Influence of solidification conditions on mechanical properties of Mg-10Gd-3Y-0.5Zr magnesium alloy

LIN Jin-bao(林金保)1, 2, PENG Li-ming(彭立明)1,WANG Qu-dong(王渠东)1,

ZHOU Yang(周阳)1, DING Wen-jiang(丁文江)1

1. National Engineering Research Center for Light Alloy Net Forming, Shanghai Jiao Tong University,

Shanghai 200030, China;

2. School of Applied Science, Taiyuan University of Science and Technology, Taiyuan 030024, China

Received 15 July 2007; accepted 10 September 2007

Abstract:

Mg-10Gd-3Y-0.5Zr alloy was cast in a step-like mould with five different cooling rates. The as-cast microstructures of the different steps were examined with optical microscope(OM) and scanning electron microscope(SEM). The room temperature mechanical properties were examined by tensile test. The results show that the microstructures are refined and the second phase particles are distributed much uniformly with the increase of cooling rate. The increase of yield strength, ultimate strength and elongation can be ascribed mainly to the strengthening effect of fine grains. The relationship between grain size and yield strength/hardness agrees with the Hall-Petch behavior.

Key words:

Mg-Gd-Y alloy; solidification condition; microstructure; mechanical properties;

1 Introduction

Mg alloys are especially attractive for aeronautical and automotive industry applications due to their combination of lightmass, good castability, high specific strength and stiffness[1-3]. However, the lower strength and creep resistance at elevated temperature limit their wide applications. Recently, it has been reported by ROKHLIN et al[4], KAMADO et al[5] and HE et al[6-7] that the Mg-Gd-Y magnesium alloy is better than the conventional Al or Mg alloys in strength and creep properties. However, the elongation of those alloys is very low (less than 1% in cast-T6 condition and typical 5% in extruded-T5 condition) due to their high content of rare earth metals and the existence of inclusions such as oxide and non-melted rare earth metals[4-7]. Thus, it is urgent to develop effective and economical method to increase the ambient ductility of Mg-Gd-Y alloy.

As is well known, the mechanical properties of Mg alloy depend sensitively on the casting conditions. In previous work[8], it has been found that the mechanical properties of ZK60 alloy enhance obviously with the increase of cooling rate due to the refinement of microstructure[9-10]. So, the mechanical properties may be enhanced by controlling solidification too. However, the effect of casting conditions on the microstructures and mechanical properties of Mg-Gd-Y alloy is more complex due to the high content of rare earth elements. In this study, the effects of cooling rate on the microstructures and mechanical properties of Mg-10Gd- 3Y-0.5Zr (GW103K) alloy were investigated.

2 Experimental

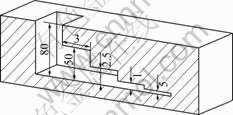

The GW103K alloy was prepared from Mg-20%Gd (mass fraction) and Mg-20%Y (mass fraction) master alloys in a mild steel crucible with the protection of a mixed gas atmosphere of 1% SF6 and 99% CO2 (volume fraction). The melt was held at 720 ℃ for 20 min and then poured into a step-like permanent mould (Fig.1), which provided five different cooling rates of about 1.5, 1.7, 2.3, 4.3 and 18.5 ℃/s, respectively[8]. The mould was coated with CaCO3 with a sodium silicate binder and preheated to 200 ℃. Table 1 lists the compositions of the investigated alloy. Tensile specimens with a gage section of 15.0 mm×3.5mm×2.0 mm were cut by electric spark machining from the centre of each step of the casting, whose codes and locations are shown in Fig.2. Tensile testing was carried out on a Zwick-20 kN material test machine at a crosshead speed of 1 mm/min.

Table 1 Compositions of Mg-Gd-Y (mass fraction, %)

Fig.1 Half-sectional view of step-like casting mould

Specimens were etched in a solution of 5 g picric acid+5 g acetic acid+100 mL ethyl alcohol for micro- structure observation. The grain size was determined using a linear intercept method from a large number of nonoverlapping measurements. Microstructural examina- tion was performed in an optical microscope (OM, LEICA MEF4M), scanning electron microscope (SEM, JEOL-6460). The hardness was obtained on the HV-30 macro hardness machine.

Fig.2 Schematic diagram of sampling position for mechanical testing and microstructure observation

3 Results and discussion

3.1 Microstructure

The optical microstructures of as-cast GW103K alloy in the center of different steps are shown in Fig.3 (Ⅰ-Ⅴ). The results indicate that the alloy mainly consists of granular phase of α-Mg and some rare earth-rich phases which randomly distribute along grain boundaries[11]. From step Ⅰ to step Ⅴ, with the cooling rate increase from 1.5 to 18.5 ℃/s[8], the grain size decreases and the dendrite density increases obviously with the reducing of the step height, that is to say, the microstructure is refined with the increase of the cooling rate. The linearly intercepted grain sizes of each step are 71.4, 68.0, 61.2, 42 and 35 ?m, respectively. Furthermore, the grain boundary area is increased; the coarse rare earth-rich phase is refined and its distribution becomes more uniform. Moreover, the original flat grain surfaces become more rough due to the increase of cooling rate.

Fig.3 Optical micrographs of center of each step of GW103K step-like casting

Fig.4 shows the SEM images of step Ⅰ, Ⅲ and Ⅴ of the step-like casting, respectively. It can be seen that both the matrix grains and second phases along the grain boundaries are all refined with the increasing cooling rate.

Fig.4 SEM images of stepⅠ, Ⅲ and Ⅴ of step-like casting

3.2 Mechanical properties

Fig.5 shows the tensile properties of each step of GW103K step-like casting in the as-cast and T6 (500 ℃, 8 h+225 ℃, 16 h) condition, respectively. From stepⅠto step Ⅴ, with the increase of cooling rate, it can be seen that the tensile strength, yield strength and elongation are increased in both as-cast and T6 conditions, though the increase ranges are different. Among the mechanical properties, the enhancement of elongation is more obvious. For example, from stepⅠto step Ⅴ, with the reduction of step height, the elongation increases from 2.2% to 3% in as-cast condition and from 1.7% to 2.6% in T6 condition, with the increase ratio being 36% and 52%, respectively. Compared with the elongation, the enhancement of tensile strength is not obvious. From stepⅠto stepⅤ, the yield strength increases by 9 MPa (about 6%) and tensile strength increases by 10 MPa (about 4.3%) in as-cast condition. In T6 condition, the value is 6 MPa (2.5%) and 31MPa (10%), respectively.

Fig.5 Tensile properties of each step of GW103K step-like casting in as-cast (a) and T6 (b) (500℃, 8 h+225 ℃, 16 h) conditions

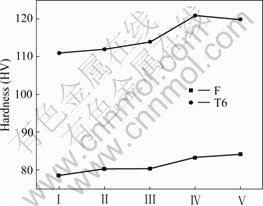

Fig.6 shows the hardness of each step of GW103K step-like casting in both as-cast and T6 conditions. It can be seen that the hardness exhibits a similar trend with the strength properties. Comparing step Ⅴ with stepⅠ, with the cooling rate increasing from 1.5℃/s to 18.5℃/s, the hardness increases by 5.4% in as-cast condition and by 4.5% in T6 condition, respectively.

Fig.6 Vickers hardnesses of each-step of GW103K step-like casting

3.3 Discussion

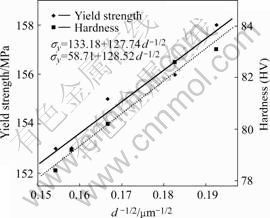

The experimental results have shown that the microstructures of GW103K alloy are obviously refined with the increase of cooling rate. The refined microstructure in as-cast alloy leads to more uniform distribution of solute elements and secondary phases on a fine scale. And the improvement of tensile properties can be ascribed to the microstructure refining and the uniform distribution of eutectic phase. The most interesting result is that, with the increase of cooling rate, the strength and elongation are enhanced at the same time, especially the elongation which is increased by 50%. This is very important for the industrial application of the Mg-Gd-Y alloy. The grain size dependence of yield strength and hardness of GW103K step-like casting are shown in Fig.7. Two good straight lines are observed, indicating agreement with Hall-Petch behavior. Moreover, two lines have a very similar slope.

Fig.7 Grain size dependence of yield strength and hardness of GW103K step-like casting

4 Conclusions

1) Five different cooling rates are achieved by step-like casting. With the increase of cooling rate, the microstructure of GW103K alloy is obviously refined.

2) With the increase of cooling rate, the strength and elongation are enhanced at the same time, especially the elongation is increased by 50%. The improvement of tensile properties can be ascribed to the microstructure refinement and the uniform distribution of eutectic phase.

3) The relationships between grain size and yield strength, hardness are both in agreement with the Hall-Petch behavior.

References

[1] SHAN Z, Gokhale A M. Utility of micro-indentation technique for characterization of the constitutive behavior of skin and interior microstructures of die-cast magnesium alloys [J]. Mater Sci Eng A, 2003, 361: 267-274.

[2] Sklenicka V, Pahutova M, Kucharova K. Creep processes in magnesium alloys and their composites [J]. Metall Mater Trans A, 2002, 33: 883-889.

[3] MA Chun-jiang, LIU Man-ping, WU Guo-hua, DING Wen-jiang, ZHU Yan-ping. Tensile properties of extruded ZK60-RE alloys [J]. Mater Sci Eng A, 2003, 349: 207-212.

[4] Rkhlin L L, Nikitina N I. Magnesium-gadolinium and magnesium-yttrium alloys [J]. Z Metallkd, 1994, 85(12): 819-823.

[5] Kamado S, Kojima Y, Ninomiya R, Kubota K, Lorimer G W. Proceedings of the Third International Magnesium Conference, 1996 [C]. UK: Institute of Materials, Manchester, 1997: 327-342.

[6] HE S M, ZENG X Q, PENG L M, GAO X, NIE J F, DING W J. Precipitation in a Mg-10Gd-3Y-0.4Zr (wt.%) alloy during isothermal ageing at 250°C [J]. Journal of Alloys and Compounds, 2006, 421(1/2): 309-313.

[7] HE S M, ZENG X Q, PENG L M, GAO X, NIE J F, DING W J. Microstructure and strengthening mechanism of high strength Mg-10Gd-2Y-0.5Zr alloy [J]. Journal of Alloys and Compounds, 2007, 427: 316-323.

[8] LIN Jin-bao, WANG Qu-dong, Peng Li-ming, ZHOU Yang, Ding Wen-jiang. Effect of cooling rate on the microstructure and mechanical properties of ZK60 alloy [J]. Materials Science Forum, 2007: 319-322

[9] Lee Y C, Dahle A K, StJohn D H. The role of solute in grain refinement of magnesium [J]. Metall Mater Trans A, 2000, 31: 2895-2906.

[10] StJohn D H, Qian M, Easton M A, Cao P, Hildebr Z. Grain refinement of magnesium alloys [J]. Metall Mater Trans A, 2005, 36: 1669-1679.

[11] ZHANG Xin-ming, CHEN Jian-mei, DENG Yun-lai, XIAO Yang, JIANG Hao, DENG Zhen-zhen. Microstructures and mechanical properties of Mg-Gd-Y-(Mn , Zr) magnesium alloys [J]. The Chinese Journal of Nonferrous Metals, 2006, 16(2): 219-227. (in Chinese)

Foundation item: Project(5133001B) supported by the National Basic Research Program (973 Program) of China

Corresponding author: LIN Jin-bao; Tel: +86-21-62932508; E-mail: linjinbao@sohu.com

(Edited by PENG Chao-qun)