文章编号:1004-0609(2010)11-2148-06

热轧Ni47Ti44Nb9形状记忆合金板材的织构及其对拉伸和恢复性能的影响

颜 莹1, 金 伟2, 周亭俊1

(1. 东北大学 材料物理与化学研究所,沈阳110004; 2. 中国科学院 金属研究所,沈阳110016)

摘 要:

采用XRD、SEM和拉伸试验机对热轧Ni47Ti44Nb9形状记忆合金板材的织构及其对拉伸和恢复性能的影响进行研究,以便为改善该合金的力学和记忆性能提供理论依据。热轧板材的织构主要为{001}áuv0?和{111}áuvw?丝,沿轧向(RD),{001}áuv0?丝织构中强组分向{001}á010?靠近,{111}áuvw?丝织构中的{111}á112?和{111}á165?组分较强;沿横向(TD),强织构组分为{001}á010?和{111}á132?;热轧板材经高于再结晶温度热处理后,沿轧向,应力诱发马氏体相变临界应力最高,与轧向成45?角方向的临界应力最低,且沿横向拉伸断口表面出现很多微裂纹;经850 ℃热处理后,临界应力随着冷速的加快而降低,且该温度下退火板材的织构对可恢复应变的影响不明显,基本在7.0%~7.4%。

关键词:

Ni47Ti44Nb9形状记忆合金;织构;拉伸性能;恢复应变;断裂;

中图分类号:TG146.4;TG139.6 文献标志码:A

Texture and its influence on tensile and recoverable properties of hot-rolled Ni47Ti44Nb9 shape memory alloy sheet

YAN Ying1, JIN Wei2, ZHOU Ting-jun1

(1. Institute of Materials Physics and Chemistry, Northeastern University, Shenyang 110004, China;

2. Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China)

Abstract:The texture and its influence on tensile and recoverable properties of hot-rolled Ni47Ti44Nb9 shape memory alloy sheet were studied by XRD, SEM and tensile tester to provide theoretic basis for improving mechanical and memory properties of the alloy. The main textures of hot-rolled sheets are {001}áuv0? and {111}áuvw? fibres. The strong components in {001}áuv0? fibre approach to {001}á010? component, and {111}á112? and {111}á165? components are stronger in {111}áuvw? fibre along RD. The {001}á010? and {111}á132? are the strong components along TD; The critical stress of stress-induced martensite transformation along RD is the maximum and the minimum is along 45? to RD for hot-rolled sheet heat-treated at temperature higher than the recrystallization temperature, and some micro-cracks appear on the fracture surface of the specimen tensioned along TD. The critical stress decreases with increasing the cooling rate at 850 ℃, and texture has no obvious influence on the recoverable strain whose values are basically in the range of 7.0%-7.4% for sheet annealed at 850 ℃.

Key words: Ni47Ti44Nb9 shape memory alloy; texture; tensile property; recovery strain; fracture

形状记忆合金部件在制备过程中往往会采用锻造、轧制以及随后退火等处理。在加工过程中,会产生形变织构,而退火时往往会产生再结晶织构。无论哪种类型织构都会对记忆合金的力学和记忆性能产生不同程度的影响。TiNi单晶的伪弹性和恢复应变强烈依赖单晶取向,其最大和最小转变应变比值可达3.4[1-2]。在富Ni的TiNi合金拉拔或轧棒中发现,B2相可形成〈111〉或〈110〉丝织构,轧制板材主要形成γ或α丝织构[3-10]。对于轧制板材,其拉伸记忆应变随与轧制方向取向不同而出现各向异性[4, 6, 10-12]。目前,对于TiNi基形状记忆合金织构及其与性能关系的研究,主要集中在TiNi合金,对Ni47Ti44Nb9形状记忆合金的织构,尤其是织构与性能关系的研究鲜见公开报道。具有宽相变滞后的Ni47Ti44Nb9合金在工程上具有广阔的应用前景,因此,研究其织构及对力学、记忆性能以及断裂方式的影响非常重要。这既可为其在工程上的应用提供参考依据,同时也为进一步揭示织构影响记忆合金力学和记忆行为的机理打下基础。

1 实验

150 kg的Ni47Ti44Nb9(摩尔分数,%)合金铸锭在850 ℃经热锻、热轧制备成3 mm厚的板材,从板材上切割金相、织构和长80 mm、宽3 mm的片状拉伸试样,然后经600、850 ℃,90 min炉冷(FC)、空冷(AC)和水淬(WQ)处理。

利用Axiover 200MAT金相显微镜、X′pert Pro MRD XRD、JEOL7001型SEM和AG-l 500KN拉伸试验机进行组织、织构、断口和性能的研究。织构测试采用CoKα辐射、管压35 kV、管流40 mA,测定B2相{110}、{200}、{211} 3个不完整极图,极图测量范围α=0~70?,β=0~360?,利用Bunge法计算晶粒取向分布函数(ODF);拉伸速率为1.2×10-3 s-1,恢复试验在-65 ℃下进行15%和17%预变形后卸载,随后升温至240 ℃。

2 结果与讨论

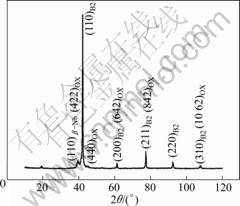

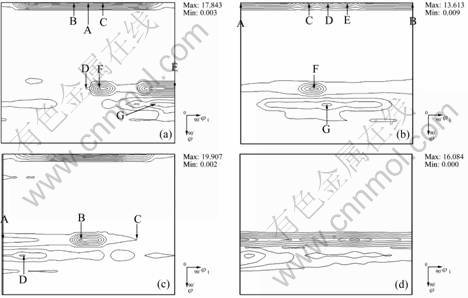

热轧板材主要由B2、β-Nb和(Ti,Nb)4Ni2O(OX)相组成(见图1)。为此,可测出B2相沿与轧向成0?、45?和90?方向上的织构组成,其φ2=45?的截面图如图2所示。

图1 热轧Ni47Ti44Nb9板材的XRD衍射谱

Fig.1 XRD spectrum of hot-rolled Ni47Ti44Nb9 sheet

图2 与轧制方向成不同角度热轧和冷轧+中间退火板材ODF的φ2=45?截面图

Fig.2 φ2=45? sections of ODFs of hot-rolled and cold-rolled plus middle-annealed sheets along different angles to RD: (a) 0? in hot-rolled sheet, texture components of A being (001)[0![]() 0], B (001)[1

0], B (001)[1![]() 0], C (001)[

0], C (001)[![]()

![]() 0], D (111)[2

0], D (111)[2![]() 5], E (111)[

5], E (111)[![]()

![]() 2], F (111)[1

2], F (111)[1![]() 5], G (332)[

5], G (332)[![]()

![]() 15]; (b) 45? in hot-rolled sheet, A (001)[1

15]; (b) 45? in hot-rolled sheet, A (001)[1![]() 0], B (001)[

0], B (001)[![]()

![]() 0], C (001)[1

0], C (001)[1![]() 0], D (001)[0

0], D (001)[0![]() 0], E (001)[

0], E (001)[![]()

![]() 0], F (111)[1

0], F (111)[1![]() 2], G (332)[3

2], G (332)[3![]() 6]; (c) 90? in hot-rolled sheet, A (111)[1

6]; (c) 90? in hot-rolled sheet, A (111)[1![]() 0], B (111)[1

0], B (111)[1![]() 2], C (111)[

2], C (111)[![]()

![]() 5], D (332)[12

5], D (332)[12![]() 3]; (d) 0? in cold-rolled and middle-annealed sheet

3]; (d) 0? in cold-rolled and middle-annealed sheet

从图2(a)可见,B2相沿轧向具有较强的{001}áuv0?、{111}áuvw? (γ-丝)和较弱的{332}áuvw?丝织构。{001}áuv0?织构中的强组分向(001)[0![]() 0]附近聚集,其取向密度为17.5843。γ-丝织构从(111)[2

0]附近聚集,其取向密度为17.5843。γ-丝织构从(111)[2![]() 5]到(111)[

5]到(111)[![]()

![]() 2],强点为(111)[1

2],强点为(111)[1![]() 5]和(111)[

5]和(111)[![]()

![]() 2]组分,取向密度分别为11.75和13.38。{332}áuvw?丝中的(332)[

2]组分,取向密度分别为11.75和13.38。{332}áuvw?丝中的(332)[![]()

![]() 15]组分较强,取向密度为6.18;与轧向成45?角的试样,{001}áuv0?丝最强(见图2(b)),但取向密度较高的组分为(001)[1

15]组分较强,取向密度为6.18;与轧向成45?角的试样,{001}áuv0?丝最强(见图2(b)),但取向密度较高的组分为(001)[1![]() 0]和(001)[

0]和(001)[![]()

![]() 0],密度为13.613。γ-丝和{332}áuvw?织构较弱,γ-丝织构中的强点为(111)[1

0],密度为13.613。γ-丝和{332}áuvw?织构较弱,γ-丝织构中的强点为(111)[1![]() 2]组分,取向密度为9.98,{332}áuvw?织构中的(332)[3

2]组分,取向密度为9.98,{332}áuvw?织构中的(332)[3![]() 6]组分取向密度为5.72;沿横向,{001}áuv0?仍为最强织构,最强组分为(001)[0

6]组分取向密度为5.72;沿横向,{001}áuv0?仍为最强织构,最强组分为(001)[0![]() 0](见图2(c)),取向密度值达19.907。γ-丝和{332}áuvw?织构仍较弱,γ-丝织构从(111)[1

0](见图2(c)),取向密度值达19.907。γ-丝和{332}áuvw?织构仍较弱,γ-丝织构从(111)[1![]() 0]到(111)[

0]到(111)[![]()

![]() 5],强点在(111)[1

5],强点在(111)[1![]() 2]组分,取向密度为11.33,{332}áuvw?织构中的(332)[12

2]组分,取向密度为11.33,{332}áuvw?织构中的(332)[12![]()

![]() 3]组分较强,取向密度为5.41。

3]组分较强,取向密度为5.41。

因此,热轧板材的织构主要为{001}áuv0?和{111}áuvw?丝织构。沿轧向,{001}áuv0?丝织构中的强点向{001}á010?组分靠近,{111}áuvw?丝织构中的强点为{111}á112?和{111}á165?组分;沿横向,强点为{001}á010?和{111}á132?;45?角方向,{001}á110?和{111}á132?组分较强。

文献[5, 8, 10]研究表明,在TiNi合金中,无论是B2相的变形还是再结晶织构主要为á110?‖RD和{111}‖ND丝,鲜见产生{001}áuv0?丝织构的研究报道。但在Ni47Ti44Nb9热轧板中{001}áuv0?织构还很强。这种织构产生的原因还有待研究。对热轧板材继续冷轧+中间退火,{001}áuv0?丝织构逐渐消失,{111}áuvw?丝织构明显增强(见图2(d)),这表明{001}áuv0?丝织构并不稳定。

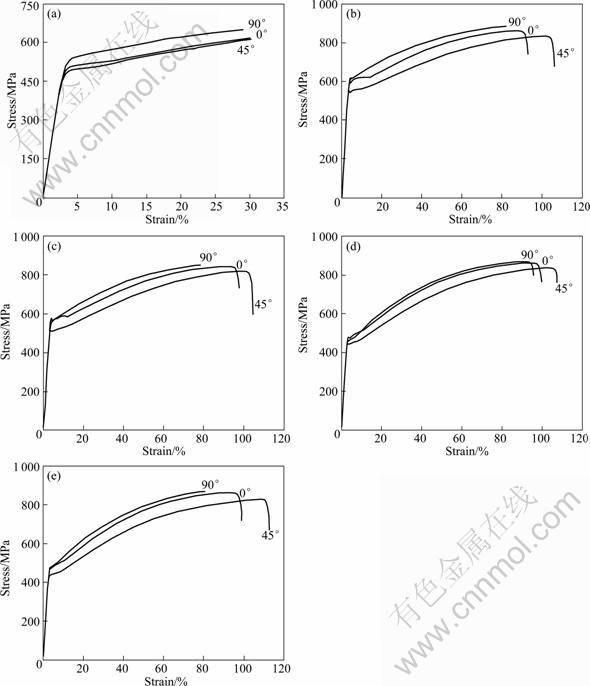

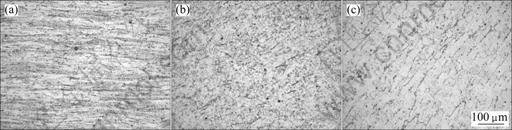

图3所示为不同热处理制度下,与轧向成不同角度试样的室温拉伸应力—应变曲线。沿轧向和横向拉伸,未出现明显的应力诱发马氏体再取向应力平台,沿45?角方向,应力平台明显(见图3(a));热处理后沿轧向拉伸,应力平台显著,尤其是退火试样(见图3(b)和(c))。 测得的室温拉伸性能见表1。由表1可知:1) 在850 ℃下,沿不同方向拉伸,退火试样的应力诱发马氏体临界应力最高,应力值在510~580 MPa,空冷(AC)与水淬(WQ)试样的临界应力较低,小于480 MPa。这是因为在退火过程中,第二相β-Nb的析出提高了母相强度,导致临界应力提高。2) 与850 ℃退火相比,600 ℃退火时的应力诱发马氏体临界应力提高,在550~615 MPa,这主要与晶粒细化有关。600 ℃时,再结晶刚结束,晶粒尺寸细小(见图4(b)),温度升到850 ℃,再结晶形成的细小晶粒长大(见图4(c)),降低了母相强度,导致临界应力下降。3) 不同热处理条件下,热轧板材的应力诱发马氏体临界应力沿轧向最高,横向次之,与轧向成45?角方向最低,而沿此方向的伸长率最高,横向伸长率最低。

文献[13-14]报道,在拉伸应力作用下,á001?取向为硬取向,á110?取向为软取向。热轧板材沿轧向、45?角和横向织构中都包括{001}á010?组分。该组分沿轧向和横向为最强,而沿45?角方向,最强的组分靠近{001}á010?。因此,导致热轧板材沿轧向和横向拉伸,应力诱发马氏体再取向平台不明显,沿45?角方向比较明显;经过600、850 ℃热处理后,由于再结晶导致原有织构组分减弱,甚至出现一些新的织构组分[15],导致应力诱发马氏体再取向平台呈现,尤其沿轧向。但由于沿轧向大部分强织构组分都聚集在{001}á010?附近,导致该方向的临界应力最高。

表1 在不同处理条件下沿热轧板材的轧向、 45?角方向和横向室温拉伸性能

Table 1 Room temperature tensile properties of hot-rolled sheets tensioned along RD, 45? to RD and TD under different conditions

图3 在不同处理条件下沿热轧板材的轧向、 45?角方向和横向拉伸的室温应力—应变曲线

Fig.3 Room temperature stress—strain curves of hot-rolled sheets tensioned along RD, 45? to RD and TD under different conditions: (a) As-hot-rolled; (b) 600 ℃, 90 min, FC; (c) 850 ℃, 90 min, FC; (d) 850 ℃, 90min, AC; (e) 850 ℃, 90 min, WQ

图4 热轧Ni47Ti44Nb9合金板材在不同条件下轧面的金相组织

Fig.4 Microstructures of rolling plane in hot-rolled Ni47Ti44Nb9 sheets under different conditions: (a) As-hot-rolled; (b) 600℃, 90 min, FC; (c) 850 ℃, 90 min, FC

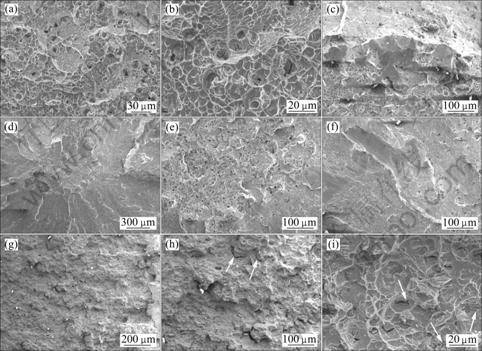

图5所示为热轧板材沿不同方向拉伸的断口形貌,所有拉伸样品的断口表面都垂直于拉伸轴且未发生颈缩。沿轧向,样品断口表面呈典型的韧窝形貌,在一些韧窝内存在孔洞(见图5(a))。在这些孔洞内分布着析出相,且大部分析出相已发生断裂(见图5(b))。在靠近中心局部区域,有明显的撕裂痕迹(见图5(c)),这表明接近中心区域是最后发生断裂的部位;沿45?角方向,除中心区域外,断口表面出现多个明显纤维区和放射区,且放射区占比例较大(见图5(d))。在纤维区,仍表现为由韧窝和一些韧窝内孔洞组成,而放射区内韧窝较浅且空洞很少(见图5(e))。 孔洞内仍分布着析出相,且一些析出相已发生断裂。在表面中心局部区域,即最后断裂区的撕裂痕迹更加明显(见图5(f));沿横向,断口表面非常平坦,韧窝也非常浅,且存在很多微裂纹(见图5(g)和(h)),韧窝内的很多析出相已发生破碎(见图5(i))。

因此,沿不同方向拉伸时,断裂都是由微孔聚集导致的。只不过沿45o角方向,微孔聚集区(即纤维区)作为裂纹源,随后,快速扩展形成放射区。而沿横向,很多微裂纹导致材料塑性下降,这与前面的拉伸性能结果一致,沿横向拉伸,伸长率最低。

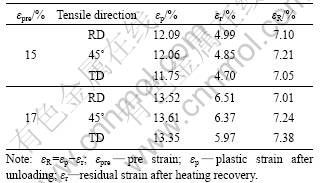

Ni47Ti44Nb9合金主要用来制备航空、航天等领域

的管接头或紧固件。在应用时,希望其强度适宜,既要满足使用性能又要方便管路连接过程中的操作。从表1可知,850 ℃退火试样的强度最适宜。因此,恢复应变只测试850℃退火试样的。在-65 ℃下进行15%、17%的预变形后,加热到240 ℃,从应变— 温度变化曲线测得的可恢复应变εr见表2。15%预变形后,沿45o角方向恢复应变最大,为7.21%。17%预变形时,沿横向恢复应变最大,为7.38%。但在不同预应变下,沿不同方向,可恢复应变基本在7.0%~7.4%。这可能是由于经850 ℃退火后,再结晶和再结晶后晶粒的长大,再加上β-Nb第二相的析出,导致织构对记忆应变影响不明显。

表2 在-65 ℃下沿不同方向预变形卸载后的恢复应变

Table 2 Recovery strains of specimens after pre-deforming along different directions at -65 ℃

图5 沿不同方向拉伸热轧板材的断口形貌

Fig.5 Fracture surfaces of hot-rolled sheets tensioned along different directions at room temperature: (a), (b), (c) 0?; (d), (e), (f) 45?; (g), (h), (i) 90? (arrows showing microcracks in Fig.5(h) and broken precipitates in Fig.5(i))

3 结论

1) 热轧板材中B2相的织构主要为{001}áuv0?和{111}áuvw?丝,但与轧向成不同角度,强织构组分不同。

2) 在相同热处理条件下,应力诱发马氏体临界应力沿轧向最高,与轧向成45?角方向最低,且在850 ℃下,临界应力随冷速的提高而下降。

3) 与轧向成不同角度拉伸的试样都表现为韧性断裂,但沿横向,断口表面存在很多微裂纹。

4) 850 ℃退火热轧板材在-65 ℃下,预变形到15%和17%后的恢复应变基本在7.0%~7.4%。

REFERENCES

[1] SABURI T, YOSHIDA M, NENNO S. Deformation behavior of shape memory Ti-Ni alloy crystals[J]. Scr Metall, 1984, 18: 363-366.

[2] BUCHHEIT T E, WERT J A. Predicting orientation-dependent stress-induced transformation and detwinning response of shape memory alloy single crystals[J]. Metall Mater Trans A, 1996, 27: 269-279.

[3] YUAN W Q, YI S. Pseudo-elastic strain estimation of textured TiNi shape memory alloys[J]. Mater Sci Eng A, 1999, 271: 439-448.

[4] INOUE H, MIWA N, INAKAZU N. Texture and shape memory strain in TiNi alloy sheets[J]. Acta Materialia, 1996, 44: 4825-4834.

[5] MIYAZAKI S, NO V H, KITAMURA K, KHANTACHAWANA A, HOSODA H. Texture of Ti-Ni rolled thin plate and sputter-deposited thin films[J]. Inter J Plasticity, 2000, 16: 1135-1154.

[6] MULDER J H, THOMA P E, BEYER J. Anisotropy of the shape memory effect in tension of cold-rolled 50.8Ti49.2Ni (at.%) sheet[J]. Z Metallkd, 1993, 84: 501-508.

[7] GALL K, LIM T J, MCDOWELL D L, SEHITOGLU H, CHUMLYAKOV Y I. The role of intergranular constraint on the stress-induced martensitic transformation in textured polycrystalline NiTi[J]. Inter J Plasticity, 2000, 16: 1189-1214.

[8] THAMBURAJA P, ANAND L. Polycrystalline shape-memory materials: Effect of crystallographic texture [J]. J Mech Phy Solids, 2001, 49: 709-737.

[9] LIU Y, XIE Z L, van HUMBEECK J, DELAEY L. Effect of texture orientation on the martensite deformation of NiTi shape memory sheet[J]. Acta Materialia, 1999, 47: 645-660.

[10] CHANG S H, WU S K. Textures in cold-rolled and annealed Ti50Ni50 shape memory alloy[J]. Scr Materialia, 2004, 50: 937-941.

[11] DALAY S, RAVICHANDRAN G, BHATTACHARYA K. Stress-induced martensitic phase transformation in thin sheets of nitinol alloys[J]. Acta Materialia, 2007, 55: 3593-3600.

[12] GAO S, YI S. Experimental study on the anisotropic behavior of textured NiTi pseudoelastic shape memory alloys[J]. Mater Sci Eng A, 2003, 362: 107-111.

[13] GALL K, SEHITOGLU H, CHUMLYAKOV Y, KIREEVA I V. Tension-compression asymmetry of the stress-strain response in aged single crystal and polycrystalline NiTi[J]. Acta Materialia, 1999, 47: 1203-1217.

[14] SEHITOGLU H, KARAMAN I, ANDERSON R, ZHANG X, GALL K, MAIER H J, CHUMLYAKOV Y. Compressive response of NiTi single crystals[J]. Acta Mater, 2000, 48: 3311-3326.

[15] 颜 莹, 金 伟, 曹名洲. Ni47Ti44Nb9形状记忆合金冷轧管材的组织、织构和相变[J]. 金属学报, 2008, 44(2): 139-144.

YAN Ying, JIN Wei, CAO Ming-zhou. Microstructure,texture and phase transformation of Ni47Ti44Nb9 shape memory alloy cold-rolled tube[J]. Acta Metallurgica Sinica, 2008, 44(2): 139-144.

基金项目:核燃料及材料国防科技重点实验室基金资助项目(51481130101ZK0601)

收稿日期:2009-08-27;修订日期:2010-01-02

通信作者:颜 莹,副教授,博士;电话:024-83688088;E-mail: yingyan@imp.neu.edu.cn