- Abstract:

- 1 Introduction▲

- 2 Experimental▲

- 3 Results and discussion▲

- 4 Conclusions▲

- References

- Figure

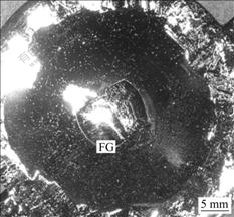

- Fig.1 Foreign grain on facet of 6H-SiC crystal

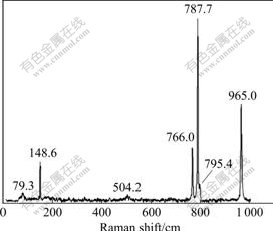

- Fig.2 Raman spectrum of foreign grain

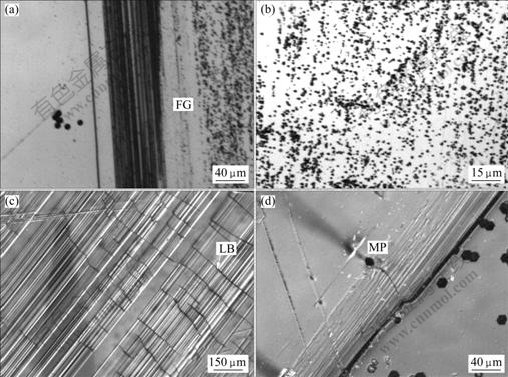

- Fig.3 Optical microphotographs of etched FG surfaces: (a) 6H-SiC (0001)-Si surface containing FG; (b) Etch pit morphology of FG surface; (c) Stacking faults and low angle grain boundaries (LB) morphology; (d) Micropipe (MP) containing tail of comet at edge of FG

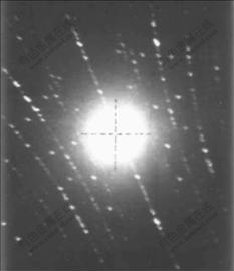

- Fig.4 Back scattering Laue pattern obtained from reflection of FG surface

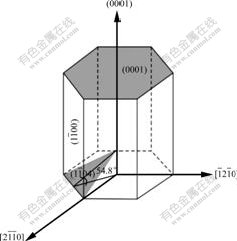

- Fig.5 Schematic representation of () plane and () plane (Inclination between () plane and (0001) plane is about 54.8?)

- Fig.6 Photograph of a longitudinal cut sample along [0001] direction

- Fig.7 X-ray powder diffraction patterns of two different powder sources: (a) Powder A; (b) Powder B

J. Cent. South Univ. Technol. (2009) 16: 0344-0348

DOI: 10.1007/s11771-009-0058-7

![]()

Characterization of foreign grain on 6H-SiC facet

WANG Ying-min(王英民), LI Juan(李 娟), NING Li-na(宁丽娜),

GAO Yu-qiang(高玉强), HU Xiao-bo(胡小波), XU Xian-gang(徐现刚)

(State Key Laboratory of Crystal Materials, Shandong University, Jinan 250100, China)

Abstract:

6H-SiC single crystals were grown by sublimation method. It is found that foreign grains occur frequently on the facets of the crystals. To characterize the foreign grain, a longitudinal and a sectional cut samples were prepared by standard mechanical processing method. Raman spectrum confirms that the foreign grain is actually a mis-oriented 6H-SiC grain. The surface structure of the foreign grain was studied by chemical etching and optical microscopy. It is shown that etch pits in foreign grain region take the shape of isosceles triangle, which are different from those in mono-crystalline region, and high density stacking faults are observed on the surface of the foreign grain. The orientation of foreign grain surface is determined to be (![]() ) plane by back-scattering X-ray Laue image. The X-ray powder diffraction reveals that the powder is partly graphitized after a long crystal growth run. Therefore it is believed that the loss of Si results in the formation of C inclusions, which is responsible for the nucleation of foreign grain in the facet region.

) plane by back-scattering X-ray Laue image. The X-ray powder diffraction reveals that the powder is partly graphitized after a long crystal growth run. Therefore it is believed that the loss of Si results in the formation of C inclusions, which is responsible for the nucleation of foreign grain in the facet region.

Key words:

6H-SiC; surface morphology; foreign grain; sublimation method;

1 Introduction

Silicon carbide has a wide bandgap, high breakdown electric field, high saturated electron drift velocity and high thermal conductivity. All these unique characteristics make it become the key material for high power, high temperature, high frequency electronic devices based on SiC and GaN [1-5]. But the application of the SiC semiconductor material is still limited due to the lack of high quality SiC single crystals. SiC single crystals are generally grown by sublimation method. In the procedure of crystal growth, the parameters, such as temperature, vapor compositions and pressure, could not be controlled precisely. Therefore, the growth procedure is not easily repeated and some defects such as micropipes, hexagonal voids, low angle grain boundaries, structure polytypes and stacking faults often appear in the crystals [6-10]. Despite the recent improvements concerning the reduction of these defects, the origin and control of some structural imperfections such as micropipe and foreign grain are still under discussion and are not fully understood. As for the foreign grain, TUOMINEN et al [11] reported that the misoriented region was formed due to large micropipes and growth spiral. But its polytype structure was not identified and the orientation of the grain was not determined.

In this work, the foreign grains (FGs) occurred on the facet of 6H-SiC boules were characterized. The crystallographic orientation of the FG was determined by the back-scattering X-ray Laue technique. In addition, the formation mechanism of the FG was studied.

2 Experimental

6H-SiC single crystals were grown by sublimation method in an argon atmosphere. The growth procedure was described in detail elsewhere [12-16]. It was found that the FG occurred frequently on facet. In multiple crystal growth runs, the FGs assumed the same regular shapes with different grain sizes. Here, a crystal ingot with a distinct FG was selected as the research object. A cross section sample cut from the ingot was prepared by a standard mechanical processing method. Then it was etched in a molten KOH solution at about 500 ℃. The etch pits were observed by optical microscopy. In order to understand the evolution of the FG following crystal growth, a longitudinal cut sample containing a FG was also prepared, and the FG evolution procedure could be observed directly by naked eyes due to its mis-oriented structure. The polytype of the FG was identified by micro-Raman spectroscopy and its crystallographic orientation was determined by the back-scattering X-ray Laue technique.

3 Results and discussion

Fig.1 shows the photograph of the FG on the facet

Fig.1 Foreign grain on facet of 6H-SiC crystal

of 6H-SiC crystal. As seen in Fig.1, the FG covers the most area of facet. According to the result of the Raman spectrum (Fig.2), the FG is identified to be 6H-SiC crystal, i.e. the FG is actually a mis-oriented 6H-SiC grain. This result is different from that obtained by CIECHONSKI et al [17] who thought that FG was a 4H-SiC grain.

Fig.3 shows the optical microphotographs of etched FG surfaces. In Fig.3(a), the boundary between the FG and the (0001) plane is clearly visible due to different etching rates for both planes. In FG region, there is a number of etch pits, whereas only a few etch pits appear in monocrystalline region. Fig.3(b) shows a magnified

Fig.2 Raman spectrum of foreign grain

image of FG region in which a great number of etch pits with the same shape can be distinctly identified. It should be noted that these etch pits in the FG region assume the shape of isosceles triangle, which are different from those in mono-crystalline region. This implies that the orientation of the FG deviates from (0001) plane. LI et al [18] obtained 6H-SiC using (![]() ) seed and observed the etch pits of (

) seed and observed the etch pits of (![]() ) wafer. Comparing the shapes of etch pits on (

) wafer. Comparing the shapes of etch pits on (![]() ) plane for their samples with those in FG region, it is found that both etch pits take the same shape. Therefore, it is deduced that the surface of the FG is probably the (

) plane for their samples with those in FG region, it is found that both etch pits take the same shape. Therefore, it is deduced that the surface of the FG is probably the (![]() ) plane.

) plane.

Fig.3 Optical microphotographs of etched FG surfaces: (a) 6H-SiC (0001)-Si surface containing FG; (b) Etch pit morphology of FG surface; (c) Stacking faults and low angle grain boundaries (LB) morphology; (d) Micropipe (MP) containing tail of comet at edge of FG

Besides the etch pits, high density stacking faults are also observed at the periphery of FG surface, as shown in Fig.3(c). As well known, the formation possibilities of stacking faults in SiC single crystals are closely related to seed orientation [19]. In general, the single crystal grown along [![]() ] direction contains a large number of stacking faults, whose density is at least 10 times higher than that of the crystal grown along [

] direction contains a large number of stacking faults, whose density is at least 10 times higher than that of the crystal grown along [![]() ] direction and 1×103 times higher than that of the crystal grown along [0001] direction [20]. Therefore, the occurrence of stacking faults in FG region indicates indirectly that the orientation of the FG deviates from the [0001] direction.

] direction and 1×103 times higher than that of the crystal grown along [0001] direction [20]. Therefore, the occurrence of stacking faults in FG region indicates indirectly that the orientation of the FG deviates from the [0001] direction.

Micropipe is a hollow tube penetrating through the entire SiC crystals along the [0001] c-axis, which often appears in the sublimation grown SiC crystals [21-23]. At the edge of the FG, etch pit from the outcrop of a micropipe on surface is observed, as shown in Fig.3(d). It can be seen that the shape of the etch pit in FG region is not a normal hexagon. Due to the high transparency of the crystal, we can see the trace of the micropipe in different depths of the crystal that looks like a tail of comet. This also illustrates that the surface of FG deviates from [0001] direction.

In order to determine the orientation of a FG surface, the back-scattering X-ray Laue image is taken, as shown in Fig.4. The surface of the FG is indexed to be (![]() ) plane, which is in agreement with our prediction above mentioned. The diffraction pattern is not so clear due to the structure defects in FG. Fig.5 shows a schematic drawing of the position of the (

) plane, which is in agreement with our prediction above mentioned. The diffraction pattern is not so clear due to the structure defects in FG. Fig.5 shows a schematic drawing of the position of the (![]() ) plane in respect to the (0001) and the (

) plane in respect to the (0001) and the (![]() ) planes. (

) planes. (![]() ) plane is inclined of about 54.8? in respect to the (0001) plane.

) plane is inclined of about 54.8? in respect to the (0001) plane.

In order to understand the evolution of growth interface and the formation mechanism of FG, the nitrogen

Fig.4 Back scattering Laue pattern obtained from reflection of FG surface

Fig.5 Schematic representation of (![]() ) plane and (

) plane and (![]() ) plane (Inclination between (

) plane (Inclination between (![]() ) plane and (0001) plane is about 54.8?)

) plane and (0001) plane is about 54.8?)

doped striation was introduced in the procedure of 6H-SiC crystal growth. Fig.6 shows the photograph of a longitudinal cut slice of 6H-SiC single crystal. From Fig.6, we can see that the FG nucleates nearly in the central point of the facet. Following the crystal growth run, the FG grows gradually into a larger grain and occupies a larger central area of the facet. If the influence of convection of vapor on the growth rate is neglected, the nitrogen doped striation can be treated approximately as the temperature isotherm except for the facet area. Therefore, we know that the temperature isotherm is convex, from the distribution of the nitrogen doped striation. In this case, the supercooling in the facet area is higher than that in the periphery area, and the peak of the supercooling is located in the center of the facet. Because the FG is rarely observed at the initial stage of crystal growth and often occurs after several ten hours growth run, we propose the possible formation mechanism of the FG in following paragraphs.

Fig.6 Photograph of a longitudinal cut sample along [0001] direction

In sublimated SiC gas, the main vapor species consist of Si, SiC2, Si2C, and SiC in which Si vapor has the highest equilibrium partial pressure [24]. Therefore, the species ratio in the vapor phase may change due to the relatively quick escape of Si vapor as soon as crystal growth starts.

Fig.7 shows X-ray powder diffraction patterns of two different powder sources. Powder A and powder B

Fig.7 X-ray powder diffraction patterns of two different powder sources: (a) Powder A; (b) Powder B

originate from the sources after growing for 5 and 80 h, respectively. From the X-ray diffraction pattern, we can see that only 6H-SiC is detected in powder A whereas powder B consists of 6H-SiC and carbon. This result illustrates that the SiC source is graphitized partly after long crystal growth run, which is in agreement with those from other research groups [25-28].

Now let us consider the chemical reaction occurred on the crystal-gas interface where SiC2 combines with Si to form SiC solid. In case of the loss of Si, the reaction cannot be fully completed and C particles are left on the interface. Due to the existence of C inclusions, the stability of crystal growth is disturbed. Sometimes, the step flow is interrupted, which results in the loss of the growth step information. Furthermore, the mis-oriented region is formed behind the C inclusion as observed by ROST et al [29]. Following the growth run, the mis-oriented region or foreign grain becomes larger. Because the central region of facet has the highest supercooling, the FG is easily nucleated in this region. The orientation of FG is probably random. However, the planes with the low surface energies appear preferentially because of the requirement of the lowest free energy for crystal growth. It is confirmed in our experiment that sometimes the surface of FG is (![]() ) plane.

) plane.

4 Conclusions

(1) The etch pits in FG region assume the shape of isosceles triangle, which are different from those in mono-crystalline region because the orientation of FG deviates from (0001) plane.

(2) The polytype of the FG is identified to be 6H-SiC by the Raman spectrum.

(3) The back-scattering X-ray Laue image confirms that the appearance face of the FG in our experiment is (![]() ) plane that is the low free energy plane in SiC crystal.

) plane that is the low free energy plane in SiC crystal.

(4) After long crystal growth run, the SiC source is partly graphitized. This results in the formation of the C inclusions, which is responsible for the formation of the FG in the facet region. Due to the requirement of the lowest free energy for crystal growth, sometimes (![]() ) plane appears in facet region as FG.

) plane appears in facet region as FG.

[1] OHTANI N, KATSUNO M, TSUGE H, FUJIMOTO T, NAKABAYASHI M, YASHIRO H, SAWAMURA M, AIGO T, HOSHINO T. Dislocation processes during SiC bulk crystal growth [J]. Microelectronic Engineering, 2006, 83: 42-145.

[2] PALMOUR J W. Energy efficiency: The commercial pull for SiC devices [J]. Mater Sci Forum, 2006, 527/529: 1129-1134.

[3] HANCOCK J M. SiC device applications: Identifying and developing commercial applications [J]. Mater Sci Forum, 2006, 527/529: 1135-1140.

[4] TOURNIER D, VELLVEHI M, GODIGNON P, MONTSERRAT J, PLANSON D, SARRUS F. Current sensing for SiC power devices [J]. Mater Sci Forum, 2006, 527/529: 1215-1218.

[5] PERLIN P, SWIETLIK T, MARONA L, CZERNECKI R, SUSKI T. Fabrication and properties of GaN-based lasers [J]. J Crystal Growth, 2008, 310: 3979-3982.

[6] HAN Rong-jiang, XU Xiang-gang, HU Xiao-bo, YU Nai-sen, WANG Ji-yang, TIAN Yu-lian, HUANG Wan-xia. Development of bulk SiC single crystal grown by physical vapor transport method [J]. Optical Materials, 2003, 23: 415-420.

[7] OHTANI N, FUJIMOTO T, KATSUNO M, AIGO T, YASHIRO H. Growth of large high-quality SiC single crystals [J]. J Crystal Growth, 2002, 237/239: 1180-1186.

[8] NAKAMURA D. Reduction of dislocation in the bulk growth of SiC crystals [J]. Mater Sci Forum, 2006, 527/529: 3-8.

[9] HUANG X R, BLACK D R, MACRANDER A T, MAJ J, CHEN Y, DUDLEY M. High-geometrical-resolution imaging of dislocation in SiC using monochromatic synchrotron topography [J]. Applied Physics Letters, 2007, 91: 231903-1-231903-3.

[10] CHEN Y, DUDLEY M, LIU K X, STAHLBUSH R E. Observations of the influence of threading dislocations on the recombination enhanced partial dislocation glide in 4H-silicon carbide epitaxial layers [J]. Applied Physics Letters, 2007, 90: 171930-1-171930-3.

[11] TUOMINEN M, YAKIMOVA R, VEHANEN A, JANZEN E. Defect origin and development in sublimation grown SiC boules [J]. Mater Sci Eng B, 1999, B57: 228-233.

[12] XU Xian-gang, HU Xiao-bo, WANG Ji-yang, JIANG Min-hua. Growth of mono-crystalline 6H-SiC with large diameter [J]. Journal of Synthetic Crystals, 2003, 32(5): 540-540. (in Chinese)

[13] HU Xiao-bo, XU Xian-gang, WANG Ji-yang, HAN Rong-jiang, DONG Jie, LI Xian-xiang, JIANG Min-hua. Growth and defects of 6H-SiC monocrystals [J]. J Chin Ceram Soc, 2004, 32: 248-254. (in Chinese)

[14] LI Xian-xiang, JIANG Shou-zhen, HU Xiao-bo, DONG Jie, LI Juan, CHEN Xiu-fang, WANG Li, XU Xian-gang, JIANG Min-hua. Polytype control in 6H-SiC grown via sublimation method [J]. Mater Sci Forum, 2006, 527/529: 95-98.

[15] WANG Ying-min, NING Li-na, CHEN Xiu-fang, PENG Yan, GAO Yu-qiang, HU Xiao-bo, XU Xian-gang, JIANG Min-hua. Growth of 3-inch 6H-SiC crystal [J]. Journal of Synthetic Crystals, 2007, 36(3): 238-239. (in Chinese)

[16] JIANG Shou-zhen, CHEN Xiu-fang, XU Xian-gang, HU Xiao-bo, NING Li-na, WANG Ying-min, LI Juan, JIANG Min-hua. Optical absorption measurements on nitrogen-doped 6H-SiC single crystals [J]. J Struct Chem, 2007, 26(10): 1171-1174.

[17] CIECHONSKI R R, SYV?J?RVI M, UL-HASSAN J, YAKIMOVA R. Structure instabilities in growth of SiC crystals [J]. J Crystal Growth, 2005, 275: e461-e466.

[18] LI J, FILIP O, EPELBAUM B M, XU X, BICKERMANN M, WINNACKER A. Growth of 4H-SiC on rhombohedral (![]() ) plane seeds [J]. J Crystal Growth, 2007, 308: 41-49.

) plane seeds [J]. J Crystal Growth, 2007, 308: 41-49.

[19] SICHE D, ALBRECHT M, DOERSCHEL J, IRMSCHER K, ROST H J, ROBBERG M, SCHULZ D. Effect of nitrogen doping on the formation of planar defect in 4H-SiC [J]. Materials Science Forum, 2005, 483/485: 39-42.

[20] TAKAHASHI J, OHTANI N, KATSUNO M, SHINOYAMA S. Sublimation growth of 6H- and 4H-SiC single crystals in the [![]() ] and [

] and [![]() ] directions [J]. J Crystal Growth, 1997, 181: 229-240.

] directions [J]. J Crystal Growth, 1997, 181: 229-240.

[21] DUDLEY M, HUANG X R, HUANG W, POWELL A, WANG S, NEUDECK P, SKOWRONSKI M. The mechanism of micropipe nucleation at inclusions in silicon carbide [J]. Applied Physics Letters, 1999, 75(6): 784-786.

[22] MAHAJAN S. Origins of micropipes in SiC crystals [J]. Applied Physics Letters, 2002, 80(23): 4321-4323.

[23] HUANG X R, DUDLEY M, VETTER W M, HUANG W, WANG S. Direct evidence of micropipe-related pure superscrew dislocations in SiC [J]. Applied Physics Letters, 1999, 74(3): 353-355.

[24] GARCON I, ROUAULT A, ANIKIN M, JAUSSAUD C, MADAR R. Study of SiC single-crystal sublimation growth conditions [J]. Mater Sci Eng B, 1995, B29: 90-93.

[25] WELLMANN P J, HOFMANN D, KADINSHI L, SELDER M, STRAUBINGER T L, WINNACKER A. Impact of SiC source material on temperature field and vapor transport during SiC PVT crystal growth process [J]. Mater Sci Forum, 2001, 353/356: 11-14.

[26] HOFMANN D, BICKERMANN M, ECKSTEIN R, KOLBL M, MULLER S G, SCHMITT E, WEBER A, WINNACKER A. Sublimation growth of silicon carbide bulk crystals: Experimental and theoretical studies on defect formation and growth rate augmentation [J]. J Crystal Growth, 1999, 198/199: 1005-1010.

[27] KARPOV D S, BORD O V, KARPOV S Y, ZHMAKIN A I, RAMM M S, MAKAROV Y N. Mass transport and powder source evolution in sublimation growth of SiC bulk crystals [J]. Mater Sci Forum, 2001, 353/356: 37-40.

[28] MULLER S G, FRICKE J, HOFMANN D, HORN R, NILSSON O, REXER B. Experimental and theoretical analysis of the thermal conductivity of SiC powder as source material for SiC bulk growth [J]. Mater Sci Forum, 2000, 338/342: 43-46.

[29] ROST H J, DOLLE J, DOERSCHEL J, SICHE D, SCHULZ D, WOLLWEBER J. Growth related distribution of secondary phase inclusions in 6H-SiC single crystals [J]. J Crystal Growth, 2001, 225: 317-321.

(Edited by CHEN Wei-ping)

Foundation item: Projects(2006AA03A145, 2007AA03Z405) supported by the National High-Tech Research and Development Program of China; Projects(50721002, 50802053) supported by the National Natural Science Foundation of China; Project (707039) supported by the Cultivation Fund of the Key Scientific and Technical Innovation Project, Ministry of Education of China

Received date: 2008-09-22; Accepted date: 2008-11-06

Corresponding author: HU Xiao-bo, Professor; PhD; Tel: +86-531-88366329; E-mail: xbhu@sdu.edu.cn

- Characterization of foreign grain on 6H-SiC facet