![]()

Trans. Nonferrous Met. Soc. China 22(2012) 1839-1848

Effects of second phases on mechanical properties and martensitic transformations of ECAPed TiNi and Ti-Mo based shape memory alloys

SONG Jie1, WANG Li-ming2, ZHANG Xiao-ning1, SUN Xiao-gang1,

JIANG Hong1, FAN Zhi-guo1, XIE Chao-ying1, WU M H3

1. State Key Laboratory of Metal Matrix Composites, School of Materials Science and Engineering,

Shanghai Jiao Tong University, Shanghai 200240, China;

2. Jiangsu Fasten Company Limited, Jiangying 214400, China;

3. Advanced Materials Technology, Edwards Life Sciences LLC, CA, USA

Received 10 November 2011; accepted 8 August 2012

Abstract:

TiNi and Ti-based shape memory alloys were processed by equal channel angular pressing (ECAP) at 673-773 K along Bc route to obtain ultrafine grains for increasing the strength of parent phase and improving the functional properties. The effects of both thermodynamically stable and metastable second phases on the mechanical properties and martensitic transformations of these alloys were investigated. It is found that thermodynamically stable Ti2Ni phase has no effect on martensitic transformation and superelasticity of Ti-rich TiNi alloy, thermodynamically stable α phase is harmful for ductility of Ti-Mo-Nb-V-Al alloy, but metastable Ti3Ni4 phase is effective for R phase transformation, martensitic transformation and superelasticity of Ni-rich TiNi alloy. The mechanisms of the second phases on the martensitic transformations and mechanical properties were discussed.

Key words:

TiNi alloy; Ti-Mo based shape memory alloy; equal channel angular pressing (ECAP); second phase; mechanical property;

1 Introduction

TiNi alloy with superior shape memory effect (SME) and superelastic properties has been used in diverse areas of applications. In order to extend its application scopes and improve its properties, equal channel angular pressing (ECAP) technique has been applied successfully to TiNi shape memory alloys, and the microstructure evolution, phase transformations and properties of TiNi alloy after ECAP have been investigated [1-6]. The ultra-fined grains, even nanostructured microstructure in TiNi alloys can be obtained after ECAP [1,2,5]. The martensitic transformation point (Ms) of TiNi alloys would decrease after process of ECAP [3-5], and mechanical properties, such as superelasticity, of TiNi alloy were improved [6]. As well known, martensitic transformation temperatures and functional properties of TiNi and Ti-Mo based shape memory alloys (SMA) are sensitive to alloy components. There are stable and metastable second phases for Ti-rich TiNi, Ni-rich TiNi or Ti-Mo based SMAs precipitated or redissolved during medium temperature thermomechanical process, which have strong effect on the matrix component contents, phase transformations and functional properties. The precipitation and redissolution behavior of these second phases during ECAP process and their effects, especially the second phase for Ti-rich TiNi alloy, are not quite clear yet. In this work, the effects of second phases on the R phase transformation and martensitic transformation and functional properties of both Ti-rich and Ni-rich TiNi alloys have been investigated.

It should be pointed out that high content of toxic Ni atoms in TiNi alloy brings constrain for its broadening medical application. Recently, Ni-free β-type titanium alloys with shape memory effect and superelasticity have attracted attention as promising functional materials for medical applications [7,8]. The superelasticity and shape memory effect of NiTi alloys are usually superior over that of the Ni-free β-type titanium alloys. Thermomechanical treatment is an effective way to improve the mechanical properties, shape memory effect and superelasticity of these alloys and the second phases have strong effect on the phase transformation behaviour and functional mechanical properties [7-9]. In order to explore a new way to enhance the functional mechanical properties of Ti-Mo based shape memory alloys, Ti-Mo based metastable β titanium alloy (Ti-9.8Mo-3.9Nb- 2V-3.1Al, mass fraction, %) has been processed by ECAP and the effects of both thermodynamically stable and metastable second phases during severe plastic deformation—ECAP process have been investigated in the present study.

2 Experimental

The initial hot forged Ti-50.9%Ni (mole fraction), Ti-50.7%Ni and Ti-50%Ni alloy rods, received from Jiangsu Fasten Company Limited, China, were annealed at 1023 K for 30 min (solution treatment), and cooled into water. Some solution treated samples were aged at 773 K, and then cooled into water. Ti-9.8Mo-3.9Nb- 2V-3.1Al (mass fraction, %) metastable β titanium alloy was received as hot rolled bars from Memry Corporation, USA. These as-received bars were solution treated at 1143 K for 1 h followed by quenching. The billets for ECAP treatment with a dimension of 10 mm×10 mm×120 mm were cut from the solution treated alloy bars. The ECAP processes were applied at 673-773 K along Bc route (the billets were rotated along clockwise direction, 90° between adjacent passes).

Specimens of 3 mm×0.8 mm×50 mm for tensile test were cut from these square bars. Tensile tests were carried out under a strain rate of 1.0×10-4 s-1. Strains were measured using a clip-on extensometer with a gauge length of 25 mm. Samples for DSC test and microstructure observation were cut from the longitudinal plane of billets parallel to the extruding direction. DSC tests were carried out at heating and cooling rates of 10 ℃/min to analyze the phase transformations behaviour. Specimens for microstructure observation were mounted, polished and then etched in a solution of water, nitric acid and hydrofluoric acid with a volume ratio of 80:15:5. Microstructures were examined by LeICA-MEF4M optical microscope and JEOL- JEM-2010 electron microscope (TEM) with an accelerating voltage of 200 kV. For TEM observation, thin foil samples were obtained by mechanical grinding to 50 μm thickness and twin jet electro polishing (5% perchloric acid, 35% butyl alcohol and 60% methyl alcohol; 30V; 243 K). Phase constitution was identified by X-ray diffraction (XRD) with Cu Kα1 radiation, obtained from a tube operated at 200 mA, 40 kV. The scan speed was 5 (°)/s.

3 Results and discussion

3.1 Re-dissolution of metastable Ti3Ni4 precipitate during ECAP process

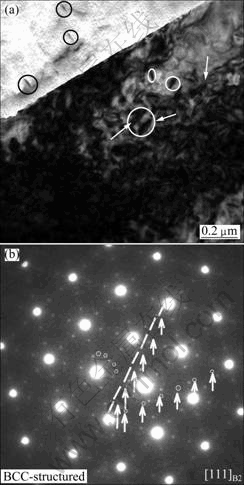

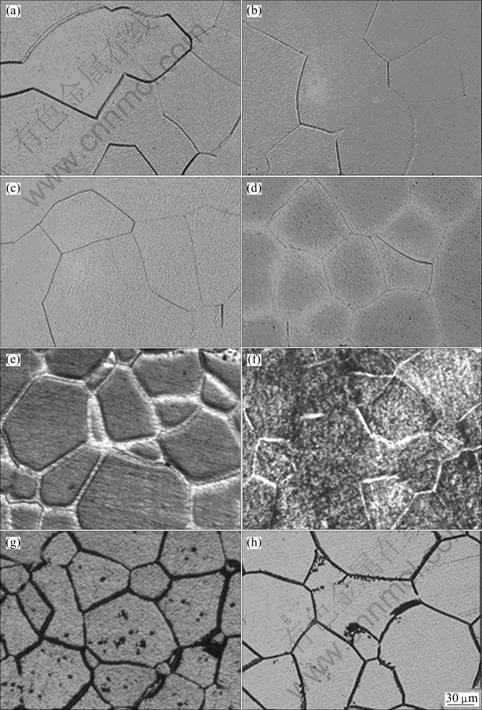

According to Ti-Ni binary diagram, there is two- phase TiNi3 + TiNi equilibrium for Ni-rich TiNi alloy. However, there is only metastable second phase Ti3Ni4 precipitated during aging at a temperature lower than 873 K for less than 2 h for near equal atomic Ni-rich TiNi alloys solution treated [10]. The microstructure of Ti-50.7%Ni alloy solution treated and aged at 773 K for 20 min is shown in Fig. 1. The Ti3Ni4 precipitates are observed in the aged specimen and the SEAD pattern obtained with a zone axis of [111]B2 is shown in Fig. 1(b), where the typical 1/7(123)B2 spots for Ti3Ni4 are marked with white arrows.

Fig. 1 Microstructures of Ti-50.7% Ni alloys solution-treated followed by aging at 773 K for 60 min: (a) Bright field image; (b) SAED pattern obtained from cycle area in Fig. 1(a) with zone axis of [111]B2

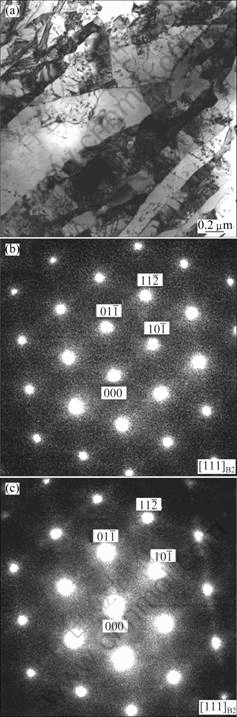

There are few Ti3Ni4 precipitates observed in Ni- rich Ti-50.7%Ni alloy after one pass of ECAP, as shown in Fig. 2, and a few Ti3Ni4 precipitates can be observed only in the regions of subgrain boundaries of Ti-50.9%Ni alloy after eight passes of ECAP treatment. The SAED pattern is inconspicuous, as shown in Fig. 3, which reveals that a re-dissolving of Ti3Ni4 precipitates occurred during medium temperature ECAP treatment.

Fig. 2 Morphology of Ti-50.7% Ni alloy after one ECAP pass: (a) Bright field image; (b, c) SAED patterns taken from Fig. 2(a)

It is seen from Fig. 3(a) that there is a complex structure containing dislocations and grain boundaries decorated with Ti3Ni4 precipitates after the ECAP treatments [4]. Ti3Ni4 precipitate re-dissolving has obvious effect on the subsequent martensite transformations. The re-dissolving of Ti3Ni4 increases the Ni content in the matrix, which can lead to the decrease of the temperature of the martensite transformation after the ECAP treatment [3-5].

Fig. 3 Morphology of Ti-50.9%Ni alloy after the eighth ECAP pass at 773 K by BC path: (a) Bright field image; (b) SAED pattern from region A in Fig. 3(a) with zone of [111]B2; (c) SAED pattern from region B in Fig. 3(a) with zone of [111]B2 (Ref. [4])

It has been reported that precipitated second phase can re-dissolve after severe plastic deformation [11-14]. XU et al [15,16] studied Al-4.11%Cu alloy and discovered that thermodynamically metastable θ' phase precipitated before ECAP almost re-dissolved after ECAP treatment, and the mechanisms of the strain- induced dissolution of precipitates were suggested. The microstructural changes of an aged Al-1.7%Cu alloy associated with severe plastic deformation have been studied, which showed that θ′ precipitates were almost completely dissolved after eight passes of ECAP. In the present study, the re-dissolution of Ti3Ni4 phase would attribute to lots of dislocation caused by severe plastic deformation (ECAP) providing more positions for the Ni atom dissolution and the activity of Ni atom at medium temperature (773 K) [3,4].

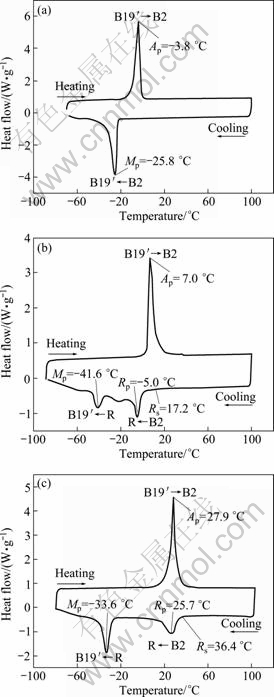

3.2 Phase transformations of ECAPed Ni-rich TiNi alloys

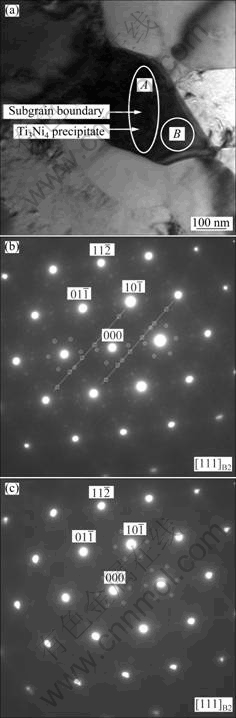

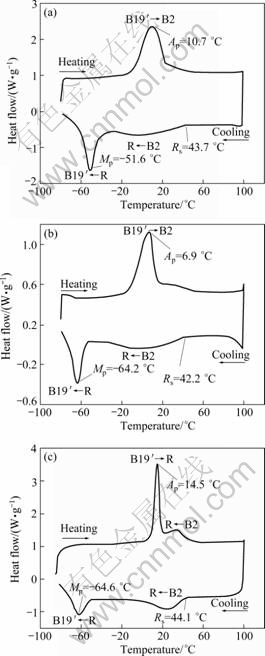

There are three phase transformations related to TiNi shape memory alloys upon cooling or heating in near equal atomic TiNi alloys: the B2→B19′, B2→R and R→B19′ transformations [17]. The DSC curves of Ni-rich Ti-50.7%Ni alloy solution treated and aged at 773 K are shown in Fig. 4. It is seen from Fig. 4(a) that there is only B2→B19′ transformation occurring on the cooling curve of solution treated sample. After aging at 773 K for 20 min, the alloy underwent two-step transformations B2→R→B19′ upon cooling, as seen in Fig. 4(b), and the martensitic transformation temperature (Mp) was slightly decreased compared with the solution treated sample. The R phase is associated with the precipitation of Ti3Ni4 phase, which is interpreted in Ref. [17].

DSC curves of Ti-50.7%Ni alloy processed by ECAP at 773 K are shown in Fig. 5. After one pass of ECAP, the martensitic transformation temperature (Mp) drops a lot, as shown in Fig. 5(a), and the B2→R transformation is observed upon cooling, but occurs within large temperature range, in contrast to the one solution treated and aged at 773 K (Fig. 4(b)). The Mp is gradually reduced with the increase of ECAP passes. It is noticed that after eight passes of ECAP, the reverse phase transformations undergo two-step B19′→R→B2 transformations on heating.

When specimens after one pass of ECAP process were aged at 773 K for 15 min, the sharp and clear B2→R transformation curves can be seen in a narrow temperature range, as shown in Fig. 4(c), which is almost the same as that of solution treated and aged specimen (Fig. 4(b)). Furthermore, the martensitic transformation temperature (Mp), R-phase transformation temperature (Rp), austenitic transformation temperature (Ap) of aged TiNi specimens were not changed along with the ECAP treatment [3]. These results reveal that the sharp and clear B2→R transformations are attributed to the fine and dense lens-like shape Ti3Ni4 phase precipitates formed during aging treatment.

Fig. 4 DSC curves of Ti-50.7%Ni alloy: (a) Solution-treated; (b) Aged at 773 K for 20 min; (c) One ECAP pass +(773 K, 15 min) (Ref. [3])

The broad and smooth B2→R phase transformation is obviously not induced by Ti3Ni4 precipitation in the ECAPed TiNi specimens, because there is a re-dissolution of Ti3Ni4 and few Ti3Ni4 precipitate (as shown in Fig. 2). It is reasonably suggested that the broad and smooth B2→R phase transformation originates from the refined grains and energy accumulation after ECAP treatments. Because the initial grains are refined dramatically after ECAP treatment, the fraction of grain boundary is largely increased and lots of defects such as dislocations are introduced into the grain interior. Extrusion force makes some dislocations slip and pile up around grain boundary. These excessive grain boundaries and dislocations in the grain interior and exterior probably stimulate the B2→R transformation, as well as suppress the R→B19′ transformation and lead to the drop of Mp. Another reason may be that ECAE process usually leads to nonuniform microstructure, which creates local stress fields for inducing the B2→R transformation, but they act as a resistance to R→B19′ transformation. These remaining Ti3Ni4 precipitates, as seen in Fig. 3, would serve as the nucleation sites of the R phase transformation and the presence of Ti3Ni4 in the B2 matrix favours the B2→R transformation.

Fig. 5 DSC curves of Ti-50.7%Ni alloy processed by ECAP at 773 K: (a) One ECAP pass; (b) 4 ECAP passes; (c) 8 ECAP passes (Ref. [3])

ECAP has advantage in achieving the bulk materials with uniform ultra-fine grains. In this study, the coarse grains of Ti-50.9%Ni alloy decreased from ~70 μm to 300-400 nm after 8 passes of ECAP, and the volume fraction of the grain boundaries increased relatively. All could be attributed to the continuous dynamic recovery/recrystallization during ECAP treatments. The refined submicron grains and microstructures also have a notable effect on the thermo-mechanical properties of the present Ti–50.9%Ni alloy [18]. These geometrical constraints including the submicron grains and the high density grain boundaries would lead to the transformation barrier and change the martensite morphology in the TiNi alloys with ultra-fine grains. They also could bring about the change of the thermal stability and martensite transformation path [19]. Thus, the reduction of martensitic phase transformation temperatures happened. When the martensite transformation was depressed, the sequence B2→ R→B19′ in nanostructure TiNi alloys was not observed, only a single B2→R transition could be observed in the nanocrystalline alloy [1,3].

3.3 Effect of stable TiNi2 phase

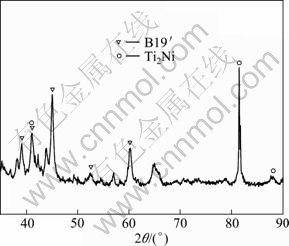

The XRD pattern of Ti-50%Ni alloy is shown in Fig. 6. There are some Ti2Ni diffraction peaks and basically B19′ diffraction peaks, which imply that the microstructure of Ti-50%Ni alloy is dual phase (B19′+Ti2Ni). Ti2Ni is a stable phase in thermodynamics.

Fig. 6 XRD pattern of solution treated Ti-50%Ni alloy

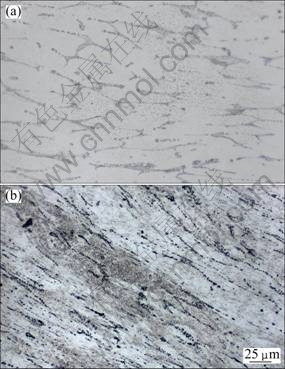

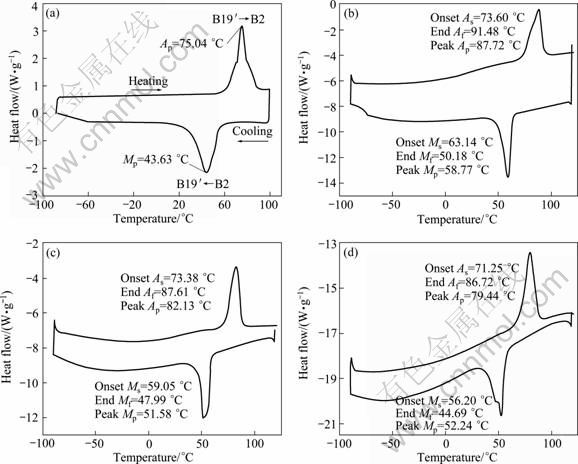

The microstructures of Ti-50%Ni alloy solution treated and after four ECAP passes are shown in Fig. 7. It is seen that severe plastic deformation occurred after four passes of ECAP process. The DSC curves of solution treated, aged and ECAPed Ti-50%Ni alloy are shown in Fig. 8. There is only B2→B19′ transformation and no B2→R transformation during cooling. There is no obvious change of martensitic transformation temperature (Mp) after aging or one pass or even four passes of ECAP treatment, which is different from those of Ti-50.7%Ni alloy (Figs. 4 and 5). These results reveal that stable Ti2Ni phase does not re-dissolve as the metastable phase Ti3Ni4 during medium temperature ECAP process or aging treatment. Aging and ECAP treatment do not affect the phase transformation behaviour of Ti-50%Ni alloy, since there is little change in Ni content of matrix.

3.4 Cycle tensile curves of TiNi alloys

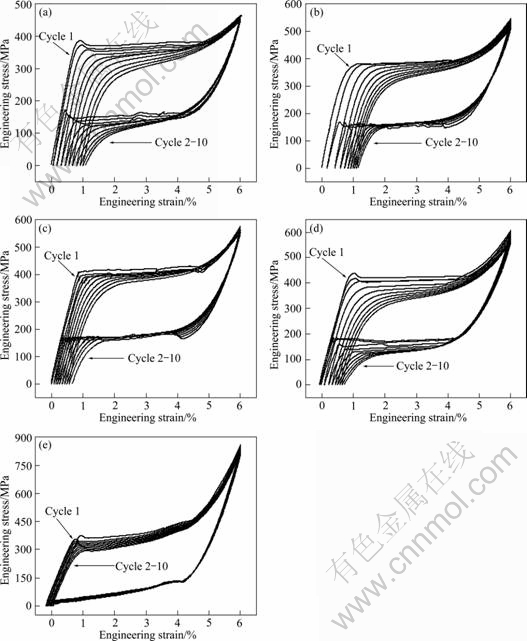

Cycle tensile curves of Ti-50.9%Ni alloy after ECAP process are shown in Fig. 9. The remaining strain decreases along with the ECAP process. A completely recoverable strain of 6% is obtained after 8 passes of ECAP process (Fig. 9(e)). However, there are little changes in the tensile curves of Ti-50%Ni alloy after ECAP process, except for a decrease of yield stress, as shown in Fig. 10, which reveals the critic stress for re-orientation of martensite variants decreases along with the ECAP treatment. The shape recovery property was not measured.

Fig. 7 TEM images showing microstructures of Ti-50%Ni alloy: (a) Solution treated; (b) 4 passes ECAPed

Fig. 8 DSC curves of Ti-50%Ni alloy: (a) Solution treated; (b) Solution treated+773 K aged for 30 min; (c) 1 pass ECAPed; (d) 4 passes ECAPed

Fig. 9 Tensile cycling loading-unloading curves of Ti-50.9%Ni alloy with different ECAP treatments in constant tensile strain of 6% at room temperature: (a) 1 pass of ECAP; (b) 2 passes of ECAP; (c) 3 passes of ECAP; (d) 4 passes of ECAP; (e) 8 passes of ECAP (Ref. [6])

Fig. 10 Mechanical behavior of solution treated and ECAP Ti-rich Ti-50% Ni alloy: (a) Solution treated; (b) 1 pass ECAPed; (c) 4 passes ECAPed

3.5 Effect of stable α-phase on Ti-Mo based shape memory alloy

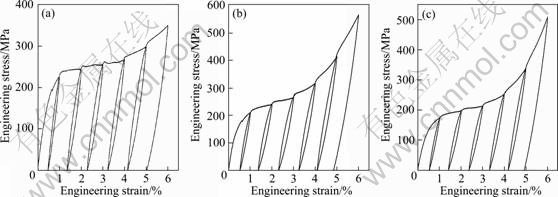

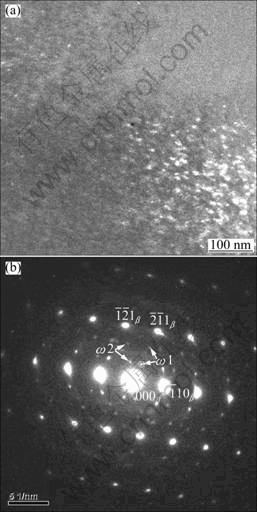

Figure 11 shows the optical micrographs of solution treated and aged Ti-9.8Mo-3.9Nb-2V-3.1Al alloy. The solution-treated specimen is single β phase. As the aging temperature increases to 673 K, very fine precipitates appear in grains, as seen in Fig. 11(d). As the aging temperature increases to 773 K, lots of fine α-phase distribute inside the grains homogeneously [13], as shown in Fig. 11(f). After aging at 673 K for 30 min, some fine isothermal ωiso phases with ellipsoidal-like precipitate shown in Fig. 12.

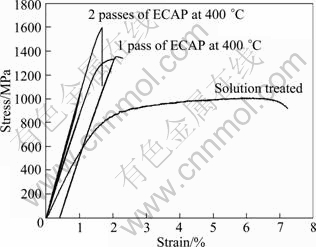

The strength of Ti-9.8Mo-3.9Nb-2V-3.1Al alloy increases sharply after ECAP process as shown in Fig. 13. However, the plasticity decreases dramatically, which can be attributed to the precipitation of α-phase and ωiso phase, which may be enhanced during ECAP treatment.

Fig. 11 Optical micrographs of solution treated Ti-9.8Mo-3.9Nb-2V-3.1Al metastable β titanium alloy (a) and aged at 573 K (b), 623 K (c), 673 K (d), 723 K (e), 773 K (f), 873 K (g) and 973 K (h)

Fig. 12 Dark field image (a) of ωiso phase in Ti-9.8Mo- 3.9Nb-2V-3.1Al alloy aged at 673 K for 30 min and SAED pattern (b)

Fig. 13 Stress—strain curves of Ti-9.8Mo-3.9Nb-2V-3.1Al alloy solution treated and ECAP processed at 673 K

After two passes of ECAP process, the plasticity is lost completely. The effects of α-phase and ωiso phase on the ECAP workability and mechanic property are still under investigation.

4 Conclusions

1) For Ni-rich TiNi alloy, there is re-dissolving of metastable Ti3Ni4 precipitates during ECAP process. After ECAP process, the B2→R transformation occurs in a broad temperature range. With increasing the passes, the martensitic transformation temperature decreases gradually.

2) For Ti-50%Ni alloy, equilibrium phase Ti2Ni does not re-dissolve during ECAP process and there is no B2→R transformation on the DSC curves. The cycle tensile curves change little after four passes of ECAP process.

3) For Ti-9.8Mo-3.9Nb-2V-3.1Al alloy, the plasticity decreases dramatically after one pass of ECAP at 673 K, because of dislocation accumulation and the ωiso phase and α-phase. After two passes of ECAP processes, the plasticity is lost completely.

References

[1] PUSHIN V G, STOLYAROV V V, VALIEV R Z, LOWE T C, ZHU Y T. Nanostructured TiNi-based shape memory alloys processed by severe plastic deformation [J]. Materials Science and Engineering A, 2005, 410-411: 386-389.

[2] FAN Z, XIE C. Shape memory behavior of Ti-50.9%Ni alloy after ECAE processes [J]. Materials Science Forum, 2007, 561-565: 2313-2316.

[3] FAN Z, XIE C. Phase transformation behaviors of Ti-50.9%Ni alloy after equal channel angular extrusion [J]. Materials Letters, 2008, 62(6-7): 800-803.

[4] ZHANG Xiao-ning, XIA Bao-yu, SONG Jie, CHEN Bin, TIAN Xiao-lin, HAO Ying-min, XIE Chao-ying. Effects of equal channel angular extrusion and aging treatment on R phase transformation behaviors and Ti3Ni4 precipitates of Ni-rich TiNi alloys [J]. Journal of Alloys and Compounds, 2011, 509: 6296-6301.

[5] ZHANG Xiao-ning, SONG Jie, XIE Chao-ying. Microstructures evolution and phase transformation behaviors of Ni-rich TiNi shape memory alloys after equal channel angular extrusion [J]. Journal of Alloys and Compounds, 2011, 509: 3006-3012.

[6] ZHANG Xiao-ning, SONG Jie, JIANG Hong, SUN Xiao-gang, XIE Chao-ying. Effects of ECAE and aging on phase transformations and superelasticity of a Ni-rich TiNi SMA [J]. Materials Science Forum 2011, 682: 185-191.

[7] ZHOU T, AINDOW M, ALPAY S P, BLACKBURN M J, WU M H. Pseudo-elastic deformation behavior in a Ti/Mo-based alloy [J]. Scripta Materialia, 2004, 50 (3): 343-348.

[8] KIM H Y, KIM J I, INAMURA T, HOSODA H, MIYAZAKI S. Effect of thermo-mechanical treatment on mechanical properties and shape memory behavior of Ti–(26–28)%Nb alloys [J]. Materials Science and Engineering A, 2006, 438-440(25): 839-843.

[9] SONG J, ZHANG X, SUN X, JIANG H, FAN Z, XIE C, WU M H. Effect of aging on superelastic behaviors of a metastable β Ti-Mo-based alloy [J]. Journal of Materials Engineering and Performance, 2012, 21(3): 366-372.

[10] XIE C Y, ZHAO L C, LEI T Q. Ti3Ni4 precipitation in Ti-51.8% shape memory alloy [J]. Acta Aeronautica et Astronautica Sinica, 1991, 12(7): 395-400. (in Chinese)

[11] HU N, XU X C, ZHANG Z Z, QU X. Effect of re-dissolution of severely deformed precipitated phase on mechanical properties of Al-Cu alloy [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(10): 1922-1931. (in Chinese)

[12] MURAYAMA M, HORITA Z, HONO K. Microstructure of two-phase Al-1.7at%Cu alloy deformed by equal-channel angular pressing [J]. Acta Materialia, 2001, 49(1): 21-29.

[13] LIU Zhi-yi, XU Xiao-chang, DANG Peng, YU Wen-bin, TAN Man-ling, WU Chun. Current situation and development of the research on re-dissolution of second phases during severe plastic deformation [J]. Heat Treatment of Metals, 2005, 30(4): 1-6. (in Chinese)

[14] HORITA Z, OHISHI K, KANEKO K. Microstructure control using severe plastic deformation [J]. Science and Technology of Advanced Materials, 2006, 7(7): 649-654.

[15] XU Xiao-chang, DANG Peng, LIU Zhi-yi, YU Wen-bin, NING Ai-lin, ZENG Su-min. Investigation on dissolution of precipitates in Al alloy deformed by equal-channel angular pressing and multi-axial compression [J]. Transactions of Materials and Heat Treatment, 2007, 28(5): 82-85. (in Chinese)

[16] XU Xiao-chang, LIU Zhi-yi, LI Yun-tao, DANG Peng, ZENG Su-min. Evolution of precipitates of Al-Cu alloy during equal-channel angular pressing at room temperature [J]. The Chinese Journal of Nonferrous Metals, 2008, 18: 1047-1052. (in Chinese)

[17] ZHOU Y, ZHANG J, FAN G, DING X, SUN J, REN X, OTSUKA K. Origin of 2-stage R-phase transformation in low-temperature aged Ni-rich Ti-Ni alloys [J]. Acta Materialia, 2005, 53(20): 5365-5377.

[18] KOCKAR B, KARAMAN I, KIM J I, CHUMLYAKOV Y I, SHARP J, YU C J. Thermomechanical cyclic response of an ultrafine-grained NiTi shape memory alloy [J]. Acta Materialia, 2008, 56(14): 3630-3646.

[19] WAITZ T, ANTRETTER T, FISCHER F D, SIMHA N K, KARNTHALER H P. Size effects on the martensitic phase transformation of NiTi nanograins [J]. Journal of the Mechanics and Physics of Solids, 2007, 55(2): 419-444.

第二相对等径弯角挤压处理TiNi合金和

Ti-Mo基合金力学性能及马氏体转变的影响

宋 杰1,王立明2, 张效宁1,孙小刚1,江 鸿1,范志国1,谢超英1,吴明雄3

1. 上海交通大学 材料科学与工程学院,金属基复合材料国家重点实验室,上海 200240;

2. 江苏法尔胜有限公司,江阴 214400;

3. 爱德华兹生命科学公司,欧文 加利福尼亚州 92614,美国

摘 要:借助ECAP技术对TiNi合金和Ti-Mo基记忆合金在673~773 K进行挤压处理,挤压路径为Bc,以获得超细晶组织,从而增强母相的强度,改进材料的性能。研究热力学稳定相及亚稳相对这两种合金的力学性能和马氏体转变的影响。结果表明,对于富钛TiNi合金,热力学稳定相Ti2Ni对马氏体转变及超弹性没有影响,而稳定相α相则可造成 Ti-Mo-Nb-V-Al塑性降低。亚稳Ti3Ni4相对富镍TiNi合金的R相变、马氏体转变及超弹性有很大影响。并对第二相对TiNi合金和Ti-Mo基合金力学性能、马氏体转变的影响进行分析。

关键词:镍钛合金;钛钼基形状记忆合金;等径弯角挤压;第二相;力学性能

(Edited by YUAN Sai-qian)

Foundation item: Project (50671067) supported by the National Natural Science Foundation of China; Project (09JC1407200) supported by the Science and Technology Committee of Shanghai, China

Corresponding author: SONG Jie; Tel: +86-21-54742608; E-mail: cyxie@sjtu.edu.cn; jies@sjtu.edu.cn; zxn100@sjtu.edu.cn

DOI: 10.1016/S1003-6326(11)61395-2

Abstract: TiNi and Ti-based shape memory alloys were processed by equal channel angular pressing (ECAP) at 673-773 K along Bc route to obtain ultrafine grains for increasing the strength of parent phase and improving the functional properties. The effects of both thermodynamically stable and metastable second phases on the mechanical properties and martensitic transformations of these alloys were investigated. It is found that thermodynamically stable Ti2Ni phase has no effect on martensitic transformation and superelasticity of Ti-rich TiNi alloy, thermodynamically stable α phase is harmful for ductility of Ti-Mo-Nb-V-Al alloy, but metastable Ti3Ni4 phase is effective for R phase transformation, martensitic transformation and superelasticity of Ni-rich TiNi alloy. The mechanisms of the second phases on the martensitic transformations and mechanical properties were discussed.