Ultrahigh frequency properties of discontinuous CoFeB/SiO2 multilayer films with high resistivity

JIANG Jian-jun(江建军), MA Qiang(马 强), BIE Shao-wei(别少伟), DU Gang(杜 刚),

TIAN Bin(田 斌), FENG Ze-kun(冯则坤), HE Hua-hui(何华辉)

Department of Electronic Science and Technology, Huazhong University of Science and Technology,Wuhan 430074, China

Received 15 July 2007; accepted 10 September 2007

Abstract:

A series of multilayers of Co36Fe46B18/SiO2 were fabricated by DC/RF magnetron sputtering, and further post-annealed in vacuum magnetic field at 200℃ for 2 h. The results show that the microstructures and electromagnetic properties of Co36Fe46B18/SiO2 multilayer films can be altered by varying the thickness of CoFeB and the process of annealing. High permeability along with high magnetic loss in the GHz frequency range is achieved in the optimized discontinuous multilayer films. Both real and imaginary parts of the complex permeability are larger than 260 at 1.6 GHz for this film, and the resistivity is as high as 1.4 mΩ?cm. The discontinuous Co36Fe46B18/SiO2 multilayers are supposed to serve as the microwave absorbers and EMI shielding materials in GHz range.

Key words:

CoFeB/SiO2; discontinuous multilayer; high frequency; permeability; resistivity;

1 Introduction

With the rapid development of information technology, a lot of researches have been carried out to develop soft magnetic thin films, which serve as core materials in electromagnetic devices, such as microinductors, near-field electromagnetic noise suppressors, and microwave absorbers that operate in the GHz frequency range[1-2]. It is well known that the magnetic properties of the films required for GHz order high frequency applications are high saturation magnetization(4πMs), an appropriate anisotropy field Hk that increases the self-resonant frequency and high electrical resistivity ρ that reduces eddy current loss[3-5]. Nanogranular magnetic thin films exhibit both high electrical resistivity and good soft magnetic due to their unique microstructures, which consist of nanometer-scale ferromagnetic metal particles dispersed in an insulating amorphous phase. It is, therefore, attractive for the above applications.

In order to fabricate such nanogranular films with desirable magnetic properties and high resistivity, the main challenge lies in optimizing the volume fractions of the ferromagnetic phase and the insulating amorphous one and tailoring the microstructure of the films. The purpose of this work is to present a novel method for fabricating the Co36Fe46B18/SiO2 multilayer nanogranular films with excellent soft magnetic properties suitable for high-frequency applications up to the GHz range. Compared with reactive sputtering[6] and co-deposition[7], the fabrication of the granular structure in this study takes advantage of the growth conditions of the Co36Fe46B18 metal layer on the SiO2 insulator that is between the discontinuous islands state and continuous film state due to their difference in surface energies. The samples were prepared by many sequential depositions of thin layers of Co36Fe46B18 and SiO2. When the nominal thickness of the Co36Fe46B18 metal layer is kept below a critical thickness for each deposition, the films consist of metal particles around nanometer size dispersed in an insulating matrix. The electric and magnetic properties of the films were investigated in this work.

2 Experimental

Co36Fe46B18/SiO2 nanogranular films were deposited on water-cooled glass substrates (Coring 7059) by sequential magnetron sputtering from two separate targets of Co36Fe46B18 and SiO2. The base pressure was less than 5×10-5 Pa. Sputtering was carried out in an Ar atmosphere with a pressure of 0.5 Pa at ambient temperature, with RF and DC input power of 80 W and 40W for SiO2(99.99%) and Co36Fe46B18(99.99%) targets, respectively. The resulting deposition rates were 0.36 nm/min for SiO2 and 3.6 nm/min for Co36Fe46B18. All samples contained 30 bilayers of Co36Fe46B18/SiO2 with a bottom layer and a top layer of 2 nm SiO2. The thickness of each single layer was determined from the deposition time calculated from the deposition rate. The Co36Fe46B18 thickness t varied from 0.7 to 1.5 nm, and the SiO2 thickness was kept constant and equal to 0.8 nm from one multilayer to another. Therefore, the structure of the discontinuous multilayer film was denoted as [Co36Fe46B18(![]() nm)/SiO2(0.8 nm)]30. In order to induce a uniaxial anisotropy in the film plane a magnetic field of 24 kA/m was applied during deposition. After deposition, all samples were annealed at 200 ℃ for 2 h in a vacuum furnace of 3×10-5 Pa with a field of 100 kA/m parallel to the easy axis of films.

nm)/SiO2(0.8 nm)]30. In order to induce a uniaxial anisotropy in the film plane a magnetic field of 24 kA/m was applied during deposition. After deposition, all samples were annealed at 200 ℃ for 2 h in a vacuum furnace of 3×10-5 Pa with a field of 100 kA/m parallel to the easy axis of films.

The microstructures of the films were analyzed by JEM-2010 high-resolution transmission electron microscopy. The crystalline structures of the films were determined by 2θ/θ X-ray diffraction(XRD) with Cu Kα radiation. Saturation magnetization(4πMs), coercivity and in-plane magnetic anisotropy field Hk were measured by a DMS Model 4 HF vibrating sample magnetometer (VSM) of ADE Technologies at room temperature. The electrical resistivity(ρ) of the films was measured by a conventional four probes method. Complex permeability in the frequency range of 0.5-5 GHz was measured by the microstrip method with a HP8722ES vector network analyzer[8].

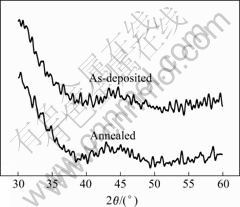

3 Results and discussionFig.1 shows the X-ray diffraction patterns of representative as-deposited and annealed [Co36Fe46B18 (t nm)/SiO2(0.8 nm)]30 films, respectively. The XRD patterns only contain broad diffuse peak. The broad diffuse peak indicates that the film samples are all amorphous[9]. Hence, the magnetocryalline anisotropy is essentially absent for all the samples in this work, as a result of lack of long-range ordering in atomic arrangement.

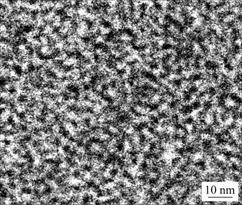

Bright field TEM plane micrograph of the [Co36Fe46B18(t nm)/SiO2(0.8 nm)]30 film when t=0.9 nm is shown in Fig.2. Co36Fe46B18 is dark image and SiO2 is bright one. Due to the fact that the metallic component has much higher surface tension than the insulator, the metal layer does not wet the oxide and, below some

Fig.1 XRD patterns of as-deposited and annealed [Co36Fe46B18 (0.9 nm)/SiO2(0.8 nm)]30 film

Fig.2 Bright field TEM micrograph of [Co36Fe46B18(0.9 nm)/ SiO2(0.8 nm)]30 granular film

thickness, it breaks up into almost spherical nanogranules[10]. As shown in Fig.2, [Co36Fe46B18(0.9 nm)/SiO2(0.8 nm)]30 film is discontinuous and forms a granular structure, and the diameters of both metallic and insulative particles are near 4 nm. The metallic particles are not completely isolated, but some of them impinge on each other because the volume fraction of the metallic phase approaches the percolation threshold. The thickness of the insulative layers between the particles is very small and some of the particles are in contact physically. Thus the multilayer nanogranular films exhibit that soft magnetic properties can be obtained by many sequential depositions of thin layers of Co36Fe46B18 and SiO2 since one would expect that the particles are magnetically coupled[11]. Also, it might be able to control the resistivity and magnetic properties by altering each single layer thickness.

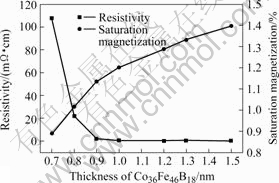

Fig.3 shows 4πMs and ρ as functions of t. 4πMs increases monotonously with an increase in t, mainly attributing to the increased magnetic phase. Furthermore, the microstructure effect resulting from an increase of CoFeB enlarges the magnetic particle size and diminishes the interface area between the magnetic particles and the insulative SiO2 phases. Thus, atomic moments of the surface Co or Fe abutted SiO2 were less distorted by interface energy and more magnetic phases formed, increasing 4πMs of the granular films[12].

Fig.3 Saturation magnetization(4πMs) and resistivity(ρ) vs thickness of Co36Fe46B18 layer

The value of ρ increases abruptly with a decrease in t, especially when t is less than 0.9 nm. More metallic particles were wrapped by insulative SiO2 and also thickness of the insulative layers between the particles became thicker with less CoFeB. Thus, contribution from the metallic conduction was lowered and the electron tunnel-hopping effect spanning insulative layers was strengthened, making ρ increase considerably[12]. Moreover, when the CoFeB metal thickness is more than 0.9 nm, ρ changes little and is in the order of hundreds of μΩ?cm. This indicates that the structure of metal layer changes from island to more continuous film as the CoFeB metal thickness increases and thickness of CoFeB of t=0.9 nm for [Co36Fe46B18 (t nm)/SiO2(0.8 nm)]30 is proved to be approaching to the percolation threshold.

Based on the above results, the multilayer films have optimal thickness range of Co36Fe46B18 layer for higher resistivity as well as good soft magnetic

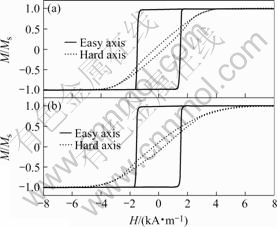

Fig.4 Easy and hard magnetic hysteresis loops of[Co36Fe46B18(0.9 nm)/SiO2(0.8 nm)]30 granular films: (a) As-deposited; (b) Magnetic field annealed at 200 ℃ for 2 h

properties. Fig.4(a) shows easy and hard axis magnetic hysteresis loops of the as-deposited discontinuous [Co36Fe46B18(0.9 nm)/SiO2(0.8 nm)]30 multilayer films. It is found that there exists a strong uniaxial anisotropy in the film plane, in which an easy axis is shown to be nearly parallel to the direction of applied field during deposition, and a hard axis perpendicular to the easy axis. The easy axis loop is very square while the hard axis loop is nearly closed and almost linear. Hence, the value of the uniaxial magnetic anisotropy field, Hk, estimated from the magnetic hysteresis loops in Fig.4(a), is as high as about 2 800 A/m for the as-deposited [Co36Fe46B18 (0.9 nm)/SiO2(0.8 nm)]30 film. Such in-plane anisotropy is mainly due to the induced anisotropy by applying field sputtering[13]. The observed field-induced anisotropy during deposition in the presence of applied magnetic field is most likely a result of the alignment of local atomic-pair ordering in the amorphous matrix[14]. It is also possible that some anisotropy in the stress or magnetostriction may be caused by the local atomic pairing.

In addition to uniaxial magnetic anisotropy, low coercivity indicates favorable soft magnetism. The small value of coercivity is attributed to the existence of some magnetic interaction among the particles. Approaching the percolation threshold, the formation of a connecting network of small particles starts to occur. Under such conditions, the particles are magnetically coupled. As a result, the films exhibit a soft magnetization behavior[15].

The as-deposited films are generally under residual stress. This residual stress, once relieved by modest annealing, becomes a driving force to change the microstructure. In general, the microstructural evolution associated with post-annealing includes defect healing, nucleation and grain growth. The [Co36Fe46B18(0.9 nm)/SiO2(0.8 nm)]30 film was chosen for static magnetic field annealing study. The easy and hard axis magnetic hysteresis loops of the annealed [Co36Fe46B18(0.9 nm)/ SiO2(0.8 nm)]30 multilayer films are shown in Fig.4(b). After annealing under a uniform in-plane magnetic field of 100 kA/m, the uniaxial anisotropy is enhanced. However, the resistivity value is nearly constant through the annealing. The annealed film has saturation magnetization of 1.13 T, resistivity of 1.4 mΩ·cm. Moreover, it shows an in-plane uniaxial anisotropy of about 3 600 A/m. It is 800 A/m higher compared to the as-deposited film. The enhancement of uniaxial magnetic anisotropy would lead to a high ferromagnetic resonance (FMR) frequency, thus increasing the upper limit of the applied frequency.

For films with an in-plane uniaxial anisotropy the Landau-Lifshitz equation[16] that manifests the basic dynamics of magnetic moment can be simplified to

![]() (1)

(1)

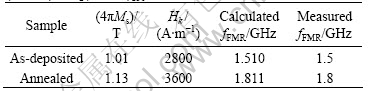

where γ is the gyromagnetic constant (γ=2×105 m/(A?s)-1), Ms and Hk are the saturation magnetization and the uniaxial anisotropy field, respectively. Using Eqn.(1), the ferromagnetic resonance frequency of the as-deposited and annealed films was calculated for comparison. In the computation, the values such as the saturation magnetization 4πMs and the anisotropy field Hk are taken from measurements and listed in Table 1. As can be seen from Table 1, by annealing in vacuum magnetic field, the anisotropy value increases from 2 800 to 3 600 A/m and there is a corresponding increase in the ferromagnetic resonance frequency from 1.510 to 1.811 GHz.

Table 1 Calculated soft magnetic properties of [Co36Fe46B18 (0.9 nm)/SiO2(0.8 nm)]30 thin films annealed at 200 ℃ for 2 h

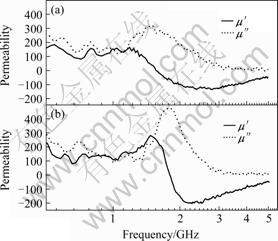

Complex permeability spectra at 0.5-5GHz for [Co36Fe46B18(t nm)/SiO2(0.8 nm)]30 films as-deposited and annealed under the conditions of 200 ℃×2 h when t=0.9 nm are measured and shown in Fig.5. For the as-deposited film, both μ′ and μ″ retain larger than 100 until 1.3 GHz and the resonant frequency fFMR is about 1.5 GHz, which is in good agreement with the calculated results. The nanogranular film near the percolation threshold possesses not only relatively large saturation magnetization (4πMs>11.3 kGs) but also high resistivity (ρ>1.4 mΩ?cm), which can suppress the macroscopical eddy current effect. Furthermore, the strengthened

Fig.5 Complex permeability spectra of[Co36Fe46B18(0.9 nm)/ SiO2(0.8 nm)]30 films: (a) As-deposited; (b) Magnetic field annealed at 200 ℃ for 2 h

interaction between magnetic particles in nanometer size makes the rotation magnetization process more easy. Thus, the film presents good soft magnetic properties and high permeability. The induced moderate magnetic anisotropy field makes the resonance appear near 1.5 GHz and the microwave loss is increased. On the other hand, loss can also originate from displacement current loss from the distributing capacitance effect between the metallic particles.

For the film annealed, as shown in Fig.5(b), it is obvious that the resonant frequency rises above 1.8 GHz and the resonant peak becomes more obvious compared with that of the as-deposited sample. Both μ′ and μ″ maintain larger than 100 until 1.7 GHz and larger than 260 at 1.6 GHz. These apparent changes in the complex permeability spectra indicate that the effective magnetic anisotropy field of the annealed film gets enhanced, which results from the microstructural evolution.

The combination of large microwave permeability, high magnetic loss, high resistivity, and moderately high ferromagnetic resonance frequency makes this film potentially useful for EMI shielding materials or microwave absorber design.

4 Conclusions1) Co36Fe46B18/SiO2 multilayer nanogranular films with excellent soft magnetic properties, high saturation magnetization, and high resistivity are fabricated using discontinuous multilayer alternate sputtering and annealing under a uniform in-plane magnetic field. The optimal properties are found in the annealed [Co36Fe46B18 (0.9 nm)/SiO2(0.8 nm)]30 films.

2) This film exhibits the excellent high frequency properties with high saturation magnetization of 1.13 T and high in-plane uniaxial anisotropy field of 3 600 A/m. Both real and imaginary parts of the complex permeability are larger than 260 at 1.6 GHz for this film; the resistivity of this film is as high as 1.4 mΩ?cm.

3) The discontinuous Co36Fe46B18/SiO2 multilayers are supposed to serve as the microwave absorbers and EMI shielding materials in GHz range.

AcknowledgmentsThe authors would like to thank Dr. CAI Jian-wang for providing the sputtering equipments in our experiments and valuable suggestion with him. The authors are also grateful to Dr. LIU Yi-fan, Dr. NI Jing and Dr. ZHANG Li-jiao for magnetic properties measurements. All of them are in the State Key Laboratory of Magnetism, Institute of Physics, Chinese Academy of Sciences.

References[1] BEKKER V, SEEMANN K, LEISTE H, ZIEBERT C. New CMOS compatible soft ferromagnetic materials with in-plane uniaxial anisotropy for h.f. micro-inductor applications[J]. J Magn Magn Mater, 2005, 290/291: 1434-1437.

[2] YOSHIDA S, ONO H, TSUDA F, ITO T, SHIMADA Y, YAMAGUCHI M, ARAI K I, OHNUMA S, MASUMOTO T. High-frequency noise suppression in downsized circuits using magnetic granular films[J]. IEEE Trans Magn, 2001, 37(4): 2401-2403.

[3] LAX B, BUTTON K J. Microwave ferrites and ferrimagnetics[M]. New York: McGraw-Hill, 1962: 159-160.

[4] OHNUMA S, FUJIMORI H, MITANI S, MASUMOTO T. High-frequency magnetic properties in metal-nonmetal granular films[J]. J Appl Phys, 1996, 79(8): 5130-5135.

[5] SHIMADA Y, YAMAGUCHI M, OHNUMA S, ITOH T, LI W D, IKEDA S, KIM K H, NAGURA H. Granular thin films with high RF permeability[J]. IEEE Trans Magn, 2003, 39(5): 3052-3056.

[6] OHNUMA S, LEE H J, KOBAYASHI N, FUJIMORI H, MASUMOTO T. Co-Zr-O nano-granular thin films with improved high frequency soft-magnetic properties[J]. IEEE Trans Magn, 2001, 37(4): 2251-2254.

[7] MUNAKATA M, MOTOYAMA M, YAGI M, ITO T, SHIMADA Y, YAMAGUCHI M, ARAI K I. Very high electrical resistivity and heteroamorphous structure of soft magnetic (Co35.6Fe50B14.4)-(SiO2) thin films[J]. IEEE Trans Magn, 2002, 38(5): 3147-3149.

[8] BEKKER V, SEEMANN K, LEISTEH. A new strip line broad-band measurement evaluation for determining the complex permeability of thin ferromagnetic films[J]. J Magn Magn Mater, 2004, 270: 327-332.

[9] ZHAO Fang, WU You-shi, SHI Yuan-chang, ZHOU Guo-rong, XU Ai-hua. Effects of quenching conditions on crystallization behavior of amorphous Al90Ni5Ce5 alloys[J]. Trans Nonferrous Met Soc China, 2003, 13(1): 88-91.

[10] BABONNEAU D, PETROFF F, MAURICE J L, FETTAR F, VAUR?S A, NAUDON A. Evidence for a self-organized growth in granular Co/Al2O3 multilayers[J]. Appl Phys Lett, 2000, 76(20): 2892-2894.

[11] OHNUMA M, HONO K, ONODETA H, OHNUMA S, FUJIMORI H, PEDERSEN J S. Microstructures and magnetic properties of Co-Al-O granular thin films[J]. J Appl Phys, 2000, 87(2): 817-823.

[12] DENG Lian-wen, FENG Ze-kun, JIANG Jiang-jun, HE Hua-hui. Percolation and microwave characteristics of CoFeB-SiO2 nano-granular films[J]. J Magn Magn Mater, 2007, 309: 285-289.

[13] TAKAHASHI H, WATANABE K, HOSHINO K, HOSHIYA H, YOSHIDA N, KIMURA H, NAKAMOTO K, HAMAKAWA Y, KAWABE T. Nano-granular metal/insulator multilayer for reader shielding materials[J]. IEEE Trans Magn, 2001, 37(4): 1758-1760.

[14] SLONCZEWSKI J C, RADO G. Magnetism (vol.1)[M]. New York: Academic Press, 1963: 205-206.

[15] HERZER G. Soft magnetic nanocrystalline materials[J]. Scripta Metall Mater, 1995, 33(10/11): 1741-1756.

[16] FERGEN I, SEEMANN K, WETH A V D, SCHUPPEN A. Soft ferromagnetic thin films for high frequency applications[J]. J Magn Magn Mater, 2002, 242/245: 146-151.

Foundation item: Project(50771047) supported by the National Natural Science Foundation of China; Project(NCET-04-0702) supported by the New Century Excellent Talents in University, China; Project(2005ABB002) supported by the Elitist in Natural Science Foundation of Hubei Province, China

Corresponding author: JIANG Jian-jun; Tel: +86-27-87544472; E-mail: jiangjj@mail.hust.edu.cn