label of experimental alloys under different heat treatment processes

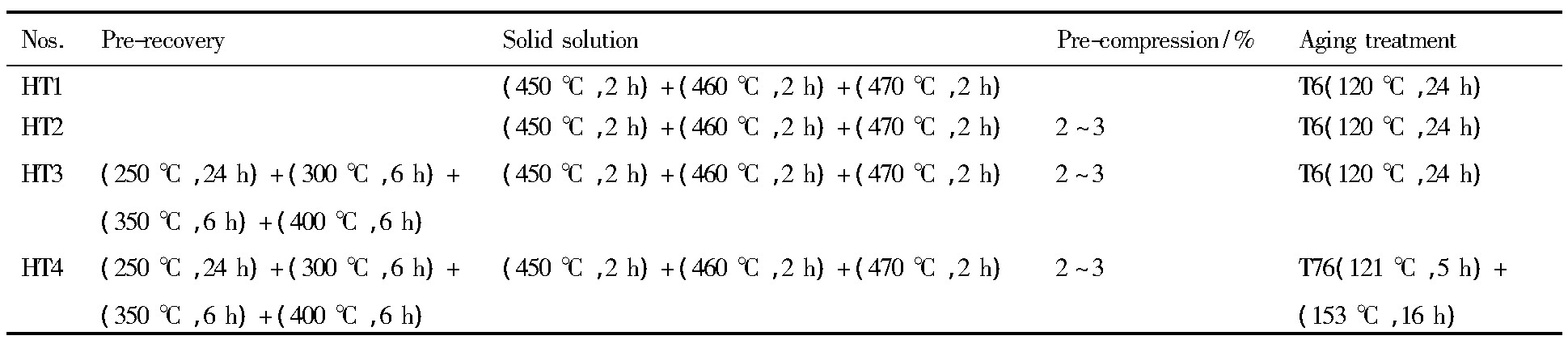

表3 实验合金不同热处理工艺的步骤Table 3 Heat treatment procedures used for experimental aluminum alloy 下载原图

表3 实验合金不同热处理工艺的步骤Table 3 Heat treatment procedures used for experimental aluminum alloy

2结果与讨论

2.1金相组织

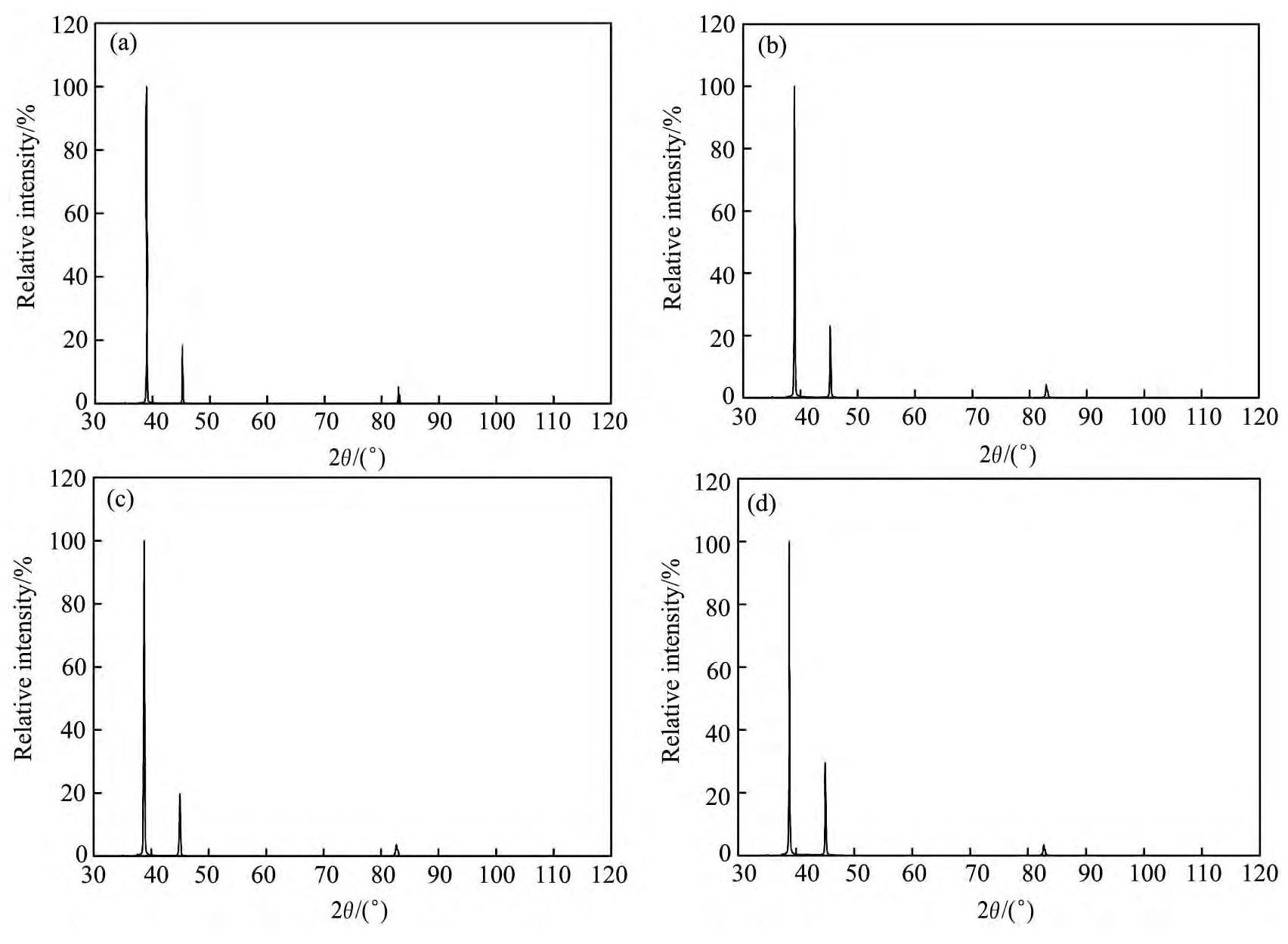

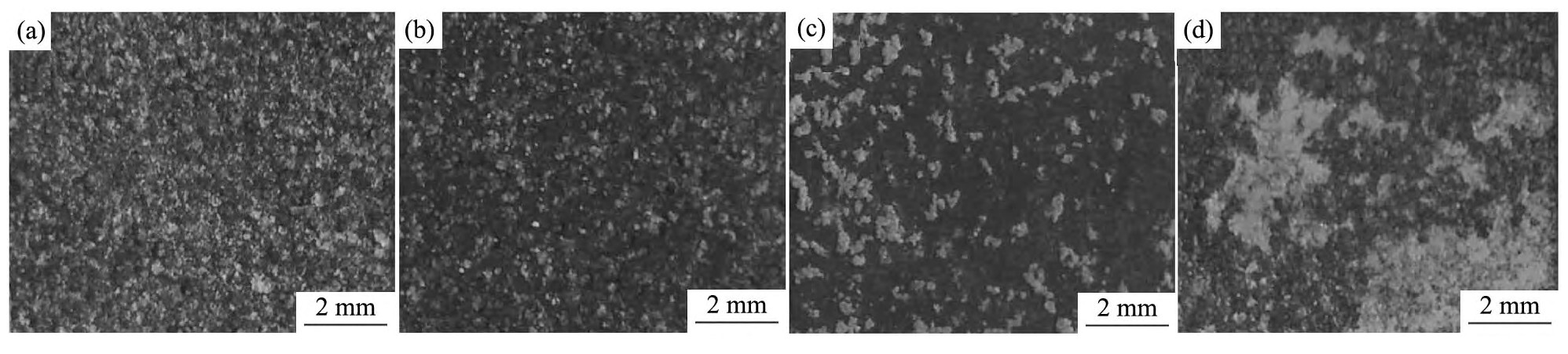

图1所示为实验超高强铝合金经4种不同时效热处理工艺处理后的金相组织图。可以看出,图1(b)比(a)中晶粒细小,且弥散析出更多强化相,但其晶界处聚集的粗大相更多更大;图1(c),(d)中的晶粒比图1(b)中更加细小,图1(c)中较多晶粒发生再结晶长大,图1(d)中晶粒更加均匀但其晶界处聚集部分较大的难溶第二相。可以得出结论:预压缩能够有效地细化合金晶粒,引入位错促进析出强化相更多更均匀地析出;预回复能够使合金晶粒近一步细化,但会发生部分再结晶;T76时效态下合金的晶粒更加均匀,但晶界处易聚集一些较大的难溶第二相。

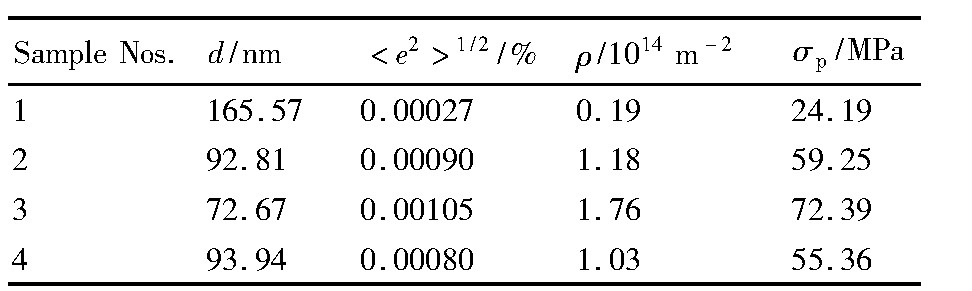

2.2 XRD分析与位错密度

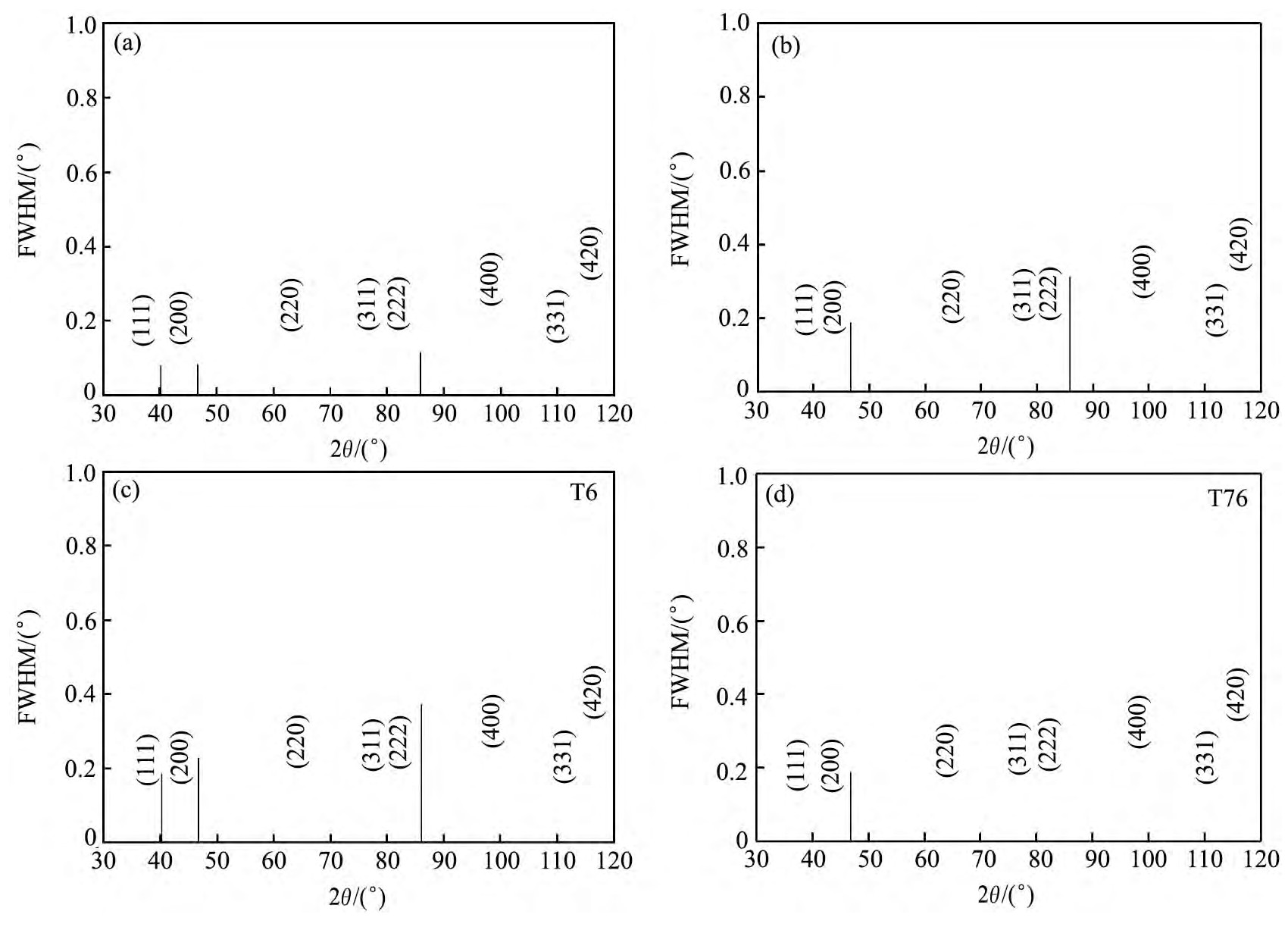

图2和3分别为试样1,2,3和4的XRD分析谱及其半高峰宽图。可以看出,4种不同的热处理工艺对合金的晶体取向有不同程度的影响,总体上看,经预压缩处理后,试样2和4的半高峰宽相差不大,但明显大于未经预压缩处理的试样1,小于经预回复-固溶-预压缩-T6工艺处理的试样3,说明经预处理(预回复和预压缩)后,合金内部晶格应变和位错密度相对较高,这使得试样1位错对强度的贡献小于试样2,3和4,试样3的位错强度贡献值最高。

图1 实验铝合金挤压材经不同热处理工艺加工后的金相组织图Fig.1 OM images of microstructures for experimental aluminum alloy after different heat treatment processes

(a)Sample 1;(b)Sample 2;(c)Sample 3;(d)Sample 4

图2 实验合金的XRD分析谱图Fig.2 XRD patterns of experimental aluminum alloys

(a)Sample 1;(b)Sample 2;(c)Sample 3;(d)Sample 4

图3 实验合金的半高峰宽图Fig.3 Full width at half maximum(FWHM)of experimental aluminum alloys

(a)Sample 1;(b)Sample 2;(c)Sample 3;(d)Sample 4

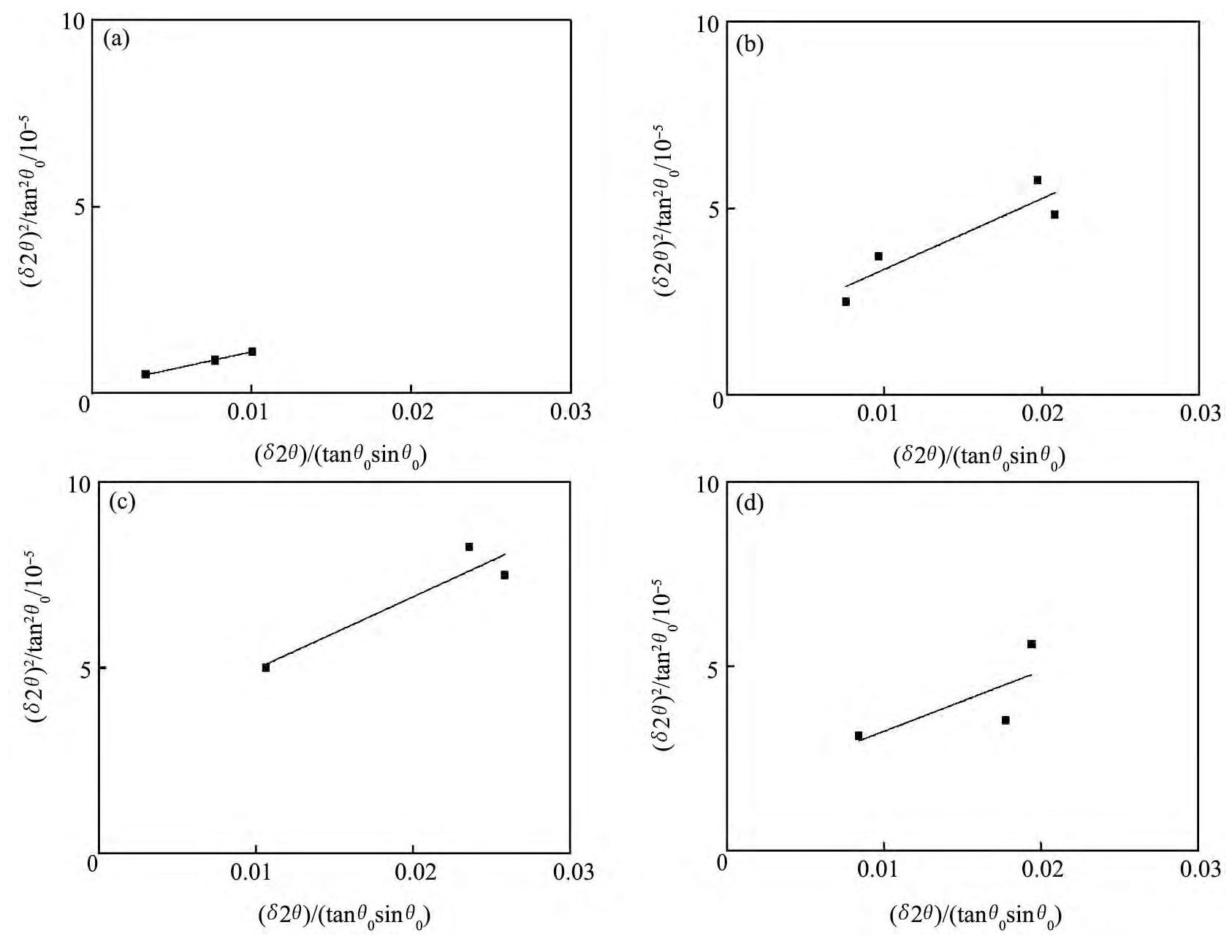

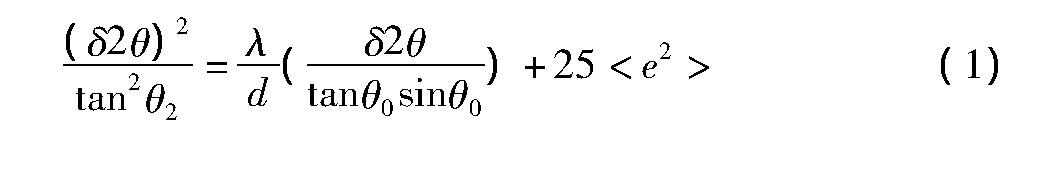

关于位错密度对合金性能的影响,可通过图4中(δ2θ)2/tan2θ0与(δ2θ)/(tanθ0sinθ0)间的关系反映出来。

XRD相干衍射区尺寸(d)、晶格畸变(<e>)与半高峰宽(δ2θ)、各衍射峰最高峰位置(θ0)、Cu Kα射线波长(λ)之间的关系,一般用函数

位错密度(ρ)与XRD相干衍射区尺寸(d)、平均晶格应变(<e2>1/2)之间的关系可以用函数

式中b为柏氏矢量,对于Al合金,b=0.286nm

位错对强度的贡献(σp)与位错密度(ρ)之间的关系由Taylor函数

式中Taylor位向因子M=3.06(不考虑织构时),数值因子α=0.24

图4 从XRD数据计算XRD相干衍射区尺寸和晶格应变值Fig.4 Integral breadth analysis to calculate average crystallite size and lattice strain values from XRD data

(a)Sample 1;(b)Sample 2;(c)Sample 3;(d)Sample 4

表4 XRD数据计算的微观结构与力学性能参数Table 4 Microstructural and mechanical features calculat-ed from XRD data 下载原图

表4 XRD数据计算的微观结构与力学性能参数Table 4 Microstructural and mechanical features calculat-ed from XRD data

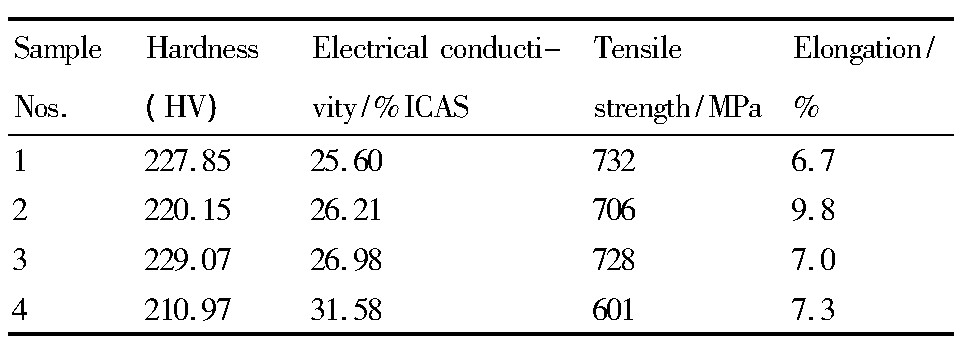

2.3力学性能

表5所示为实验合金在不同热处理工艺下的硬度、电导率、抗拉强度及伸长率值。铝合金的硬度和电导率值与合金的强度和抗腐蚀性能正相关,即硬度值越高,合金的强度越高;电导率值越大,合金的抗腐蚀性能越好

表5 实验合金在不同热处理工艺下的力学性能Table 5 Mechanical properties of experimental alloy after different heat treatment processes 下载原图

表5 实验合金在不同热处理工艺下的力学性能Table 5 Mechanical properties of experimental alloy after different heat treatment processes

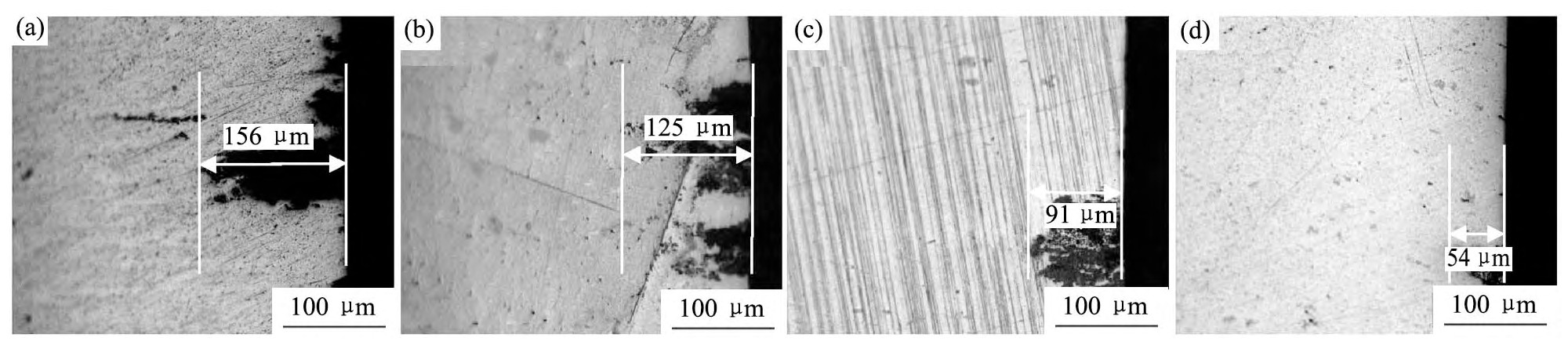

图5 实验合金在不同热处理工艺下的晶间腐蚀形貌图Fig.5 Inter-granular corrosion morphologies of experimental aluminum alloy after different heat treatment processes

(a)Sample 1;(b)Sample 2;(c)Sample 3;(d)Sample 4

图6 实验合金在不同热处理工艺下的剥落腐蚀形貌图Fig.6 Exfoliation corrosion morphologies of experimental aluminum alloy after different heat treatment processes

(a)Sample 1;(b)Sample 2;(c)Sample 3;(d)Sample 4

2.4抗腐蚀性能

2.4.1晶间腐蚀

图5为实验合金在不同热处理工艺下的晶间腐蚀形貌图。通过标尺测量,得到试样1,2,3和4的腐蚀深度分别为156μm(4级),125μm(4级),91μm(3级)和54μm(3级),可以发现从试样1~4合金的抗晶间腐蚀性能越来越好。因此得出结论:预压缩和预回复退火可以显著改善合金的抗晶间腐蚀性能;与T6时效相比,T76时效能大大地提升合金的抗晶间腐蚀性能,这一结论与电导率的规律变化相一致。

2.4.2剥落腐蚀

图6为合金在不同热处理工艺下的剥落腐蚀宏观形貌图。抗剥落腐蚀性能主要取决于抗晶间腐蚀和晶粒形貌。从图6可以看出,与未经预回复处理的试样1和2相比,经预回复处理的试样3和4合金表面具有较多的灰白色区域,这是未发生剥落腐蚀的铝合金本色;经评估,试样1和2合金腐蚀等级为EB级,试样3为EA级,试样4为PC级。因此预回复处理可提高合金的抗剥落腐蚀性能;预压缩能略微提高合金的抗剥落腐蚀性能,但不明显;试样4合金的抗剥落腐蚀性能较试样3明显改善,说明T76时效较T6时效有更好的抗剥落腐蚀性能,这一结论与合金的抗晶间腐蚀性能规律相符。

3结论

1.预回复能够细化合金晶粒,抑制再结晶;提高位错强化,保留合金中的位错;提高合金的强度;改善合金的抗腐蚀性能。

2.预压缩能够在合金内部引入位错,促进合金时效时强化相弥散析出;细化晶粒,有效地提高合金的塑性,但会略微降低合金的强度;同时预压缩可以改善合金的抗腐蚀性能。

3.传统T76时效能够显著提高合金的抗腐蚀性能,但硬度相对T6时效下降约17.5%,对合金的强度损伤太大,在实际生产应用中不可取。

4.含锆锶复合微合金化的超高强Al-10.78Zn-2.78Mg-2.59Cu-0.221Zr-0.0465Sr铝合金挤压材的最佳热处理工艺为预回复(250℃×24 h+300℃×6 h+350℃×6 h+400℃×6 h)-固溶(450℃×2 h+460℃×2 h+470℃×2 h)-预压缩(2%~3%)-T6时效(120℃×24 h),此时合金具有良好的综合性能。

参考文献