Microstructure and nanoindentation hardness of Ag/Fe multilayers

ZHU Xiao-ying(朱晓莹)1, 2, LIU Xue-jing(刘雪敬)1, ZENG Fei(曾 飞)1, PAN Feng(潘 峰)1

1. Laboratory of Advanced Materials, Department of Materials Science and Engineering,

Tsinghua University, Beijing 100084, China;

2. National Key Laboratory for Remanufacturing, Academy of Armored Forces Engineering, Beijing 100072, China

Received 14 April 2009; accepted 5 June 2009

Abstract:

Ag/Fe multilayers with well compositional modulation periodicity of 4-60 nm were prepared at room temperature by evaporation deposition using an ultra high vacuum (UHV) chamber. Their microstructure and hardness were investigated using XRD, TEM and nanoindentation. The fcc/bcc type multilayers show a textured polycrystalline growth with Ag (111) and Fe (110) in Ag layers and Fe layers, respectively. The hardness increases with decreasing periodicity and approaches the maximum of 6.36 GPa at the periodicity of 4 nm. The peak hardness is 1.51 times mixture value. The experimental results are well explained by the dislocation-image force-based model developed by Lehoczky.

Key words:

Ag/Fe multilayers; nanoindentation hardness; structure; periodicity;

1 Introduction

Multilayers have received extensive attention because of their excellent mechanical properties, especially their extremely high strength approaching 1/2 or 1/3 of the theoretical strength limit[1-4]. The evolution of film hardness as a function of periodicity has been studied and some strengthening mechanisms have been proposed. The candidate mechanisms for explaining this anomalous enhancement of strength and hardness include Hall-Petch strengthening[5], elastic modulus mismatch model[6-8], coherent stress hardening[9], solid solution strengthening[10] and structural barrier strengthening[11]. Although all the above mechanisms have explained the experimental phenomena successfully to some extent, the question that which mechanism is the dominant one to determine the hardness enhancement in multilayers is still under discussion.

For multilayers with coherent and semicoherent interfaces, HOAGLAND et al[12] concluded that the interfaces possess a very minor resistance to the slip of single dislocation and coherency strain is of major importance of strengthening. In contrast, for multilayers with incoherent interfaces, the interfaces become the obstacle to slip because of different structures and slip systems in individual layers. The factors involved in slip transfer across interfaces are more complex than coherent multilayers. WEN et al[13] examined periodicity dependence of the hardness of Ag/Co multilayers and suggested the hardness enhancement was ascribed to the combination of interface strengthening and image effect. FU et al[14] compared the mechanical properties of four fcc/bcc multilayers systems, Cu/V, Al/Nb, Cu/Cr and Cu/Nb, with Kurdjumov-Sachs orientation relationship, and found that the differences in their mechanical properties (the Hall-Petch slope and peak hardness) can be interpreted in terms of their differences in shear modulus, heat of mixing, and characteristics of interfaces. However, the investigation on this type multilayer system is still at a stage waiting for data accumulation and further experimental work is required to further clarify the strengthening mechanisms.

In this work, we investigate the nanoindentation hardness of the fcc/bcc multilayers of Ag/Fe system. Although Ag/Fe multilayers and Fe-Ag alloy films have been widely studied because of their giant magnetoresistance (MR) effects[15], so far very limited work has been done on their mechanical properties, which is very important for their application. In addition, the larger elastic mismatch and immiscible interfaces in the Ag/Fe multilayer system make it an ideal model to investigate the factors that affect the hardening mechanisms in multilayers with incoherent interfaces.

2 Experimental

Ag/Fe multilayers consisting of alternating equivalent Ag and Fe individual layers with periodicity (Λ) ranging from 4 to 60 nm were prepared at room temperature by alternate electron beam evaporation deposition of Ag and Fe using an ultra high vacuum (UHV) chamber. The deposition rates were 0.1 nm/s for both Ag and Fe. The nominal thickness of individual Ag and Fe layers was monitored by an in situ quartz oscillator. All the multilayers were deposited on Si (111) wafers with native oxide. Prior to the deposition of Ag/Fe multilayers, a 10 nm-thick Ti layer was deposited to improve the cohesion between the film and the substrate. The multilayers always started with an iron layer on the Ti layer and ended with silver as the top layer. The total thickness of the multilayers was approximately 500 nm. Pure Ag and Fe films of thickness of 500 nm were deposited as reference samples under the same deposition conditions as those for the multilayers.

The crystalline structure was analyzed by Rigaku D/max-RB X-ray diffractometer with Cu Kα radiation and transmission electron microscope (TEM). The chemical contents were determined by X-ray fluorescence (XRF). The nanoindentation hardness of the multilayers, as well as pure Ag and Fe films, were investigated by a MTS nanoindenter? using continuous stiffness measurement (CSM) technique in XP mode. The maximum indentation depth was 500 nm with a displacement resolution less than 0.01 nm. Frequency of 45 Hz was used to avoid the sensitivity to thermal drift and the loading resolution was 50 nN. A Berkovich indenter, a three-sided pyramid with the same area-to-depth function as Vickers indenter, was used in all our experiments. Ten indents were made on every sample to minimize the deviation of the results.

3 Results and discussion

3.1 Microstructure

Fig.1 shows symmetrical XRD patterns for the multilayers with Λ=4 nm and Λ=16 nm. Two main Bragg reflections are observed at 38.1? and 44.4?, respectively. The first one corresponds to Ag (111) and the second one is related to both Ag (200) and Fe (110). Besides Ag (111), Ag (200) and Fe (110), there are still some other weak peaks, indicating a polycrystalline growth of Ag and Fe layers with Ag (111) and Fe (110) out-of-plane texture.

Fig.1 XRD patterns for multilayers with Λ=4 nm (a) and Λ=16 nm (b)

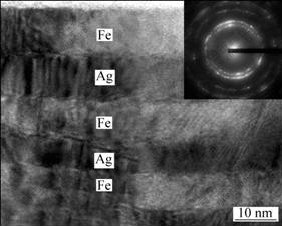

In order to further confirm the microstructure, cross-sectional TEM observation was carried out. Fig.2 shows the image of the multilayers with Λ=16 nm and corresponding selected-area diffraction (SAD) pattern. The common features of the well-defined composition modulation periodicity and sharp interfaces are verified. The SAD pattern is of ring type, which is consistent with the polycrystalline microstructure.

Fig.2 Cross-section TEM image and corresponding SAD patterns for multilayer with Λ=16 nm

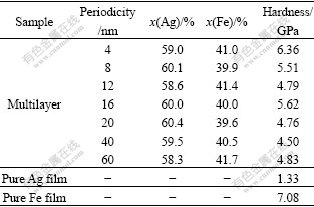

XRF was used to measure the chemical composition and the results are presented in Table 1. All the multilayers have approximately the same composition of Ag and Fe. The molar fractions of Ag and Fe are also close to the values (Ag 40.9% and Fe 59.1%) calculated based on the equal-volume assumption. The results indirectly indicate that the Ag and Fe layers have the same thickness.

Table 1 Composition and hardness of multilayers, pure Ag and Fe films

3.2 Nanoindentation hardness

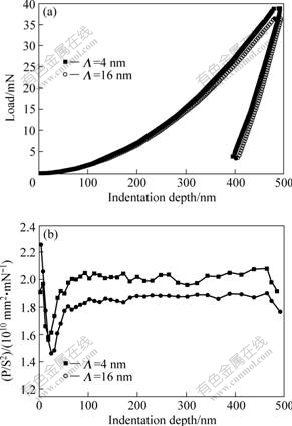

The hardness was measured continuously during the loading of the indenter by the CSM method, and the results are present in Table 1. The typical load-unload curves for the multilayers with Λ=4 and 12 nm are shown in Fig.3(a), and no pop-in events are observed. Deformation during loading segment is assumed to be both elastic and plastic as the permanent hardness impression forms. But during the unloading segment only elastic displacements are recovered. The maximum penetration depth is controlled to be 500 nm, approaching the interface between the film and the substrate. The parameter P/S2 as a function of indentation depth is given in Fig.3(b), where P is the load on the sample and S is the contact stiffness. After the initial drop and rise, which can be attributed to strain gradients, P/S2 keeps constant with the indentation depth. SAHA and NIX[16] have proved that substrate effects on the mechanical properties of thin film can be evaluated by analyzing P/S2. The constant values imply that the hard Si substrate does not influence the deformation behavior of the multilayers. It is reasonable because the Si (111) substrate is much harder than the multilayers; the plastic deformation is confined within the film and the substrate yields plastically only when the indenter penetrates the substrate.

Fig.3 Typical load-unload curves (a) and corresponding parameter P/S2 as function of indentation depth (b) for multilayers with Λ=4 and Λ=12 nm

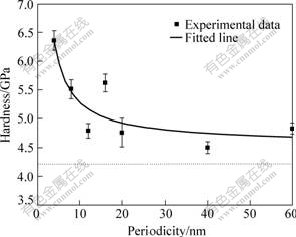

The dependence of the hardness on the periodicity is shown in Fig.4. The hardness values of the pure Ag and Fe thin films are 1.33 GPa and 7.08 GPa, respectively. This gives a rule-of-mixture hardness of

Hmix=4.21 GPa for the Ag/Fe system, shown as the dotted line in Fig.4. The hardness almost remains constant with decreasing periodicity at large periodicity (Λ≥20 nm). When the periodicity falls to less than 20 nm, despite of some scattered data, we can still find that the hardness value increases with decreasing periodicity and approaches a maximum value of 6.36 GPa at Λ=4 nm, about 51% higher than the rule-of-mixtures value.

Fig.4 Hardness of Ag/Fe multilayers as function of periodicity

The hardness enhancement in multilayers, as measured by nanoindentation, is usually interpreted as the interphase boundary hardening mechanism[4], following the Hall-Petch dependence on the periodicity:

H=H0+k/Λn (1)

where H0 is the hardness of samples with large periodicity, normally taken as the rule-of-mixture hardness value, and k and n are fitting parameters. The constant k may be representative of the difficulty of a dislocation to cross an interface, whereas the exponent n may be associated with the mechanism of plastic deformation. If we assume that the hardness enhancement can be understood as analogous to grain-boundary hardening in polycrystalline materials, the hardness data can be least-squares fitted to Eq.(1) with n=0.5. The fit of Eq.(1) to all the data points in Fig.4, shown by the solid curve, yields n=1, showing a greater exponent than the Hall-Petch relation (n=0.5). This suggests that the hardening is different from the Hall-Petch model.

Several models have been proposed to explain the periodicity dependent hardness enhancement. CHU and BARNETT[17] developed a CB model and found that when the shear stress for dislocation glides from low modulus layer to high modulus layer is increased by a large modulus mismatch, a large enough level of stress may be achieved to cause dislocation motion within the individual layers. That is to say, dislocation will bow between two adjacent interfaces. But, this CB model is concerned with multilayers where the constituents are miscible and the slip systems are the same in the different layers, and it gives an exponent of n=0.67-0.74. ANDERSON and LI[18] proposed another interpretation. They considered a situation where the dislocation is forced across the interface either by the applied shear stress from the nanoindenter or by the generation of a new dislocation in the same slip plan by a Frank-Read source, resulting in a exponent of n≈0.3. None of the described models can account for the observed behavior in our experiment. The relationship found corresponding to n=1 shows a stronger hardness dependence on the periodicity than that predicted by other model. Based on the dislocation-image model proposed by KOEHLER[6], LEHOCZKY[8] established a linear inverse-layer- thickness dependence, according to:

![]() (2)

(2)

with

![]() (3)

(3)

where φA and φB are the volume fractions; EA and EB are the elastic moduli of the constituent materials A and B. For the present system, A and B represent Fe and Ag, respectively. The experimental values of elastic moduli of Fe and Ag are 198 and 90 GPa, respectively; and the theoretical value of H0 gives 5.15 GPa, which is very close to the value of 4.56 GPa given by the fit of the experimental data.

One of the greatest interests of Lehoczky’s work lies in the calculation of the maximum yield stress which is obtained if the thickness of individual layer is less than a critical value. The yield stress for multilayers with equal layer thickness of Fe and Ag can be given by

![]() (4)

(4)

where ![]() (5)

(5)

Taking the Poisson’s ratios, ν, as 0.37 and 0.29, we calculate the shear moduli G of Ag and Fe, using G=E/2(1+ν), as GAg=33 GPa and GFe=77 GPa. Then, using the relationship ![]() HAg/3 and the experimental hardness of Ag film, we obtain the maximum yield strength predicted by Eq.(4) for Ag/Fe multilayers with the same volume fraction and find it to be 1.54 GPa. This value corresponds to a maximum hardness of 4.62 GPa which is only 73% of the peak hardness of 6.36 GPa in our experiment obtained at Λ=4 nm. One possible interpretation for the underestimate of the peak hardness is that the dislocation-image force-based model does not take the barriers of interfaces into account. In fact, for multilayers with coherent or semicoherent interfaces, the interfaces possess a very minor resistance to the slip of dislocation because the slip planes and slip directions are nearly continuous across the interfaces[12]. Factors such as shear modulus mismatch or coherent stresses may determine the transmission stress for dislocations. Therefore, the peak strength of multilayers can be evaluated by Koehler’s modulus difference model or Cahn’s coherency stress model solely. Whereas, in the present study, the incoherent interfaces between Ag layer and Fe layer act as an obstacle to dislocation slip. Firstly, the slip systems of dislocations are {111} <110> in fcc Ag layers and {110} <111> in bcc Fe layers. Different structure and slip systems in Ag and Fe layers make the interfaces barriers to dislocations transmission. Moreover, the lattice mismatch δ calculated based on the lattice-mismatch model proposed by LI et al[19] equals 35%. This large value indicates a higher misfit dislocation density and stronger interaction between the interface and the gliding dislocation, leading to a higher interface strengthening ability. Actually, the interface strengthening ability is not only dependent on the lattice constant mismatch but also dependent on the specific interfaces structure. The jump in hardness at the periodicity of 12 nm and 16 nm may be associated with the various crystallographic orientations at the interfaces, which will be further studied in the further.

HAg/3 and the experimental hardness of Ag film, we obtain the maximum yield strength predicted by Eq.(4) for Ag/Fe multilayers with the same volume fraction and find it to be 1.54 GPa. This value corresponds to a maximum hardness of 4.62 GPa which is only 73% of the peak hardness of 6.36 GPa in our experiment obtained at Λ=4 nm. One possible interpretation for the underestimate of the peak hardness is that the dislocation-image force-based model does not take the barriers of interfaces into account. In fact, for multilayers with coherent or semicoherent interfaces, the interfaces possess a very minor resistance to the slip of dislocation because the slip planes and slip directions are nearly continuous across the interfaces[12]. Factors such as shear modulus mismatch or coherent stresses may determine the transmission stress for dislocations. Therefore, the peak strength of multilayers can be evaluated by Koehler’s modulus difference model or Cahn’s coherency stress model solely. Whereas, in the present study, the incoherent interfaces between Ag layer and Fe layer act as an obstacle to dislocation slip. Firstly, the slip systems of dislocations are {111} <110> in fcc Ag layers and {110} <111> in bcc Fe layers. Different structure and slip systems in Ag and Fe layers make the interfaces barriers to dislocations transmission. Moreover, the lattice mismatch δ calculated based on the lattice-mismatch model proposed by LI et al[19] equals 35%. This large value indicates a higher misfit dislocation density and stronger interaction between the interface and the gliding dislocation, leading to a higher interface strengthening ability. Actually, the interface strengthening ability is not only dependent on the lattice constant mismatch but also dependent on the specific interfaces structure. The jump in hardness at the periodicity of 12 nm and 16 nm may be associated with the various crystallographic orientations at the interfaces, which will be further studied in the further.

4 Conclusions

1) Ag/Fe multilayers with well compositional modulation structure were prepared by evaporation deposition. Their microstructure and hardness were investigated using XRD, TEM and nanoindentation. The multilayers show a textured polycrystalline growth with Ag (111) and Fe (110) in Ag layers and Fe layers, respectively.

2) The hardness increases with decreasing periodicity and the peak hardness of 6.36 GPa is obtained at the periodicity of 4 nm, showing 51% hardness enhancement compared with the rule of mixture value.

3) The periodicity dependence of hardness can be well interpreted by the dislocation-image force-based model developed by Lehoczky. Whereas the peak hardness is larger than the value predicted, which may be ascribed to the contribution of interfaces as an obstacle to dislocation slip.

References

[1] MISRA A, KUNG H. Deformation behavior of nanostructured metallic multilayers [J]. Advanced Engineering Materials, 2001, 3(4): 217-222.

[2] WEN S P, ZONG R L, ZENG F, GAO Y, PAN F. Evaluation modulus and hardness enhacement in evaporated Cu/W multilayers [J]. Acta Materialia, 2007, 55: 345-351.

[3] AN Jian, ZHANG Qing-yu. Characterization and wear properties of nanoscaled TiN/TaN multilayer coatings [J]. Transactions of Nonferrous Metals Society of China, 2006, 16(S1): 59-64.

[4] MIAO Qiang, CUI Cai-e, PAN Jun-de, ZHANG Ping-ze. Improving wear resistance of magnesium alloy AZ91D by TiN-CrN multilayer coating [J]. Transactions of Nonferrous Metals Society of China, 2006, 16(S3): 1802-1805.

[5] CAMMARATA R C, SCHLESINGER T E, KIM C, QADRI S B, EDELSTEIN A S. Nanoindentation study of the mechanical properties of copper-nickel multilayered thin films [J]. Applied Physic Letter, 1990, 56: 1862-1864.

[6] KOEHLER J S. Attempt to design a strong solid [J]. Physical Reviwe B, 1970, 2(2): 547-551.

[7] LEHOCZKY S L. Strength enhancement in thin-layered Al-Cu laminates [J]. Journal of Applied Physics, 1978, 49(11): 5479-5485.

[8] LEHOCZKY S L. Retardation of dislocation generation and motion in thin-layered metal laminates [J]. Physical Review Letters, 1978, 41(26): 1814-1818.

[9] CAHN J W. Hardening by spinodal decomposition [J]. Acta Metallurgica, 1963, 11(12): 1275-1282.

[10] KIM C, QADRI S B, SCANLON M R, CAMMARATA R C. Low-dimension structural properties and microindentation studies of ion-beam-sputtered multilayers of Ag/Al films [J]. Thin Solid Film, 1994, 240: 52-55.

[11] XU Jun-hua, KAMIKO M, ZHOU Yao-min, LU Guang-hong, YAMANOTO R, YU Li-hua, KOJIMA I. Structure transformations and superhardness effects in V/Ti nanostructured multilayers [J]. Applied Physics Letters, 2002, 81(7): 1189-1191.

[12] HOAGLAND R G, KURTZ R J, HENAGER C H Jr. Slip resistance of interfaces and the strength of metallic multilayer composites [J]. Scripta Materialia, 2004, 50: 775-779.

[13] WEN S P, ZENG F, GAO Y, PAN F. Microstructure and nanoindentation investigation of magnetron sputtering Ag/Co multilayers [J]. Surface and Coatings Technology, 2006, 201: 1262-1266.

[14] FU E G, LI Nan, MISRA A, HOAGLAND R G, WANG H, ZHANG X. Mechanical properties of sputtered Cu/V and Al/Nb multilayer films [J]. Mater Sci Eng A, 2008, 493: 283-287.

[15] TSOUKATOS A, WAN H, HADJIPANAYIS G C, UNRUH K M, LI Z G. Giant magnetoresistance studies in (Fe,Co)-Ag films [J]. Journal of Applied Physics, 1993, 73(10): 5509-5511.

[16] SAHA R, NIX W D. Effects of the substrate on the determination of thin film mechanical properties by nanoindentation [J]. Acta Materialia, 2002, 50: 23-38.

[17] CHU Xi, BARNETT S A. Model of superlattice yield stress and hardness enhancements [J]. Journal of Applied Physics, 1995, 77(9): 4403-4411.

[18] ANDERSON P M, LI C. Hall-Petch relations for multilayered materials [J]. Nanostructured Materials, 1995, 5: 349-362.

[19] LI Y P, ZHANG G P, WANG W, TAN J, ZHU S J. On interface strengthening ability in metallic multilayers [J]. Scripta Materialia, 2007, 57: 117-120.

Foundation item: Projects(50871060, 50772055) supported by the National Natural Science Foundation of China; Project(2007AA03Z426) supported by High-tech Research and Development Program of China

Corresponding author: PAN Feng; Tel: +86-10-62772907; E-mail: panf@mail.tsinghua.edu.cn

DOI: 10.1016/S1003-6326(09)60105-9