文章编号:1004-0609(2015)-01-0086-12

碳纳米管增强镁基复合材料弹性模量的研究进展

袁秋红1,曾效舒1,刘 勇1,周国华2,罗 雷1,吴俊斌1

(1. 南昌大学 机电工程学院,南昌 330031;

2. 宜春学院 物理科学与工程技术学院,宜春 336000)

摘 要:

为满足结构件对高弹性模量镁基复合材料的需求,寻找理想的增强相和探索适合的复合工艺是镁基复合材料的发展趋势,向镁合金中添加碳纳米管(Carbon nanotubes,CNTs)增强相,具有强化细晶、应力转移、位错和热残余应力等作用,有利于改善镁合金强度和弹性模量等力学性能。从CNTs增强镁基复合材料制备工艺以及CNTs对复合材料弹性模量的影响等方面,详细地介绍了近年来CNTs增强镁基复合材料弹性模量的研究进展,并对未来研究方向提出若干建议。

关键词:

中图分类号:TG146.2+2;TB333 文献标志码:A

Research progress of elastic modulus of magnesium matrix composite reinforced by carbon nanotubes

YUAN Qiu-hong1, ZENG Xiao-shu1, LIU Yong1, ZHOU Guo-hua2, LUO Lei1, WU Jun-bin1

(1. College of Mechatronics Engineering, Nanchang University, Nanchang 330031, China;

2. College of Physical Science and Technology, Yichun University, Yichun 336000, China)

Abstract: In order to meet the demand for structural parts with high elastic modulus of magnesium matrix composites, the key point is to find the ideal reinforcement and explore the suitable processing. The addition of carbon nanotubes(CNTs) in magnesium alloy can strength the fine-grained, stress transfer, dislocation and thermal residual stress, which is prefer to improve the tensile strength, elastic modulus and other mechanical properties of magnesium alloy. The research progress of magnesium matrix composite reinforced with CNTs was introduced based on the preparation technology of magnesium matrix composite by CNTs. The effects of CNTs on the elastic modulus of composite were specially focused. Furthermore, some research trends were also suggested.

Key words: carbon nanotube; magnesium alloy; composite; elastic modulus

镁基复合材料具有密度小、强度高和热稳定性好等一系列优点,在汽车、航空航天、国防军工、3C产品等领域具有广泛的应用前景[1-4]。然而,目前镁基复合材料低弹性模量严重制约其作为结构材料的广泛应用。为满足结构件对高弹性模量镁基复合材料的需求,寻求理想的增强相,探索适合的制备工艺是镁基复合材料的发展趋势。CNTs弹性模量极高(E=0.4~4.5TPa,平均值1.8TPa[5])且热稳定性好[6],将其加入镁合金中,具有强化细晶、应力转移、位错和热残余应力等作用[4, 7],有利于改善镁合金强度和弹性模量等力学性能,是提高镁基复合材料弹性模量理想的增强相[8-9]。目前,有关CNTs增强镁基复合材料力学性能方面的研究主要集中在强度、硬度、耐磨性能和塑性等方面[10-19],而涉及弹性模量方面的研究还比较少,CNTs增强镁基复合材料弹性模量的机理研究也远不够。本文作者从CNTs/镁基复合材料制备工艺,CNTs对复合材料弹性模量的影响等方面入手,介绍近年来CNTs增强镁基复合材料弹性模量的研究现状,分析其中存在的关键问题,指出了制备高弹性模量CNTs/镁基复合材料的发展方向。

1 CNTs增强镁基复合材料的制备工艺

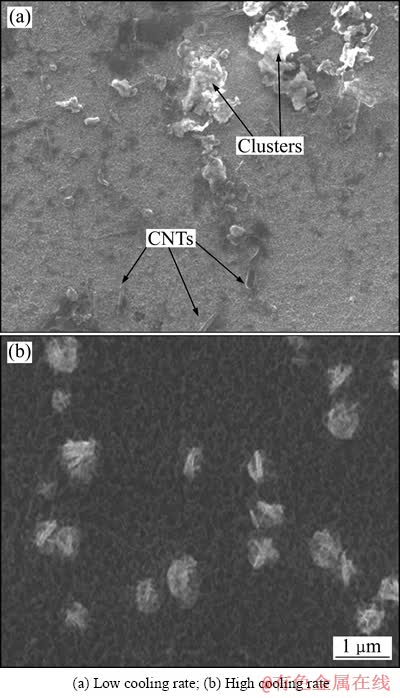

CNTs表面能高和比表面积大的特点[20-21]使其极容易团聚,因此,要制备高性能CNTs/镁基复合材料需解决以下3个问题:1) CNTs在基体中均匀分散性问题[22-23];2) 降低CNTs的表面能,提高与基体的界面结合强度[24-26];3) 在复合材料制备过程中,如何保持基体中CNTs的结构完整性[27-28]。目前,围绕以上问题衍生出来的制备工艺主要有铸造法[10, 29](搅拌铸造法和熔体浸渗法等)和粉末冶金[17]两类。搅拌铸造法因工艺简单、成本低而广泛应用于复合材料的制备[30]。然而,单独的搅拌铸造工艺往往难以制备出CNTs分散性较好的复合材料,通常需增添一些新的处理工艺加以改进,如LI等[31]将CNTs与镁合金熔体搅拌和超声分散后,通过提高熔体的凝固速率,改善了CNTs在基体中的分散性。图1所示为凝固速率对CNTs分散性的影响。由图1可看出,凝固速率慢时,CNTs容易被凝固界面推向晶界处而聚集,造成晶界处CNTs团聚较严重(见图1(a));凝固速率快时,固液界面的快速推进使CNTs有利于被凝固的晶粒捕获而均匀地分布于晶粒内(见图1(b))。曾效舒等[32]将金属粉与CNTs球磨混合均匀后加压成型制得CNTs/金属复合压块;然后将CNTs/金属复合压块添加到金属或合金液中制备复合材料;该工艺在一定程度上解决了铸造法CNTs添加难、分散难的问题,且工艺简单、成本低,具有工业化应用前景。此外,对CNTs进行表面改性处理(如CNTs表面包覆镍[33]、SiO2[34]、TiO2[35]等)后,探索与之相匹配的铸造工艺是目前该领域的研究重点之一。

粉末冶金法[16, 36]由于增强体和基体的比例易于调整和控制,且组织均匀、致密性好等优点同样受到了广泛的关注。球磨分散与液态分散是目前粉末冶金中使用最多的分散手段,但都存在不足。球磨法能起到较好的分散效果,但球磨过程中碳纳米管易损伤,从而影响了其增强效果[37]。液态分散法通常是将CNTs加入有机溶剂中先超声分散后,再加入镁合金粉进行机械搅拌分散或超声分散,其缺点是当停止搅拌后两者易分层而难以获得稳定的分散效果[38],CNTs强化作用同样不明显。此外,采用粉末冶金工艺制备的CNTs/镁基复合材料,CNTs多分布于晶界处,难于融入晶粒内部的特点,使CNTs应力转移强化、位错强化和热残余应力强化等作用难以充分体现,复合材料弹性模量整体偏低。

图1 凝固速率对碳纳米管分散性的影响[31]

Fig. 1 Effect of solidification rate on dispersion of CNTs[31]

如何更好地解决CNTs分散性、界面结合质量和保持其在基体中的结构完整性这三大难题,依然是未来探索高弹性模量CNTs/镁基复合材料制备工艺领域的研究热门。以现有工艺为基础探索新的CNTs分散和复合工艺(如CNTs表面改性处理[39-40]、预分散处理[13]等)来改善CNTs的分散性及界面结合质量是目前开发高弹性模量CNTs/镁基复合材料的发展趋势,也是目前CNTs/镁基复合材料制备工艺领域研究的热点之一。

2 CNTs对镁基复合材料弹性模量的影响

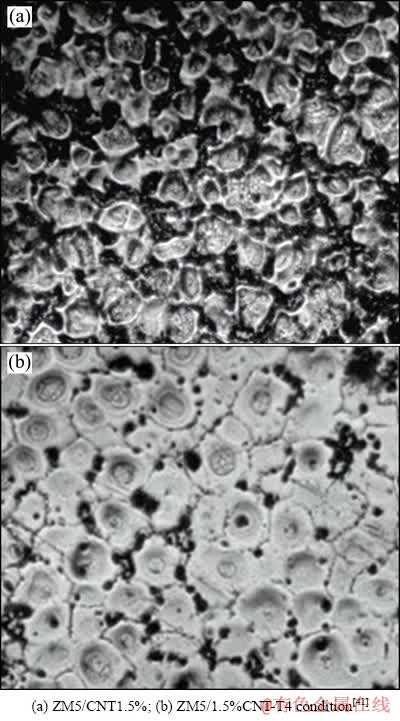

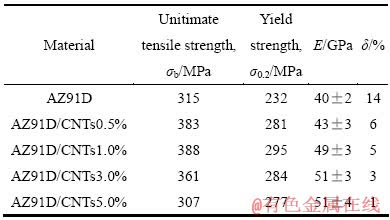

要获得高弹性模量CNTs/镁基复合材料,制备工艺极其重要。如何改善CNTs在基体中分散性,是其中的一个难点。近十年来,引起了广泛的关注,如姚孝寒等[41]采用搅拌铸造法,在较高的速搅拌速度下(1200 r/min),向ZM5镁合金熔体中加入少量CNTs(小于1.5%(质量分数))后,浇铸(温度为700 ℃)制得ZM5/CNTs复合材料,但所得复合材料弹性模量普遍较低,最大也只有47.6 GPa。从金相组织中可发现,晶界处有许多黑色夹杂物(见图2(a)),固溶处理后更明显(见图2(b)),经证实这些黑色物为CNTs团聚引入的夹杂。由此可见,单独提高搅拌速率不但难以改善CNTs的分散性还容易将气体带入镁熔体中,增加了夹杂几率,而且复合材料弹性模量普遍较低。LIU等[42]降低了搅拌速率,即以300~500 r/min搅拌速率加入CNTs后,再导入超声进一步分散(将直径为40 mm的变幅杆插入熔体35 mm后,以20 kHz频率超声分散15 min)后,采用浇铸和挤压工艺制得CNTs分散性好,弹性模量较高的AZ91D/CNTs1.5%复合材料(弹性模量为64.3 GPa,比基体的提高了45.1%(见表1))。低速搅拌分散有利于CNTs与镁熔体形成宏观上的均匀分散,超声与挤压工艺则有利于CNTs形成微观上的均匀分散,两种分散工艺的综合效应极大地改善了CNTs在镁熔体中的分散性,复合材料弹性模量增幅较大。

图2 ZM5/CNT1.5%复合材料金相组织[41]

Fig. 2 Microstructures of ZM5/CNT1.5% composite[41]

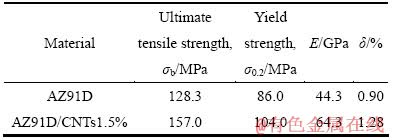

表1 铸态AZ91D和AZ91D/CNTs1.5%复合材料力学性能[42]

Table 1 Mechanical properties of as-cast AZ91D and AZ91D/ CNTs1.5% composite [42]

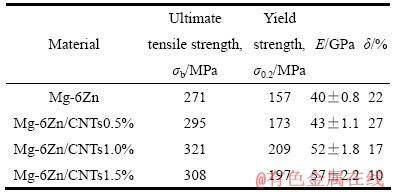

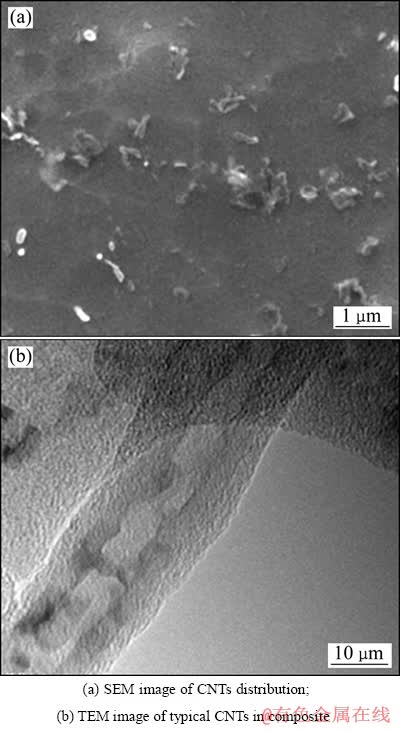

增加分散力度可以获得较好的分散效果,LI等[43]整合了液态分散技术、搅拌分散技术和超声分散技术,获得了较好的分散效果。具体工艺如下。1) CNTs预分散处理:将分散剂TNADIS和CNTs(TNADIS与CNTs质量比为1:8)溶入酒精溶液中,常温下超声分散15 min和机械搅拌30 min(搅拌速度为250 r/min)后,添加300 g镁屑,持续搅拌(速度不变)直到酒精挥发完全得到碳纳米管镁屑混合物(在通风橱中操作有利酒精挥发);2) 熔炼:将640 g镁锭和60 g锌锭在CO2+SF6保护气氛下加热到720 ℃熔化,待温度降至600 ℃后,迅速将预处理过的CNTs镁屑混合物加入熔体中,搅拌分散10 min(搅拌速度为800~1200 r/min),随后升温至690 ℃超声分散20 min后(超声功率500 W)浇铸制得Mg-6Zn/CNTs复合材料试样;3) 热挤压:将浇铸试样切成d 60 mm×35 mm并在350 ℃温度下调质处理12 h后,挤压(挤压温度350℃,挤压比20:1)制得所需复合材料。该工艺制备的复合材料弹性模量最大值为59.2 GPa,比基体提升了48%(见表2)。经SEM和TEM等测试分析发现,CNTs在基体中不仅分布较均匀(见图3(a)),而且结构较完整(见图3(b))。将CNTs与镁屑混合后一起加入熔体中,在镁屑“载体”的作用下碳纳米管能较好的浸入熔体中,多次超声分散和搅拌分散改善了CNTs在基体中的分散性,加之基体中CNTs结构较完整,使CNTs更有利于发挥各种强化作用,复合材料弹性模量增幅较大。

表2 Mg-6Zn/CNTs复合材料的力学性能[43]

Table 2 Mechanical properties of Mg-6Zn/CNTs composite [43]

图3 CNTs增强镁基复合材料挤压态的显微组织[43]

Fig. 3 Microstructures of as-extruded Mg-based composites reinforced with CNTs[43]

球磨分散是另一条阳光之路。SHIMIZU等[2]改进了球磨方式,即先将直径为100 μm的镁粉球磨6 h变成颗粒细小的镁粉后,与5 μm长的CNTs球磨5 h进行混合,经真空热压烧结与热挤压成型制得AZ91D/CNTs复合材料。结果显示:复合材料弹性模量最大为55 GPa,比基体的提高了37.5%;当CNTs 含量分别为3.0%和5.0%时,复合材料弹性模量相差不大(在51 GPa左右波动)(见表3)。经SEM和TEM测试分析发现:当CNTs含量小于3.0%时,可以获得较好的分散效果;CNTs含量过多时,分散效果变差,特别是含量达到5.0%时,CNTs团聚现象较严重。镁粉颗粒细小有利于两者球磨均匀,真空热压烧结与热挤压工艺有利于制备出高致密度复合材料,但球磨工艺容易造成CNTs结构损伤,且粉末冶金法制备的复合材料中碳纳米管普遍分布于晶界附近,较难融于晶粒内部,虽然可以通过固溶处理来改善,但至今效果不佳。因此,该工艺需寻找一个平衡点,即在低程度或不破坏CNTs结构的前提下,获得最佳的分散效果。

表3 AZ91D/CNTs复合材料的力学性能[2]

Table 3 Mechanical properties of AZ91/CNTs composite[2]

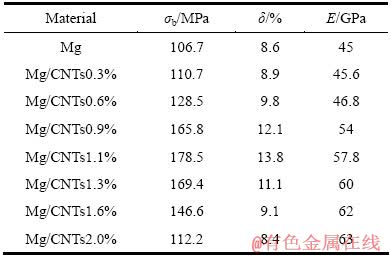

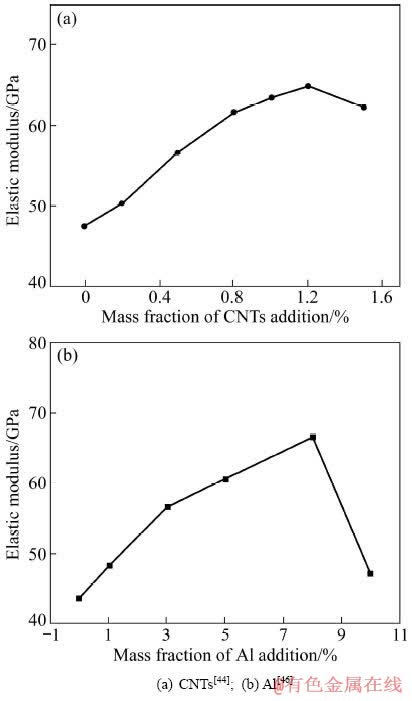

提高CNTs/镁基复合材料弹性模量和改善界面结合是另一个关键,在获得CNTs分散性好的前提下,界面结合质量极为重要。袁秋红[44]通过化学镀工艺在CNTs表面包覆一层镍后,采用搅拌分散法(搅拌速率为200 r/min,搅拌温度为605~610 ℃)加入CNTs后,真空吸铸制得包覆镍CNTs增强的AM60复合材料;得出了CNTs含量对复合材料弹性模量的影响规律;当CNTs含量为1.2%时,复合材料弹性模量最大为65.04GPa,比基体提高了36.44%(见图4(a))。研究认为:复合材料弹性模量的提高受益于化学包覆镍CNTs分散性的改善和界面结合强度的提高;当CNTs含量超过1.2%时,该工艺不仅难以将CNTs分散均匀,反而形成了夹杂,复合材料弹性模量变差。不足之处是未能从界面行为深入探讨复合材料弹性模量提升的增强机理。徐莺歌[45]采用浇铸法制得包覆镍CNTs增强的镁复合材料,提高了搅拌分散温度(710 ℃),也得到了相同的变化规律,但复合材料弹性模量最大值出现在CNTs含量为2.0%处(见表4)。包覆镍工艺改善了CNTs与基体的界面结合质量,CNTs能更好地承担外来载荷,使得基体分担的载荷得到很大程度的降低,应力转移强化作用明显,复合材料弹性模量大幅提高。从以上的工艺过程和结果说明,CNTs含量及其在基体中的分散性与界面结合强度是影响复合材料弹性模量的主要因素之一,后者提高了搅拌分散温度,降低了熔体的黏度,有利于改善CNTs的分散性,但同样也增加了CNTs被烧损的风险而降低了增强效果。此外,徐莺歌[45]采用相同工艺制备了AZ91D/CNTs+SiCp复合材料,当CNTs和SiCp含量分别是1.1%和3.0%时,复合材料弹性模量达到最大值70.8 GPa,比基体提高了57.3%。虽然同样未能从微观界面行为深入探讨CNTs的增强机理,但提供了一种新思路,即探索能与CNTs相搭配的多相混杂增强体系或许更易获得高弹性模量镁基复合材料。

表4 Mg/CNTs复合材料的力学性能[45]

Table 4 Mechanical properties of Mg/CNTs composite[45]

另外,复合材料弹性模量的提高与基体成分密切相关。周国华等[46]在确定了最佳CNTs含量后,从基体成分设计出发,通过调整Al含量,采用搅拌铸造工艺制备了1.0%CNTs/Mg-1Zn-0.25Mn-xAl (x=0,1,3,5,8,10;包覆镍CNTs)复合材料,得出了镁基复合材料弹性模量随Al含量的增加呈先增后降的变化规律。当Al含量为8.0%时,复合材料弹性模量最大为66.78 GPa,比基体的(43.85 GPa)提高了52.06%(见图4(b))。研究认为:高温条件下Al含量过多时(超过 8%),CNTs易被铝腐蚀(4Al+3C→Al4C3[47]),甚至造成CNTs结构的严重破坏,CNTs结构的破坏使其丧失了增强相的功能,复合材料弹性模量变差。由此可见,基体成分的不同不仅决定着自身的弹性模量,还影响着与CNTs的复合效果。

图4 CNTs[44]和铝[46]含量对CNTs/镁基复合材料弹性模量的影响

Fig. 4 Effects of CNTs[44] and Al[46] contents on elastic modulus of CNTs/magnesium matrix composite

综上可知,CNTs对镁基复合材料弹性模量影响的因素主要有:1) CNTs含量及其在基体中的分散性;2) CNTs与基体的界面结合质量;3) CNTs与镁合金基体成分的匹配性。

3 CNTs增强镁基复合材料弹性模量的理论模型

从细观力学角度出发,建立精准的CNTs/镁基复合材料弹性模量预测模型有助于探索CNTs提高镁基复合材料弹性模量的增强机理,有助于设计和开发高弹性模量CNTs/镁基复合材料。目前,用于预测CNTs/金属基复合材料弹性模量的理论模型主要有混合定律模型(ROM)、Halpin-Tsai模型、Cox模型、改进的Eshelby模型、Hashin-Shtrikman模型和Dispersion- Based模型等[48-51]。

为便于理解,下述模型中,E代表弹性模量;φ代表体积分数;ε代表体积模量;μ代表刚度模量;ν为泊松比,下标m、f分别代表与基体和CNTs的相关参数。

1) 混合定律模型(ROM)

该模型假设CNTs平行、连续且均匀地分布于基体中,复合材料受载时,应力均匀地分布在CNTs和基体上,其表达式为[52]

当负载平行于CNTs长度方向时:

(1)

(1)

当负载垂直于CNTs长度方向时:

(2)

(2)

但该模型计算值与实验值偏差很大,其原因是复合材料受载时,载荷要有效地传递到细小的CNTs上过于理想化,因此,改进的混合定律模型中引入了一个载荷传递有效因子η(通常取值为1/5),其解析表达式为

(3)

(3)

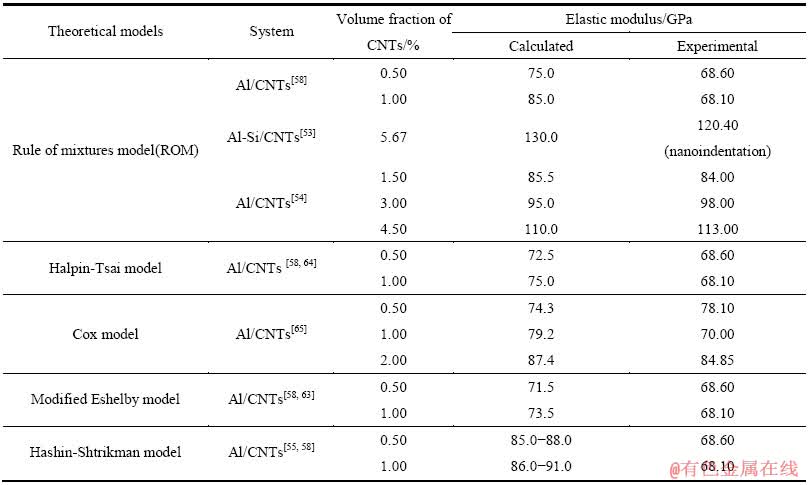

LAHA等[53]采用该模型预测出Al-23%Si-10% CNTs复合材料弹性模量值为130 GPa,其理论值比实验值120.4 GPa稍大(见表8),原因是计算过程中未考虑复合材料在成型过程中缩孔缩松带来的影响。CHOI等[54]采用球磨和热挤压工艺制备了分散性和致密性更好的CNTs/Al基复合材料,经测试复合材料弹性模量与该模型载荷传递有效因子η取1时(η取1/5时误差很大)的计算结果非常接近(弹性模量计算值与理论值见表8),说明载荷传递有效因子η与CNTs在基体中的分散性和复合材料的致密性有一定关系。

2) Halpin-Tsai模型

Halpin和Tsai在Hill自洽模型基础上建立了Halpin-Tsai模型[55]。该模型考虑增强体几何形状(CNTs长径比)的变化对单向纤维增强的复合材料弹性模量的影响,且随着增强体几何形状从颗粒状向纤维状转变(长径比趋于无穷大),会导致相同增强体体积分数下复合材料弹性模量呈数量级的增加[56],其解析表达式为[57]

(4)

(4)

(5)

(5)

(6)

(6)

式中:l与D分别为CNTs长度和直径。

该模型理论计算值与BAKSHI等[58]采用冷喷涂工艺,选用不同长度和直径的CNTs制备的铝基复合材料弹性模量吻合的比较好(见表8)。

3) Cox模型

由于CNTs在基体中的分布方向是随机的,要使CNTs在基体中呈有序分布几乎不太可能,因此Cox引入CNTs分布的随机性,建立了Cox模型,其表达式为[59-61]:

(7)

(7)

(8)

(8)

(9)

(9)

式中:η0=1/5,s=2l/r。

CHOI等[54]采用粉末冶金法制备的CNTs/Al复合材料,在CNTs含量小于2%时,弹性模量实验值与计算值很接近(见表8);当CNTs含量更高时,其分散性变差,复合材料弹性模量理论值与实验值相差也变大。

4) 改进的Eshelby模型

该模型是以Eshelby等效夹杂理论为基础建立的[62],该模型只有当增强体长径比较小时才与实验值吻合较好。CHEN等[63]在该模型的基础上,结合CNTs体积含量与复合材料缩孔等因素导出了复合材料水平方向的弹性模量计算公式:

(10)

(10)

式中: 为水平方向基体泊松比;

为水平方向基体泊松比; 为表示水平方向碳纳米管泊松比。BAKSHI等[58]采用该模型计算了热喷涂成型的Al-CNTs复合材料弹性模量,计算值比实验值要高很多(见表8),其原因是CNTs与基体结合不牢固。

为表示水平方向碳纳米管泊松比。BAKSHI等[58]采用该模型计算了热喷涂成型的Al-CNTs复合材料弹性模量,计算值比实验值要高很多(见表8),其原因是CNTs与基体结合不牢固。

5) Hashin-Shtrikman模型

HASHIN等[51]以变分原理为基础建立了Hashin-Shtrikman模型。该模型可预测出复合材料弹性模量最小边界值和最大边界值;最小边界值对应于CNTs分布不均匀,复合材料各项异性较明显状态,最大边界值对应于CNTs均匀分布,复合材料各项同性状态。由于该模型计算得出的复合材料弹性模量上限值大部分都高于其它模型的计算值(见表8),因此,该模型常用来预测复合材料弹性模量极限值。

6) Dispersion-Based模型

在现有制备工艺中,CNTs团聚几乎不可避免的,尤其当CNTs含量较高时,团聚更为严重;然而,团聚的CNTs若与基体浸润性较好,仍然可以起到一定的增强作用。基于此,VILLORIA等[66]充分考虑了该因素的实际影响,建立了Dispersion-Based模型,该模型表达式为

(11)

(11)

式中:E11、k23、μ12、μ23和v12取决于复合材料属性,表达式分别为

(12)

(12)

(13)

(13)

表8 Al/CNTs复合材料弹性模量计算值与实验值对比[48]

Table 8 Comparison of experimental and calculated values of elastic modulus of Al/CNTs composites[48]

(14)

(14)

(15)

(15)

(16)

(16)

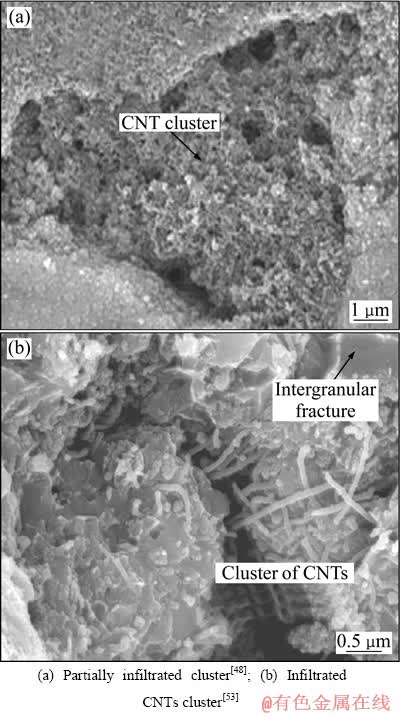

式中:φf为团聚CNTs体积分数,k为体积模量。该模型在预测CNTs/环氧树脂复合材料弹性模量时,计算值与实验值非常接近(如CNTs含量为0.1%和0.5%时,复合材料弹性模量计算值为2.924 GPa和2.686 GPa,实验值分别为2.909 GPa和2.659 GPa[66])。但用于预测CNTs/金属基复合材料弹性模量时,则需满足团聚的CNTs与金属液浸润性好、界面结合紧密,团聚的CNTs不会引入夹杂、缩孔等缺陷。该模型计算Al-12%Si/CNTs50%复合材料弹性模量为229 GPa,远高于实验值,其原因是所有团聚的CNTs都赋予了一定的强化作用,而实际工艺中添加如此多的CNTs,不但难以均匀分散,反而形成夹杂(如图5(a)箭头所指),两者的背道而驰致使理论与实验值相差悬殊;而图5(b)所示为Al-23%Si/CNTs10%复合材料断口形貌,形貌中同样可发现团聚的CNTs,但其浸润较好,界面结合较紧密,该复合材料弹性模量明显提高,为120.4 GPa,比基体提高了近78%,说明团聚的CNTs可以起到一定的增强效果,这与该模型中的假设条件相适应。

图5 Al-Si/CNTs复合材料SEM断口形貌[48,53]

Fig. 5 SEM images of fracture surface of Al-Si/CNTs composite

近年来,在以上理论模型基础上探索CNTs/镁基复合材料弹性模量理论模型受到越来越多的关注,如刘贵立等[67]在混合定律模型基础上建立了包覆铜碳纳米管增强镁基复合材料空间轴对称分析模型,并推导出了复合材料弹性模量临界计算公式:

(17)

(17)

式中:f为增强体体积分数;Ek为复合材料弹性模量临界值;Ef为表示增强基弹性模量;Em为基体弹性模量。经计算发现,较高的长径比可以提高复合材料整体弹性模量,长径比为45,整体弹性模量临界值为49 GPa。祝杰[68]在剪切模型基础上,将碳纳米管看作弹性柱壳增强体(长度为2l,外径为2a,外层有效厚度为δ),界面结合均视为理想界面的情况下,建立了碳纳米管代表性体积元的三相同轴柱壳模型,推出了CNTs/镁基复合材料弹性模量解析表达式:

(18)

(18)

(19)

(19)

(20)

(20)

(21)

(21)

(22)

(22)

(23)

(23)

(24)

(24)

(25)

(25)

(26)

(26)

(27)

(27)

(28)

(28)

(29)

(29)

式中:νf、νn、νm、Ef、En、Em分别为CNTs、界面层和镁基体的有效泊松比和弹性模量; 、

、 、

、 、q、D′、Dn、D11、D21、D22为镁基复合材料性能常数;βA为CNTs的横截面面积之比;R为单元体到管中心的距离;b为界面到管中心的距离。经该模型计算分析得出:CNTs/镁基复合材料界面层的泊松比和弹性模量较小时对复合材料弹性模量影响较大;界面层厚度决定了弹性模量的大小,这与实验中采用包覆镍处理后的CNTs因改善界面结合而能获得更高的弹性模量的结论相吻合[45]。此外,当CNTs体积分数超过4.0%时,复合材料弹性模量趋于一稳定值,CNTs含量与长度的变化对复合材料弹性模量的影响有限;该结论与SHIMIZU等[2]的实验结果,当CNTs体积分数超过3.0%时,复合材料弹性模量维持在51 GPa左右吻合的比较好。

、q、D′、Dn、D11、D21、D22为镁基复合材料性能常数;βA为CNTs的横截面面积之比;R为单元体到管中心的距离;b为界面到管中心的距离。经该模型计算分析得出:CNTs/镁基复合材料界面层的泊松比和弹性模量较小时对复合材料弹性模量影响较大;界面层厚度决定了弹性模量的大小,这与实验中采用包覆镍处理后的CNTs因改善界面结合而能获得更高的弹性模量的结论相吻合[45]。此外,当CNTs体积分数超过4.0%时,复合材料弹性模量趋于一稳定值,CNTs含量与长度的变化对复合材料弹性模量的影响有限;该结论与SHIMIZU等[2]的实验结果,当CNTs体积分数超过3.0%时,复合材料弹性模量维持在51 GPa左右吻合的比较好。

于超[69]利用复合材料应变能变化的方法建立了碳纳米管增强镁基复合材料的细观力学模型,并探索了CNTs长度和界面结合强度对复合材料有效弹性模量的影响。该模型假设基体和CNTs是均匀、连续和各向同性的材料;并假设被选取的整个单元在受载过程中,各部分粘结良好,无相对滑移,且不考虑泊松比效应;导出了有效弹性模量计算公式:

(30)

(30)

式中:Em为基体有效模量;ΔU1为复合材料应变能变化,σ为远场应力,φ为CNTs体积分数,D和L为单元体直径和长度。经该模型计算与分析得出:随CNTs长度的增大,复合材料的有效弹性模量也不断增加;CNTs与镁基体间的界面层对复合材料载荷传递起着关键作用,界面层对复合材料有效弹性模量有较大的影响。但该模型的计算结果与实验值相差较大,尤其是CNTs含量超过2.0%时,偏差越大(如对于软界面结合的短CNTs(长度30 nm),当含量为2.0%时,弹性模量为87.8 GPa,而含量增加到10.0%时,弹性模量为259.8 GPa)。该模型假设条件过于理想化是导致偏差过大的主要原因,在该模型的基础上结合实际工艺困难,引入一些影响因子或许可以得到与实际更接近的理论模型。

此外,ZHOU等[70]从分子动力学模型角度出发,研究了包覆镍处理后的CNTs与镁基体的界面结合微观行为,经计算发现,包覆镍后的CNTs与镁基体的界面结合强度远大于未包覆镍CNTs的界面结合强度,且包有双层镍原子的CNTs比单层镍原子的CNTs界面结合强度更高。就定性而言,该结论与目前的实验结果一致。

复合材料弹性模量预测是一个复杂的问题,它涉及到基体和增强相的性能、形状、分布以及界面间的相互作用和材料的微观结构等问题,对实验数据的依赖性也较强。很显然,CNTs/镁基复合材料弹性模量理论预测模型的研究还处于起步阶段,也是未来开发高弹性模量CNTs/镁基复合材料的研究热点之一。

4 结语

在碳纳米管增强镁基复合材料的开发和实际应用过程中,如何改善和提高复合材料的弹性模量,是目前最受关注的研究热点。其中,改善CNTs在基体中的分散性,提高CNTs与基体的界面结合,则是该领域最为关注的两个研究重点。目前,通过改进制备工艺等措施虽然取得了一定的进展,但仍有许多问题需进一步深入的研究。

1) 通过合金成分设计,探索与CNTs相匹配的镁基体合金。

2) 探索新的分散工艺,改善CNTs在镁合金基体中的分散性。

3) 探索新的CNTs表面改性工艺,提高CNTs与镁合金基体的界面结合质量。

4) 借鉴CNTs增强其它金属基复合材料弹性模量预测模型,建立和优化CNTs增强镁基复合材料弹性模量理论预测模型。

5) 探索CNTs与镁合金的反应条件,通过工艺控制实现CNTs与镁合金基体的轻微界面反应来提高界面结合质量,从而提升复合材料的弹性模量。

6) 探索与CNTs相匹配的增强相,制备多相混杂增强的镁基复合材料。

REFERENCES

[1] Morisada Y, Fujii H, Nagaoka T, Fukusumi T. MWCNTs/AZ31 surface composites fabricated by friction stir processing[J]. Materials Science and Engineering A, 2006, 419(1/2): 344-348.

[2] Shimizu Y, Miki S, Soga T, Itoh I, Todoroki H, Hosono T, Sakaki K. Multi-walled carbon nanotube-reinforced magnesium alloy composites[J]. Scripta Materialia, 2008, 58(4): 267-270.

[3] 陈亚光, 蔡晓兰, 王开军, 蒋太炜. 碳纳米管增强镁基复合材料的研究现状及发展[J]. 材料导报, 2012, 26(11): 110-112.

CHEN Ya-guang, CAI Xiao-lan, WANG Kai-jun, JIANG Tai-wei. Research progress in carbon nanotubes reinforced magnesium matrix composites[J]. Materials Review, 2012, 26(11): 110-112.

[4] 徐 强, 曾效舒, 周国华. 钟罩浸块铸造法制备的CNTs/AZ31镁基复合材料的力学性能[J]. 中国有色金属学报, 2010, 20(2): 189-194.

XU Qiang, ZENG Xiao-shu, ZHOU Guo-hua. Mechanical properties of CNTs/AZ31 composites prepared by adding CNTs block with plunger[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(2): 189-194.

[5] Treacy M, Ebbesen T, Gibson J. Exceptionally high Young's modulus observed for individual carbon nanotubes[J]. Nature, 1996, 381(6584): 678-680.

[6] 易国军, 陈小华, 蒋文忠, 张 刚, 陈传盛. 碳纳米管的表面改性与镍的包覆[J]. 中国有色金属学报, 2004, 14(3): 479-483.

YI Guo-jun, CHEN Xiao-hua, JIANG Wen-zhong, ZHANG Gang, CHEN Chuan-shen. Surface modification and nickel coating of carbon nanotubes[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(3): 479-483.

[7] 李维学, 祝 杰, 戴剑锋, 王 青. 碳纳米管增强镁基复合材料强化机制的解析法研究[J]. 材料导报, 2012, 26(4): 131-135.

LI Wei-xue, ZHU Jie, DAI Jian-feng, WANG Qing. An analytical solution for strengthening mechanisms of carbon nanotube reinforced magnesium matrix composite[J]. Materials Review, 2012, 26(4): 131-135.

[8] ZHOU S M, ZHANG X B, DING Z P, MIN C Y, XU G L, ZHU W M. Fabrication and tribological properties of carbon nanotubes reinforced Al composites prepared by pressureless infiltration technique[J]. Composites Part A: Applied Science and Manufacturing, 2007, 38(2): 301-306.

[9] Kuzumaki T, Miyazawa K, Ichinose H, Ito K. Processing of carbon nanotube reinforced aluminum composite[J]. Journal of Materials Reseach, 1998, 13(9): 2445-2449.

[10] ZENG X S, LIU Y,HUANG Q Y. Effects of carbon nanotubes on the microstructure and mechanical properties of the wrought Mg-2.0Zn alloy[J]. Materials Science and Engineering A, 2013, 571(13): 150-154.

[11] Goh C S, Wei J, Lee L C, Gupta M. Ductility improvement and fatigue studies in Mg-CNT nanocomposites[J]. Composites Science and Technology, 2008, 68(6): 1432-1439.

[12] LI Q, Viereckl A, Rottmair C A, Singer R F. Improved processing of carbon nanotube/magnesium alloy composites[J]. Composites Science and Technology, 2009, 69(7/8): 1193-1199.

[13] Kondoh K, Fukuda H, Umeda J, Imai H, Fugetsu B, Endo M. Microstructural and mechanical analysis of carbon nanotube reinforced magnesium alloy powder composites[J]. Materials Science and Engineering A, 2010, 527(16/17): 4103-4108.

[14] Paramsothy M, Tan X H, Chan J, Kwok R,Gupta H. Carbon nanotube addition to concentrated magnesium alloy AZ81: Enhanced ductility with occasional significant increase in strength[J]. Materials and Design, 2013, 45(3): 15-23.

[15] Srinivasan M, Loganathan C, Kamaraj M, NGUYEN, Q B, GUPTA, MNARAYANASAMY, R. Sliding wear behaviour of AZ31B magnesium alloy and nano-composite[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(1): 60-65.

[16] Fukuda H, Kondoh K, Umeda J, Fugetsu B. Interfacial analysis between Mg matrix and carbon nanotubes in Mg-6 wt.% Al alloy matrix composites reinforced with carbon nanotubes[J]. Composites Science and Technology, 2011, 71(5): 705-709.

[17] Fukuda H, Kondoh K, Umeda J, Fugetsu B. Fabrication of magnesium based composites reinforced with carbon nanotubes having superior mechanical properties[J]. Materials Chemistry and Physics, 2011, 127(3): 451-458.

[18] Fukuda H, Szpunar J A, Kondoh K, Chromik R. The influence of carbon nanotubes on the corrosion behaviour of AZ31B magnesium alloy[J]. Corrosion Science, 2010, 52(12): 3917-3923.

[19] AUNG N N, ZHOU W, GOH C S, NAI S M L, WEI J. Effect of carbon nanotubes on corrosion of Mg-CNT composites[J]. Corrosion Science, 2010, 52(5): 1551-1553.

[20] HWANG J Y, LIM B K, TILEY J, BANERJEE R, HONG S H. Interface analysis of ultra-high strength carbon nanotube/nickel composites processed by molecular level mixing[J]. Carbon, 2013, 57(6): 282-287.

[21] Cha S I, Kim K T, Arshad S N, Hong H S. Extraordinary strengthening effect of carbon nanotubes in metal-matrix nanocomposites processed by molecular-level mixing[J]. Advanced Materials, 2005, 17(11): 1377-1381.

[22] SUN F, SHI C, RHEE K Y, ZHAO N Q. In situ synthesis of CNTs in Mg powder at low temperature for fabricating reinforced Mg composites[J]. Journal of Alloys and Compounds, 2013, 551(25): 496-501.

[23] YOO S J, HAN S H, KIM W J. Magnesium matrix composites fabricated by using accumulative roll bonding of magnesium sheets coated with carbon-nanotube-containing aluminum powders[J]. Scripta Materialia, 2012, 67(2): 129-132.

[24] SO K P, JEONG J C, PARK J G, PARK H K, CHOI Y H, NOH D H, JEONG H Y, BIAWAS C D, HONG C H, LEE Y H. SiC formation on carbon nanotube surface for improving wettability with aluminum[J]. Composites Science and Technology, 2013, 74(24): 6-13.

[25] JEONG H Y, SO K P, BAE J J, CHAE S H, LY T H, KIM T H, KEUM D H, KIM C K, HWANG J S, CHOI Y J, LEE Y H. Tailoring oxidation of Al particles morphologically controlled bycarbon nanotubes[J]. Energy, 2013, 55(15): 1143-1151.

[26] FIROOZBAKHT M, MONIRVAGHEFI S M, NIROUMAND B. Electroless composite coating of Ni-P-carbon nanotubes on magnesium powder[J]. Journal of Alloys and Compounds, 2011, 509(S1): 496-502.

[27] 谷万里, 盛文斌. 碳纳米管在与铜粉混合球磨过程中的形态演化[J]. 中国有色金属学报, 2008, 18(9): 1674-1679.

GU Wan-li, SHEN Wen-bin. Morphology transformation of carbon nanotubes mixed with copper powder during mechanical ball milling process[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(9): 1674-1679.

[28] LIU Z Y, XU S J, XIAO B L, XUE P, WANG W G, MA Z Y. Effect of ball-milling time on mechanical properties of carbon nanotubes reinforced aluminum matrix composites[J]. Composites Part A: Applied Science and Manufacturing, 2012, 43(12): 2161-2168.

[29] LI Q, ROTTMAIR C A, SINGER R F. CNT reinforced light metal composites produced by melt stirring and by high pressure die casting[J]. Composites Science and Technology, 2010, 70(16): 2242-2247.

[30] ZENG X, ZHOU G, XU Q, XIONG Y J, LUO C, WU J C. A new technique for dispersion of carbon nanotube in a metal melt[J]. Materials Science and Engineering A, 2010, 527(20): 5335-5340.

[31] Li C D, Wang X J, Liu W Q, Shi H L, Ding C, Hu X S, Zheng M Y, Wu K. Effect of solidification on microstructures and mechanical properties of carbon nanotubes reinforced magnesium matrix composite[J]. Materials and Design, 2014, 58(7): 204-208.

[32] 曾效舒, 周国华, 徐 强, 朱 丹. 一种添加碳纳米管到金属熔体中的方法: 中国, 200910115456. 1[P]. 2009-10-28.

ZENG Xiao-shu, ZHOU Guo-hua, XU Qiang, ZHU Dan. A new technique for dispersion of carbon nanotube in a metal melt: China, 200910115456. 1[P]. 2009-10-28.

[33] 徐 强, 曾效舒, 徐耀勇, 袁秋红. 包覆镍CNTs/AM60复合材料铸态显微组织与力学性能[J]. 机械工程材料, 2009, 33(10): 53-56.

XU Qiang, ZENG Xiao-shu, XU Yao-yong, YUAN Qiu-hong. Microstructure and mechanical properites of carbon nanotubes coated by Ni/AM60 alloy composite[J]. Materials for Mechanical Engineering, 2009, 33(10): 53-56.

[34] CHUNG M, CHEN L, WANG W, LAI Y, YANG P F, LIN H P. Effects of mesoporous silica coated multi-wall carbon nanotubes on the mechanical and thermal properties of epoxy nanocomposites[EB/OL]. http://dx.doi.org/10.1016/j.jtice.2014. 05.009.

[35] ZHENG C, CHEN W, YE X. Study on Au nanoparticles, TiO2 nanoclusters, and SiO2 nanoshells coated multi-wall carbon nanotubes/silica gel-glass[J]. Optical Materials, 2012, 34(7): 1042-1047.

[36] KONDOH K, FUKUDA H, UMEDA J. Microstructural and mechanical behavior of multi-walled carbon nanotubes reinforced Al-Mg-Si alloy composites in aging treatment[J]. Carbon, 2014, 72: 15-21.

[37] Yoo S J, Han S H, Kim W J. Strength and strain hardening of aluminum matrix composites with randomly dispersed nanometer-length fragmented carbon nanotubes[J]. Scripta Materialia, 2013, 68(9): 711-714.

[38] Jiang L, Fan G, Li Z, Kai x h. An approach to the uniform dispersion of a high volume fraction of carbon nanotubes in aluminum powder[J]. Carbon, 2011, 49(6): 1965-1971.

[39] Lu D, Jiang Y, Zhou R. Wear performance of nano-Al2O3 particles and CNTs reinforced magnesium matrix composites by friction stir processing[J]. Wear, 2013, 305(1/2): 286-290.

[40] Park Y, Cho K, Park I, park y. Fabrication and mechanical properties of magnesium matrix composite reinforced with Si coated carbon nanotubes[J]. Procedia Engineering, 2011, 10(8): 1446-1450.

[41] 姚孝寒, 曾效舒, 戚道华. 镁合金(ZM5)/碳纳米管复合材料力学性能研究[J]. 南昌大学学报: 工科版, 2006, 28(2): 126-129.

YAO Xiao-han, ZENG Xiao-shu, QI Dao-hua. The research of mechanics properties of the magnesiumalloy (ZM5) /carbon nanotube composite material[J]. Journal of Nanchang University: Engineering & Technology, 2006, 28(2): 126-129.

[42] Liu S, Gao F, Zhang Q, zhou x, li w z. Fabrication of carbon nanotubes reinforced AZ91D composites by ultrasonic processing[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(7): 1222-1227.

[43] Li C D, Wang X J, Liu w q, wu k, shi h l. Microstructure and strengthening mechanism of carbon nanotubes reinforced magnesium matrix composite[J]. Materials Science and Engineering A, 2014, 5(3): 222-240.

[44] 袁秋红. 碳纳米管增强AM60镁基复合材料的研究[D]. 南昌: 南昌大学, 2008: 15-41.

YUAN Qiu-hong. The research of carbon nanotubes reinforeed AM60 magnesium matrix composites[D]. Nanchang: Nanchang University, 2008: 15-41.

[45] 徐莺歌. 碳纳米管增强镁基复合材料的力学性能研究[D]. 兰州: 兰州理工大学, 2010: 15-60.

XU Ying-ge. Study on the mechanical properties of magnesium matrix composites reinforced by carbon nanotubes[D]. Lanzhou: Lanzhou University of Technology, 2010: 15-60.

[46] 周国华, 曾效舒, 袁秋红. 铝含量对碳纳米管/镁基复合材料的影响[J]. 特种铸造及有色合金, 2008, 28(8): 635-637.

ZHOU Guo-hua, ZENG Xiao-shu, YUAN Qiu-hong. Effects of Al content on microstructure and properties of carbon nanotubes/magnesium matrix alloy composites[J]. Special Casting and Nonferrous Alloys, 2008, 28(8): 635-637.

[47] 刘 白, 邓福铭, 曲敬信. 碳纳米管增强铝基复合材料的设计与研究[J]. 兵器材料科学与工程, 2003, 26(6): 54-57.

LIU Bai, DENG Fu-ming, QU Jing-xin. Design and research of carbon nanotubes reinforced aluminum matrix composite[J]. Ordnance Material Science and Engineering, 2003, 26(6): 54-57.

[48] Agarwal A, Debrupa S r B. Carbon nanotubes reinforced metal matrix composites[M]. Boca Raton, U.S.: CRC Press, 2011: 170-181.

[49] 张 娟. 短纤维增强金属基复合材料热残余应力及其对力学行为的影响[D]. 成都: 西南交通大学, 2002: 10-41.

ZHANG Juan. Thermal residual stress in short fiber reinforced metal matrix composites and its effect on the mechanical behavior[D]. Chengdu: Southwest Jiao tong University, 2002: 10-41.

[50] Hill R. A. Self-consistent mechanics of composite materials[J]. Journal of the Mechanics and Physics of Solids, 1965, 13(4): 213-222.

[51] Hashin Z, Shtrikman S. A variational approach to the theory of the elastic behaviour of multiphase materials[J]. Journal of the Mechanics and Physics of Solids, 1963, 11(2): 127-140.

[52] Liu G R. A step-by-step method of rule-of-mixture of fiber-and particle-reinforced composite materials[J]. Composite Structures, 40(3/4): 313-322.

[53] Laha T, Chen Y, Lahiri D. Tensile properties of carbon nanotube reinforced aluminum nanocomposite fabricated by plasma spray forming[J]. Composites Part A: Applied Science and Manufacturing, 2009, 40(5): 589-594.

[54] Choi H, Shin J, min b, park j, bae d. Reinforcing effects of carbon nanotubes in structural aluminum matrix nanocomposites[J]. Journal of Materials Research, 2009, 26(9): 2610-2616.

[55] Hashin Z, strikman S. On some variational principles in anisotropic and nonhomogeneous elasticity[J]. J Mech Phys Solids, 1962, 10(6): 335-342.

[56] Halpin J C, Kardos J L. The Halpin-Tsai equations: A review[J]. Polymer Engineering and Science, 2004, 16(5): 344-352.

[57] Qian D, Dickey E C, Andrews R. Load transfer and deformation mechanisms in carbon nanotube-polysty-rene composites[J]. Applied Physics Letters, 2000, 76(20): 2868-2870.

[58] Bakshi S R, Singh V, Balani K. Carbon nanotube reinforced aluminum composite coating via cold spraying[J]. Surface and Coatings Technology, 2008, 202(21): 5162-5169.

[59] Cox H L. The elasticity and strength of paper and other fibrous objects[J]. British Journal of Applied physics 1952, 3(3): 72-79.

[60] Kelly A, Tyson W R. Tensile properties of fibre-reinforced metals: Copper/tungsten and copper/ molybdenum[J]. Journal of the Mechanics and Physics of Solids, 1965, 13(6): 329-350.

[61] Hill R. Theory of mechanical properties of fibre-strengthened materials: I. Elastic behaviour[J]. Journal of the Mechanics and Physics of Solids, 1964, 12(4): 199-212.

[62] Eshelby J D. The determination of the elastic field of an ellipsoidal inclusion, and related problems[J]. Proceedings of the Royal Society. Series A. Mathematical and Physical Sciences, 1957, 24(12): 376-396.

[63] Chen Y, Balani K, agarwal a. Modified Eshelby tensor modeling for elastic property prediction of carbon nanotube reinforced ceramic nanocomposites[J]. Applied Physics Letters, 2007, 9(3): 91-93.

[64] COLEMAN J N, KHAN U, BLAU W J, GUN K Y K. Small but strong: A review of the mechanical properties of carbon nanotube-polymer composites[J]. Carbon, 2006, 44(9): 1624-1652.

[65] George R, Kashyap K T, Rahul R. Strengthening in carbon nanotube/aluminium(CNT/Al) composites[J]. Scripta Materialia, 2005, 53(10): 1159-1163.

[66] GUZM N DE VILLORIA R, MIRAVETE A. Mechanical model to evaluate the effect of the dispersion in nanocomposites[J]. Acta Materialia, 2007, 55(9): 3025-3031.

N DE VILLORIA R, MIRAVETE A. Mechanical model to evaluate the effect of the dispersion in nanocomposites[J]. Acta Materialia, 2007, 55(9): 3025-3031.

[67] 刘贵立, 杨忠华, 栗 青. 碳纳米管增强镁基复合材料长径比对力学性能影响的有限元分析[J]. 科学技术与工程, 2010, 10(23): 5630-5633.

LIU Gui-li, YANG Zhou-hua, LI Qing. Finite element analysis of mechanics properties of aspect ratio of carbon nanotues reinforced magnesium matrix composite materia1[J]. Science Technology and Engineering, 2010, 10(23): 5630-5633.

[68] 祝 杰. 碳纳米管增强镁基复合材料细观力学分析[D]. 兰州: 兰州理工大学, 2011: 24-29.

ZHU Jie. Micromechanics analysis of carbon nanotube reinforced magnesium matrix composites[D]. Lanzhou: Lanzhou University of Technology, 2011: 24-29.

[69] 于 超. 碳纳米管增强镁基复合材料的力学性能分析[D]. 沈阳: 沈阳工业大学, 2013: 24-34.

YU Chao. The analysis of mechanical properties of the carbon nanotube reinforced magnesium matrix composite material[D]. Shenyang: Shenyang University of Technology, 2013: 24-34.

[70] 周 霞, 吴少华, 张仁杰. 镍涂层对碳纳米管/镁复合材料界面结合强度影响的分子动力学模拟[J]. 计算力学学报, 2013, 30(Z1): 54-57.

ZHOU Xia, WU Shao-hua, ZHANG Ren-jie. Mole cular simulation of the influence of nickel coating on the interfacial bonding strength of carbon nanotubel magnesium composites[J]. Chinese Journal of Computational Mechanics, 2013, 30(Z1): 54-57.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51464034);香江学者计划(XJ2012025);中国博士后科学基金资助项目(2012T50594,2014M551866);江西省博士后科研项目(2014KY11);江西省研究生创新专项资金项目(YC2014-B005);南昌市对外科技合作项目(2012-DWHZ-XCL@JDYTH-001);江西省教育厅科学基金资助项目(GJJ13069)

收稿日期:2014-05-25;修订日期:2014-09-22

通信作者:刘 勇,教授,博士;电话:0791-83969611;E-mail:liuyong@ncu.edu.cn

摘 要:为满足结构件对高弹性模量镁基复合材料的需求,寻找理想的增强相和探索适合的复合工艺是镁基复合材料的发展趋势,向镁合金中添加碳纳米管(Carbon nanotubes,CNTs)增强相,具有强化细晶、应力转移、位错和热残余应力等作用,有利于改善镁合金强度和弹性模量等力学性能。从CNTs增强镁基复合材料制备工艺以及CNTs对复合材料弹性模量的影响等方面,详细地介绍了近年来CNTs增强镁基复合材料弹性模量的研究进展,并对未来研究方向提出若干建议。

[3] 陈亚光, 蔡晓兰, 王开军, 蒋太炜. 碳纳米管增强镁基复合材料的研究现状及发展[J]. 材料导报, 2012, 26(11): 110-112.

[4] 徐 强, 曾效舒, 周国华. 钟罩浸块铸造法制备的CNTs/AZ31镁基复合材料的力学性能[J]. 中国有色金属学报, 2010, 20(2): 189-194.

[6] 易国军, 陈小华, 蒋文忠, 张 刚, 陈传盛. 碳纳米管的表面改性与镍的包覆[J]. 中国有色金属学报, 2004, 14(3): 479-483.

[7] 李维学, 祝 杰, 戴剑锋, 王 青. 碳纳米管增强镁基复合材料强化机制的解析法研究[J]. 材料导报, 2012, 26(4): 131-135.

[27] 谷万里, 盛文斌. 碳纳米管在与铜粉混合球磨过程中的形态演化[J]. 中国有色金属学报, 2008, 18(9): 1674-1679.

[32] 曾效舒, 周国华, 徐 强, 朱 丹. 一种添加碳纳米管到金属熔体中的方法: 中国, 200910115456. 1[P]. 2009-10-28.

[33] 徐 强, 曾效舒, 徐耀勇, 袁秋红. 包覆镍CNTs/AM60复合材料铸态显微组织与力学性能[J]. 机械工程材料, 2009, 33(10): 53-56.

[41] 姚孝寒, 曾效舒, 戚道华. 镁合金(ZM5)/碳纳米管复合材料力学性能研究[J]. 南昌大学学报: 工科版, 2006, 28(2): 126-129.

[44] 袁秋红. 碳纳米管增强AM60镁基复合材料的研究[D]. 南昌: 南昌大学, 2008: 15-41.

[45] 徐莺歌. 碳纳米管增强镁基复合材料的力学性能研究[D]. 兰州: 兰州理工大学, 2010: 15-60.

[46] 周国华, 曾效舒, 袁秋红. 铝含量对碳纳米管/镁基复合材料的影响[J]. 特种铸造及有色合金, 2008, 28(8): 635-637.

[47] 刘 白, 邓福铭, 曲敬信. 碳纳米管增强铝基复合材料的设计与研究[J]. 兵器材料科学与工程, 2003, 26(6): 54-57.

[49] 张 娟. 短纤维增强金属基复合材料热残余应力及其对力学行为的影响[D]. 成都: 西南交通大学, 2002: 10-41.

[67] 刘贵立, 杨忠华, 栗 青. 碳纳米管增强镁基复合材料长径比对力学性能影响的有限元分析[J]. 科学技术与工程, 2010, 10(23): 5630-5633.

[68] 祝 杰. 碳纳米管增强镁基复合材料细观力学分析[D]. 兰州: 兰州理工大学, 2011: 24-29.

[69] 于 超. 碳纳米管增强镁基复合材料的力学性能分析[D]. 沈阳: 沈阳工业大学, 2013: 24-34.

[70] 周 霞, 吴少华, 张仁杰. 镍涂层对碳纳米管/镁复合材料界面结合强度影响的分子动力学模拟[J]. 计算力学学报, 2013, 30(Z1): 54-57.