网络首发时间: 2017-01-03 10:50

淬速对Nd9Fe70Ti3C1Nb3B14快淬薄带晶化相变和磁性能的影响

宁波大学材料科学与化学工程学院

摘 要:

采用不同的淬速 (辊速Vs=10, 15, 20, 25, 30 m·s-1) 制备了Nd9Fe70Ti3C1Nb3B14合金快淬薄带, 并研究了薄带的晶化相变及其退火后的磁性能随快淬速度提高而发生的变化。结果表明:在淬速15和20 m·s-1之间有一个临界淬速, 在临界淬速以下制备的低淬速薄带由非晶和少量Nd2Fe14B, Fe3B和α-Fe纳米晶组成, 而在临界淬速以上制备的高淬速薄带由完全非晶构成。随着淬速的提高, 薄带中非晶的热稳定性逐步提高。低淬速薄带晶化过程的相变为AP+Nd2Fe14B+Fe3B+α-Fe→Nd2Fe14B+Fe3B+α-Fe+Nd3Fe20B2→Nd2Fe14B+Fe3B+α-Fe, 而高淬速薄带晶化过程的相变为AP→AP'+Nd3Fe20B2→Fe3B+Nd3Fe20B2→Nd2Fe14B+Fe3B+α-Fe。优化退火后, 尽管不同淬速薄带的剩磁差别不大, 但低淬速薄带的最佳矫顽力和磁能积分别比高淬速薄带的高28.41%和20.12%。

关键词:

中图分类号: TG156

作者简介:徐山雪 (1992-) , 女, 安徽淮南人, 硕士研究生, 研究方向:磁性材料;E-mail:1316457683@qq.com;;潘晶, 教授;电话:13616564207;E-mail:panjing@nbu.edu.cn;

收稿日期:2016-12-01

基金:国家自然科学基金项目 (51174121, 51274125);浙江省重点科技创新团队项目 (2012R10016-08);宁波大学王宽诚幸福基金项目资助;

Crystallization Phase Transition and Magnetic Properties of Melt-Spun Nd9Fe70Ti3C1Nb3B14 Ribbons with Different Quenching Wheel Speeds

Xu Shanxue Pan Jing Liu Xincai Zhao Li

Faculty of Materials Science and Chemical Engineering, Ningbo University

Abstract:

A series of Nd9Fe70Ti3C1Nb3B15 melt-spun ribbons were prepared by rapid quenching at different wheel speeds ( Vs= 10, 15, 20, 25, 30 m·s-1) , and the changes of their crystallization phase transition and magnetic properties after post annealing with the increase of quenching wheel speed were investigated. The results showed that there was a critical quenching wheel speed Vc, which was between 15 and 20 m·s-1. When Vswas below Vc, the ribbons ( named low quenching speed ribbons) consisted of amorphous phase and a little amount of Nd2Fe14B, Fe3B and α-Fe nanocrystals, but when Vswas above Vc, the ribbons ( named high quenching speed ribbons) consisted of complete amorphous. The thermal stability was enhanced with Vsincreasing. The crystallization phase transition of low and high quenching speed ribbons could be deduced respectively as follows: AP + Nd2Fe14B + Fe3B + α-Fe →Nd2Fe14B + Fe3B+ α-Fe + Nd3 Fe20 B2→Nd2Fe14B + Fe3B + α-Fe; and AP→AP' + Nd3Fe20B2→Fe3B + Nd3 Fe20 B2→Nd2Fe14B + Fe3B + α-Fe. After the optimal annealing, the optimum coercivity and energy product of the former were 28. 41% and 20. 12% higher than that of the latter, respectively, with their remanence values very close.

Keyword:

nanocomposite permanent alloy; quenching wheel speed; crystallization phase transition; magnetic properties;

Received: 2016-12-01

熔体快淬是研究制备纳米复合永磁材料最为常用的工艺方法。以往对RE2Fe14B/α-Fe型合金 (RE代表Nd, Pr或Dy) 的相关研究较多[1,2,3,4,5,6,7,8,9]。研究也已表明, 薄带的快淬组织对其后续退火组织及其磁性能有显著而复杂的影响, 而快淬速度是决定薄带快淬组织的主要工艺因素[2,3,7,8,9]。由于 (Nd, Pr) 7-11FebalB10-15基合金含有适中的Nd和B元素, 使其比高B含量的Fe3B/RE2Fe14B型合金 (含3%~4%Nd和19%~21%B (原子分数) ) 具有潜在的更高的矫顽力, 而又比低B含量的RE2Fe14B/α-Fe型合金 (含7%~11%Nd和5%~6%B) 具有更强的非晶形成能力。因此, 采用熔体快淬工艺制备这种新型纳米复合永磁材料 (包含RE2Fe14B, Fe3B和α-Fe纳米晶) 的研究近年来开始增多[10,11,12,13,14,15,16,17]。但这些研究集中在添加微量合金元素来改善微观组织及其磁性能[10,11,12,13,14,15,16], 而有关快淬速度影响的研究很缺乏[17]。本文在保持其他工艺条件不变的情况下, 首次详细研究了淬速对Nd9Fe70Ti3C1Nb3B14快淬薄带的晶化相变及其退火后的磁性能的影响。

1实验

采用纯度为99.5%的Nd和纯度为99.9%的Fe, Nb, Ti, C以及Fe-20%B (质量分数) 中间合金配制名义成分为Nd9Fe70Ti3C1Nb3B14的合金。将其置于真空电弧熔炼炉中, 以氩气作为保护气体在炉内进行熔炼, 反复熔炼6次以保证合金成分的均匀, 制备成合金铸锭。将铸锭破碎成小块放入LZK-12A型真空感应快淬炉中重熔, 接着在氩气保护下将合金熔体喷射到水冷铜辊上, 制备辊速Vs分别为10, 15, 20, 25和30 m·s-1的快淬薄带。将快淬薄带置于高温真空炉中进行晶化退火。

采用D8 Advance (Cu Kα) X射线衍射仪 (XRD) 分析微观组织。采用NETZSCH DSC 404F1型差示扫描量热仪 (DSC) 在20 K·min-1升温速率下分析合金的晶化行为, 并结合不同温度下晶化组织的XRD结果推断合金的晶化相变。采用物理性能测试系统 (PPMS) 中自带的振动样品磁强计 (VSM) 测量退火后薄带的磁性能, 最大充磁场为3 T。

2结果与讨论

2.1不同淬速薄带的淬态组织结构及其晶化转变

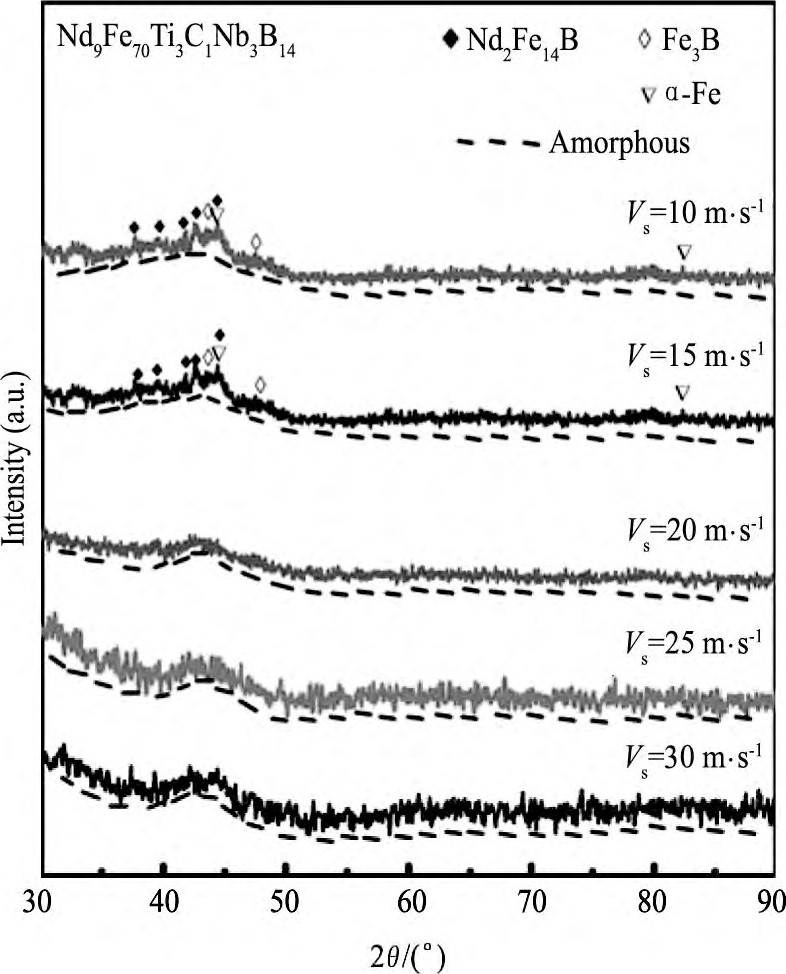

图1为不同淬速的Nd9Fe70Ti3C1Nb3B14薄带的X射线衍射图谱。可以看出, 当淬速Vs为10和15 m·s-1时, 样品的XRD图显示出在非晶漫散射峰上有微弱的Nd2Fe14B, Fe3B和α-Fe相的衍射峰, 这表明快淬组织由非晶和少量Nd2Fe14B, Fe3B和α-Fe纳米晶组成。当淬速为20, 25和30 m·s-1时, 样品的XRD图呈现典型的非晶漫散射峰, 这表明快淬组织为完全非晶结构。由此可见, Nd9Fe70Ti3C1Nb3B14快淬薄带获得完全非晶结构的临界淬速Vc介于15和20 m·s-1之间, 比RE2Fe14B/α-Fe型合金快淬薄带的临界值 (通常在30 m·s-1以上) 小很多[8,18]。一方面Nd9Fe70Ti3C1Nb3B14合金的B含量较高, 另一方面合金中还添加了较多的Nb, 这都是其非晶形成能力较高的原因[13,16]。

图1 不同淬速的Nd9Fe70Ti3C1Nb3B14薄带的X射线衍射图谱Fig.1 XRD patterns of Nd9Fe70Ti3C1Nb3B14ribbons prepared at various wheel speeds

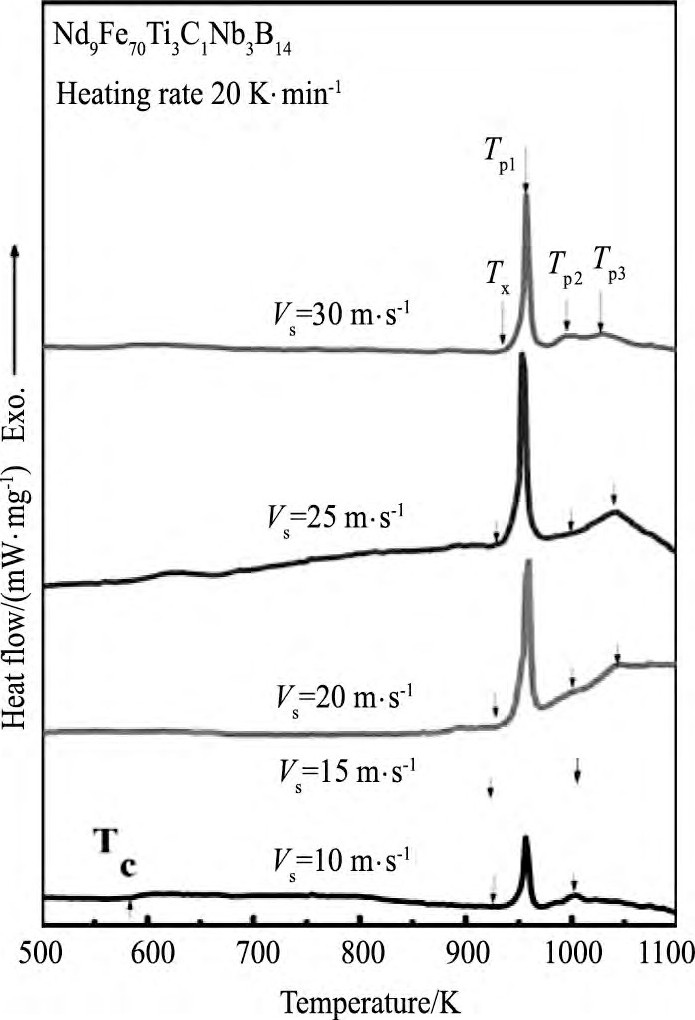

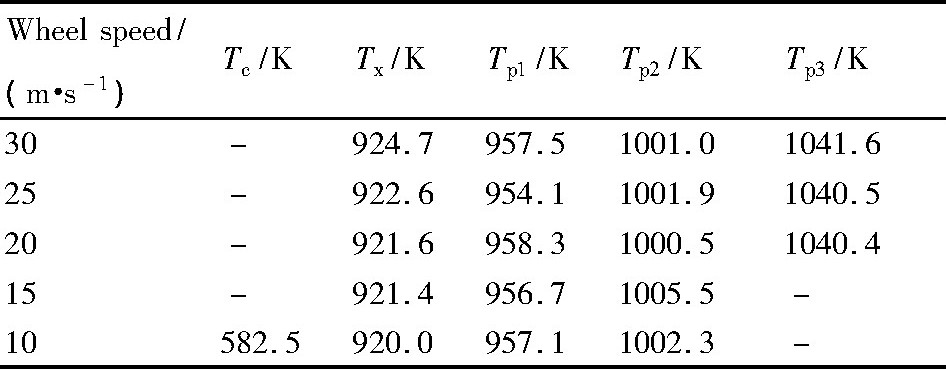

图2为不同淬速下的Nd9Fe70Ti3C1Nb3B14快淬薄带的连续加热DSC曲线。采用热分析仪自带的NETZSCH-Proteus软件对DSC曲线进行分析, 得到的特征温度 (晶化起始温度Tx, 放热峰值温度Tp和居里温度Tc) 列于表1。在Vs为10 m·s-1的薄带的DSC曲线上, 可以看到Nd2Fe14B相的居里点Tc[19], 表明其快淬组织中存在较多的Nd2Fe14B相。在所有薄带的DSC曲线上都出现了放热峰, 并且放热峰的面积随着Vs的提高而明显变大, 说明薄带的快淬组织中都含有非晶相并且非晶相的含量随着Vs的提高而增大。根据Inoue等的研究[20], Vs为10, 15, 20, 25和30 m·s-1的样品所对应的约化晶化温度Trx (Trx=Tx/TL, 其中Tx为表1中数值, TL=1479.5 K为我们前期研究结果[21]) 分别为0.6218, 0.6228, 0.6230, 0.6236, 0.6250, 这逐渐增大的Trx值反映出合金的非晶形成能力随其快淬速度的提高而增强。上述对DSC的分析结果与图1 XRD所反映的结果一致。

图2 不同淬速的Nd9Fe70Ti3C1Nb3B14薄带的DSC曲线Fig.2DSC curves for Nd9Fe70Ti3C1Nb3B14ribbons prepared at various wheel speeds

表1 不同淬速的Nd9Fe70Ti3C1Nb3B14薄带的DSC曲线上的特征温度Table 1Characteristic temperatures on DSC curves of Nd9Fe70Ti3C1Nb3B14ribbons prepared at vari-ous wheel speeds 下载原图

表1 不同淬速的Nd9Fe70Ti3C1Nb3B14薄带的DSC曲线上的特征温度Table 1Characteristic temperatures on DSC curves of Nd9Fe70Ti3C1Nb3B14ribbons prepared at vari-ous wheel speeds

从表1可以看出, 随着淬速的提高, 样品的起始晶化温度逐步提高, 共提高了4.7 K。这是非晶的热稳定性随淬速的提高而逐渐提高所致。低淬速薄带 (Vs=10, 15 m·s-1<Vc的薄带) 的微观组织中存在少量、细小的晶相 (图1) , 它们能促使非晶发生非均质形核, 从而降低非晶的热稳定性。而高淬速薄带 (Vs=20, 25, 30 m·s-1>Vc的薄带) 的微观组织是完全非晶相, 其中发生的是均质形核过程, 因而非晶的热稳定性较高。随着淬速的提高, 薄带的混合组织中的晶相数量逐渐减少, 而薄带的完全非晶组织的成分和结构更加均匀, 致使其起始晶化温度逐步提高。

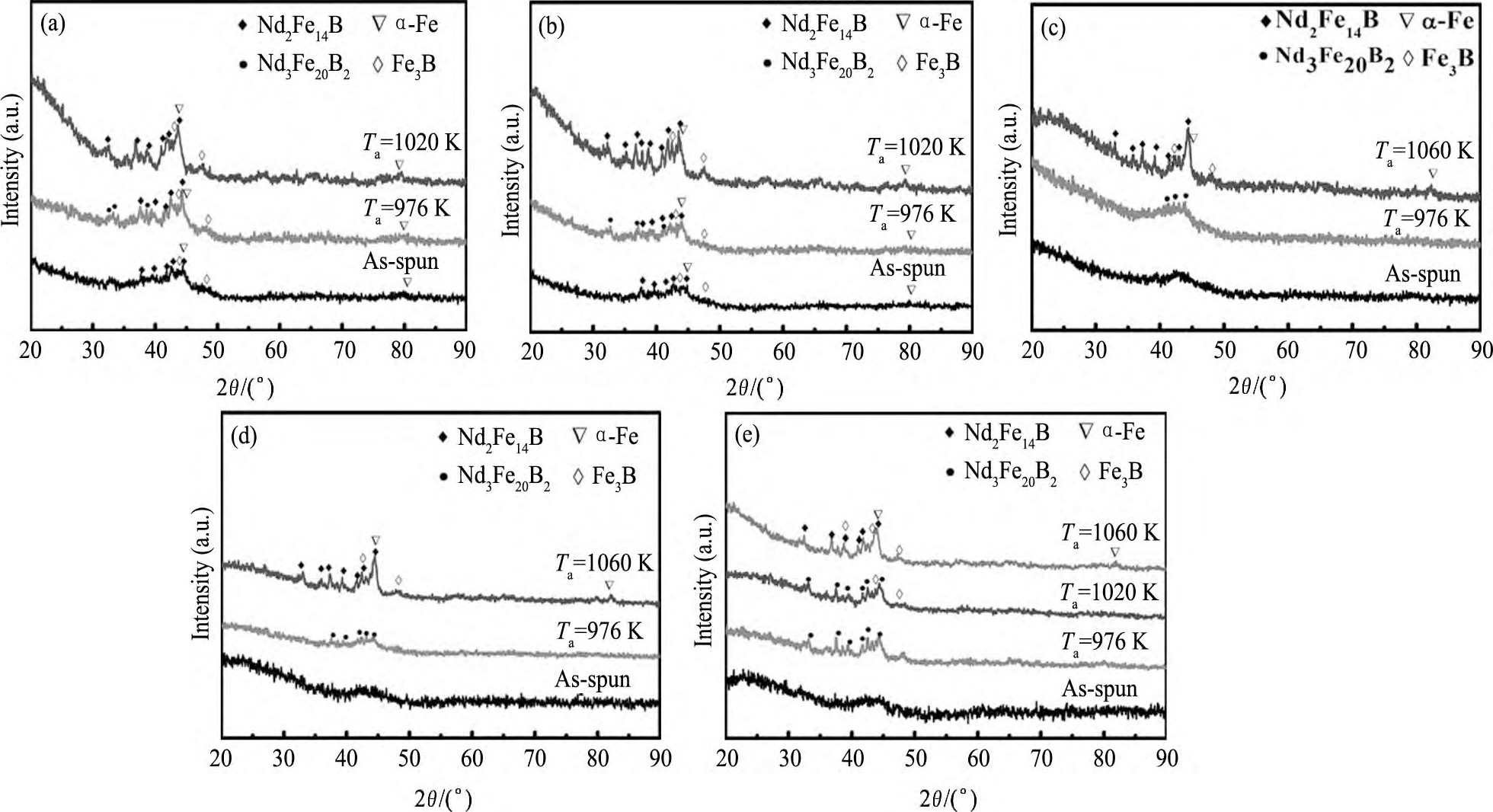

从图2还可以看到, 低淬速薄带的DSC曲线上有两个放热峰, 而高淬速薄带的DSC曲线有3个放热峰。这意味着低淬速薄带和高淬速薄带的晶化行为有显著的差别。为了明确每个放热峰所对应的相变, 在每个放热峰值温度 (表1) 以上15~20 K选取退火温度Ta对薄带进行退火处理, 并对退火组织进行XRD相结构分析。从图3 (a, b) 可以看出, 当低淬速薄带经过976 K (高于第一个放热峰值温度约19 K) 退火后, Nd2Fe14B, Fe3B和α-Fe相的衍射峰明显地增强, 非晶漫散射峰消失, 同时出现了亚稳相Nd3Fe20B2的衍射峰[22]。这表明DSC曲线上第一个较强的放热峰对应着非晶向亚稳相Nd3Fe20B2的转变和Nd2Fe14B, Fe3B和α-Fe纳米晶的长大。当低淬速薄带经过1020 K (高于第二个放热峰值温度约20 K) 退火后, Nd3Fe20B2相衍射峰消失, Nd2Fe14B和α-Fe相衍射峰进一步增强。这表明它们DSC曲线上第二个较弱的放热峰对应着亚稳相Nd3Fe20B2分解成Nd2Fe14B和α-Fe相的转变。从图3 (c~e) 可以看出, 当高淬速薄带经过976 K (高于第一个放热峰值温度约20 K) 退火后, 非晶漫散射峰上出现了亚稳相Nd3Fe20B2相衍射峰。这表明DSC曲线上第一个较强的放热峰对应着部分非晶相向亚稳相Nd3Fe20B2转变。当高淬速薄带经过1020 K (高于第一个放热峰值温度约20 K) 退火后, 非晶漫散射峰消失, 出现了Fe3B相的衍射峰。这说明DSC曲线中第二个较弱放热峰对应着剩余非晶相向Fe3B相的转变。当高淬速薄带经过1060 K (高于第三个放热峰值温度约20 K) 退火后, Nd3Fe20B2亚稳相的衍射峰消失, 出现了Nd2Fe14B和α-Fe相衍射峰。这表明DSC曲线中第三个较弱放热峰对应着Nd3Fe20B2亚稳相分解成Nd2Fe14B和α-Fe相的转变。根据上述实验结果与分析, 可推断低淬速薄带的晶化相变为AP+Nd2Fe14B+Fe3B+α-Fe→Nd2Fe14B+Fe3B+α-Fe+Nd3Fe20B2→Nd2Fe14B+Fe3B+α-Fe, 而高淬速薄带的晶化相变为AP→AP'+Nd3Fe20B2→Fe3B+Nd3Fe20B2→Nd2Fe14B+Fe3B+α-Fe。由此可见, 在高淬速薄带中, 完全非晶组织的晶化转变分两步完成。当高淬速薄带中的非晶的一部分发生相变后, 剩余非晶因自身成分的变化而导致热稳定性提高。因而, 剩余非晶需要在更高温度下才能晶化[23]。这导致了高淬速薄带与低淬速薄带的晶化行为的差别, 并且前者完成晶化的最终温度比后者的提高了44 K。

图3 不同淬速的Nd9Fe70Ti3C1Nb3B14薄带经过不同温度退火处理5 min后的XRD图谱Fig.3 XRD patterns of Nd9Fe70Ti3C1Nb3B14ribbons prepared at various wheel speeds after annealed at various temperatures for 5 min (a) 10 m·s-1; (b) 15 m·s-1; (c) 20 m·s-1; (d) 25 m·s-1; (e) 30 m·s-1

2.2不同淬速薄带经晶化处理后的磁性能

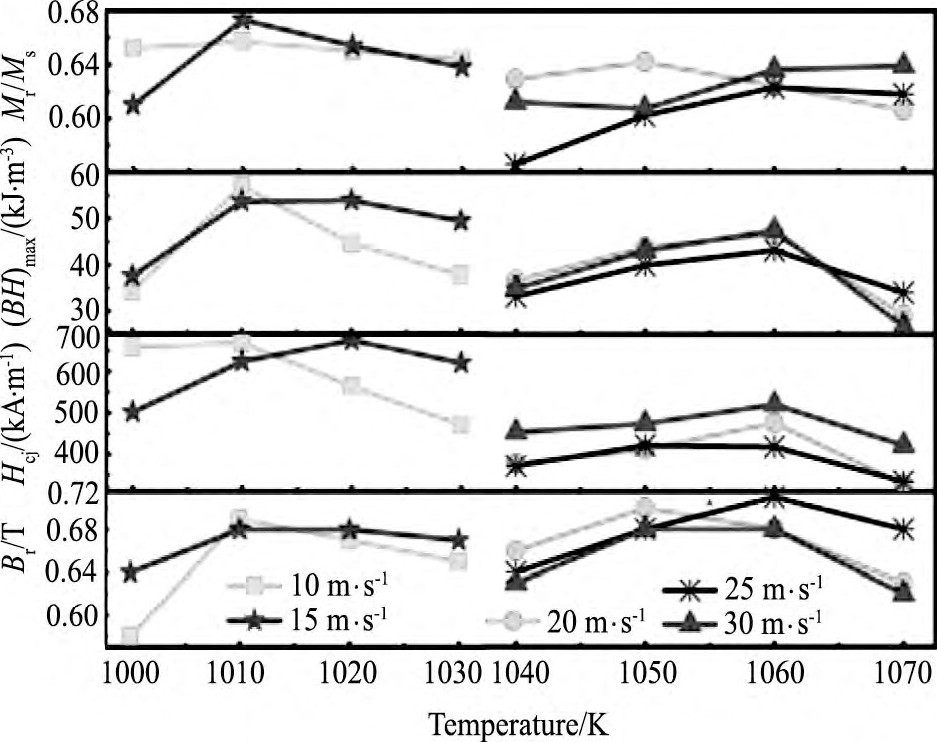

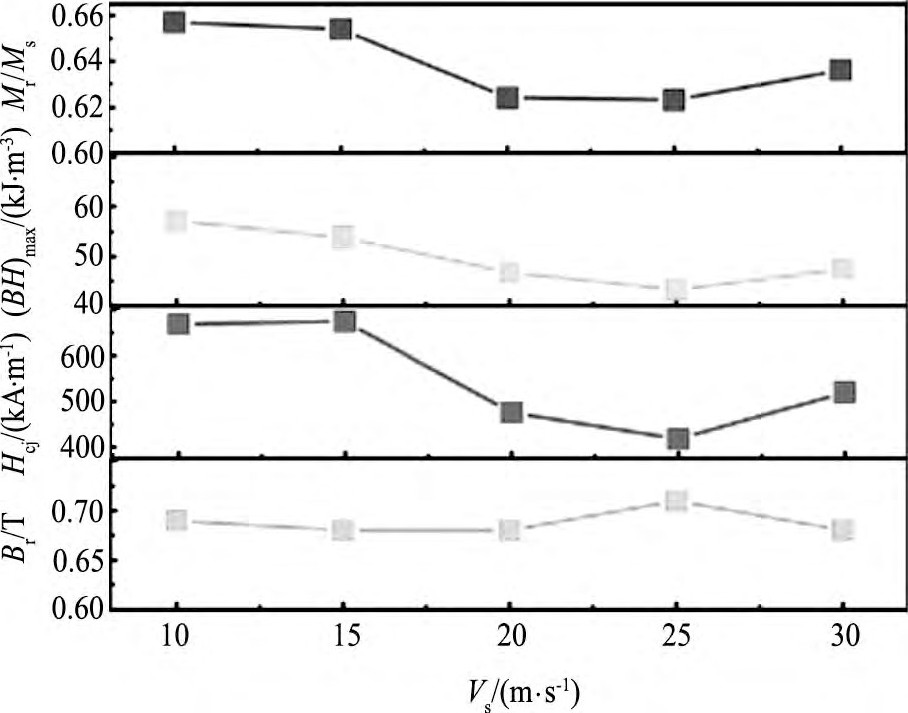

对于低淬速薄带, 在其Nd3Fe20B2亚稳相分解所对应的第二个放热峰值温度附近选取退火温度Ta=1000, 1010, 1020, 1030 K;而对于高淬速薄带, 在其Nd3Fe20B2亚稳相分解所对应的第3个放热峰温度附近选取退火温度Ta=1040, 1050, 1060, 1070 K。对所有薄带在Ta下进行10 min退火处理, 随后测量它们的磁性能。图4反映了不同淬速的薄带退火后的磁性能随退火温度的变化。由图4可见, 低淬速薄带的退火实验温度区间大大低于高淬速薄带。所有薄带的剩磁、矫顽力和磁能积随退火温度的提高呈现出先增大后减小的变化, 并且磁性能极大值所对应的退火温度都高于它们各自亚稳相分解的温度。这表明, 所有薄带获得最佳磁性能时的退火组织由硬磁性的Nd2Fe14B相和软磁性的Fe3B和α-Fe相构成。值得注意的是, 薄带的淬速越低, 其矫顽力和剩磁取得最大值的最佳退火温度也越低, 只是这种现象在高淬速薄带中不如在低淬速薄带中那么明显。这与淬态微观组织的热稳定性随淬速降低而下降直接相关。

图4 不同淬速的Nd9Fe70Ti3C1Nb3B14薄带在不同温度下退火10 min后的磁性能与退火温度的关系图Fig.4 Dependence of Br, Hcj, (BH) maxand Mr/Mson annea-ling temperatures of Nd9Fe70Ti3C1Nb3B14ribbons pre-pared at various wheel speeds after annealed at various temperatures for 10 min

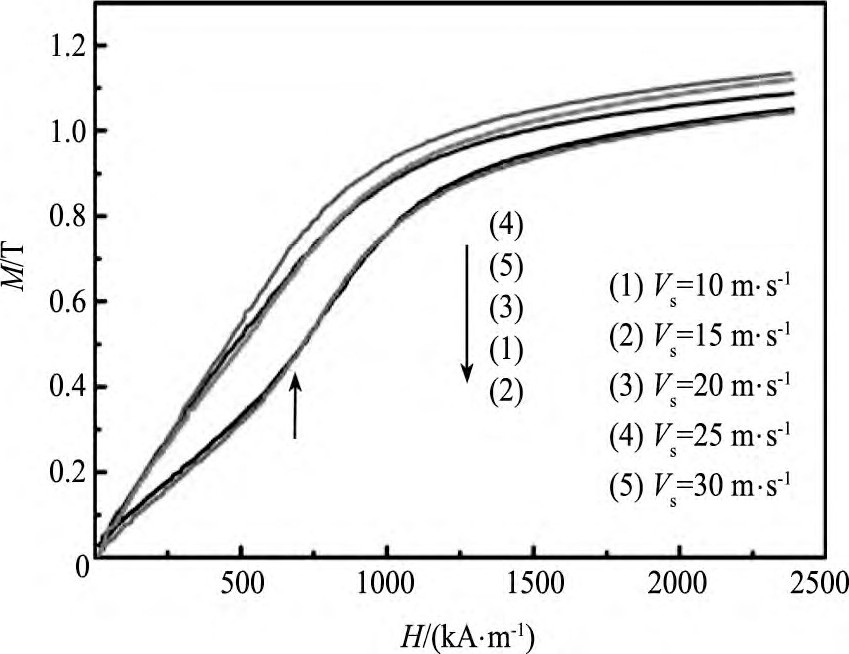

图5为不同淬速的薄带经过优化退火处理后的磁性能和剩磁比。可以看到, 不同淬速薄带的剩磁Br值差别不大, 在0.67~0.72之间变化。而低淬速薄带的矫顽力却都比高淬速薄带的矫顽力大很多, 这导致前者的磁能积也显著地高于后者。在低淬速薄带中, 淬速为10 m·s-1的薄带的矫顽力Hcj和磁能积 (BH) max较大, 它们分别为668.12k A·m-1和57.08 k J·m-3;而在高淬速薄带中, 淬速为30 m·s-1的薄带的Hcj和 (BH) max最大, 它们分别为520.30 k A·m-1和47.52 k J·m-3。前者的最佳Hcj和 (BH) max比后者的分别高出28.41%和20.12%。从图5还可以看到, 所有薄带的剩磁比Mr/Ms都大于0.62, 这是软、硬磁相之间发生交换耦合作用的结果, 这也说明所有薄带经过优化退火后得到了尺寸合适的Nd2Fe14B, Fe3B和α-Fe纳米晶。值得注意的是, 低淬速薄带的剩磁比显著高于高淬速薄带, 表明前者的软、硬磁相间的交换耦合作用更强, 也反映出前者的退火组织更为细小而均匀[16]。图6是优化退火处理后的薄带的初始磁化曲线。可以看到, 在低场区段上低淬速薄带的磁化强度增长较慢, 而当外磁场达到660 k A·m-1 (图6中箭头所示) 时, 其磁化强度的增长开始显著地加快。这表明在低淬速薄带中反磁化畴的移动受到的钉扎比高淬速薄带中的更强, 而这种钉扎来源于软、硬磁性相之间的交换耦合场以及晶界[24]。因此, 低淬速薄带的退火组织比高淬速薄带的更为细小而均匀决定了它们具有更的高矫顽力[16,24,25,26]。低淬速薄带的淬态组织中除了非晶, 还有从合金熔体中弥散析出的Nd2Fe14B, Fe3B和α-Fe纳米晶以及近程有序结构, 使非晶在晶化初期就形成了大量的晶核, 从而抑制了晶粒的粗化。而高淬速薄带的淬态组织是完全非晶, 其中晶核的形成是一个持续的过程, 可能导致晶化初期形成的晶粒尺寸与晶化后期形成的晶粒尺寸有很大差异。而且, 高淬速薄带的优化退火温度显著高于低淬速薄带, 这有利于其中晶粒的长大。比较可知, 淬速为10 m·s-1的低淬速薄带经1010 K晶化处理10 min后得到了最佳综合磁性能:Br=0.69 T, Hcj=668.12 k A·m-1, (BH) max=57.08 k J·m-3, Mr/Ms=0.657。

图5 不同淬速的Nd9Fe70Ti3C1Nb3B14薄带经过最佳退火处理后的磁性能图Fig.5Magnetic properties of Nd9Fe70Ti3C1Nb3B14ribbons prepared at various wheel speeds after optimal annea-ling treatment

图6 不同淬速的Nd9Fe70Ti3C1Nb3B14薄带经最佳热处理后的初始磁化曲线Fig.6 Initial magnetization curves of Nd9Fe70Ti3C1Nb3B14rib-bons prepared at various wheel speeds after optimal an-nealing treatment

3结论

1.Nd9Fe70Ti3C1Nb3B14薄带获得完全非晶结构的临界淬速介于15~20 m·s-1之间。在临界淬速以下制备的低淬速薄带由大量非晶和少量Nd2Fe14B, Fe3B和α-Fe纳米晶组成, 而在临界淬速以上制备的高淬速薄带由完全非晶构成。

2.随着淬速提高, 薄带中非晶的热稳定性增强。低淬速薄带晶化过程的相变为AP+Nd2Fe14B+Fe3B+α-Fe→Nd2Fe14B+Fe3B+α-Fe+Nd3Fe20B2→Nd2Fe14B+Fe3B+α-Fe。高淬速薄带晶化过程的相变为AP→AP'+Nd3Fe20B2→Fe3B+Nd3Fe20B2→Nd2Fe14B+Fe3B+α-Fe。

3.经过优化退火后, 低淬速薄带的最佳磁性能为Br=0.69 T, Hcj=668.12 k A·m-1, (BH) max=57.08 k J·m-3和Mr/Ms=0.657;而高淬速薄带的最佳磁性能为Br=0.69 T, Hcj=520.30 k A·m-1, (BH) max47.52 k J·m-3和Mr/Ms=0.639。前者的Hcj和 (BH) max分别比后者高28.41%和20.12%。

参考文献